Patents

Literature

182results about How to "Guaranteed installation strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

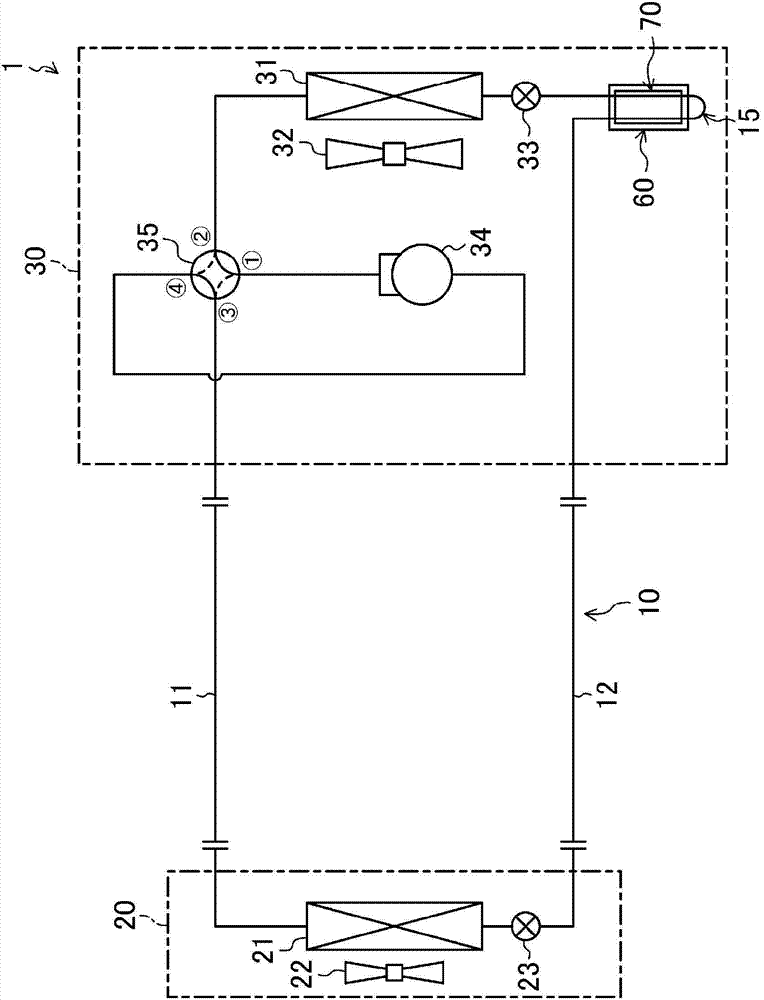

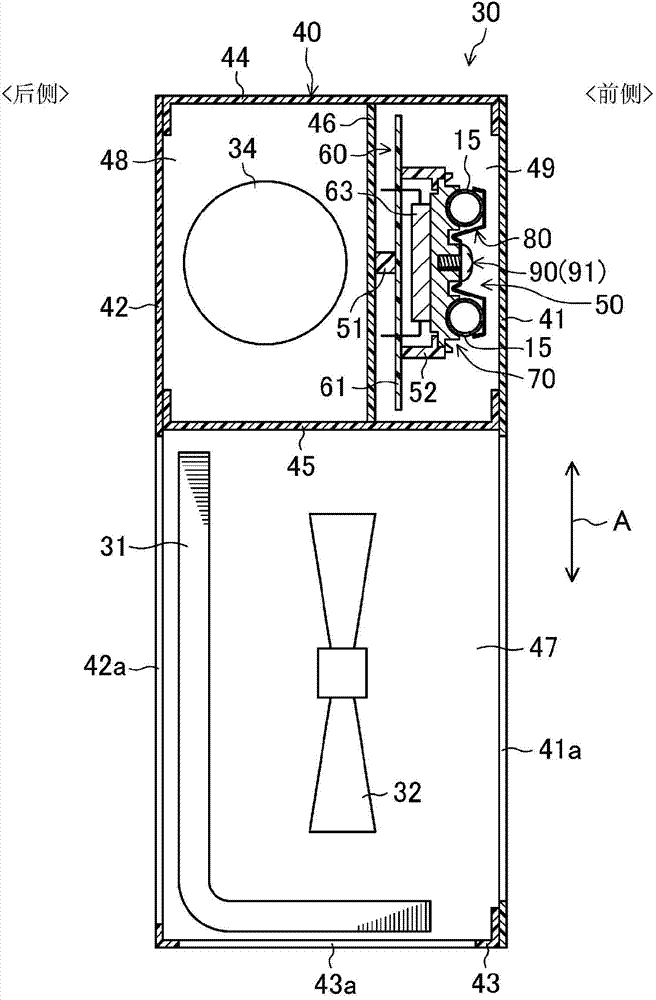

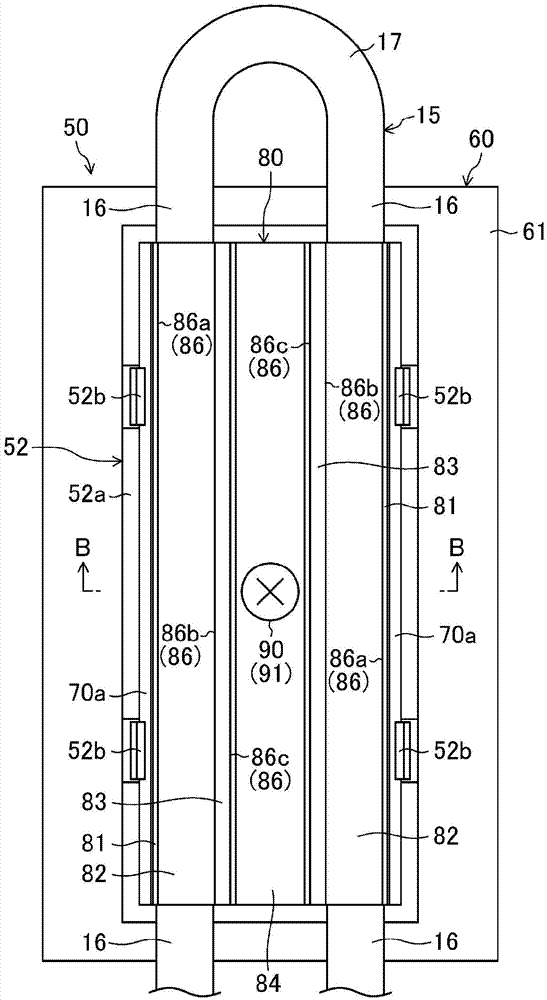

Installation structure for coolant pipe

ActiveCN103688605AIncrease contact areaReduce thermal resistanceCompressorSemiconductor/solid-state device detailsEngineeringRefrigerant

The present invention provides a coolant pipe installation structure which can reliably retain a coolant pipe and which can sufficiently decrease the thermal resistance between a coolant pipe and a heat-transmitting member. A heat-transmitting member (70) having a vertical groove part (72) into which a coolant pipe (15) fits, and which thermally contacts with a component to be cooled (63), is provided. An elastic member (80) formed in a long plate shape which extends in the extension direction of the coolant pipe (15), and having an opposing part (82) opposite the coolant pipe (15), is provided. A pushing structure (90) which pushes the elastic member (80) to the heat-transfer member (70) side is provided.

