Chromium-free passivation solution for surface of hot-dip zinc-aluminum-magnesium steel plate and preparation method of hot-dip zinc-aluminum-magnesium chromium-free passivation plate

A chromium-free passivation, hot-dip galvanizing technology, applied in the direction of metal material coating process, can solve the problems of poor blackening resistance and corrosion resistance, unfavorable product application, lack of coating performance, etc., to achieve good environmental protection, The effect of good stability and excellent paintability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] 2. Preparation of hot-dip galvanized aluminum-magnesium chromium-free passivation plate:

[0030] Prepare hot-dip galvanized aluminum-magnesium alloy coated steel plate by conventional method, the chromium-free passivation solution on the surface of hot-dip galvanized aluminum-magnesium steel plate prepared in step 1 is coated on the surface of 2.5%Al-1.5%Mg-0.1%Si-Zn respectively by roll coating On the hot-dip galvanized aluminum-magnesium alloy coated steel plate, it is cured at a curing temperature of 95°C for 15 seconds to form a chromium-free passivation coating with a thickness of 0.5-2 μm, and cooled to room temperature to obtain a hot-dip galvanized aluminum-magnesium alloy coated chromium-free passivation coating. passivation plate passivation plate.

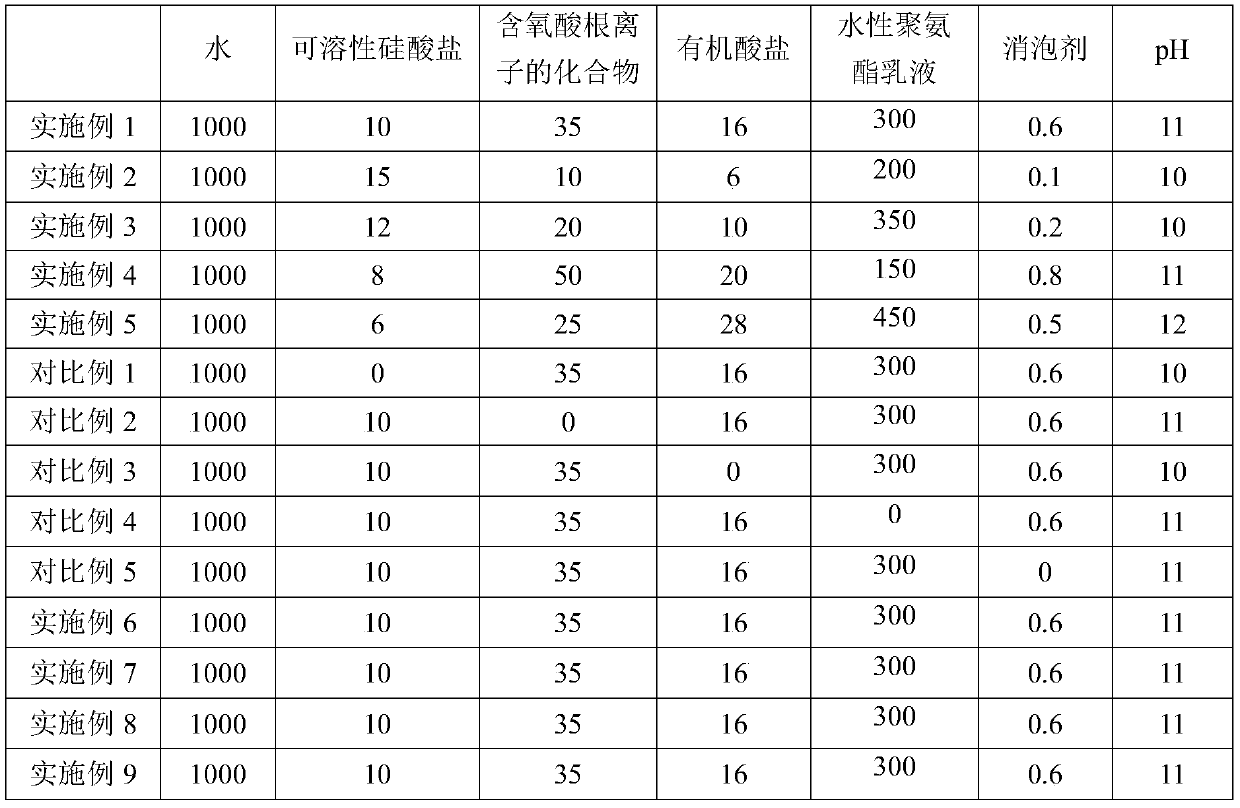

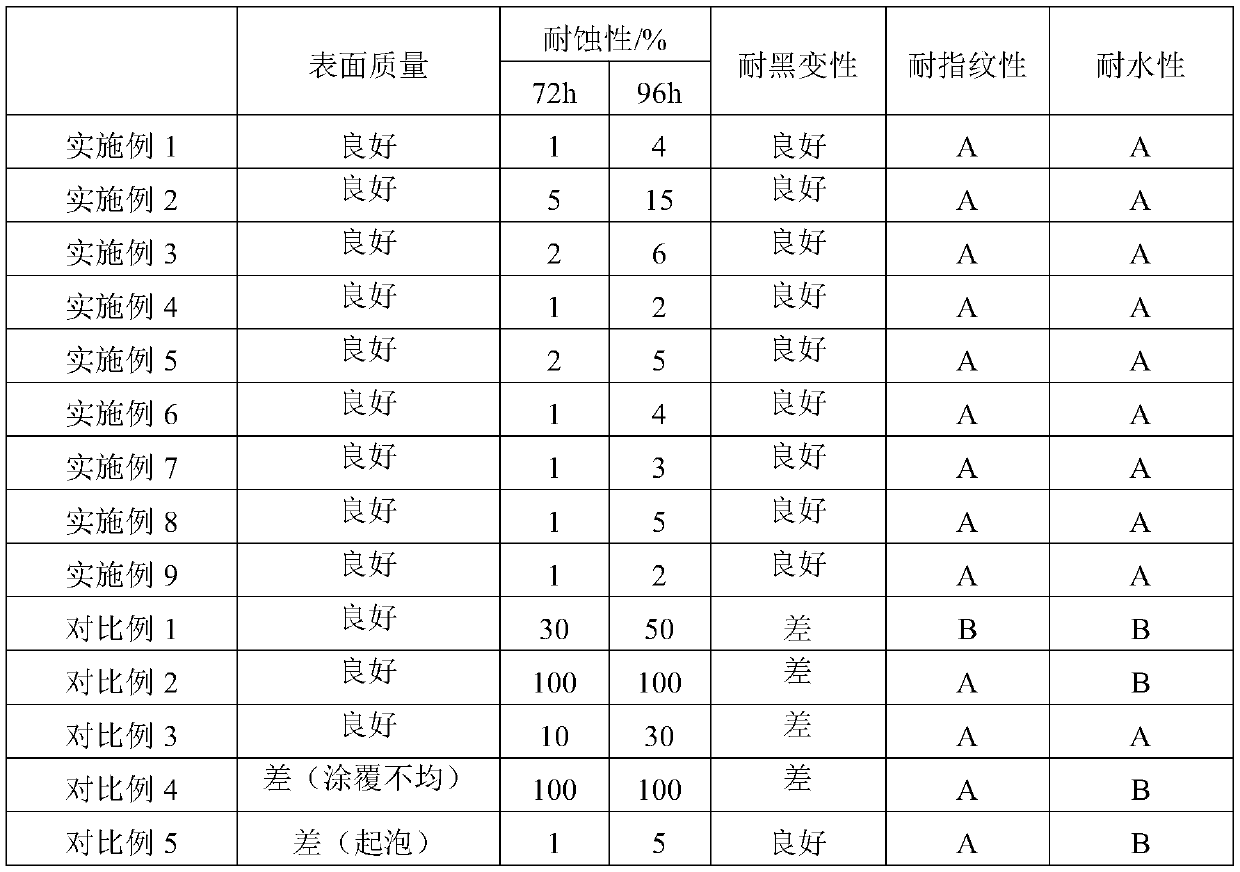

[0031] Chromium-free passivation solution (parts by weight) and pH on the surface of the steel plate in table 1

[0032]

[0033] In embodiment 1-9 and comparative example 1-5, the specific selection of each ...

Embodiment 7

[0036] In embodiment 7, different from embodiment 1, the compound of strong oxidizing oxyacid ion is sodium periodate Na 5 IO 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com