Dealcoholization type cured organosilicone sealant and preparation method thereof

An organosilicon and dealcoholized technology, applied in adhesives and other directions, can solve the problems of no transparent effect, complex production process, instantaneous viscosity increase, etc., to meet the requirements of industrial scale-up production, short process steps, and less demanding process requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

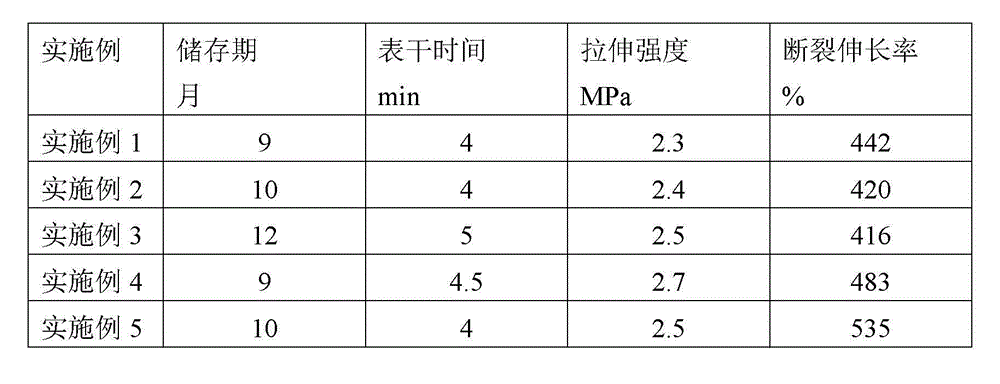

Examples

Embodiment 1

[0020] A) To prepare 107 end-capped silicone oil (also called synthetic 107 end-capped silicone oil), 100 parts of double-ended hydroxyl polydimethylsiloxane and methyltrimethoxysilane weighed in parts by weight and with a viscosity of 5000CP Put 5 parts into the reaction container, react at a reaction temperature of 80°C for 120min under stirring, and raise the temperature to 140°C after the reaction is completed and vacuumize until the vacuum degree is lower than -0.1MPa, and the vacuuming time is 60min. Remove the unreacted crosslinking agent, that is, remove the unreacted methyltrimethoxysilane, vacuumize and cool to room temperature under nitrogen protection gas to obtain 107 blocked silicone oil;

[0021] B) Prepare the finished product, mix the 107 end-capped silicone oil obtained in step A) with 10 parts of calcium carbonate with a particle size of 5000 mesh and a water content of less than 0.1% in parts by weight, and then vacuumize and stir, that is Stir in a vacuum ...

Embodiment 2

[0023] A) To prepare 107 end-capped silicone oil (also called synthetic 107 end-capped silicone oil), 100 parts of double-ended hydroxyl polydimethylsiloxane and methyltrimethoxysilane weighed in parts by weight and with a viscosity of 5000CP Put 7 parts into the reaction container, react at a reaction temperature of 75°C for 130 minutes under stirring, and raise the temperature to 135°C after the reaction is completed and vacuumize until the vacuum degree is lower than -0.1MPa. Remove the unreacted crosslinking agent, that is, remove the unreacted methyltrimethoxysilane, vacuumize and cool to room temperature under nitrogen protection gas to obtain 107 blocked silicone oil;

[0024] B) To prepare the finished product, mix the 107 end-capped silicone oil obtained in step A) with 100 parts of calcium carbonate with a particle size of 3000 mesh and a water content of less than 0.1% in parts by weight, and then vacuumize and stir. The vacuum degree of vacuum is lower than -0.1MPa...

Embodiment 3

[0026] Only change the viscosity of the double-terminated hydroxyl polydimethylsiloxane in step A) to 2000CP, change the crosslinking agent to 5.5 parts by weight of vinyltrimethoxysilane, and change the reaction temperature and time to 85°C and 110min, change the heating temperature after the reaction to 145°C, and change the vacuuming time to 55min; only change the reinforcing filler in step B) to be synthesized by the gas phase method and have a moisture content of less than 0.6%. Silicon dioxide, the parts by weight of this silicon dioxide is 200 parts, the time of vacuum stirring is changed to 22min, the combination of KH792 and KH560 is used instead of the silane coupling agent, and the parts by weight of KH792 is 0.3 parts, And the parts by weight of KH560 is 0.4 parts, the parts by weight of catalyst dibutyl tin diacetate is changed into 0.02 parts, the time of stirring is then changed into 18min, and all the other are the same as the description to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com