Novel polyimide precursor composition and use thereof

A polyimide precursor and composition technology, which is applied in semiconductor/solid-state device manufacturing, photosensitive materials used in optomechanical equipment, instruments, etc., can solve the problem that wiring materials are difficult to withstand high temperature, and achieve good physical properties, The effect of good performance and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

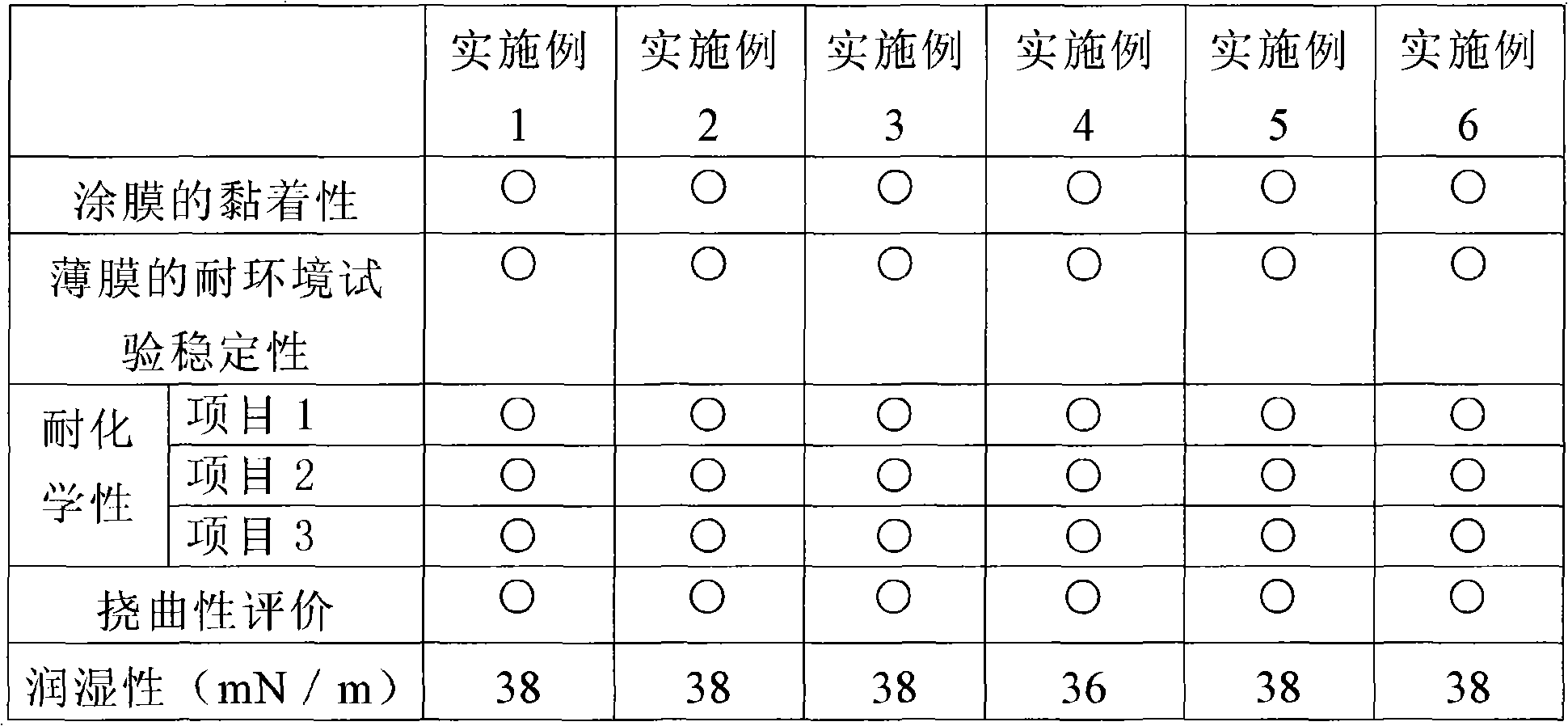

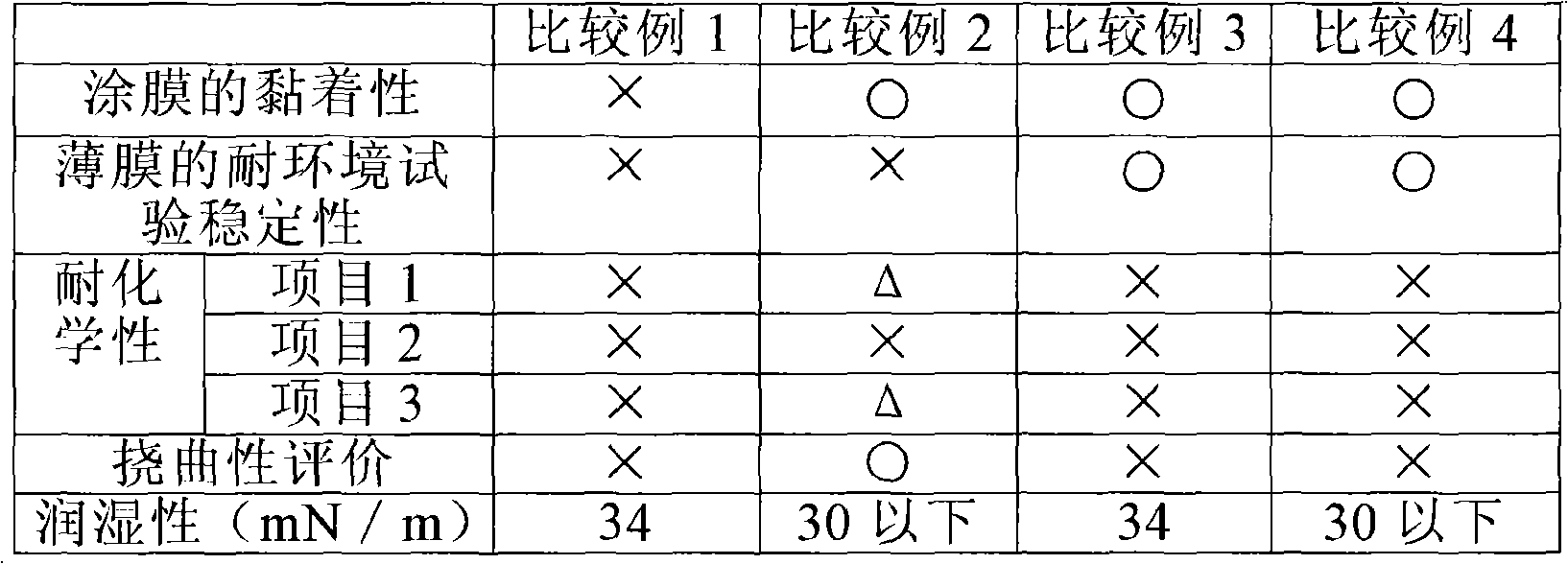

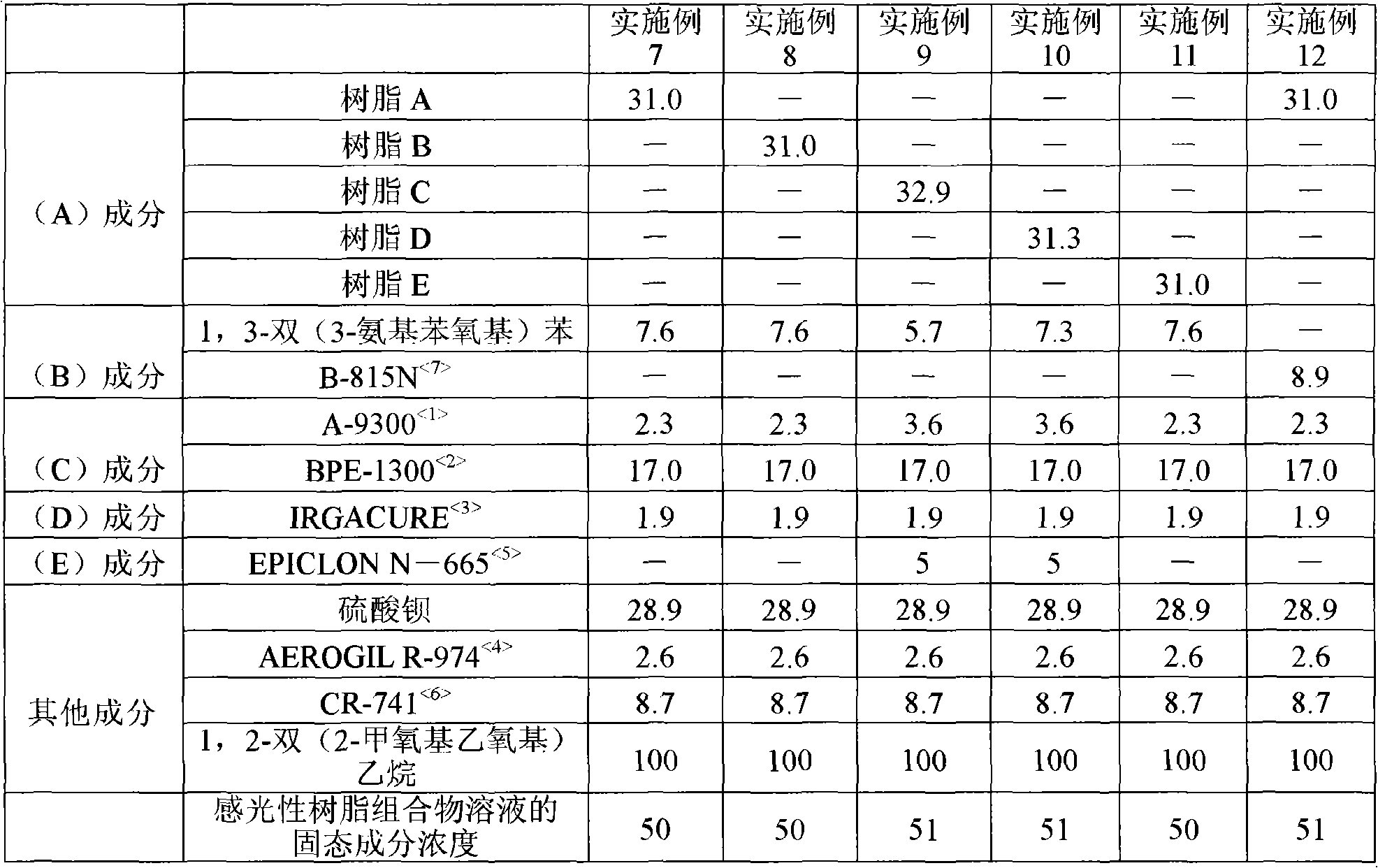

Examples

preparation example Construction

[0101] [Method for preparing terminal acid anhydride urethane imide oligomer]

[0102] Various methods are mentioned as the reaction method of the terminal isocyanate compound and tetracarboxylic dianhydride in the manufacturing method of the terminal acid anhydride urethane imide oligomer. Hereinafter, a typical reaction method among them will be illustrated. The reaction method in the present invention is not particularly limited as long as the terminal can contain tetracarboxylic dianhydride.

