Coating solution for forming insulating film, method for forming insulating film of non-oriented electrical steel sheet and non-oriented electrical steel sheet by using it

A technology of insulating film and coating, which is applied in the coating process and coating of metal materials, can solve the problems of gloss reduction and compatibility reduction, and achieve the effect of excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

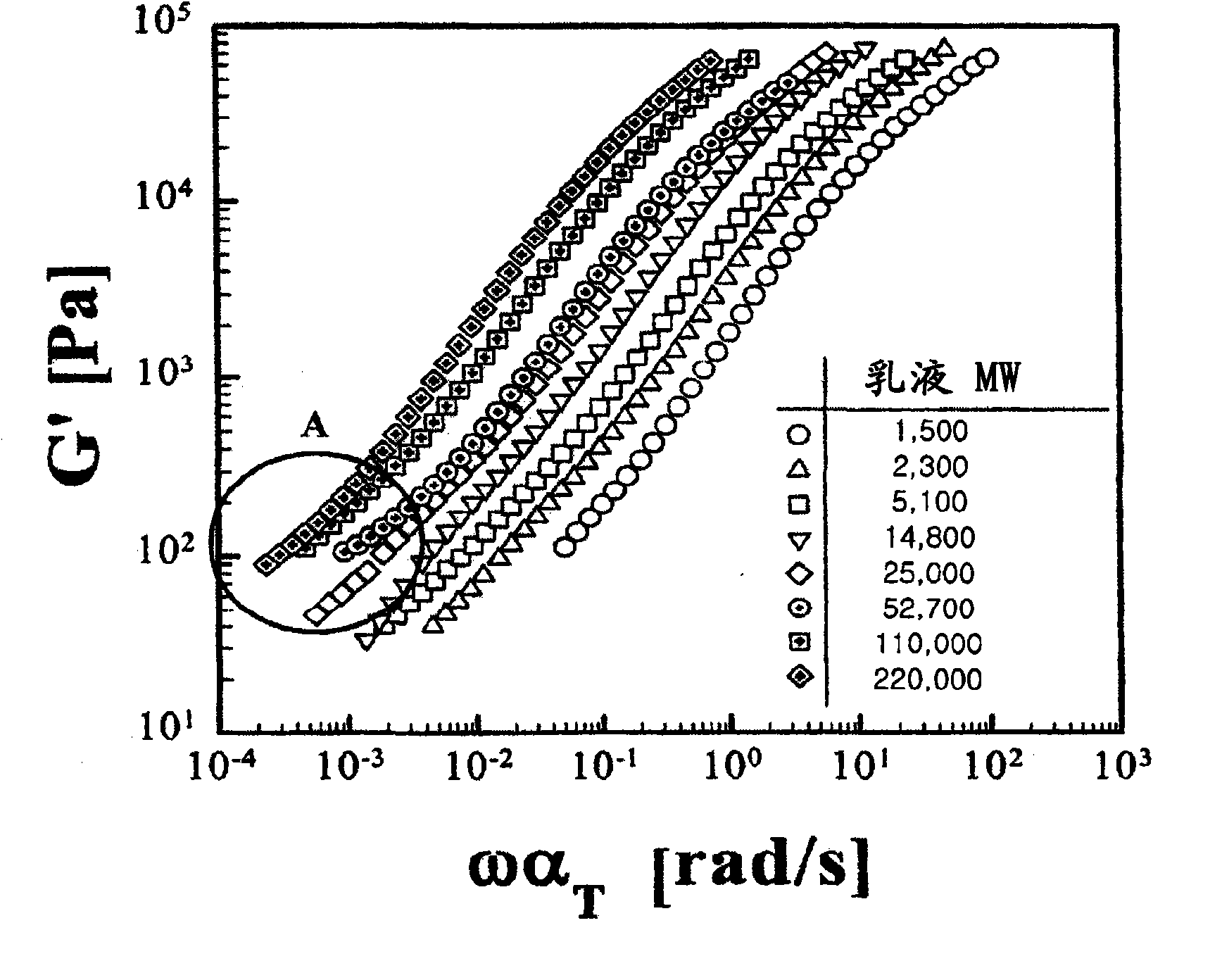

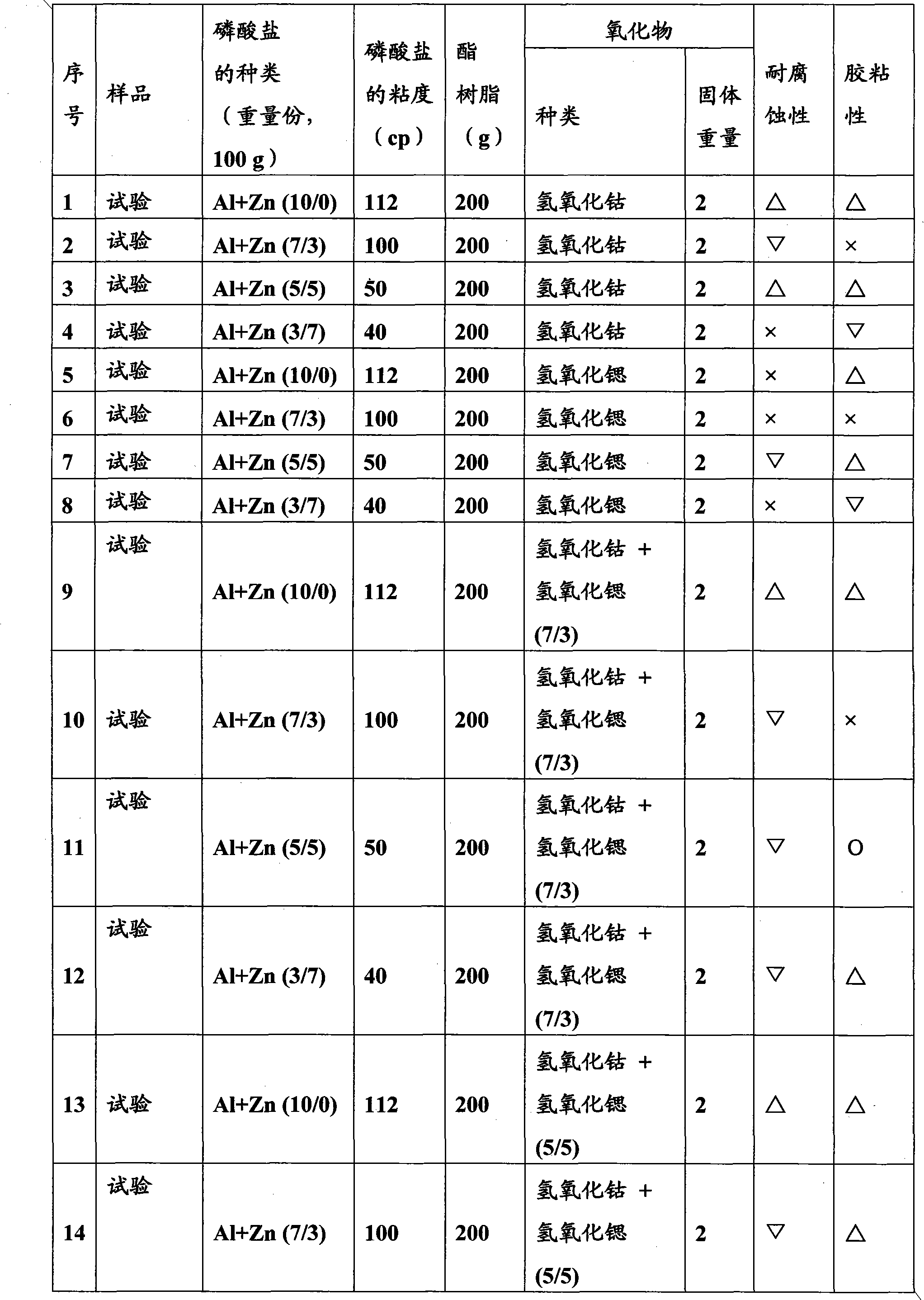

