Preparation method of antibacterial halogen-free flame-retardant nylon alloy material

A technology of flame-retardant nylon and alloy materials, applied in the field of polymer material preparation, which can solve the problems of secondary pollution, poisonous and harmful, etc., and achieve the effect of resisting bacterial erosion and shortening the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

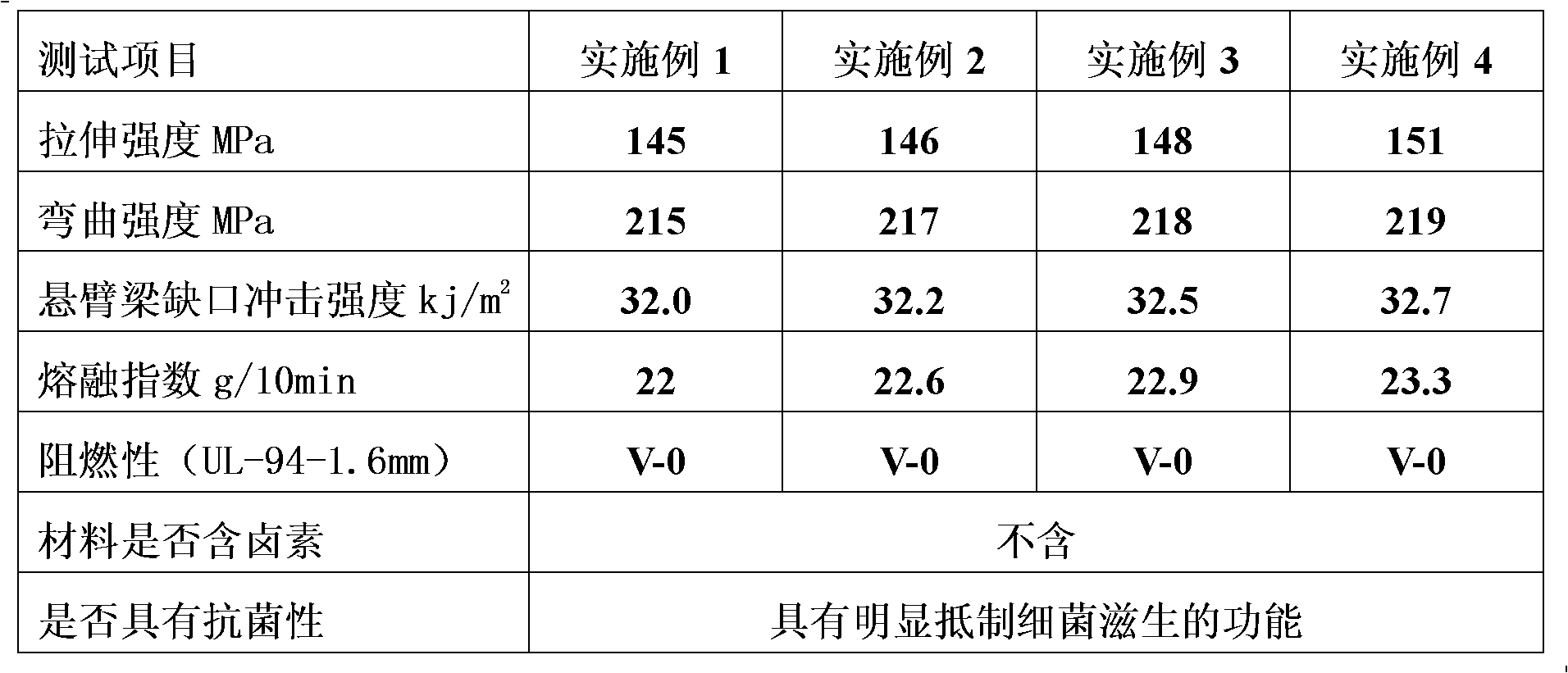

Examples

Embodiment 1

[0018] A) Preparation of granulated materials, weighing 60.2 parts of nylon 66 resin (melting point: 220°C), 30.4 parts of nylon 1010 resin (melting point: 230°C), and 20.3 parts of acrylonitrile-butadiene-styrene copolymer in parts by weight , 0.8 part of vinyl three (beta methoxyethoxy) silanes and 28.1 parts of melamine ammonium polyphosphate, and drop into the high-speed mixer and mix 10min, then drop into 1.2 parts of plastic antibacterial agents of silver ions loaded by parts by weight , 0.4 parts of tetrakis [methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 45 parts of alkali-free chopped glass fibers with a length of 3 mm and distearic acid 0.4 part of amide, and continue mixing for 6 minutes to obtain granulated material;

[0019] B) Granulation, put the granulated material obtained in step A) into a parallel twin-screw extruder for melt extrusion, the extrusion temperature is: 240°C in the first zone, 250°C in the second to fifth zones ...

Embodiment 2

[0021] A) Preparation of granulated material, weighing 62.5 parts of nylon 66 resin (melting point: 220°C), 33.2 parts of nylon 1010 resin (melting point: 230°C), and 25.2 parts of acrylonitrile-butadiene-styrene copolymer in parts by weight , 1.3 parts of vinyl tris (beta methoxyethoxy) silanes and 30.5 parts of melamine ammonium polyphosphate, and drop into high-speed mixer and mix 8min, then drop into 1.6 parts of plastic antibacterial agent of the silver ion that takes by weight , 0.5 parts of tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 47.2 parts of alkali-free chopped glass fibers with a length of 3 mm and distearic acid Amide 0.6 part, and continue to mix 7min, obtain granulated material;

[0022] B) Granulation, put the granulated material obtained in step A) into a parallel twin-screw extruder for melt extrusion, the extrusion temperature is: 240°C in the first zone, 250°C in the second to fifth zones and 245 in the sixth z...

Embodiment 3

[0024] A) Preparation of granulated material, weighing 64.2 parts of nylon 66 resin (melting point: 220°C), 34.5 parts of nylon 1010 resin (melting point: 230°C), and 28.3 parts of acrylonitrile-butadiene-styrene copolymer in parts by weight , 1.4 parts of vinyl three (beta methoxyethoxyl) silanes and 33.2 parts of melamine ammonium polyphosphate, and drop into high-speed mixer and mix 11min, then drop into 1.8 parts of plastics antibacterial agent of carrying silver ion that takes by weight , 0.7 parts of tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 48.8 parts of alkali-free chopped glass fibers with a length of 3 mm and distearic acid Amide 0.8 part, and continue to mix 4min, obtain granulated material;

[0025] B) Granulation, put the granulated material obtained in step A) into a parallel twin-screw extruder for melt extrusion, the extrusion temperature is: 240°C in the first zone, 250°C in the second to fifth zones and 245 in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com