Owner:DAIKIN IND LTD

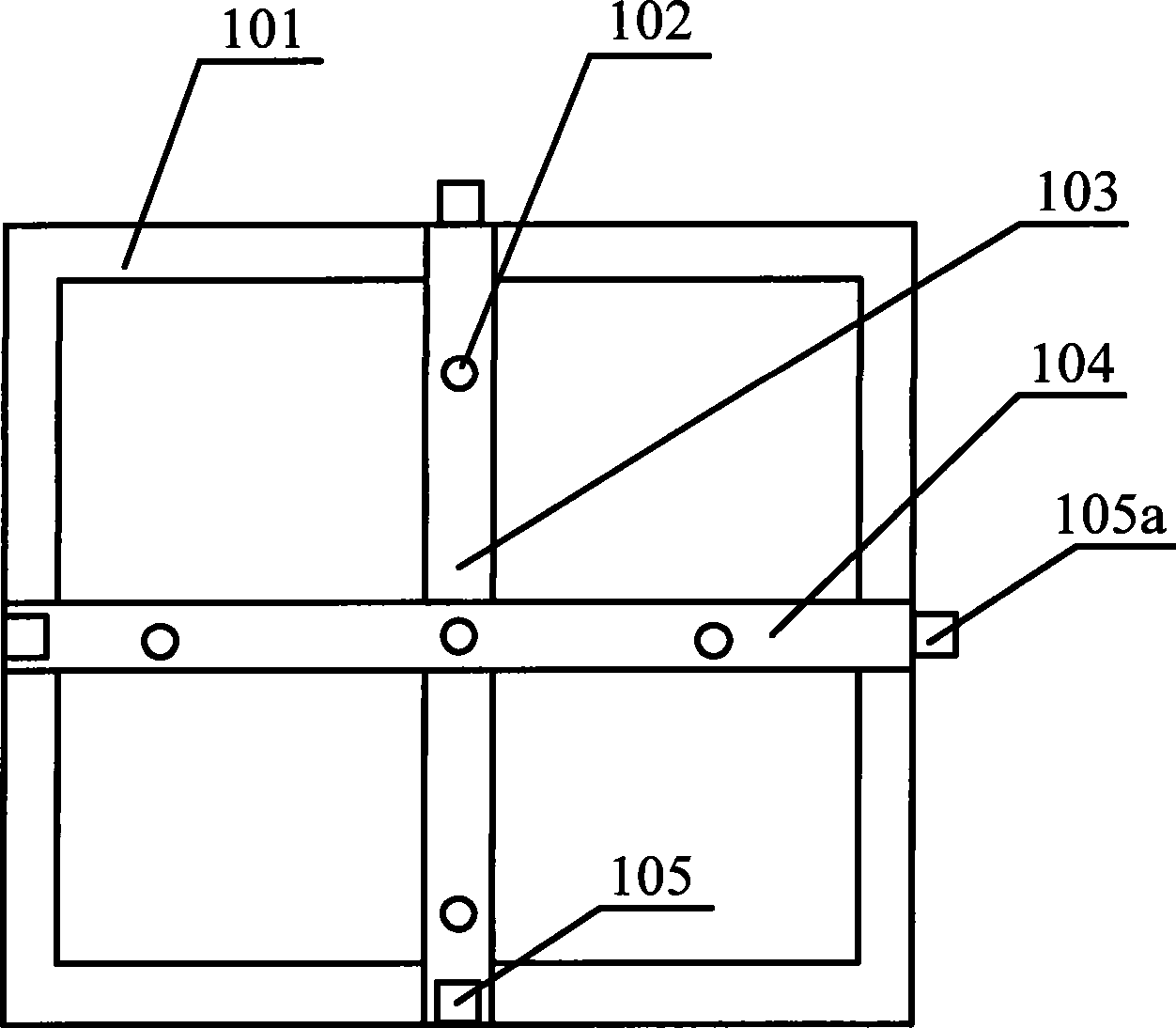

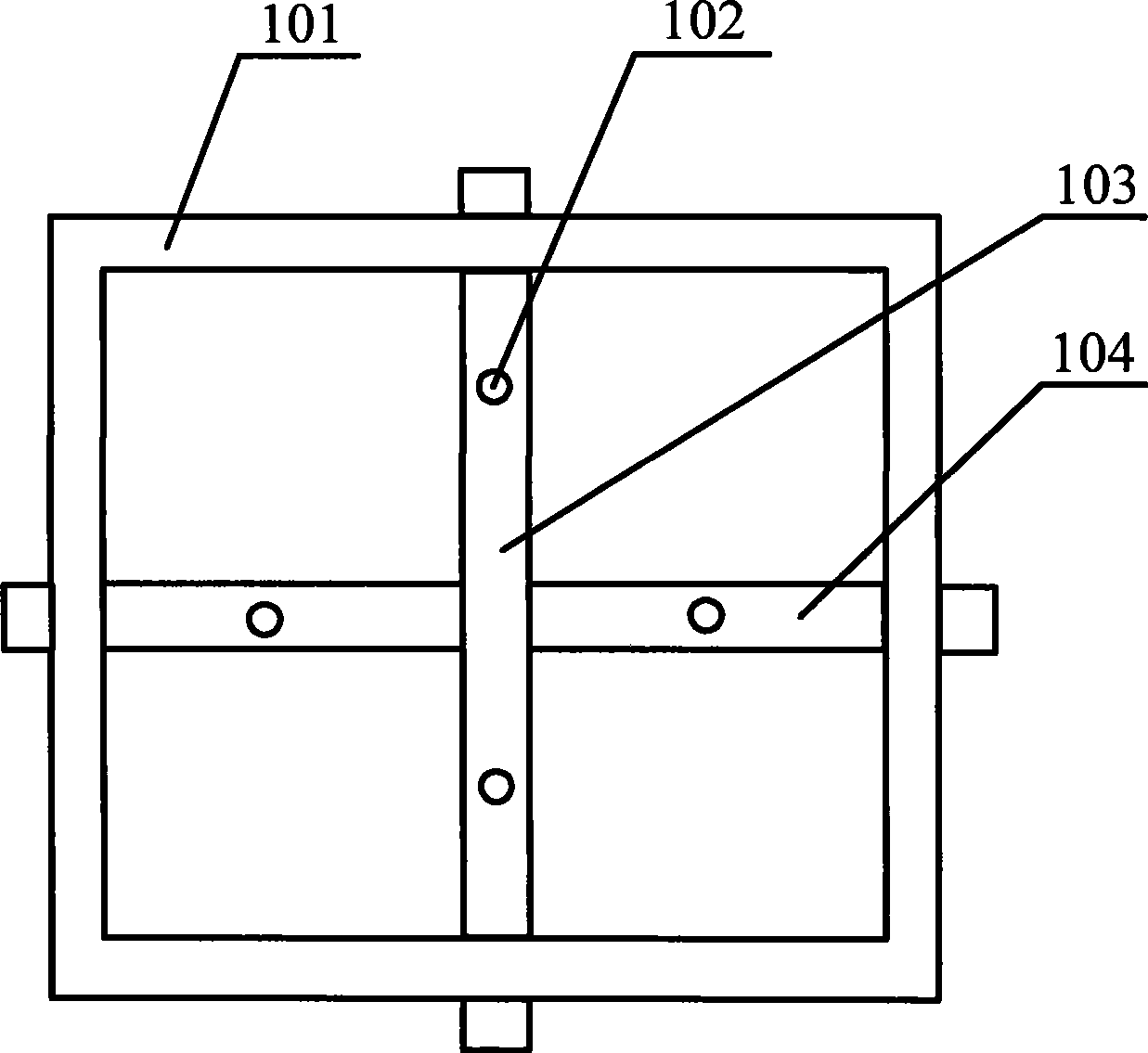

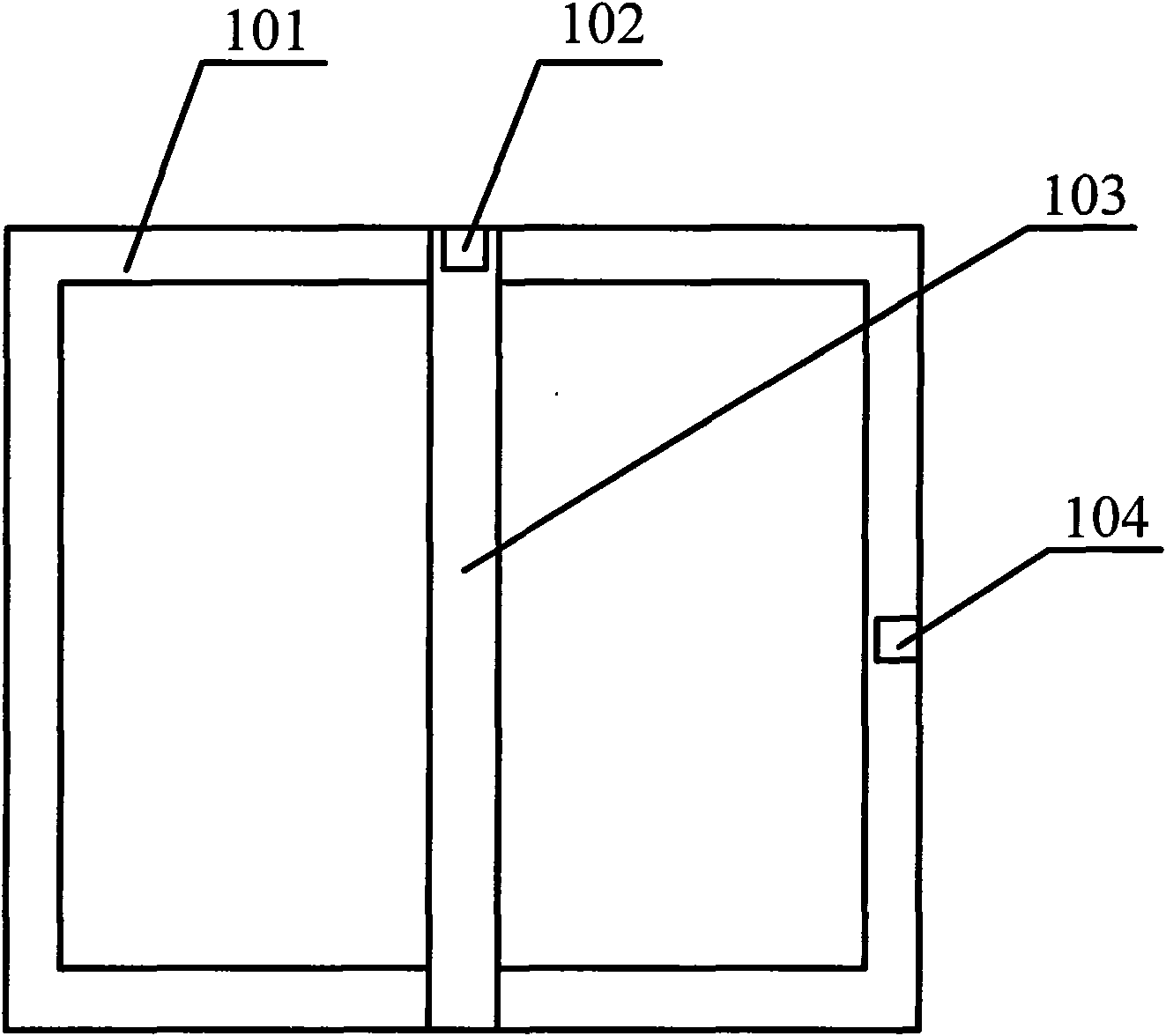

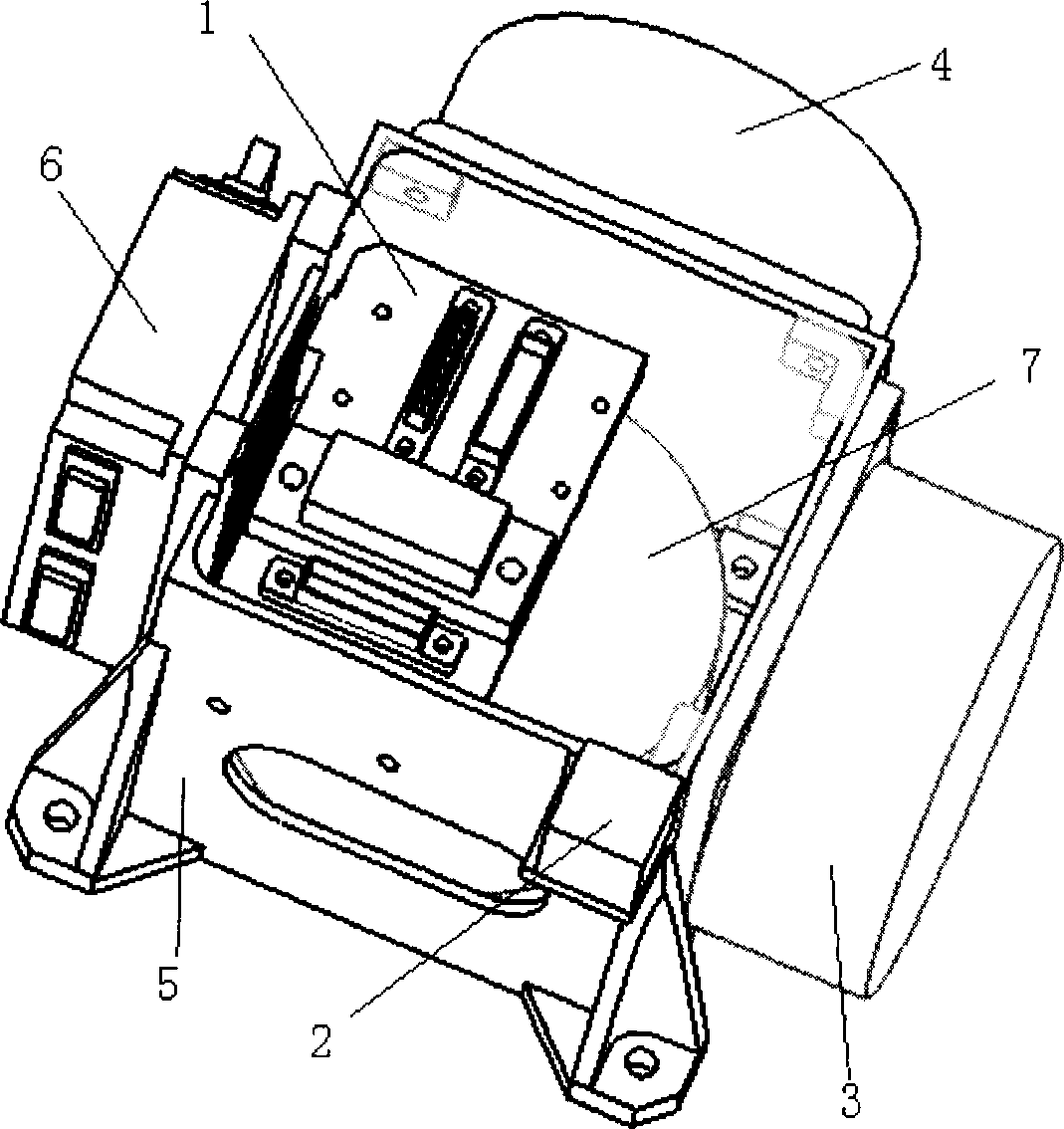

Installing structure for LED display screen and the LED display screen

The invention discloses an installing structure for LED display screen and the LED display screen. The installing structure for LED display screen comprises at least one rigid supporting structure and a plastic frame; the rigid supporting structure and the plastic frame are mutually fixed; the rigid supporting structure is used for forming a rigid supporting plane; the rigid supporting structure is provided with at least one fixed position used for fixing at least one external LED display module; the rigid supporting structure is also provided with a connecting structure for connecting the other rigid supporting structures. The installing structure in the invention makes the LED display screen have a agile installation, precise installation and makes the LED display screen more convenient in the process of moving and delivery.

