Method for preparing polyaluminum ferric chloride by using iron-containing acid pickle and aluminum ash

A technology of polyaluminum ferric chloride and waste acid liquid, which is applied in the fields of ferric halide, flocculation/sedimentation water/sewage treatment, etc., can solve problems that have not been seen before, and achieve the effect of convenient operation, easy operation and short process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

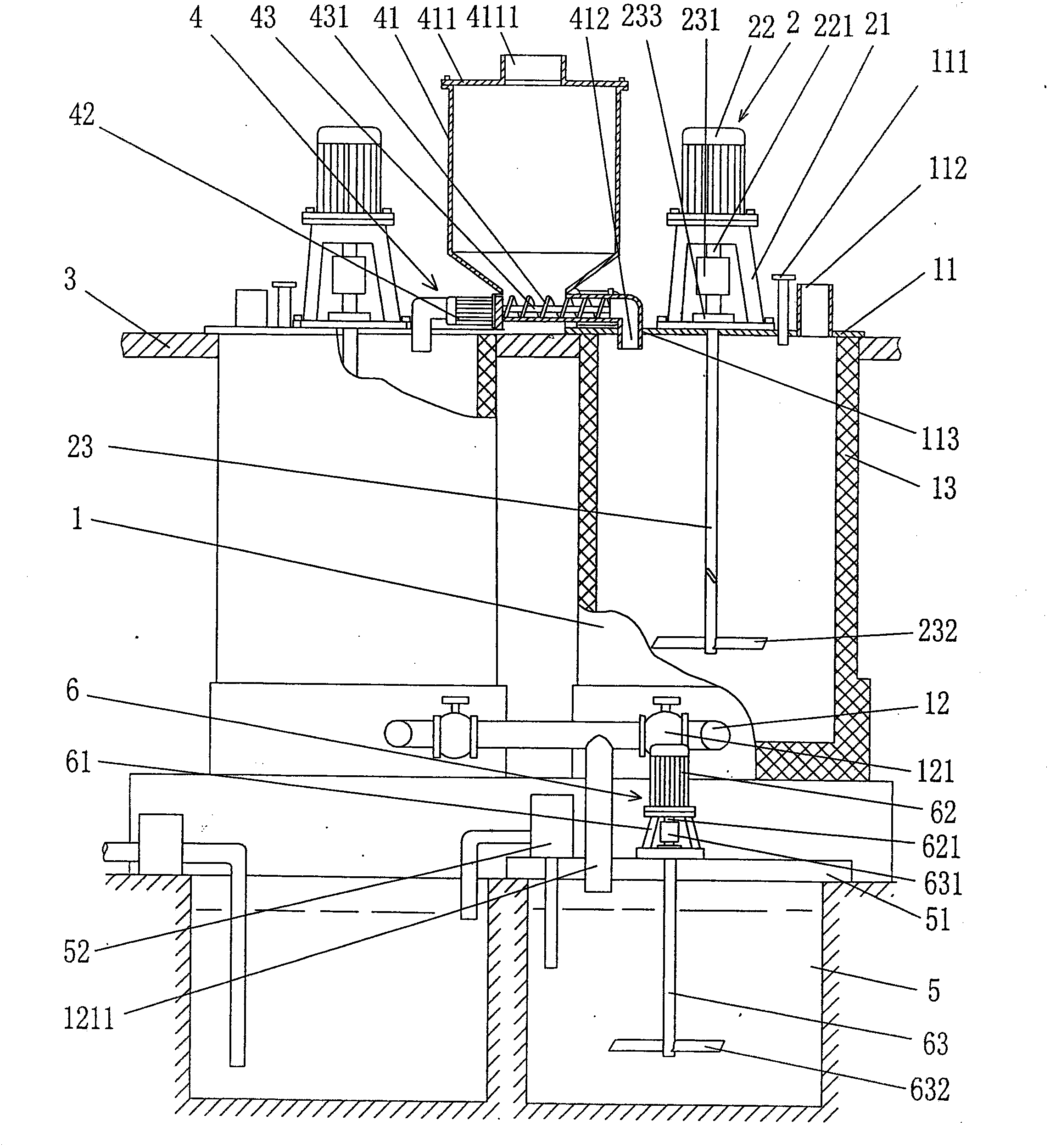

[0032] A) equipped with a reaction device, the specific structure of the reaction device, please refer to figure 1 , in the figure 1 Provided is a reaction vessel 1 supported on the ground or built on the basis of the ground in the state of use. A reaction vessel 1 is provided on the reaction vessel top cover 11 of the reaction vessel 1 for introducing iron-containing waste acid into The iron-containing waste acid liquid in the reaction vessel 1 is introduced into an interface 111 and an exhaust gas interface 112 for drawing out the exhaust gas in the reaction vessel 1, and a reaction vessel 1 is provided on the lower side of the reaction vessel 1. The reactant lead-out interface 12 of object drawing; Provide a stirring mechanism 2, this stirring mechanism 2 is arranged on the described reaction vessel top cover 11, and is positioned at the central position of reaction vessel top cover 11, and this stirring mechanism 2 also stretches to In the reaction vessel 1; a working pla...

Embodiment 2

[0043] Only change the mass percent concentration of the dilute hydrochloric acid in step B) to 37%, change the iron-containing waste acid solution to a mass percent concentration of 10% and produce iron-containing waste acid solution by electroplating, and replace the iron-containing waste acid solution The mass percent concentration of the concentration is increased to 18%, that is, the mass percent concentration of the obtained iron-containing waste acid stock solution is 18%; the stirring speed of the stirring shaft 23 of the stirring mechanism 2 in step C) is changed to 150rpm, and the first time In the feeding process, the reaction time of aluminum ash and iron-containing waste acid stock solution was changed to 170min. In the second feeding process, the reaction time of aluminum ash and iron-containing waste acid stock solution was changed to 140min. In the third feeding process, aluminum ash The reaction time with the iron-containing waste acid stock solution was change...

Embodiment 3

[0045] Only change the mass percentage concentration of dilute hydrochloric acid in step B) to 36%, and use the iron-containing waste acid solution with a mass percentage concentration of 12% instead of the iron-containing waste acid produced by the steel plate manufacturer for cleaning the steel plate, that is, pickling liquid, the mass percent concentration of the iron-containing waste acid solution is increased to 16.5%, that is, the mass percent concentration is 16.5% of the iron-containing waste acid stock solution; the stirring speed of the stirring shaft 23 of the stirring mechanism 2 in the step C) is changed to Change the reaction time of aluminum ash and iron-containing waste acid stock solution to 190min in the first feeding process, and change the reaction time of aluminum ash and iron-containing waste acid stock solution to 100min in the second feeding process. In the third feeding process, the reaction time of aluminum ash and iron-containing waste acid stock solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com