Steel Sheet For Container, And Method For Producing Steel Sheet For Container

A manufacturing method and technology for steel plates, applied in chemical instruments and methods, manufacturing tools, coating of superimposed layers, etc., can solve the problem of corrosion resistance, coating adhesion or film adhesion reduction, hexavalent chromium keeping away, Hexavalent chromium is harmful and other problems, to achieve the effect of excellent film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

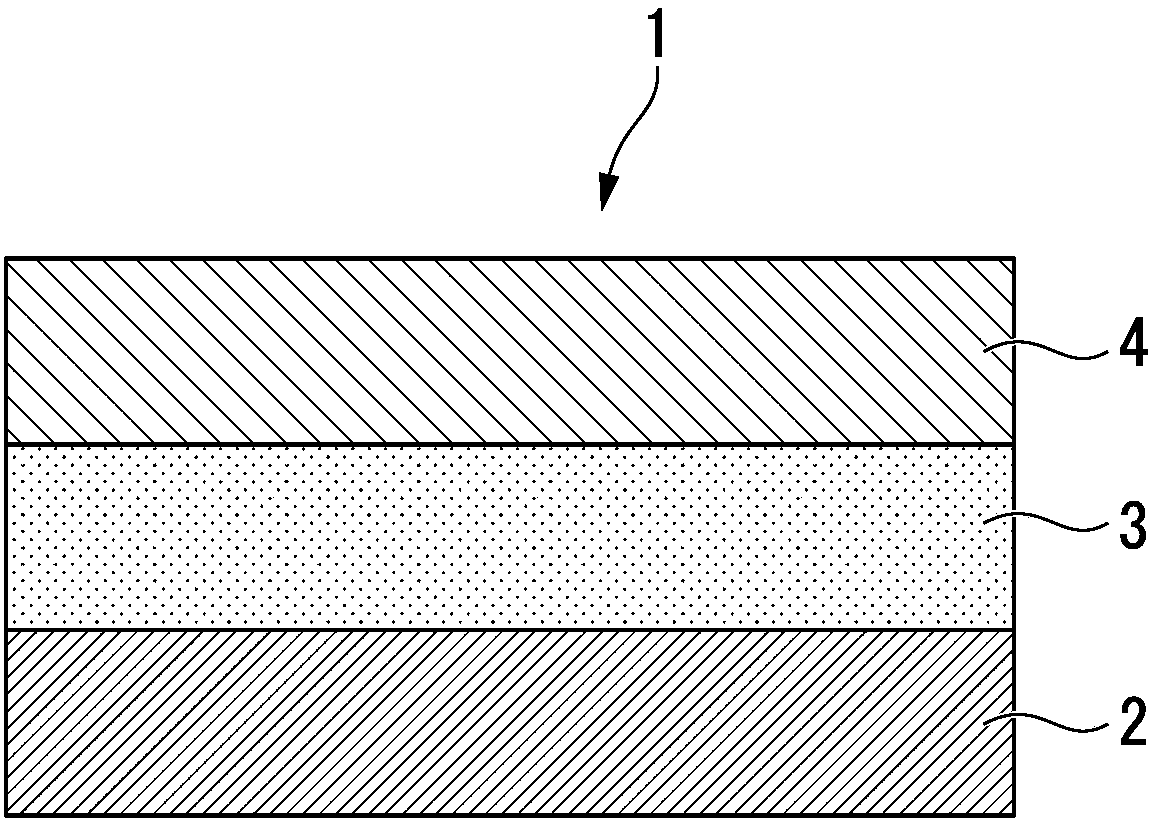

[0063] figure 1 A configuration diagram showing a steel plate 1 for a container according to the first embodiment of the present invention.

[0064] The steel plate 1 for containers has: a steel plate 2 ; a Sn plating layer 3 formed on the steel plate 2 ; and a chemical conversion treatment film layer 4 formed on the Sn plating layer 3 .

[0065] The steel plate 2 used in this embodiment is not particularly limited, and steel plates generally used as container materials can be used. The manufacturing method, material, etc. of the steel plate 2 are not particularly limited, as long as it is manufactured through processes such as hot rolling, pickling, cold rolling, annealing, and temper rolling in a normal steel billet manufacturing process.

[0066] The content of Sn in the Sn plating layer 3 is 300 mg / m in terms of metal Sn amount 2 ~5600mg / m 2 .

