Waterborne inorganic zinc-rich coating capable of realizing long-term corrosion protection based on single coating layer

An inorganic zinc-rich coating and water-based technology, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve the problems of phase separation and organic polymer aging easily, affecting the anti-corrosion performance of the coating film, and high requirements for substrate treatment. Long-term outdoor weather resistance, excellent salt spray resistance and corrosion resistance, and the effect of improving crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

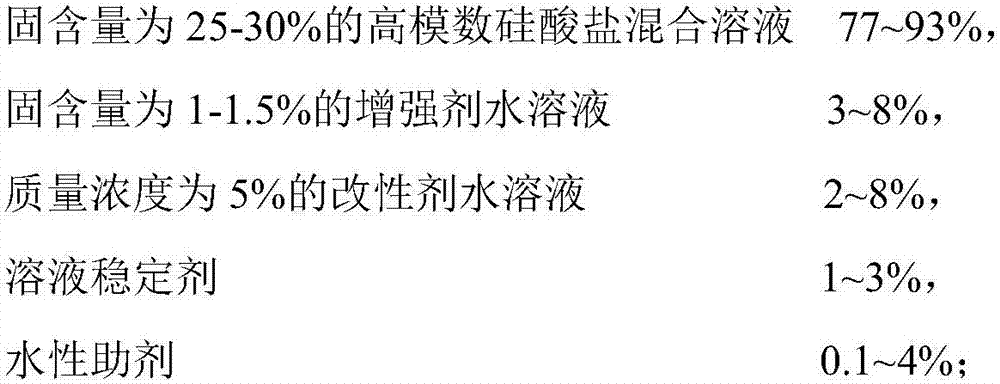

[0028] Weigh respectively 150 kilograms of potassium silicate solution and lithium silicate solution with a modulus of 4.0 and a solid content of 26%, and after being uniformly dispersed under stirring, slowly add 4 kilograms of 3-aminopropyltriethoxysilane. Add 18 kg of sodium oligoacrylate aqueous solution with a mass concentration of 5% under medium-speed stirring, then add 15 kg of boric acid aqueous solution with a solid content of 1.5% under medium-speed stirring, and finally add 1.2 kg of BYK-190 and 2.5 kg of cellulose , 0.5 kg of BYK-348, 1.0 kg of BYK-019, after the reaction is completed, the liquid A component is obtained.

[0029] Mix 92 kg of 800-mesh active zinc powder with 2 kg of nano-silica fume powder, 2 kg of nano-aluminum phosphate, 2 kg of nano-zinc oxide, and 2 kg of nano-silicon oxide to obtain component B of the powder.

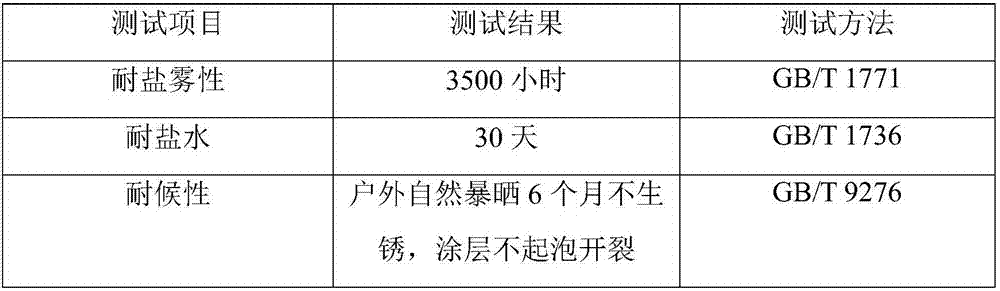

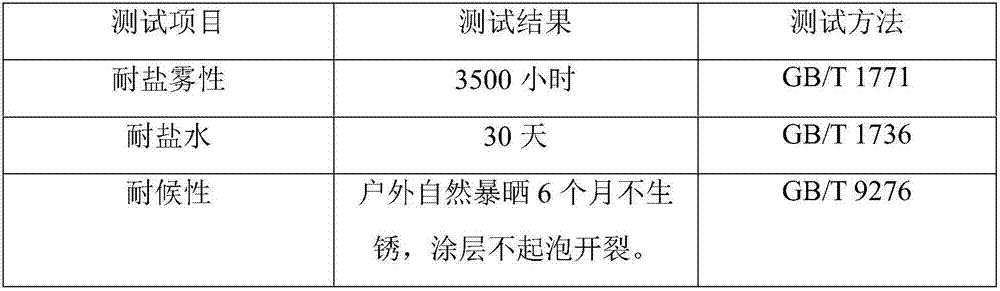

[0030] Mix liquid component A and powder component B uniformly at a mass ratio of 1:2.5 to obtain the required water-based inorganic ...

Embodiment 2

[0034] Weigh 100 kg of potassium silicate solution, 100 kg of sodium silicate solution and 100 kg of lithium silicate solution with a modulus of 3.8 and a solid content of 30%, and disperse evenly under stirring, slowly add 5 kg of methyl trimethoxy base silane, add 20 kg of oligoacrylamide aqueous solution with a mass concentration of 3% under medium-speed stirring, then add 20 kg of borax aqueous solution with a solid content of 1% under medium-speed stirring, and finally add 1.2 kg BYK- 191. 1.0 kg of BYK-020, 1.0 kg of titanate coupling agent, 2.5 kg of modified bentonite, and 0.8 kg of BYK-349. After the reaction is completed, the liquid component A is obtained.

[0035] Mix 92.5 kg of 500-mesh active zinc powder with 2 kg of nano-silica fume powder, 2.5 kg of nano-zinc oxide, 2.5 kg of nano-cerium oxide, and 0.5 kg of nano-calcium carbonate to obtain component B of the powder.

[0036] Mix liquid component A and powder component B uniformly at a mass ratio of 1:3.0 to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com