Surface treatment liquid for zinc-based coated steel sheet, zinc-based coated steel sheet with surface-treated film, and method for producing the same

A surface treatment liquid and surface treatment technology, applied in the field of zinc-based plated steel sheets, can solve problems such as unresearched, insufficient, and damaged appearance of sweat resistance, solvent resistance, and heat cracking resistance, and achieve storage stability Excellent, excellent coating adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120](1) Test board

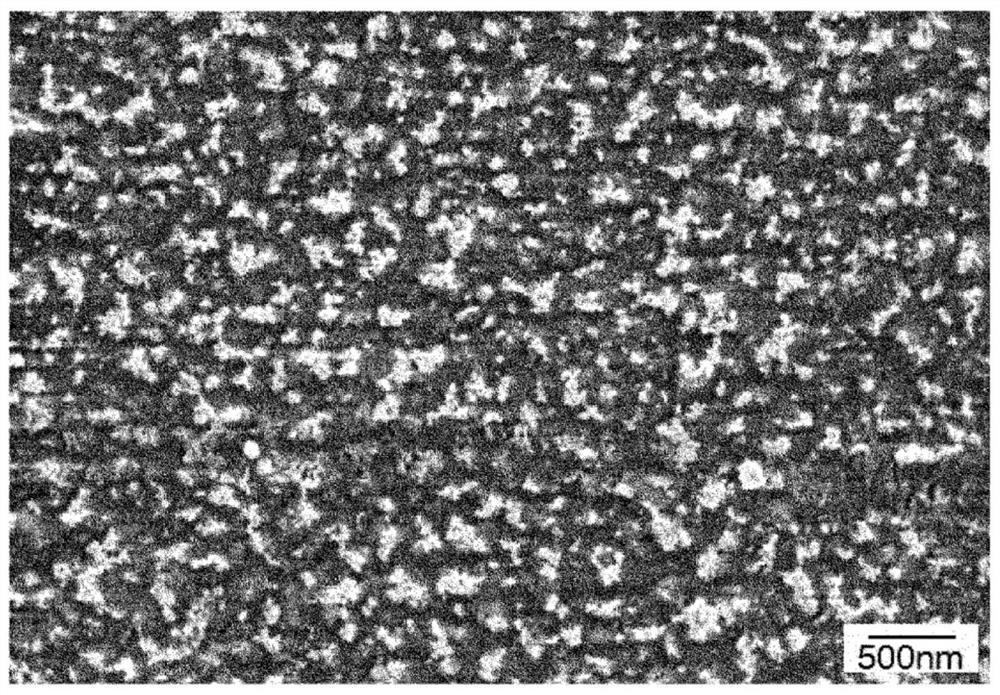

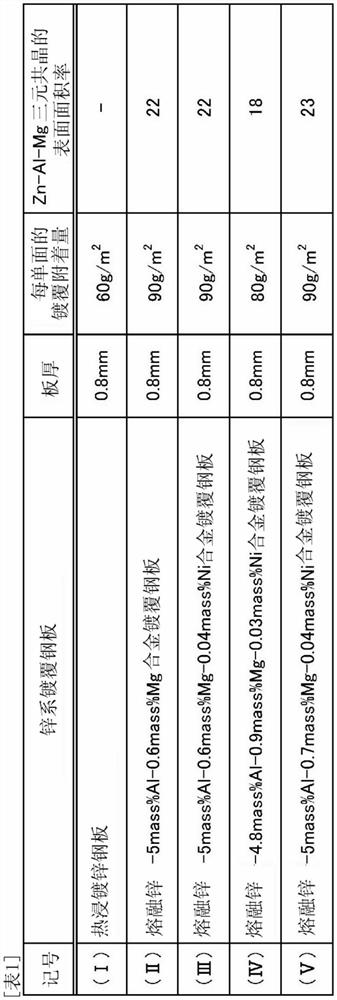

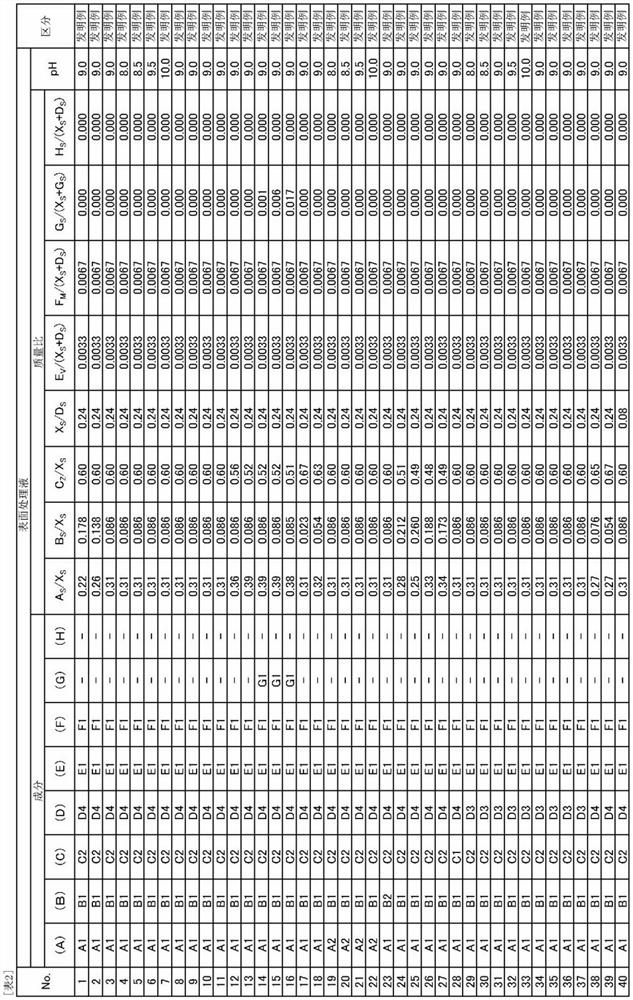

[0121]The various zinc-based coated steel sheets shown below were used as test plates. In addition, the zinc-based plating layer is formed on both sides of the steel sheet, and the adhesion amount in Table 1 refers to the adhesion amount of the zinc-based plating layer per one side. In addition, the surface area ratio of the Zn—Al—Mg ternary eutectic obtained by the following method is also shown in Table 1. That is, the untreated part of the surface of the plating layer was observed by SEM at an observation magnification of 100 times. Next, Mg mapping is performed through EDS in the same field of view. The analysis result is subjected to image analysis to convert white and black into two gradations. The area ratio of the Zn—Al—Mg system ternary eutectic is calculated from the two-tone gradation image. The same evaluation was performed in any 8 fields of view, and finally the area ratios of all fields of view were arithmetic averaged, and the obtained average val...

Embodiment 2

[0280]The preparation of (1) test plate, (2) pretreatment (cleaning), and (3) surface treatment liquid was performed in the same manner as in Example 1 above.

[0281](4) Treatment method

[0282]Use a bar coater to apply the surface treatment liquid of No. 93 in Table 2 to the pre-treated test plate shown in the "Steel Plate" column of Table 4, and then put it directly into the oven without washing with water. Single side formation with adhesion amount (in each single side) 900mg / m2The surface treatment film. At this time, set the temperature of the test plate and the temperature of the surface treatment liquid when the surface treatment liquid is applied to TSAnd TL, Will TS-TLIt is shown in Table 4 as ΔT. In addition, regarding the drying of the applied surface treatment liquid, Table 4 shows the pre-drying time t (seconds) until the test plate is placed in the oven and the highest value in the subsequent heat drying in the oven Plate temperature PMT. It should be noted that the adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com