Hot-dip Zn-Al alloy coated steel sheet and process for the production thereof

A zn-al, hot-dip technology, applied in the hot-dip plating process, metal material coating process, coating, etc., can solve the problems of easy cracks in the coating, poor processability, and reduced blackening resistance of plated steel sheets, etc. problem, to achieve the effect of excellent processability and excellent blackening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

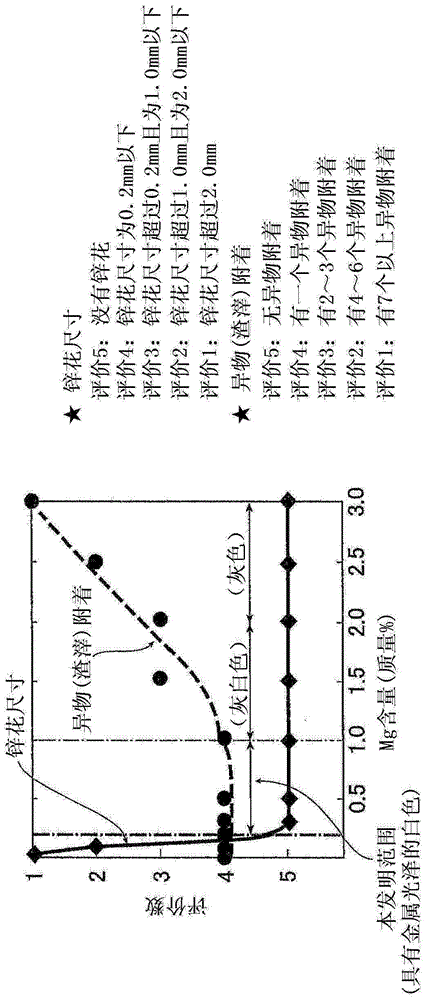

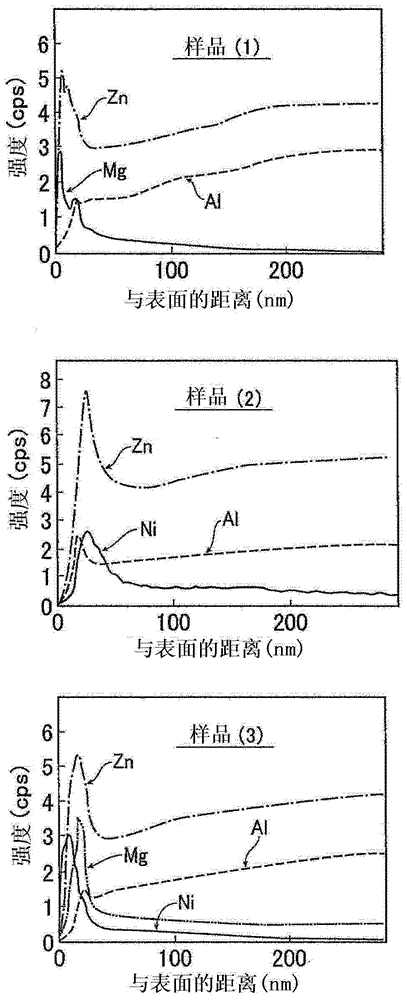

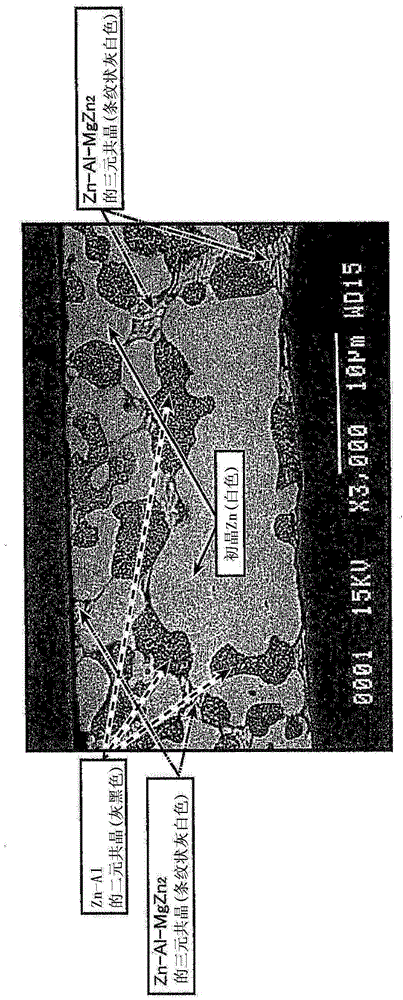

[0097] In the continuous hot-dip Zn-Al alloy equipment, the non-annealed Al-killed steel sheet with a thickness of 0.5mm and a width of 1500mm is hot-dipped to produce a hot-dip Zn-Al alloy steel sheet. The results of evaluating the plating appearance and blackening resistance of the obtained plated steel sheets were compared with the plating composition (average composition) of each plated steel sheet, the presence or absence and degree of Ni enrichment in the outermost layer of the plating layer, and the plating treatment conditions. (The temperature of the plating solution, the immersion time of the plating solution, and the cooling rate for cooling to 250° C. after plating) are shown in Table 1 and Table 2 together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com