Rolling method for composite strip of stainless steel and straight carbon steel

A technology of clad strip and plain carbon steel, applied in metal rolling and other directions, can solve the problems of metal clad plate without market competitiveness, low yield, complex process, etc., to achieve overall combination effect guarantee, high yield, The effect of short process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

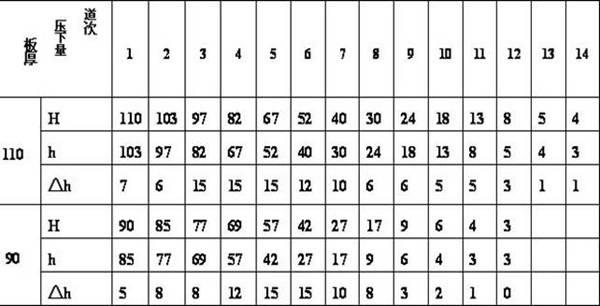

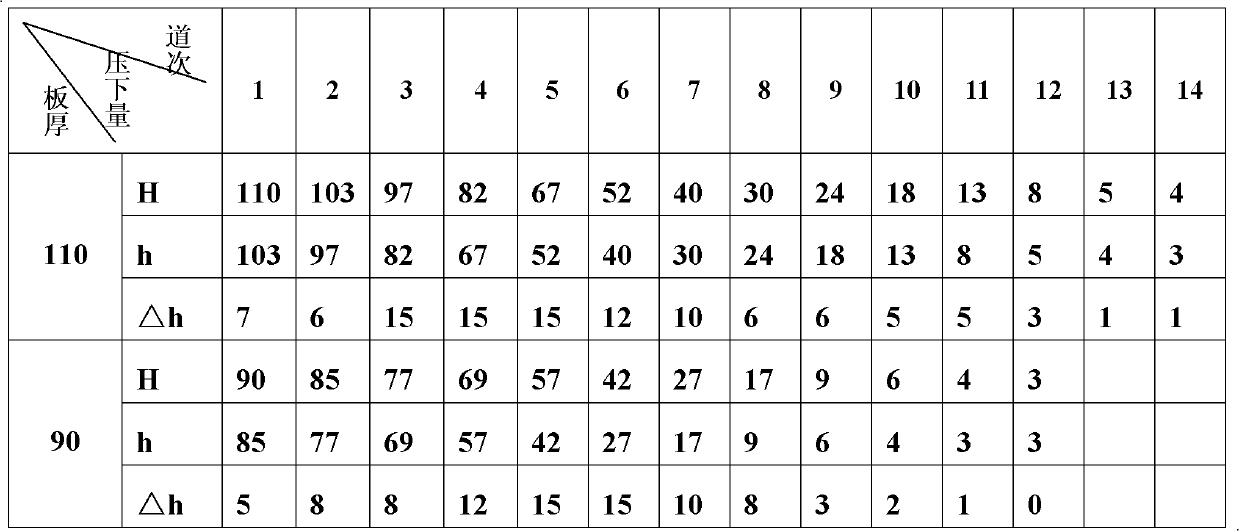

Embodiment 1

[0030] Take the stainless steel and common carbon steel composite strip with a rolling specification of 0.5 mm in thickness of stainless steel and 2.5 mm in thickness of common carbon steel as an example.

[0031] A) Prepare materials, select the ordinary carbon steel billet with a thickness of 100mm and the grade of 08AL as the base plate, select the grade with a thickness of 10mm as the OCr18Ni9 stainless steel plate as the cladding plate, and blank the selected substrate, specifically: adopt gas cutting method to 08AL (08 means that the mass fraction of carbon in the steel is 0.08%, A means the quality grade, L means the tensile properties, 08AL is a kind of well-known high-quality carbon structural steel) substrate blanking, and the stainless steel is cut by plasma cutting The blanking of the doubler board, the diagonal error of the blanked substrate and the doubler board should be controlled within ≤ 5mm to obtain the base board blank and the doubler board blank;

[0032]...

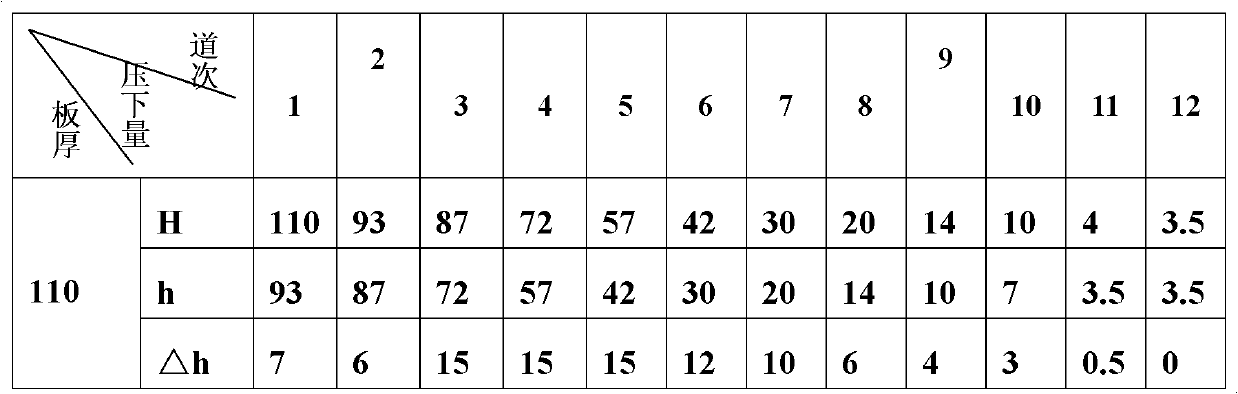

Embodiment 2

[0041] Take the composite strip of stainless steel and common carbon steel whose rolling specification is 0.5 mm in thickness of stainless steel and 2.0 mm in thickness of common carbon steel as an example.

[0042] A) Prepare the material, select the ordinary carbon steel billet with a thickness of 95mm as the 08AL grade as the base plate, choose the OOCr18Ni10 stainless steel plate with a thickness of 9mm as the cladding plate, and blank the selected base plate, specifically: adopt gas cutting method to 08AL (08 means that the mass fraction of carbon in the steel is 0.08%, A means the quality grade, L means the tensile properties, 08AL is a kind of well-known high-quality carbon structural steel) substrate blanking, and the stainless steel is cut by plasma cutting The blanking of the doubler board, the diagonal error of the blanked substrate and the doubler board should be controlled within ≤ 5mm to obtain the base board blank and the doubler board blank;

[0043] B) Pretrea...

Embodiment 3

[0052] Take the composite strip of stainless steel and common carbon steel whose rolling specification is 0.5mm thick of stainless steel and 1.5mm thick of common carbon steel as an example.

[0053] A) Prepare materials, select the ordinary carbon steel billet with a thickness of 90mm as the grade of 08AL as the base plate, select the grade with a thickness of 10mm as the OOCr17Ni14Mo stainless steel plate as the cladding plate, and blank the selected base plate, specifically: adopt gas cutting method to 08AL (08 means that the mass fraction of carbon in the steel is 0.08%, A means the quality grade, L means the tensile properties, 08AL is a kind of well-known high-quality carbon structural steel) substrate blanking, and the stainless steel is cut by plasma cutting The blanking of the doubler board, the diagonal error of the blanked substrate and the doubler board should be controlled within ≤ 5mm to obtain the base board blank and the doubler board blank;

[0054] B) Pretrea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com