Surface treating agent for medium-aluminum zinc-aluminum-magnesium coated steel plate and manufacturing method thereof

A surface treatment agent, a technology for coating steel plates, applied in the direction of metal material coating process, etc., can solve the problems of weak anti-oxidation ability, instability, affecting the product's resistance to blackening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

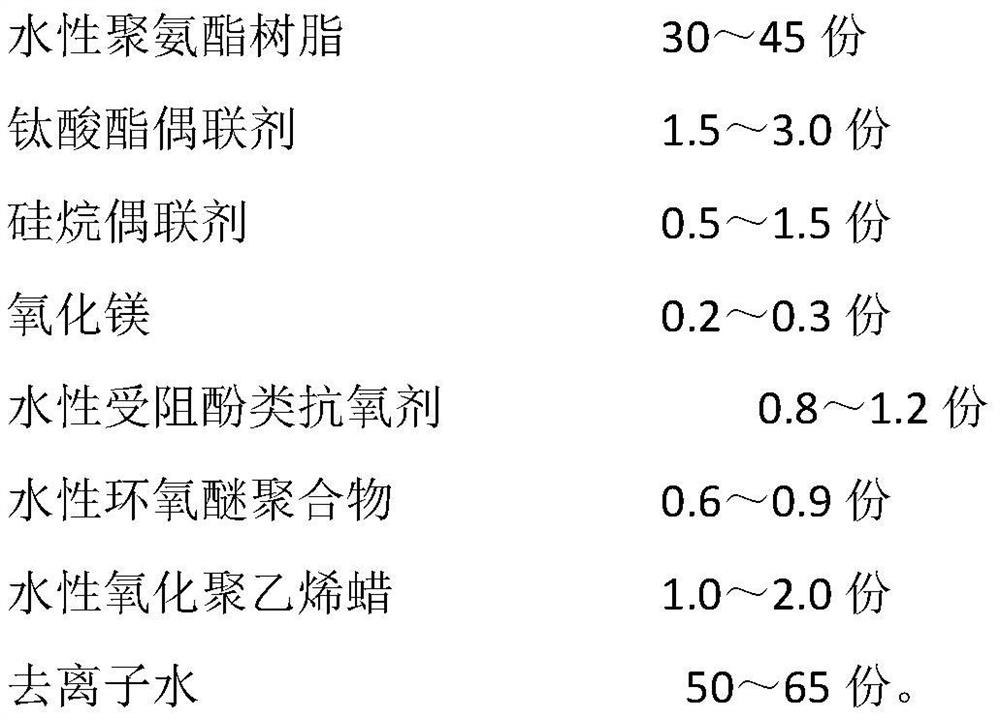

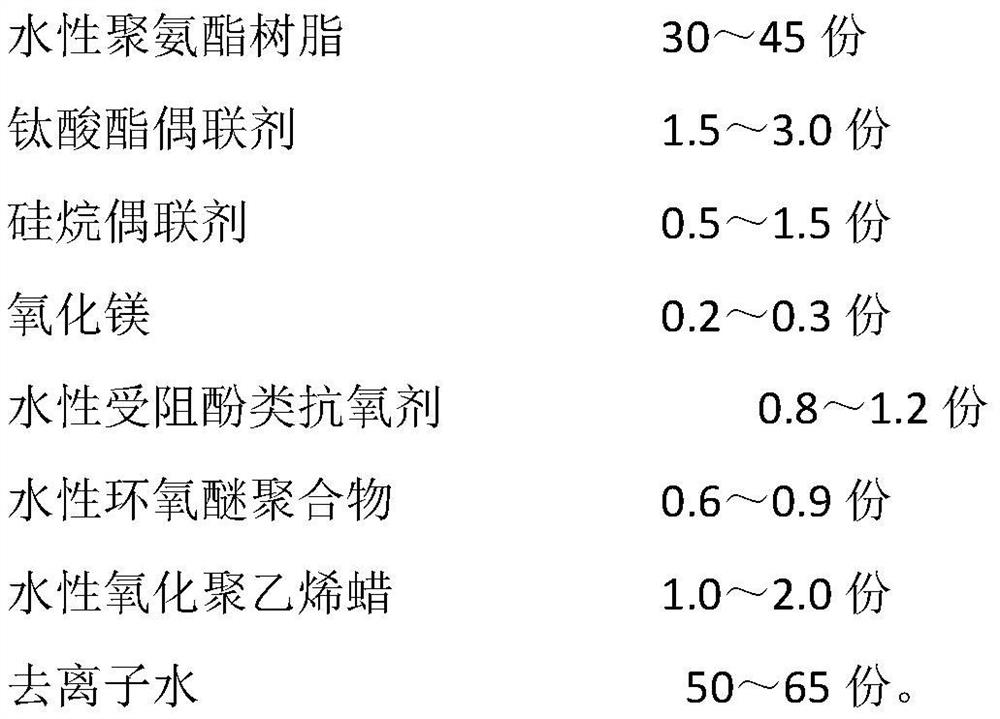

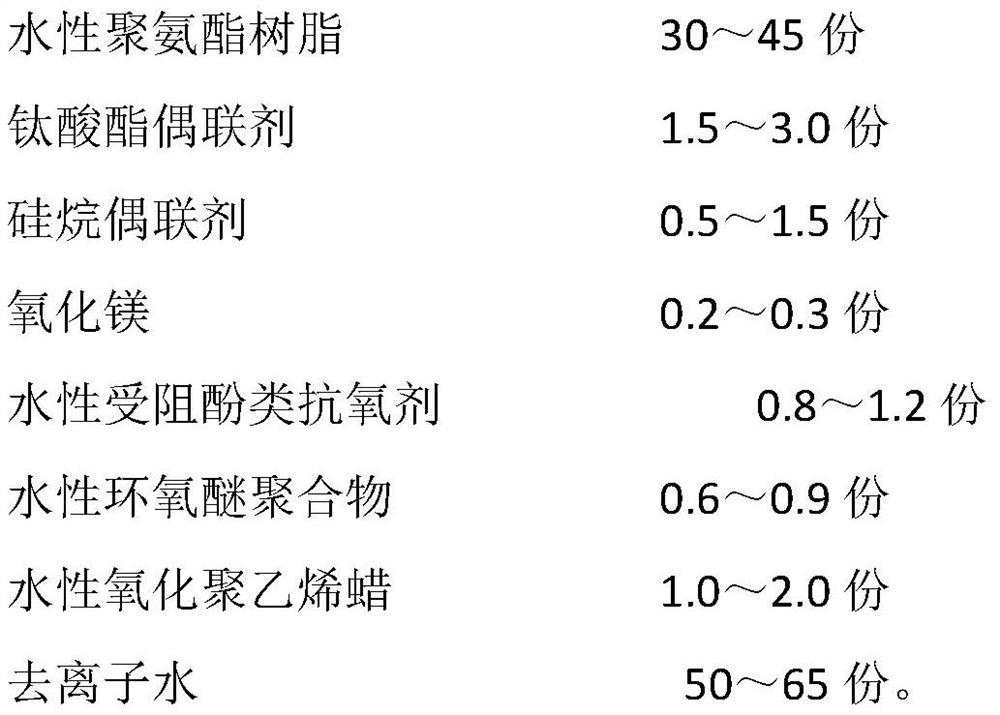

Method used

Image

Examples

Embodiment 1

[0047] At room temperature, add deionized water into the reaction kettle, add water-based polyurethane resin while stirring, and stir for 30 minutes; then add titanate coupling agent while stirring, and stir for 30 minutes; then add silane coupling agent while stirring, and stir 60min; add magnesium oxide while stirring, stir for 45min; add water-based hindered phenolic antioxidant, stir for 15min; water-based epoxy ether polymer, stir for 30min; water-based oxidized polyethylene wax, stir for 30min.

Embodiment 2

[0049]At room temperature, add deionized water into the reaction kettle, add water-based polyurethane resin while stirring, and stir for 30 minutes; then add titanate coupling agent while stirring, and stir for 30 minutes; then add silane coupling agent while stirring, and stir 60min; add magnesium oxide while stirring, stir for 45min; add water-based hindered phenolic antioxidant, stir for 30min; water-based epoxy ether polymer, stir for 15min; water-based oxidized polyethylene wax, stir for 15min.

Embodiment 3

[0051] At room temperature, add deionized water into the reaction kettle, add water-based polyurethane resin while stirring, and stir for 30 minutes; then add titanate coupling agent while stirring, and stir for 30 minutes; then add silane coupling agent while stirring, and stir 60min; add magnesium oxide while stirring, stir for 30min; add water-based hindered phenolic antioxidant, stir for 15min; water-based epoxy ether polymer, stir for 15min; water-based oxidized polyethylene wax, stir for 30min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com