Hot-dip galvanized aluminum-magnesium alloy coated steel plate and preparation method

A technology of aluminum-magnesium alloy and coated steel plate, applied in heat treatment equipment, hot-dip coating process, metal material coating process, etc., can solve the problems of backward technology and late production start, and achieve good surface quality and mechanical properties, excellent durability The effect of corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing a hot-dip galvanized aluminum-magnesium alloy coated steel plate, characterized in that: the steps of the method are:

[0038] S1, the steel plate after cold rolling is carried out chemical degreasing treatment, obtains the steel plate with clean surface, and the surface roughness of steel plate is 0.5~1.5 μ m, and plate shape I-Unit is less than 15;

[0039] S2, heat-treating the steel plate in step S1 to obtain a heat-treated steel plate;

[0040] S3, the heat-treated steel plate is sequentially subjected to hot-dip plating, air knife purging, and cooling to obtain a zinc-aluminum-magnesium alloy coated steel plate;

[0041] S4, the zinc-aluminum-magnesium alloy-coated steel sheet is subjected to skinning and stretching and straightening in sequence to obtain a zinc-aluminum-magnesium alloy-coated steel sheet with excellent surface quality and plate shape;

[0042] S5, carrying out environmental protection passivation and anti-fingerprint post-...

Embodiment 11

[0070] When the sample of Example 11 (Zn-1.8Al-0.9Mg-0.05Si-Mn (trace amount)) was subjected to accelerated corrosion in the salt spray test chamber for 480 hours, part of the white rust appeared on the edge, and when it was 600 hours, the area of the white rust expanded, and the plate Slight white rust appeared on the surface, and light and heavy red rust appeared on the edge at 2040h. Until the end of the test at 2160h, no large area of white rust appeared on the surface of the sample. It can be seen from Table 2 that the samples of other examples show the same or even better corrosion resistance in the salt spray test.

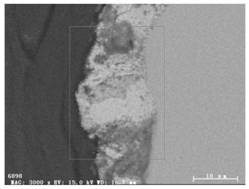

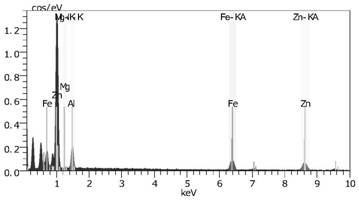

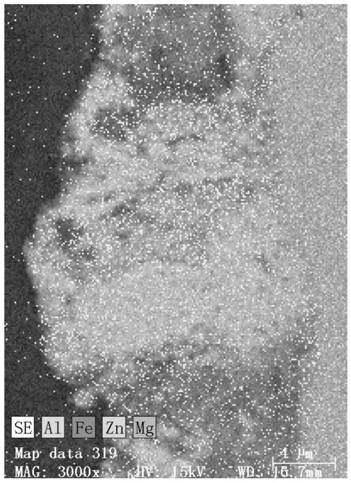

[0071] figure 1 It is the SEM scanning electron microscope interface diagram of Example 11, magnification: 3000×, high voltage: 15.0 kV. figure 2 It is the cross-sectional chemical composition analysis diagram of Example 11, high voltage: 15.0kV, pulse: 0.49kcps. image 3 It is the cross-sectional element distribution diagram of Example 11, magnific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com