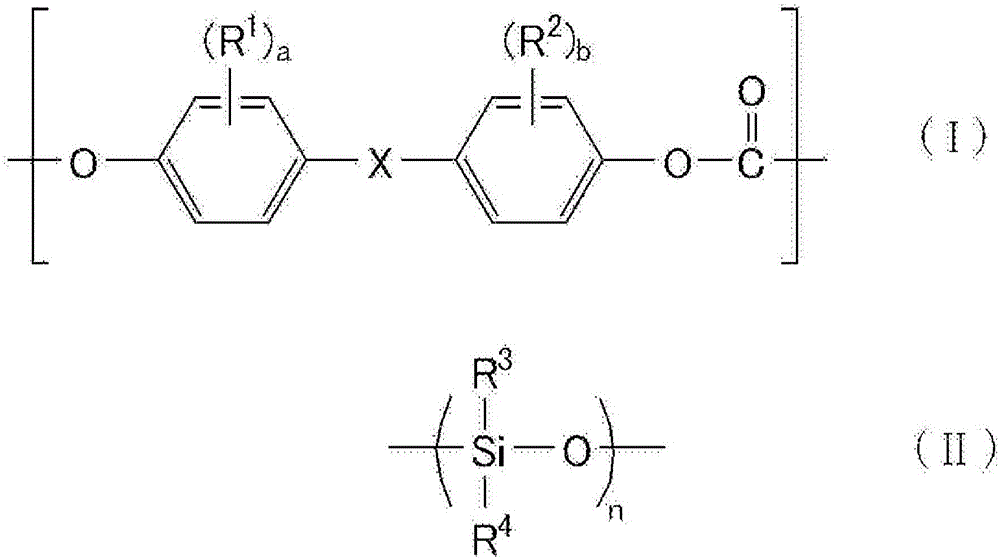

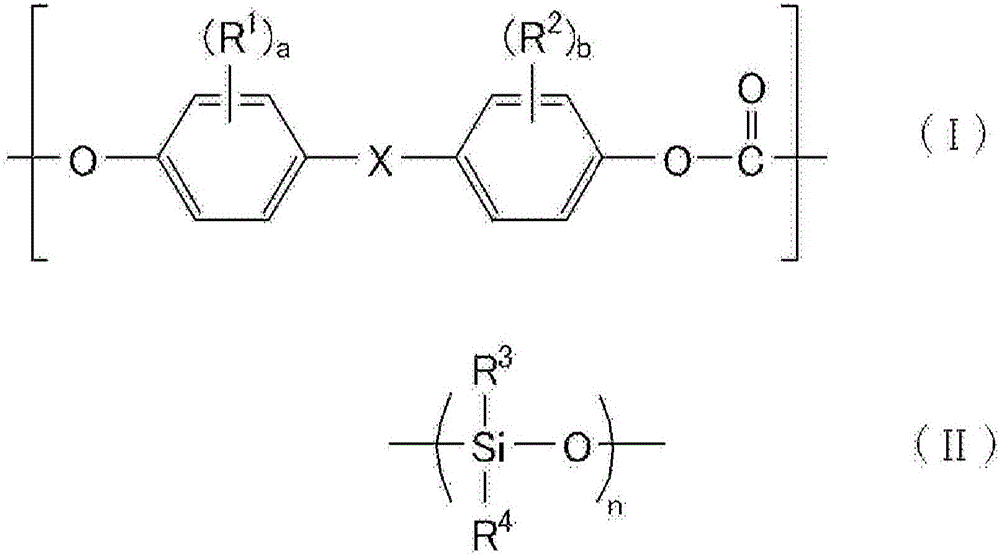

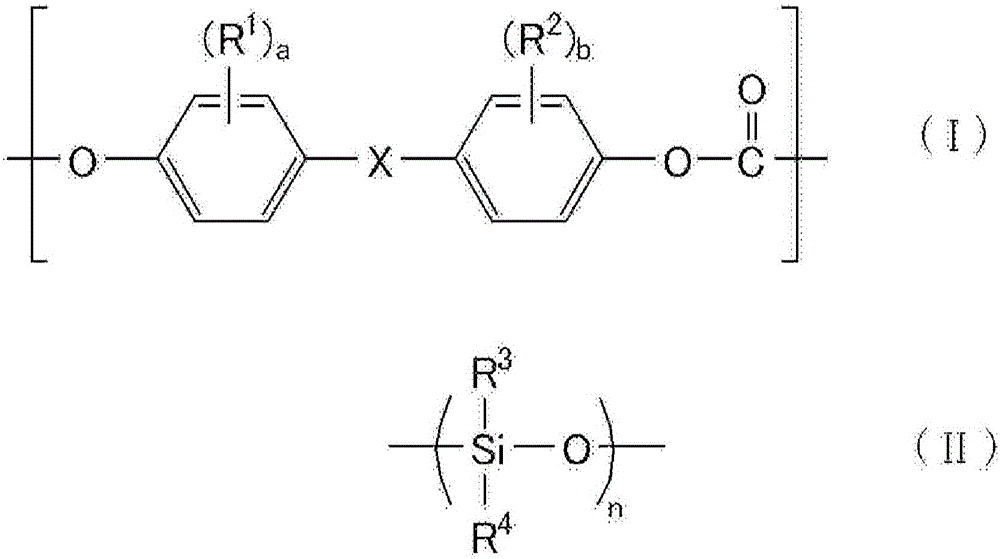

Polycarbonate resin molding material for articles to be coated, molded article and coated molded article

A technology of polycarbonate resin and polycarbonate, applied in the direction of coating, etc., can solve the problem of extremely low impact resistance and achieve the effect of excellent adhesion of the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0163]

[0164] 2,000 ppm of sodium dithionite was added to a 5.6% by mass sodium hydroxide aqueous solution relative to bisphenol A (BPA) dissolved thereafter, and bisphenol A was dissolved therein so that the bisphenol A concentration was 13.5% by mass to prepare bisphenol A aqueous sodium hydroxide solution.

[0165] With the sodium hydroxide aqueous solution of bisphenol A 40L (hereinafter, L is abbreviated as liter.) / hr, the flow rate of methylene chloride 15L / hr, and the flow rate of carbonyl chloride 4.0kg / hr, the inner diameter is 6mm, and the tube length is 30m. into the tubular reactor continuously.

[0166] The tubular reactor has a jacket portion, and cooling water is passed through the jacket to keep the temperature of the reaction solution at 40°C or lower.

[0167] The reaction solution flowing out of the tubular reactor was continuously introduced into a baffled tank reactor with an internal volume of 40 L of swept blades, and 2.8 L / hr of bisphenol A in aque...

manufacture example 1

[0171]

[0172] In a 50L tank reactor equipped with baffle plates, paddle-type stirring blades, and cooling jackets, add 15L of the polycarbonate oligomer solution produced in Preparation Example 1, 9.0L of dichloromethane, and dimethylsiloxane 384 g of o-allylphenol terminal-modified