Hot-dip zn-alloy-plated steel sheet

A hot-dip plating, steel plate technology, applied in hot-dip plating process, superimposed layer plating, metal material coating process and other directions, can solve the problems of blackening on the surface of the coating, damage to the appearance, etc., and achieve the effect of high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] (Hot dip Zn alloy plated steel sheet of the present invention)

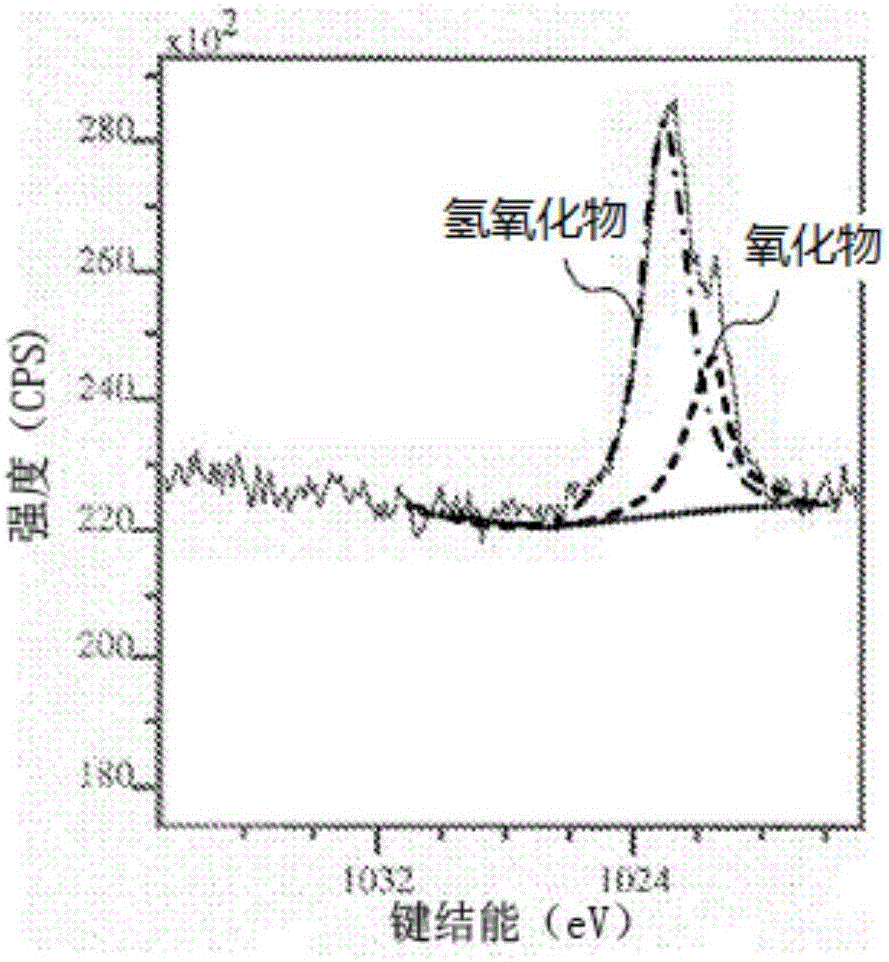

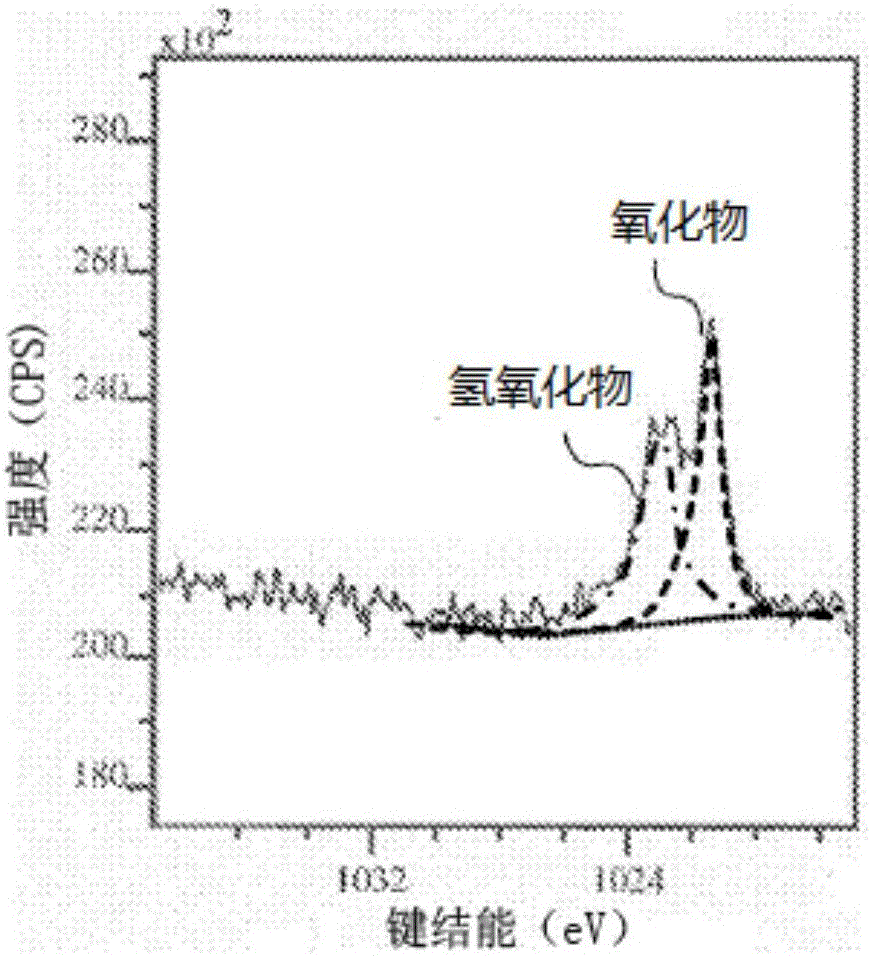

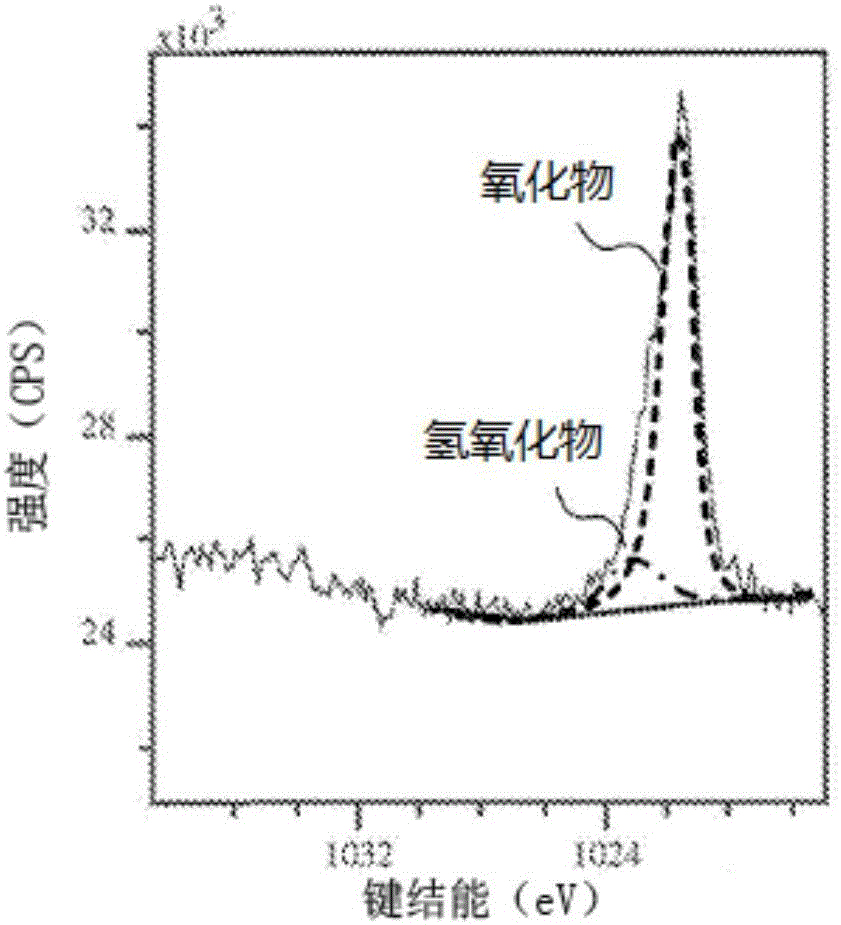

[0048] The hot-dip Zn alloy-plated steel sheet of the present invention has a base steel sheet, a hot-dip Zn alloy-plated layer, and a composite oxide film. The hot-dipped Zn alloy-plated steel sheet of the present invention has a predetermined composite oxide film, so it is excellent in blackening resistance.

[0049] The kind of base steel sheet is not particularly limited. For example, a steel plate made of low-carbon steel, medium-carbon steel, high-carbon steel, alloy steel, or the like can be used as the base steel plate. When good press formability is required, a steel sheet for deep drawing made of low-carbon Ti-added steel, low-carbon Nb-added steel, or the like is preferably used as the base steel sheet. In addition, high-strength steel sheets to which P, Si, Mn, etc. are added can also be used.

[0050] The hot-dip Zn alloy layer is disposed on the surface of the base steel sheet. The compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com