Spherical orthodontic arch wire bending robot and use method thereof

An orthodontic archwire and robot technology, applied in the field of spherical orthodontic archwire bending robots, can solve problems such as slipping and warping, hindering the bending process, and easy interference, achieving rapid response, flexible adjustment, and satisfying institutional rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

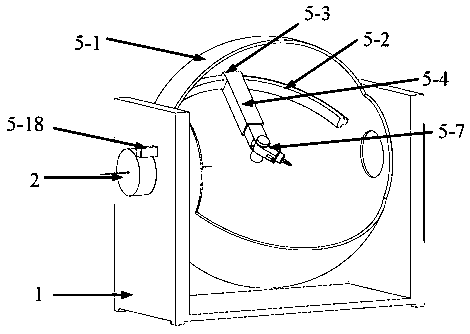

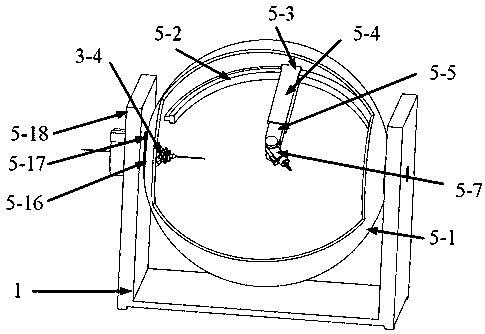

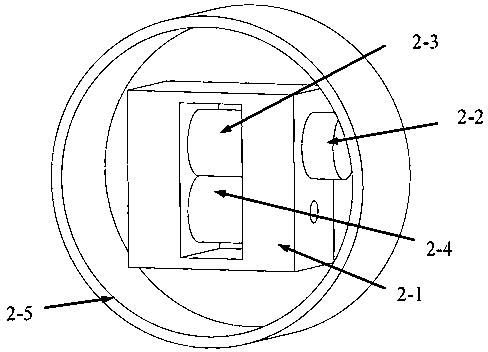

[0031] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 As shown, this embodiment adopts the following technical solutions:

[0032] A spherical orthodontic archwire bending robot and its use method, it includes a base support 1, a wire feeding mechanism 2, an angle adjustment mechanism 3, an archwire clamping mechanism 4 and a wire bending mechanical arm 5, the wire feeding mechanism 2 Connected to the outside of the left side of the base bracket 1 by bolts, the angle adjustment mechanism 3 is fixed to the inside of the left side of the base bracket 1 by bolts, the archwire clamping mechanism 4 is fixedly connected to the top of the angle adjustment mechanism 3, and the wire bending mechanical arm 5 is located in the middle part of the left and right sides of the base support 1, and is connected to the base support 1 through bearings.

[0033] Further, the wire feeding mechanism 2 includes a wire ...

Embodiment 2

[0037] Embodiment 2: The initial power-on position of the spherical orthodontic archwire bending robot;

[0038] According to the device described in Embodiment 1, when the spherical orthodontic archwire bending robot is in the initial power-on state, the angle adjustment platform I3-1, the angle adjustment platform II3-2, and the angle adjustment platform III3-3 are parallel to each other and parallel to each other. Perpendicular to the horizontal line, the angle platform II linear motor 3-4 and the angle platform III linear motor 3-5 are in contraction state; the clamping head shell 4-1 and the separate chuck 4-2 at the end of the angle adjustment platform III3-3 They are in contact with each other but not pressed tightly, the inner ring of the electromagnet 4-3 is in contact with the separate chuck 4-2 but not pressed tightly, the outer ring of the electromagnet 4-5 is in a power-off state, and the outer shell of the clamping head 4-1 is separated from the The tapered surfa...

Embodiment 3

[0039] Embodiment 3: The specific implementation of the spherical orthodontic archwire bending robot to complete the wire bending task;

[0040] According to the device described in Embodiment 1, when the wire bender needs to bend the orthodontic archwire, the archwire is sent from the wire feeding housing 2-5 to the active pressure roller 2-3 and the passive pressure roller 2- 4, the wire feeding motor 2-2 drives the active pressure roller 2-3 to drive the passive pressure roller 2-4, so that the arch wire is sent into the flexible hose 4-6 and reaches the clamping head shell 4-1; After the electromagnet outer ring 4-4 is powered on, the electromagnet inner ring 4-3 moves toward the clamping head shell 4-1, thereby pushing the split chuck 4-2 to the clamping head shell 4-1, and because The clamping head shell 4-1 and the tapered surface of the split chuck 4-2 are in contact with each other and press fit, so that the split chuck 4-2 is clamped, wherein the flexible hose 4-6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com