Tobacco foliar fertilizer and preparation method thereof

A technology for foliar fertilizer and tobacco is applied in the field of tobacco foliar fertilizer and its preparation, and can solve the problems of low quality of tobacco leaves, poor disease resistance and stress resistance of tobacco and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

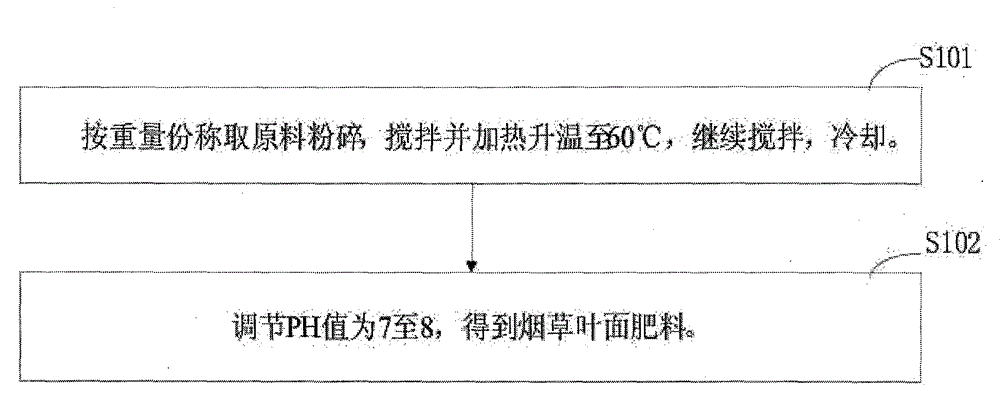

[0033] see figure 1 , the preparation method of the tobacco leaf fertilizer of one embodiment, comprises the following steps:

[0034] Step S101: Weighing and pulverizing the raw materials in parts by weight, stirring and heating to 60° C., continuing to stir, and cooling.

[0035] Step S102: adjusting the pH value to 7 to 8 with citric acid to obtain tobacco leaf fertilizer.

[0036] Weigh the raw materials according to the metering ratio, pulverize them separately, put them into the reactor in batches, and heat up to 60°C under stirring. The reactor can be preferably a high-shear reactor, which is convenient to operate and uniformly stirred.

[0037] It is preferred to program the temperature up to 60° C. at a rate of 60 revolutions per minute. At this rate of temperature increase, the rate of heat transfer among the components is reasonable.

[0038] The liquid at the beginning of the reaction is alkaline, and the pH value is adjusted to 7 to 8 with citric acid. After the...

