Method for extracting icariin from epimedium

A technology of icariin and epimedium, which is applied in the field of drug preparation, can solve the problems of discontinuous production, unfavorable industrial production, and reduction of icariin, so as to reduce extraction temperature, reduce continuous heating time, and increase investment The effect of potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

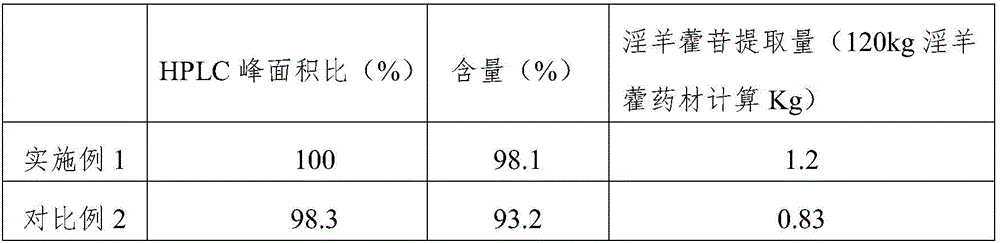

Examples

Embodiment 1

[0048] A method for extracting icariin from Epimedium, comprising the steps of:

[0049] (1) Epimedium is pulverized into 10-100 mesh powder; Epimedium powder is input in the continuous countercurrent tubular ultrasonic extraction machine with 120Kg / h speed, reversely imports 95% industrial ethanol with 800L / h flow rate, while maintaining ultrasonic extraction Under the conditions of tube temperature 35°C, ultrasonic frequency 22KHz, and ultrasonic power 32KW, extract for 25 minutes; input the extract into the liquid slag squeeze separation device, separate the slag, and press 20Kg / h for separation to obtain the extract; input the extract Concentrate under reduced pressure in a dynamic circulation low-temperature evaporation concentrator, recover the organic solvent, collect the extract, and obtain Epimedium extract;

[0050] (2) The Epimedium extract of step (1) is dissolved in water, then extracted 2 times with ethyl acetate, each time the organic solvent consumption is 1 / 3 ...

Embodiment 2

[0056] A method for extracting icariin from Epimedium, comprising the steps of:

[0057] (1) Epimedium is pulverized into 10-100 mesh powder; Epimedium powder is input in the continuous countercurrent tubular ultrasonic extraction machine with 120Kg / h speed, reversely imports 95% industrial ethanol with 900L / h flow rate, while maintaining ultrasonic extraction Under the conditions of tube temperature 42°C, ultrasonic frequency 24KHz, and ultrasonic power 32KW, extract for 30 minutes; input the extract into the liquid slag squeeze separation device, separate the slag, and press 60Kg / h for separation to obtain the extract; input the extract Concentrate under reduced pressure in a dynamic circulation low-temperature evaporation concentrator, recover the organic solvent, collect the extract, and obtain Epimedium extract;

[0058] (2) Dissolving the Epimedium extract of step (1) in water, then extracting 3 times with chloroform, each organic solvent consumption is 20% of the water ...

Embodiment 3

[0064] A method for extracting icariin from Epimedium, comprising the steps of:

[0065] (1) Epimedium is crushed into 10-100 mesh powder; Epimedium powder is input in the continuous countercurrent tubular ultrasonic extraction machine with 120Kg / h speed, reversely imports 95% industrial ethanol with 1000L / h flow rate, while maintaining ultrasonic extraction Under the conditions of tube temperature 50°C, ultrasonic frequency 27KHz, and ultrasonic power 32KW, extract for 40 minutes; input the extract into the liquid slag squeeze separation device, separate the slag, and press 100Kg / h for separation to obtain the extract; input the extract Concentrate under reduced pressure in a dynamic circulation low-temperature evaporation concentrator, recover the organic solvent, collect the extract, and obtain Epimedium extract;

[0066] (2) the Epimedium extract of step (1) is dissolved in water, then extracted 3 times with chloroform, each organic solvent consumption is equal to the volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com