[0103] Method 1: Disperse or dissolve tetracarboxylic dianhydride in an organic solvent to obtain a tetracarboxylic dianhydride solution, and gradually add a terminal isocyanate compound to the above solution. The reaction temperature at this time is preferably 100°C to 300°C, more preferably 140°C to 250°C. It is preferable to add the terminal isocyanate compound after heating to the above-mentioned temperature, and react to perform the imidization treatment at the same time. Alt...

Embodiment 1

[0209]

[0210] Methyl triglyme (17.5 g) was put into a nitrogen-pressurized separatory flask (separable flask) as a polymerization solvent, and then 17.5 g (0.1003 mol) of tolylene diisocyanate (tolylene diisocyanate) (methyl A mixture of 80% phenylene-2,4-diisocyanate and 20% tolylene-2,6-diisocyanate), the mixture was heated to 80° C. to dissolve toluene diisocyanate. Add the following solution to the above solution over one hour, namely: dissolve polyalkylene diol (polyalkylene diol) (manufactured by Asahi Kasei Co., Ltd., product name "PTXG1000" in methyl triglyme (50.0 g) ", the polyalkylene glycol represented by the following general formula (15), the average molecular weight is 1000) 40.0g (0.040mol) and polycarbonate glycol ester (produced by Asahi Kasei Co., Ltd., product name "PCDL T5651", by the following Polycarbonate represented by the general formula (16), the average molecular weight is 1000) 10.0 g (0.010 mol) of the obtained solution. The above solution wa...

Embodiment 2

[0252]

[0253] Methyl triglyme (17.5 g) was put into a separatory bottle pressurized with nitrogen as a polymerization solvent, and then toluene diisocyanate (tolylylene-2,4-diisocyanate and methyl The mixture of phenylene-2,6-diisocyanate, the mixing ratio of tolylene-2,4-diisocyanate and tolylene-2,6-diisocyanate is 80% and 20% respectively)( 17.5g (0.1003mol)), the mixture was heated to 80°C to dissolve toluene diisocyanate. Add the following solution to the above solution in one hour, namely: dissolve polyalkylene glycol (produced by Asahi Kasei Co., Ltd., product name "PTXG1000" in methyl triglyme (50.0 g) by General Polyalkylene glycol represented by formula (15), average molecular weight 1000) (50.0 g (0.050 mol)) obtained solution. The above solution was heated to reflux for 5 hours. The above-mentioned reaction solution is referred to as "intermediate body B".

[0254] Putting 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]malonic anhydride (hereinafter, abbreviated as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com