[0067] It should be noted that the "Sn coating" in this specification includes not only coatings containing metal Sn, but als...

no. 2 Embodiment approach

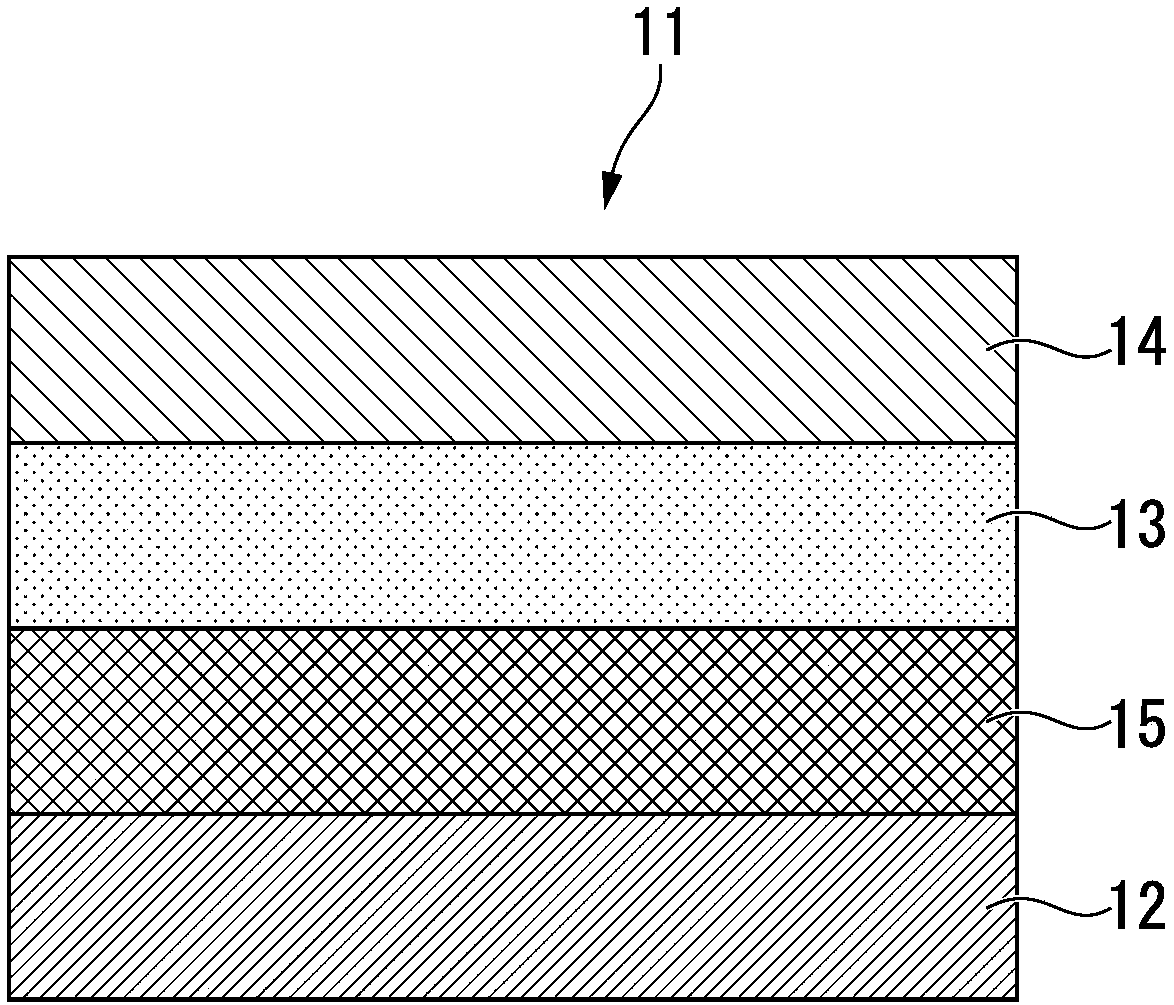

[0191] figure 2 A configuration diagram showing a steel plate 11 for a container according to a second embodiment of the present invention.

[0192] The steel sheet 11 for containers has: a steel sheet 12 ; a Ni plating layer 15 formed on the steel sheet 12 ; a Sn plating layer 13 formed on the Ni plating layer 15 ; and a chemical conversion treatment film layer 14 formed on the Sn plating layer 13 .

[0193] The Ni plating layer 15 is formed on at least one surface of the steel sheet 12 . The Ni plating layer 15 may be made of metallic Ni or may also be made of Fe—Ni alloy plating.

[0194] Since Ni is a metal having excellent corrosion resistance, since the steel sheet 11 for containers has the Ni plating layer 15, corrosion resistance can be ensured.

[0195] The corrosion resistance improves as the Ni content of the Ni plating layer 15 increases. If the Ni content is 5mg / m in terms of metallic Ni 2 Above, it has excellent corrosion resistance. On the other hand, if t...

Embodiment

[0219] Examples and comparative examples of the present invention are described below. It should be noted that the examples shown below are merely examples of steel sheets for containers and methods of manufacturing steel sheets for containers according to embodiments of the present invention, and the steel sheets for containers and methods of manufacturing steel sheets for containers according to embodiments of the present invention are not It is not limited to the examples shown below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com