Steel Sheet For Container, And Method For Producing Steel Sheet For Container

A manufacturing method and steel plate technology, applied in the direction of chemical instruments and methods, flexible coverings, electrolytic inorganic material coatings, etc., can solve the problem of corrosion resistance, coating adhesion or film adhesion reduction, harmfulness, and hexavalent Avoid problems such as chromium at a respectful distance, and achieve the effect of excellent film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0180] Examples and comparative examples of the present invention are described below, and the results are shown in Table 5. The examples shown below are merely examples of steel sheets for containers and methods of manufacturing steel sheets for containers according to embodiments of the present invention, and steel sheets for containers and methods of manufacturing steel sheets for containers according to embodiments of the present invention are not limited to those shown below. the embodiment.

[0181]

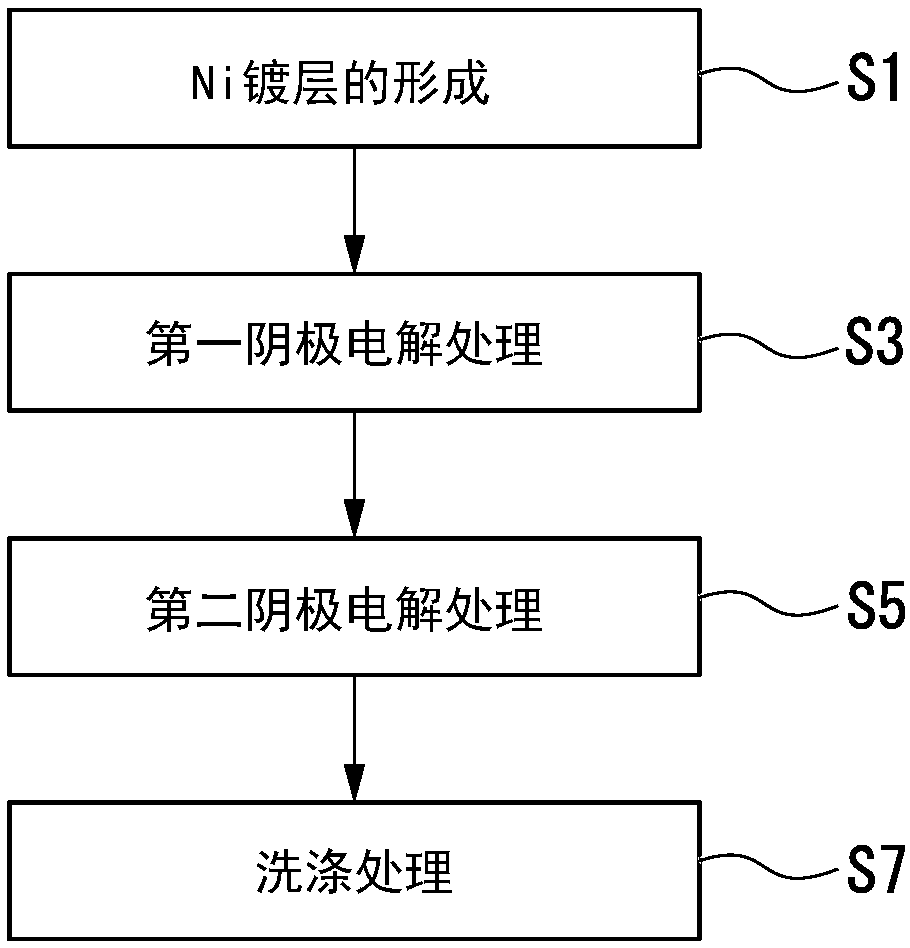

[0182] (A1) After the cold rolling, the annealed and temper-rolled steel plate was degreased and pickled, and the steel plate with nickel sulfate hexahydrate of 75 g / L and nickel chloride hexahydrate of 140 g / L was used. , boric acid 40g / L, pH 4 Watt bath, when the bath temperature is 50 ℃, the current density is 5A / dm 2 Ni-plating was performed on both sides under the condition of , and a Ni-plated steel sheet was produced. Adhesion amount adjusted by electrolysis time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com