Rubber composition having coating affinity and bellows for rail cars

A rubber composition and affinity technology, applied in vehicle parts, channels for connecting vehicles, coatings, etc., can solve the problems of lack of coating film affinity, difficulty in ensuring the adhesion between rubber and coating film, etc. To achieve the effect of excellent film adhesion, excellent flame retardant effect, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8、 comparative example 1~3

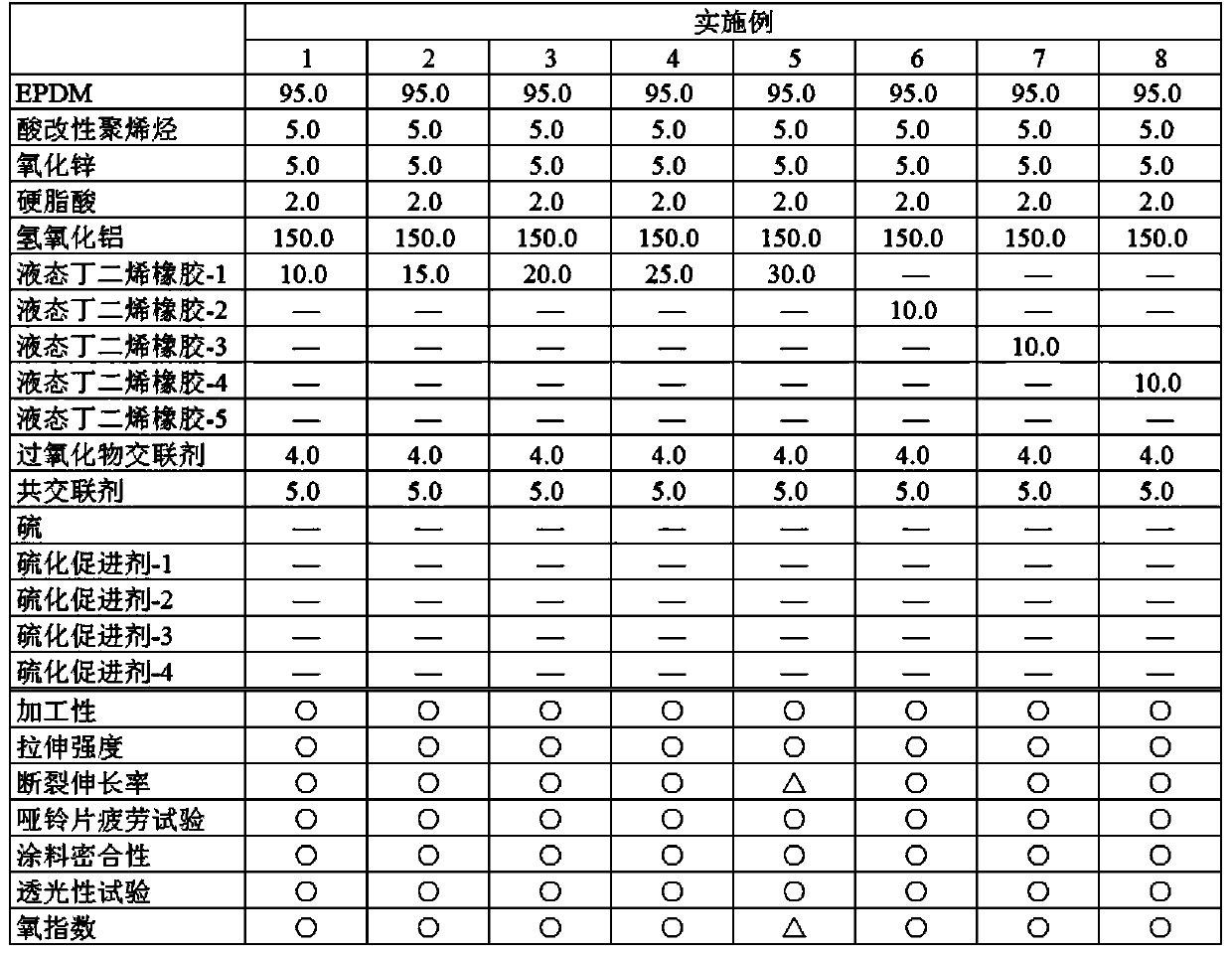

[0091] Each component shown in Table 1 and Table 2 described later was blended at the ratio shown in the table, and kneaded using a Banbury mixer and an open mill to prepare a rubber composition.

[0092] Using the rubber compositions of Examples and Comparative Examples obtained in this way, each property was evaluated according to the following criteria. The results are collectively shown in Table 1 and Table 2 below.

[0093] [processability]

[0094] The Mooney viscosity of the rubber composition (kneaded product) was measured at a test temperature of 121° C. in accordance with JIS K6300-1 (2001). Then, the Mooney viscosity (ML 1+4 121° C.) was evaluated as “◯” for a sample of 60 or less, and “×” for a sample exceeding 60.

[0095] [tensile strength, elongation at break]

[0096] The rubber composition was press-molded (vulcanized) at 150° C. for 20 minutes to prepare a rubber sheet with a thickness of 2 mm. Then, JIS No. 5 dumbbell pieces were punched out from the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com