Surface-treated metal material and aqueous metal surface treatment agent

A technology for metal surface treatment and metal material, applied in the direction of metal material coating process, thin material treatment, device for coating liquid on the surface, etc., to achieve the effect of excellent blackening resistance and excellent corrosion resistance.

Active Publication Date: 2014-03-12

NIPPON STEEL CORP +1

View PDF11 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This technology is an excellent technology that has been put into practical use as a surface-treated steel sheet with a chrome-free surface treatment that is excellent in corrosion resistance, heat resistance, fingerprint resistance, electrical conductivity, painting workability, and blackening resistance during processing. , but surface-treated steel sheets with higher performance composite coatings are also required

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

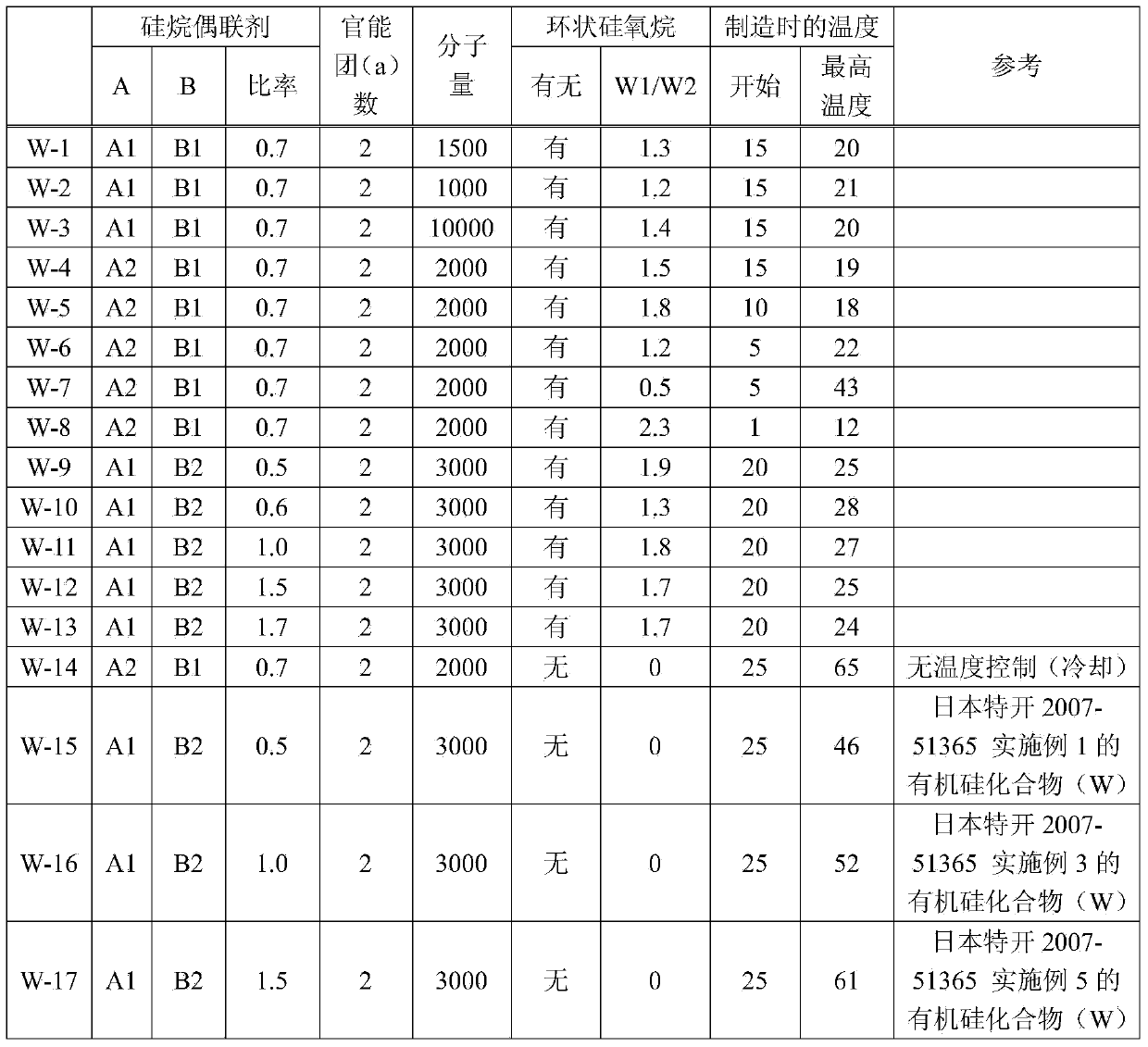

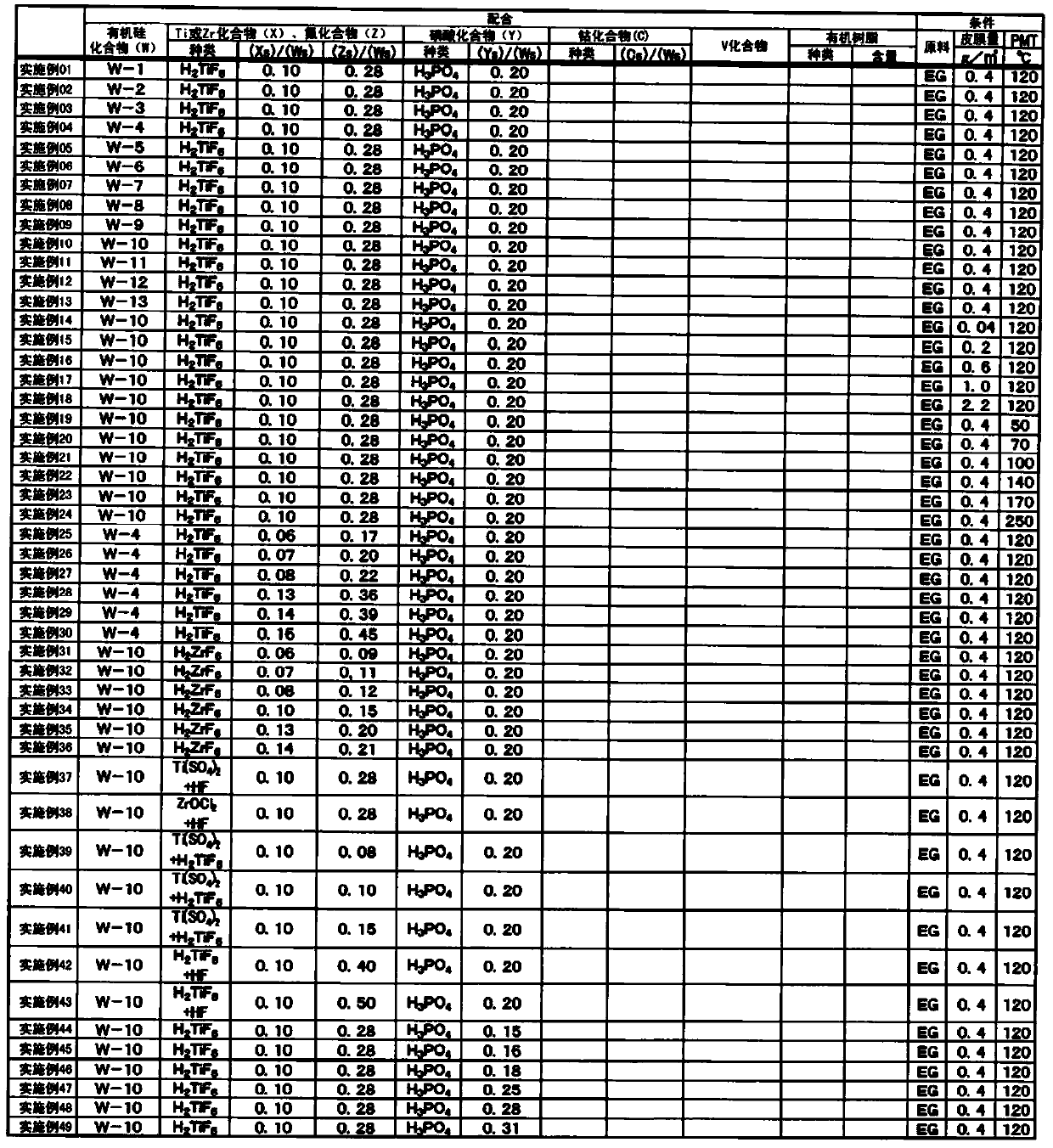

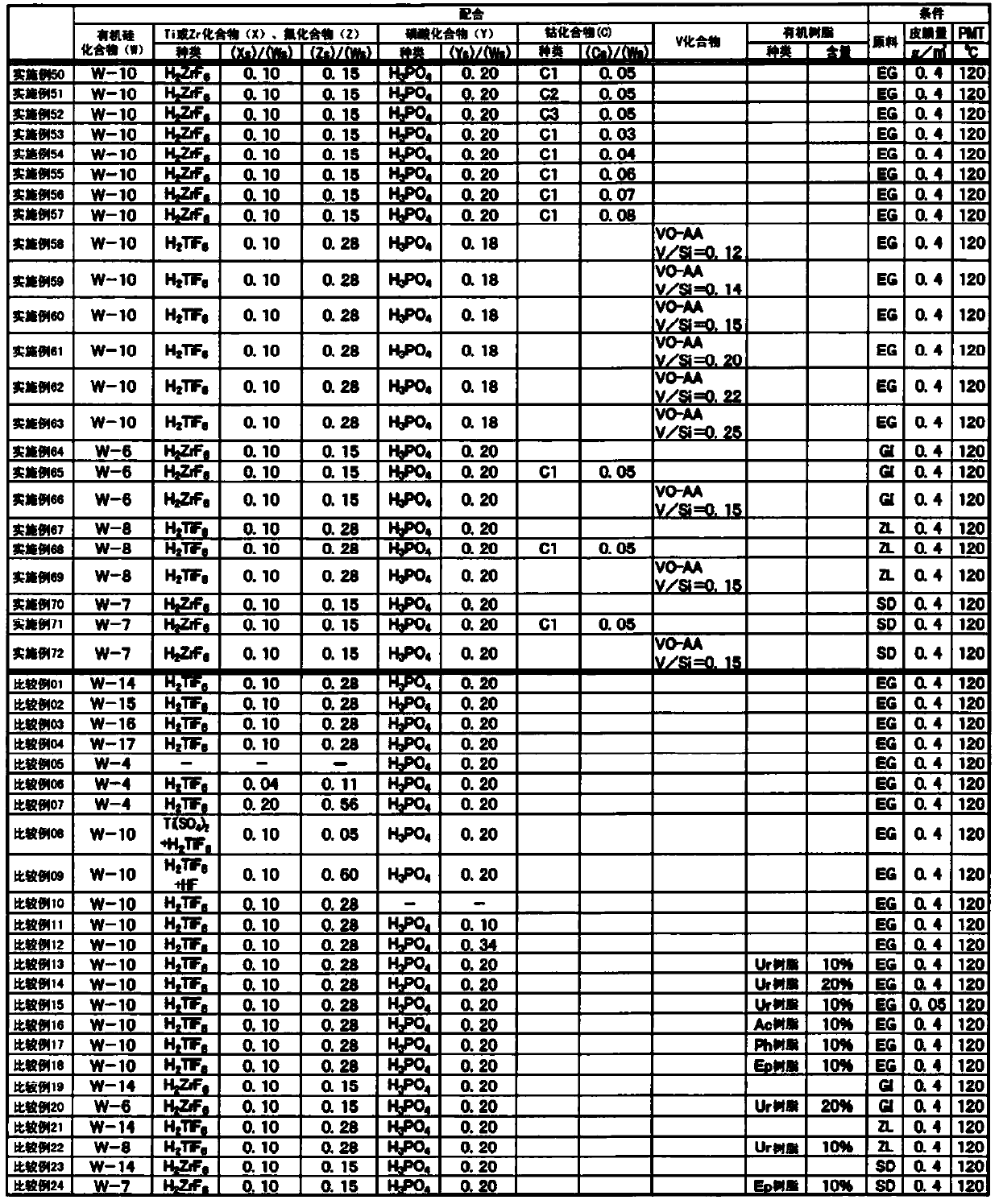

[0085] Hereinafter, the present invention will be specifically described with reference to Examples and Comparative Examples of the present invention, but the present invention is not limited thereto. Preparation of test panels, examples and comparative examples, and a method of applying a surface treatment agent for metal materials will be described below.