Hot stamp molded body

A hot stamping forming and averaging technology, applied in hot dip plating process, superimposed layer plating, coating, etc., can solve the problem that the fatigue properties of hot stamping moldings cannot be fully obtained, and the moldings cannot be sufficiently phosphated. It has the advantages of improved phosphate treatment, improved fatigue properties, and improved weldability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

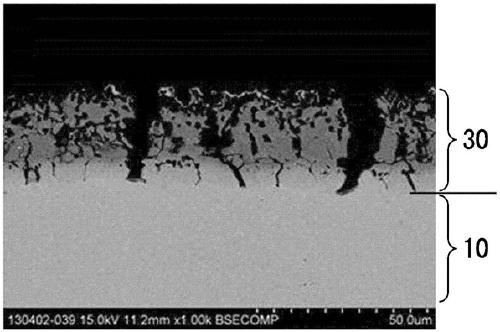

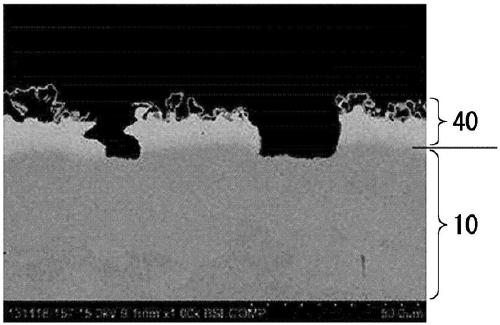

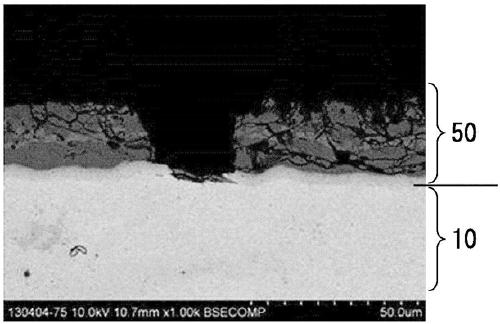

[0125] The inventors of the present invention respectively formed an Al—Zn-based plating layer, a Zn-based plating layer, and an Al-based plating layer on the base material 10 . The Al-Zn-based plating layer is set as a layer containing 55.0 mass % of Al and 45.0 mass % of Zn, the Zn-based plating layer is set as a layer containing substantially only Zn, and the Al-based plating layer is set as a layer containing substantially only Al .

[0126] Next, the steel material on which each coating layer was formed (the coated steel material including the base material and the coating layer) was put into the first heating furnace, heated to 700° C., and kept in this temperature range for 120 seconds. Then, put the coated steel material into the second heating furnace and heat it to 900°C, and then according to the steel material temperature at Ac 3 The plated steel material was taken out from the 2nd heating furnace so that the time in the range of -950 degreeC reached 30 seconds. ...

Embodiment 2

[0133] First, using molten steel having the chemical composition shown in Table 1, slabs were produced by continuous casting. Next, the slab was hot-rolled to produce a hot-rolled steel material, and the hot-rolled steel material was further pickled, and then cold-rolled to produce a cold-rolled steel material. Then, this cold-rolled steel material was used as a base material (thickness: 1.4 mm) for production of a hot-stamped body. Ac of base metal 3 The point is about 810°C.

[0134] Table 1

[0135]

[0136] Next, a plating layer was formed on the base material produced in this way using a plating bath having the composition shown in Table 2, and a steel material for hot stamping was obtained. The deposition amount of the plating layer was controlled so that the total weight of Al and Zn became the value shown in Table 2. The steel was heated to the alloying temperature shown in Table 2, and the temperature was maintained during the alloying time shown in Table 2. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com