Vibration-isolating rubber composition

A rubber composition and anti-vibration technology, which can be used in mechanical equipment, low internal friction springs, springs made of plastic materials, etc. Effects of heat resistance and low dynamic magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

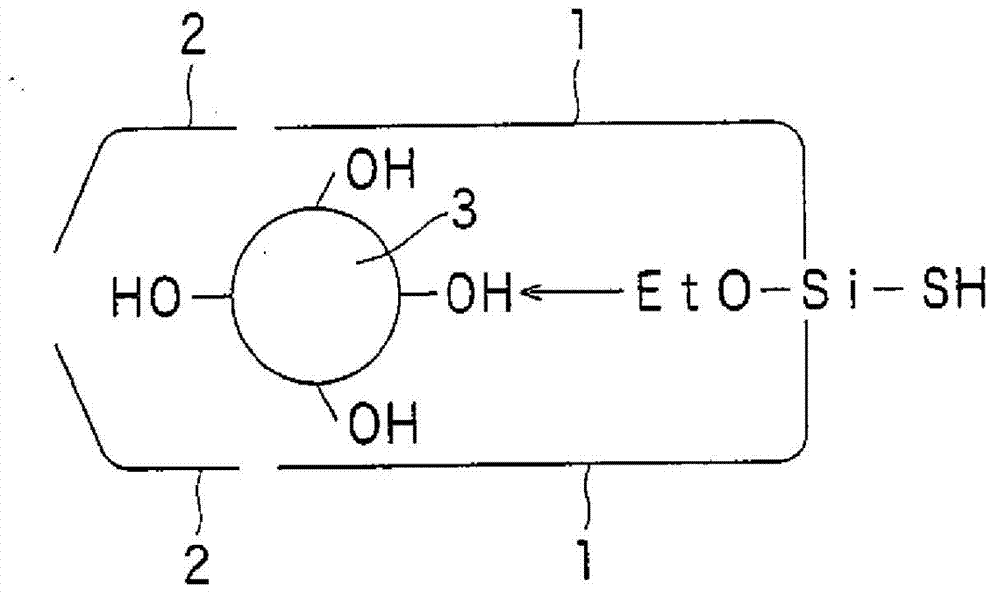

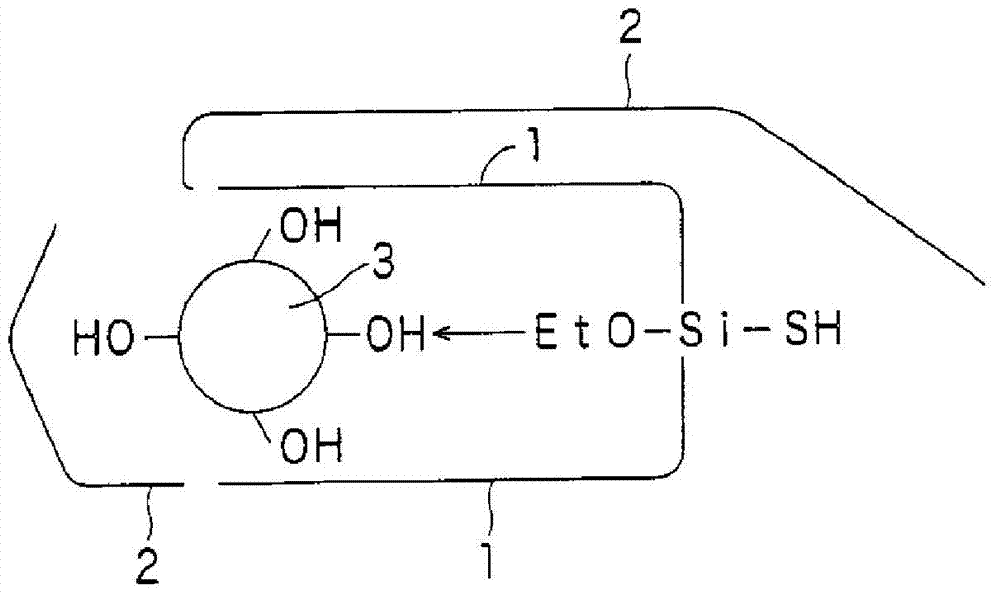

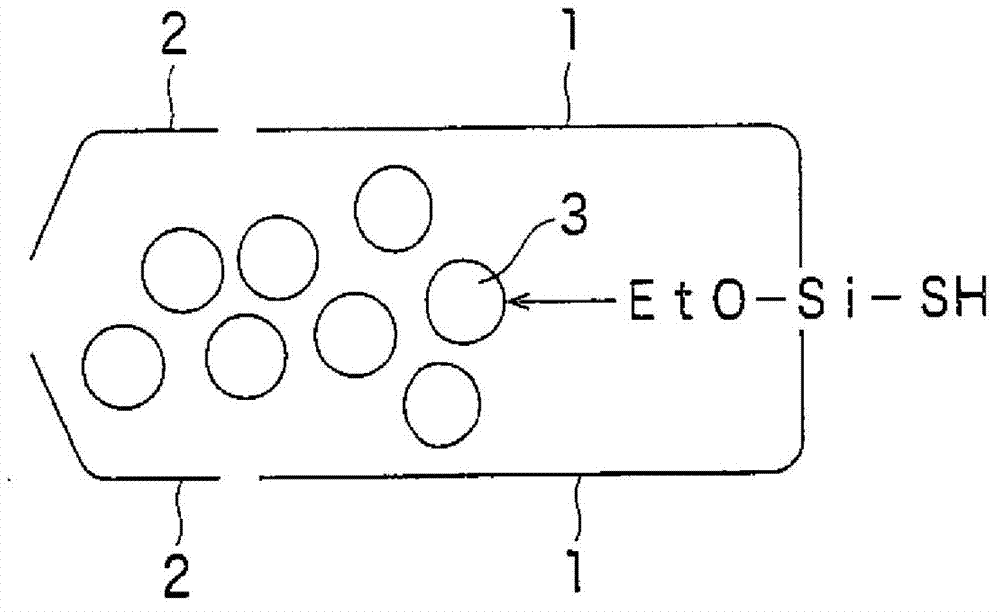

[0055] As the preparation method of the above-mentioned silica (component B), the reaction recipe of precipitated silica can be mentioned, for example, by neutralizing an aqueous alkali silicate solution (commercially available sodium silicate aqueous solution) with an inorganic salt to precipitate two It is prepared by the method of precipitation of silicon oxide. Specifically, at first, the following method can be adopted: a sodium silicate aqueous solution of a specific concentration is loaded into a specific amount of reaction container, and the method of adding an inorganic acid (unilateral addition reaction) under specific conditions; Add sodium silicate and inorganic acid (simultaneous addition method) within a certain period of time while controlling the pH and temperature in the reaction solution of a certain amount of warm water. Next, the precipitated silica slurry obtained by the above method is filtered and washed with a filter capable of washing the filter cake (...

Embodiment 1

[0166] Mix 100 parts of NR, 5 parts of zinc oxide, 1 part of stearic acid, 2 parts of anti-aging agent, 2 parts of paraffin, 5 parts of mineral oil, 2 parts of silane coupling agent (i), 30 parts of silicon dioxide (i) and vulcanization 3 parts of auxiliary agent (i), these were kneaded at 140 degreeC for 5 minutes using the Banbury internal mixer. Next, 1 part of vulcanizing agent, 2 parts of vulcanization accelerator (i) and 1 part of vulcanization accelerator (ii) were mixed therein, and kneaded at 60° C. for 5 minutes using an open roll to prepare a vibration-proof rubber composition.

Embodiment 2~34

[0167] Embodiment 2~34, comparative example 1~7

[0168] An anti-vibration rubber composition was prepared according to Example 1, except that the blending amounts of each component were changed as shown in Tables 1 to 5 described below.

[0169] Using the anti-vibration rubber compositions of Examples and Comparative Examples thus obtained, each characteristic was evaluated according to the following criteria. The results are shown together in Tables 1 to 5 described later.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com