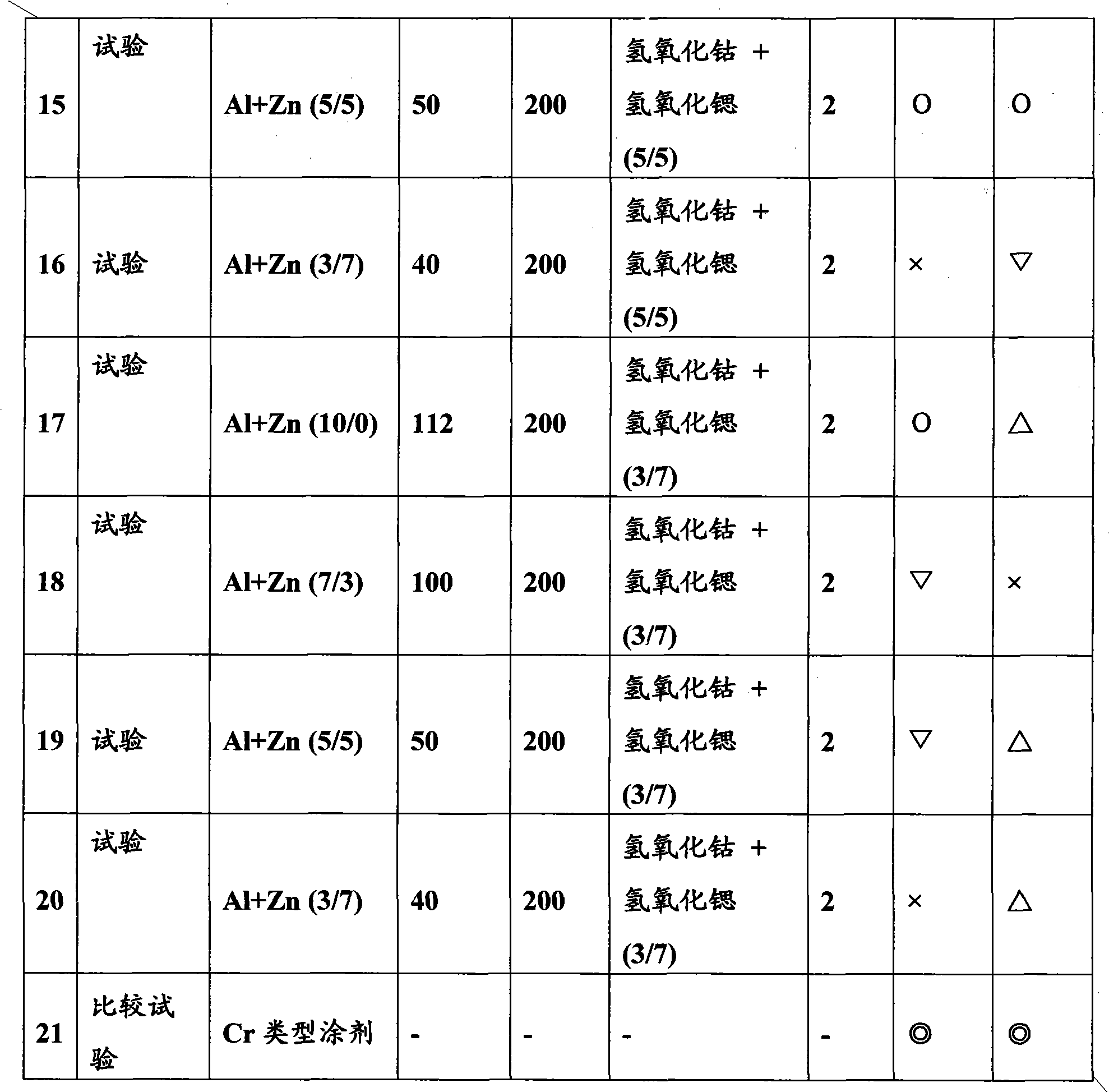

[0015] One aspect of the present invention provides a coating composition for forming an insulating film with excellent compatibility and surface gloss. Based on 100 g of a mixed solution of aluminum dihydrogen phosphate and zinc dihydrogen phosphate, the composition contains 0.5 ~5g mixed solution of cobalt hydroxide and strontium hydroxide, 150~300g polyester emulsion resin, 3~10g aluminum silicate and 0.5-6.0g chelating agent, wherein the polyester emulsion resin has a weight average molecular weight of 2,000~15,000 , 15-25% solid content and 100-500cp viscosity.

[0016] The phosphate may have a solid content of 55-60% by weight and a viscosity of 30-70 cp.

[0017] The mixed solution of cobalt hydroxide and strontium hydroxide may have a solid content of 55˜60% by weight based on the total weight of the phosphate.

[0018] The polyester emulsion resin may have a glass transition temperature (Tg) of 40˜50° C. and an acidity (pH) of 4˜5.

[0019] The chelating agent can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com