Owner:幸琳

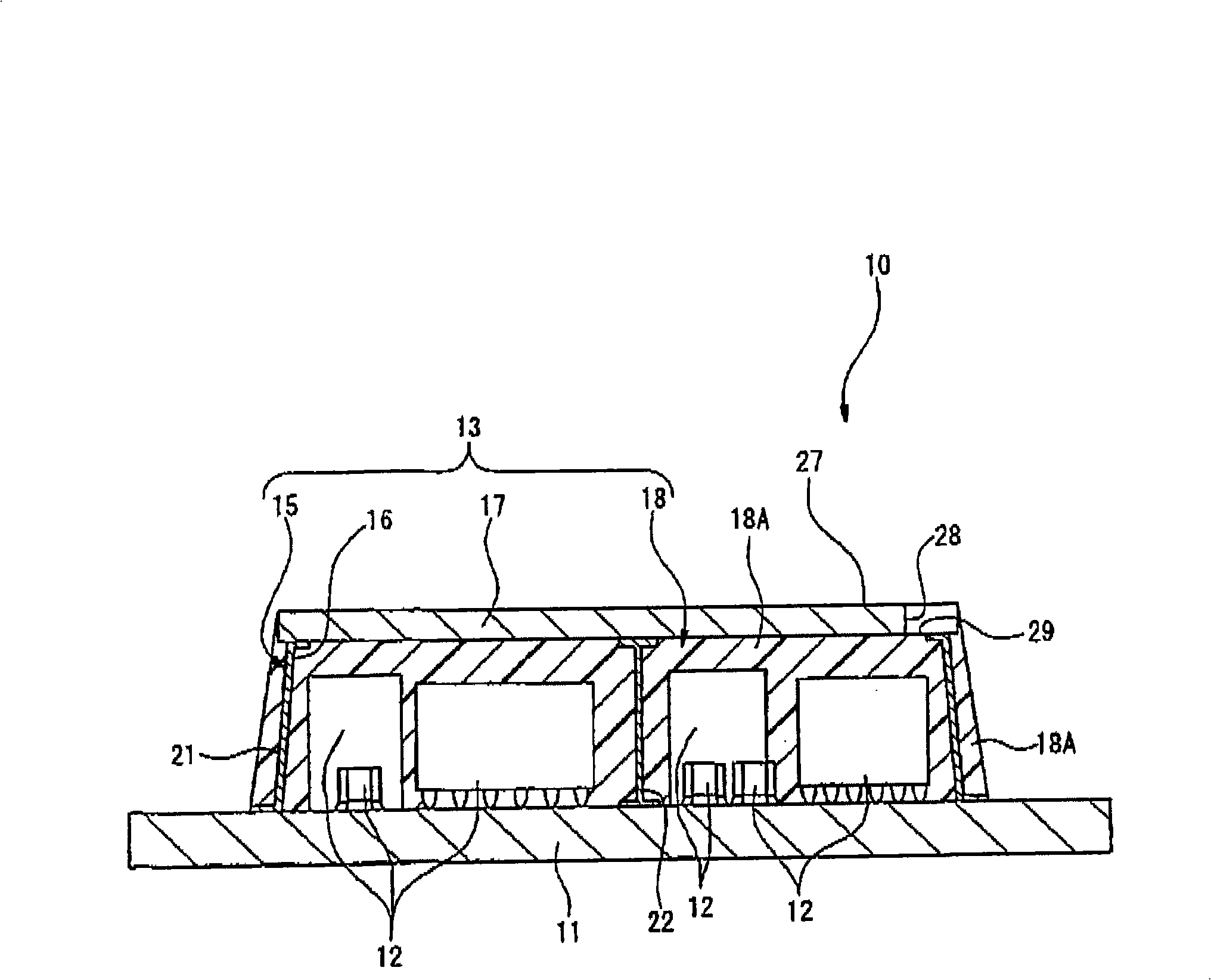

