Hot-dip zn-alloy-plated steel sheet and method for producing same

A technology of hot-dip plating and steel plate, applied in the direction of hot-dip plating process, chemical instruments and methods, liquid chemical plating, etc., can solve the problems of blackening of the coating surface, damage to the appearance, etc., and achieve the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

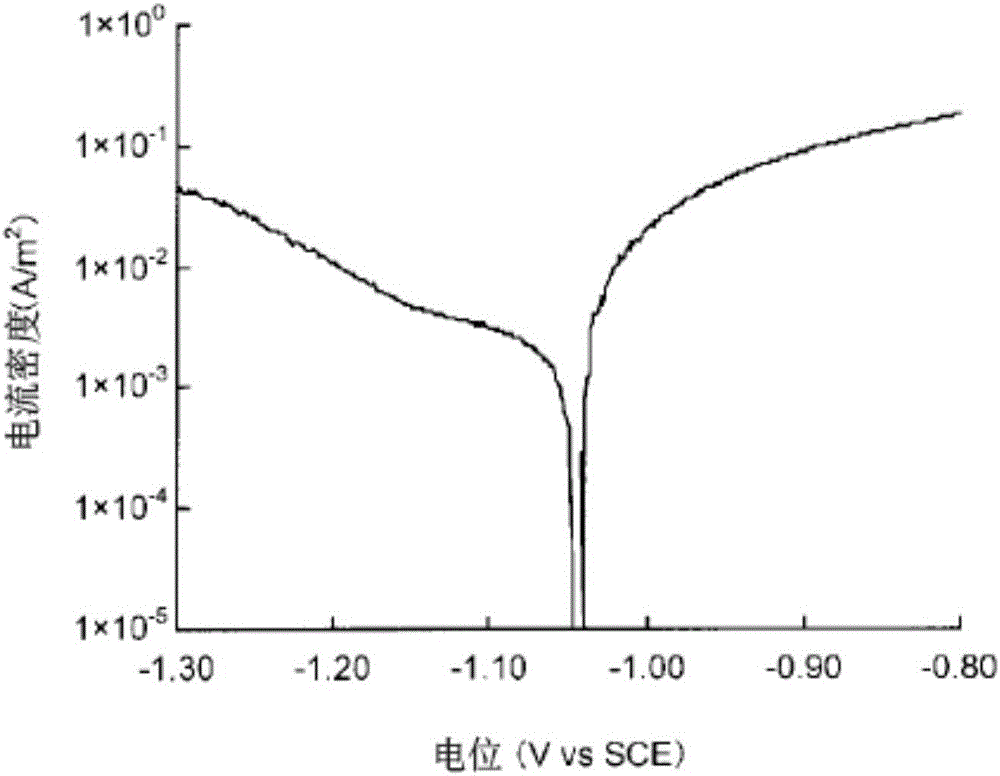

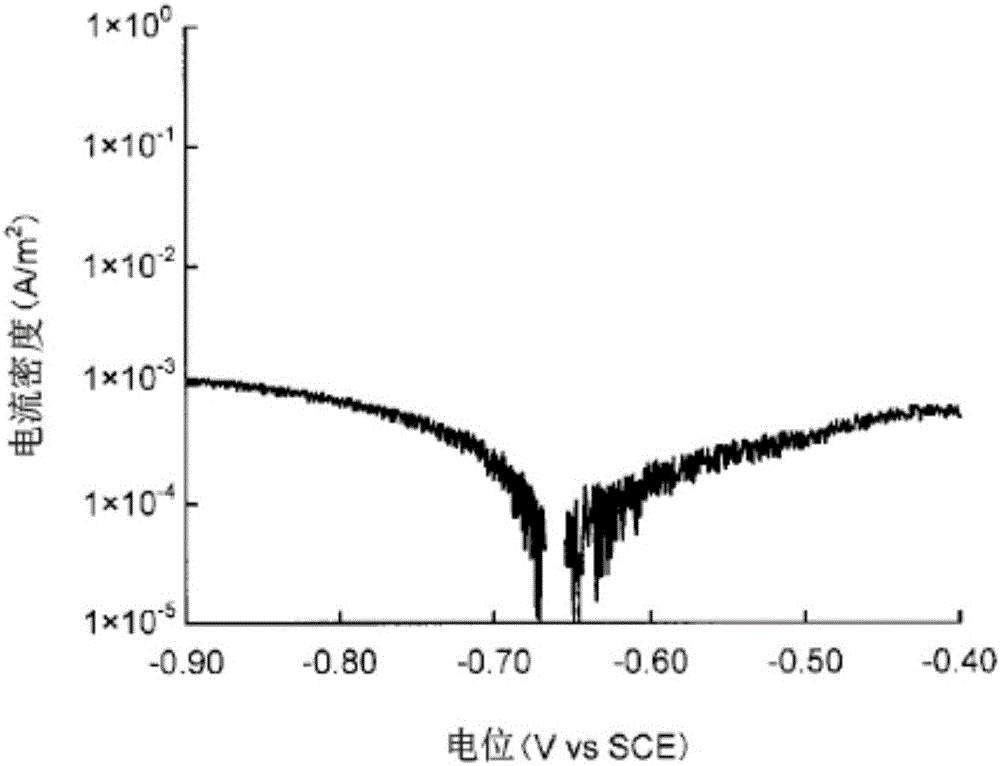

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

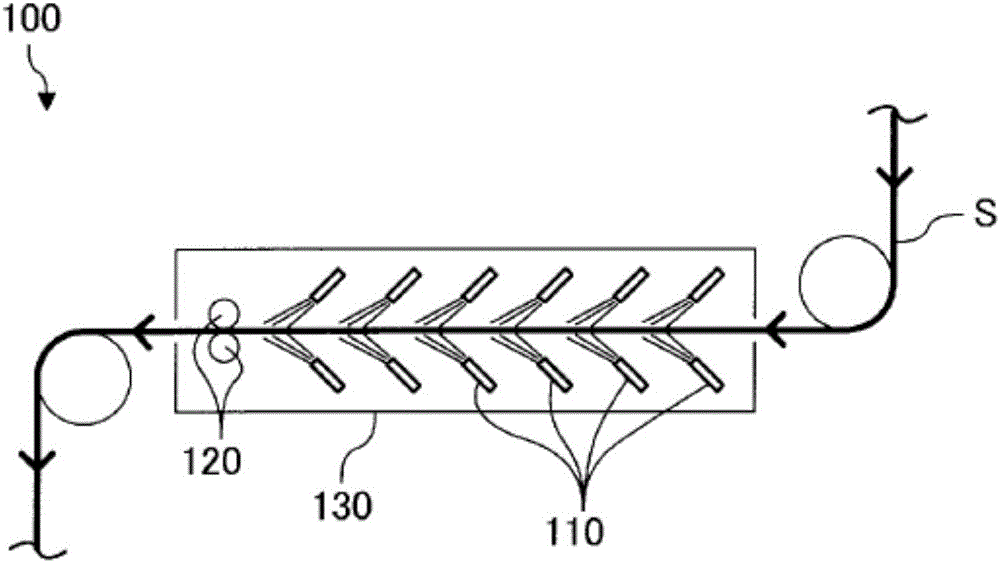

[0056](Manufacturing method of hot-dip Zn alloy plated steel sheet of the present invention)

[0057] The method for producing a hot-dip Zn alloy-plated steel sheet (hereinafter also referred to as "plated steel sheet") of the present invention has the following steps: (1) forming a hot-dip Zn alloy-plated layer (hereinafter also referred to as "plated layer") on the surface of a base steel sheet and (2) a second step of cooling the base steel sheet and the coating layer heated by the formation of the coating layer by bringing a predetermined aqueous solution into contact with the surface of the coating layer.

[0058] One of the characteristics of the production method of the present invention is that, after forming the hot-dipped Zn alloy layer, a predetermined cooling water solution is brought into contact with the surface of the plating layer to suppress blackening of the plating layer. Hereinafter, each step will be described.

[0059] (1) The first process

[0060] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com