polydimethylsiloxane (PDMS) with an average repeating number n of alkane repeating units of 90 and 8.8 mL of triethylamine were added thereto with 6.4% by mass of sodium hydroxide under stirring 1389 g of the aqueous solution was used to react the polycarbonate oligomer and the allylphenol terminal-modified PDMS for 10 minutes.

[0173] To this polymerization solution, a dichloromethane solution of p-tert-butylphenol (PTBP) (a solution obtained by dissolving 137 g of PTBP in 2.0 L of dichloromethane), an aqueous sodium hydroxide solution of bisphenol A (in 8.4 L of water 577 g of sodium hydroxide and 2.0 g of sodium dithionite were dissolved, and 1012 g of bisphenol A was dissolved in the obtai...

Embodiment 1~2 and comparative example 1~4

[0185] The components were mixed in the proportions shown in Table 1, and pelletized at a resin temperature of 280° C. using a vented 50 mmφ single-screw extruder to obtain pellets containing a polycarbonate resin molding material for coating.

[0186] The pellets obtained by the above method were injection-molded with an injection molding machine (model: IS100EN, manufactured by Toshiba Machine Co., Ltd.) under the molding conditions of a cylinder temperature of 240°C and a mold temperature of 40°C to obtain various test pieces for evaluation. .

[0187]Then, with respect to the obtained test piece, paint (manufactured by Musashi Paint Co., Ltd., main agent: CPX79 silver, curing agent: H-250, organic solvent: ester system, main agent / curing agent / organic solvent (mass ratio) = 10 / 1 / 10) to obtain a coating test piece having a coating film with a thickness of 9±1 μm. And the coating drying conditions were 80 degreeC and 30 minutes.

[0188] The performance evaluation describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com