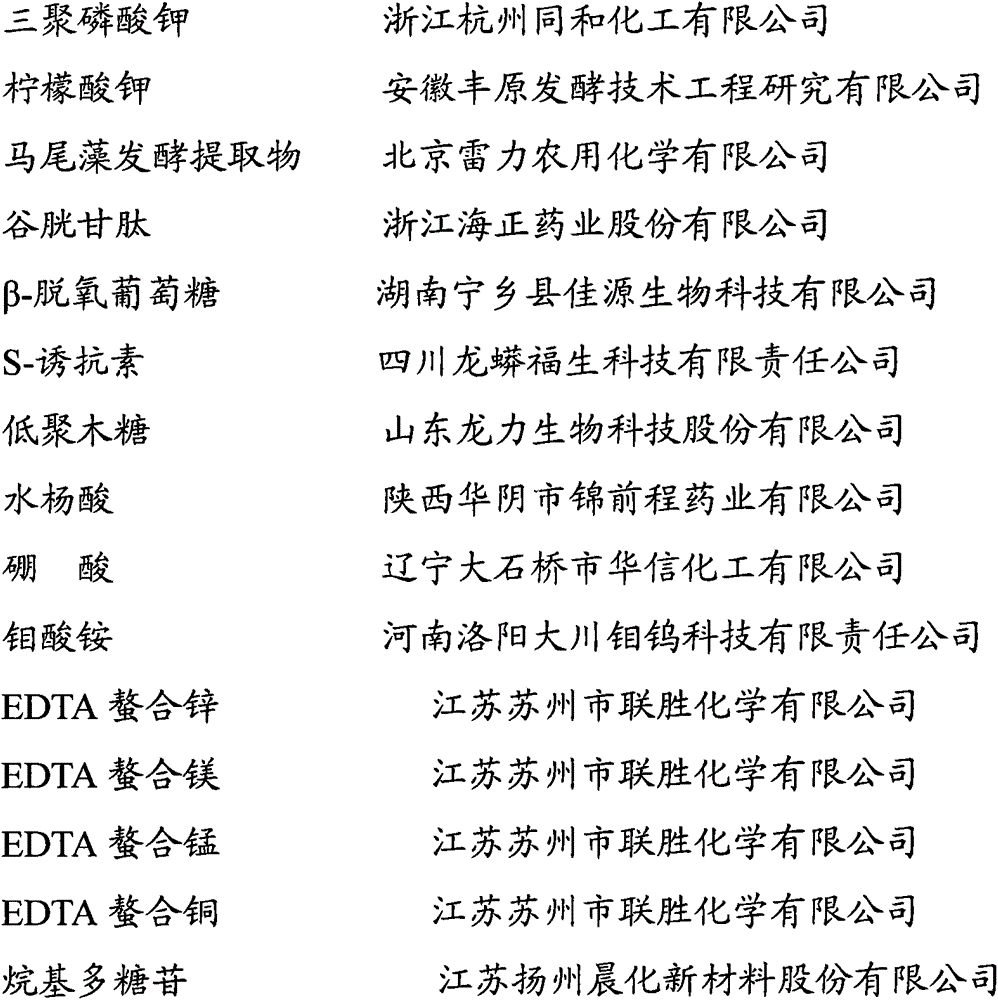

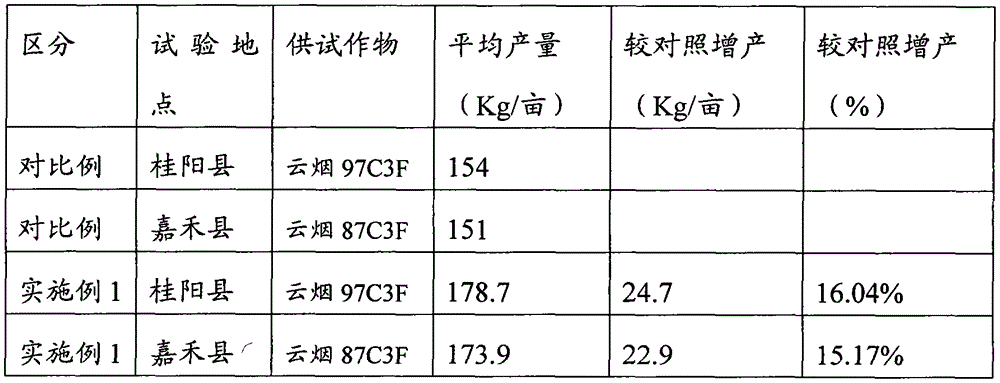

Embodiment 1

[0049] Weigh raw materials according to the following proportions: 20 parts of potassium tripolyphosphate, 20 parts of potassium citrate, 6 parts of Sargassum fermented extract, 0.5 parts of glutathione, 0.5 parts of β-deoxyglucose, 0.1 parts of S-induced 0.5 part xylooligosaccharide, 0.2 part salicylic acid, 2 parts boric acid, 0.1 part ammonium molybdate, 0.5 part EDTA chelated zinc, 0.5 EDTA chelated magnesium, 0.3 EDTA chelated manganese, EDTA chelated copper 0.3 parts and 0.5 parts of alkyl polyglucoside, 48 parts of water.

[0050] The raw materials are pulverized separately, put into a high-shear reactor for stirring in batches, heated at a speed of 60 rpm to 60°C, continued to stir, cooled, and adjusted the pH value of the liquid to 7 to 8 with citric acid to obtain a tobacco leaf fertilizer .

Embodiment 2

[0052] Weigh the raw materials according to the following proportions: 20 parts of potassium tripolyphosphate, 15 parts of potassium citrate, 3 parts of Sargassum fermented extract, 0.5 parts of glutathione, 0.5 parts of β-deoxyglucose, 0.1 parts of S-induced 0.5 part xylooligosaccharide, 0.2 part salicylic acid, 1 part boric acid, 0.1 part ammonium molybdate, 0.5 part chelated zinc EDTA, 0.5 part chelated magnesium EDTA, 0.3 part chelated manganese EDTA, 0.3 part chelated copper EDTA 0.3 parts and 0.5 parts of alkyl polyglycosides, 31 parts of water.

[0053] The raw materials are pulverized separately, put into a high-shear reactor for stirring in batches, heated at a speed of 60 rpm to 60°C, continued to stir, cooled, and adjusted the pH value of the liquid to 7 to 8 with citric acid to obtain a tobacco leaf fertilizer .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com