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

A surface-treated metal material according to the present invention is a metal material the surface of which is coated with a composite film comprising an organic silicon compound (W) having cyclic siloxane bonds, at least one type of metal compound (X) selected from the group consisting of titanium compounds and zirconium compounds, a phosphoric acid compound (Y), and a fluorine compound (Z). In each component of the composite film, the ratio (XS / WS) of the solid content weight (WS) of Si derived from the organic silicon compound (W) and the solid content weight (XS) of the at least one metal component selected from the group consisting of Ti and Zr contained in the metal compound (X) is between 0.06 and 0.16, the ratio (YS / WS) of the solid content weight (WS) and the solid content weight (YS) of P derived from the fluorine compound (Z) is between 0.15 and 0.31, and the ratio (ZS / WS) of the solid content weight (WS) and the solid content weight (ZS) of F derived from the fluorine compound (Z) is between 0.08 and 0.50.

Description

technical field [0001] The present invention relates to a chromium-free surface-treated metal material excellent in corrosion resistance, heat resistance, fingerprint resistance, electrical conductivity, coating workability, and black deposit resistance during processing, and the surface Aqueous metal surface treatment agent used in treatment. More specifically, the present invention relates to a metal material that can maintain excellent corrosion resistance without being affected by alkali degreasing, bending processing, and punching processing when processing a surface-treated metal material into a molded product. A chrome-free surface-treated metal material that is excellent in heat resistance, fingerprint resistance, electrical conductivity, coating workability, and blackening resistance during processing, and an aqueous metal surface treatment agent used for the surface treatment. [0002] This application claims priority based on Japanese Patent Application No. 2011-10...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C22/36B05D7/14B32B9/00C09D7/63

CPCC23C2222/20C23C22/44C09D7/1233C23C22/361C09D7/63Y10T428/273Y10T428/12569Y10T428/31663C23C22/36B05D7/14B32B9/00

Inventor 森下敦司金藤泰平木全芳夫高桥彰菊池郁夫山口英宏野村信治

Owner NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com