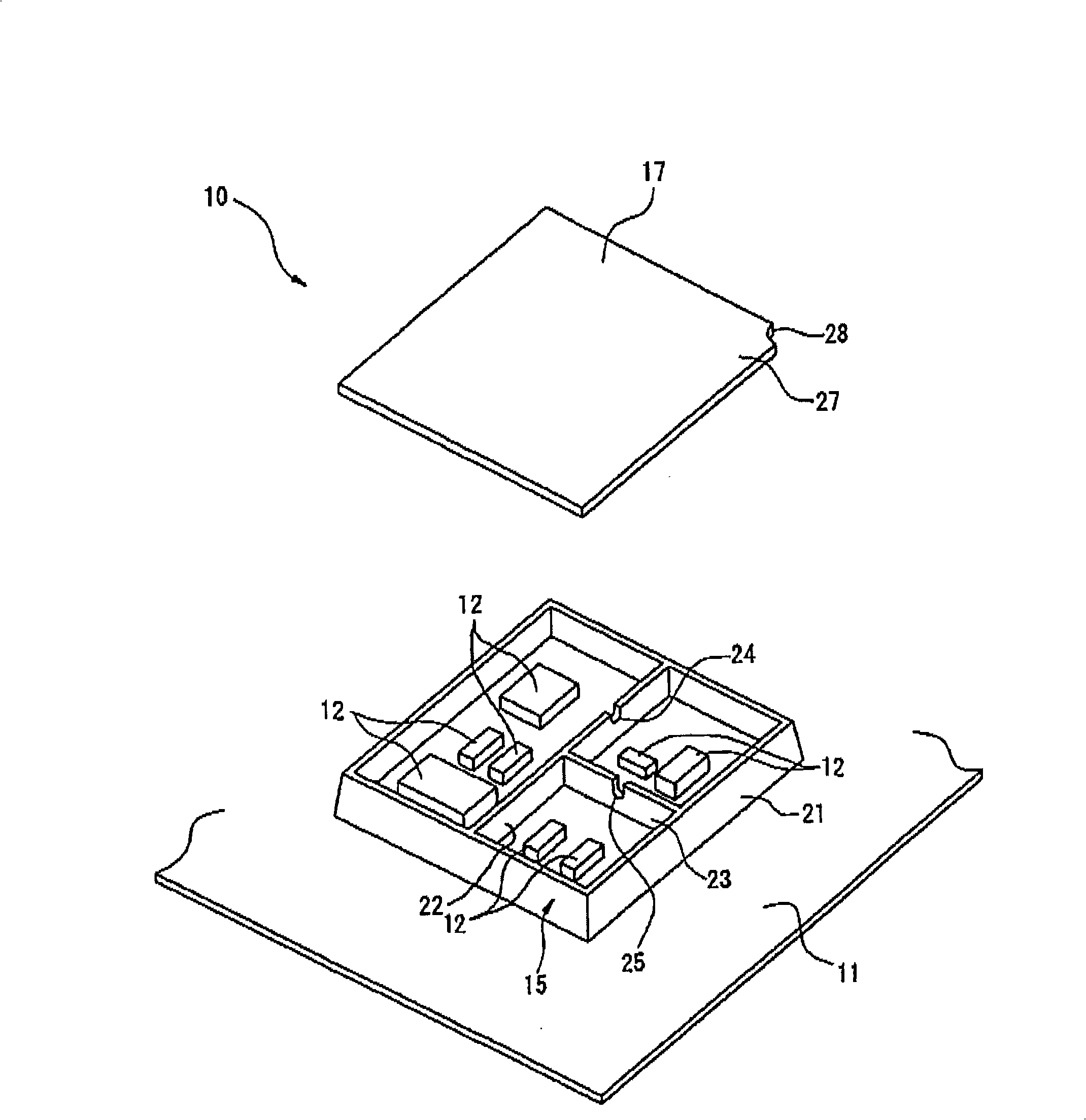

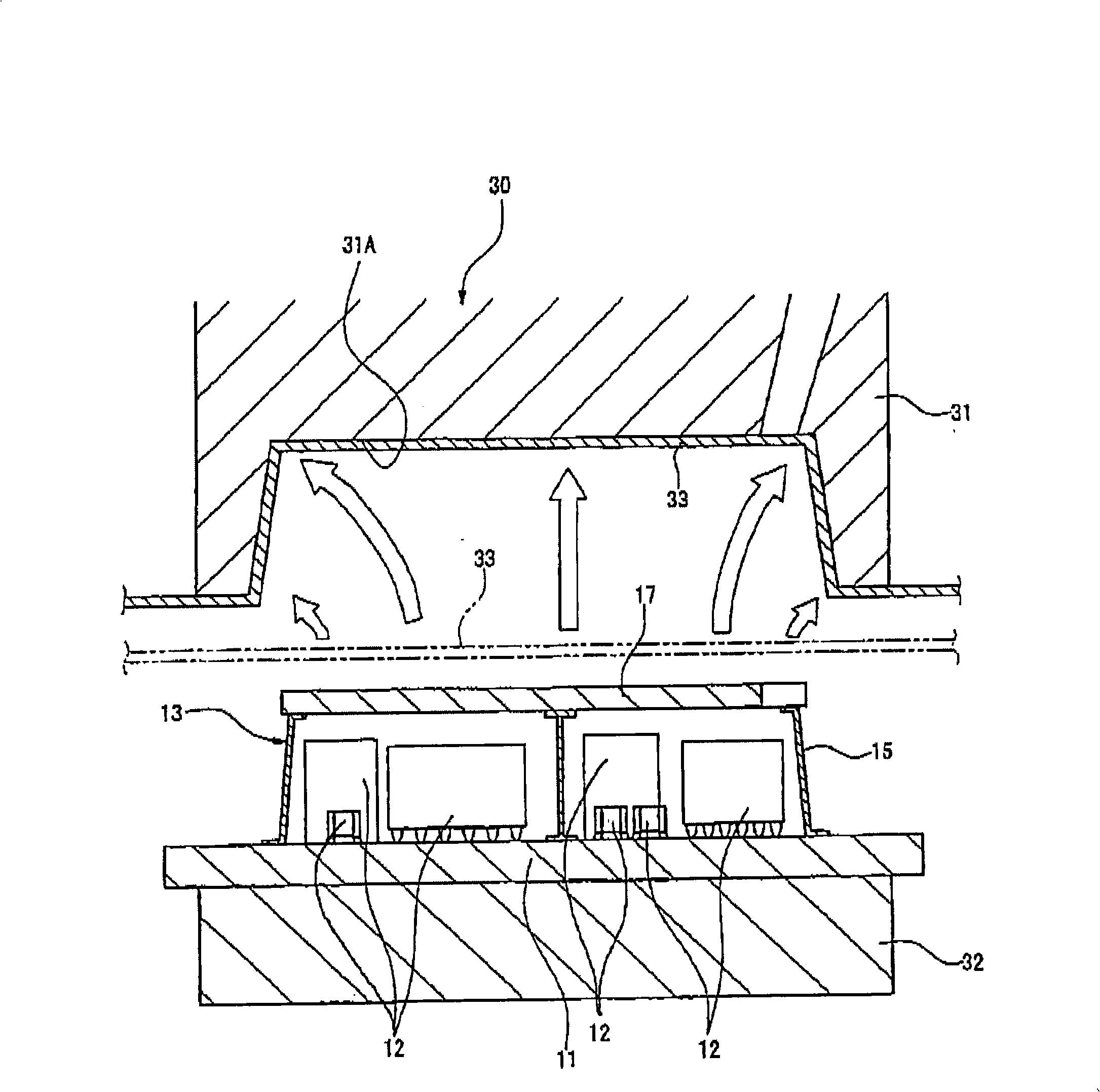

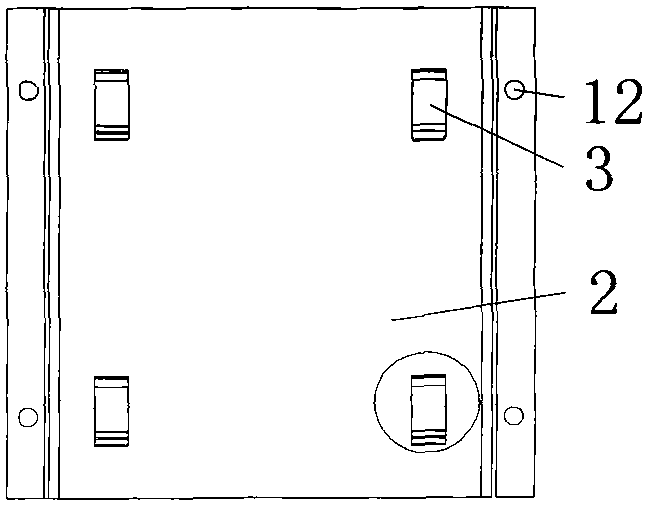

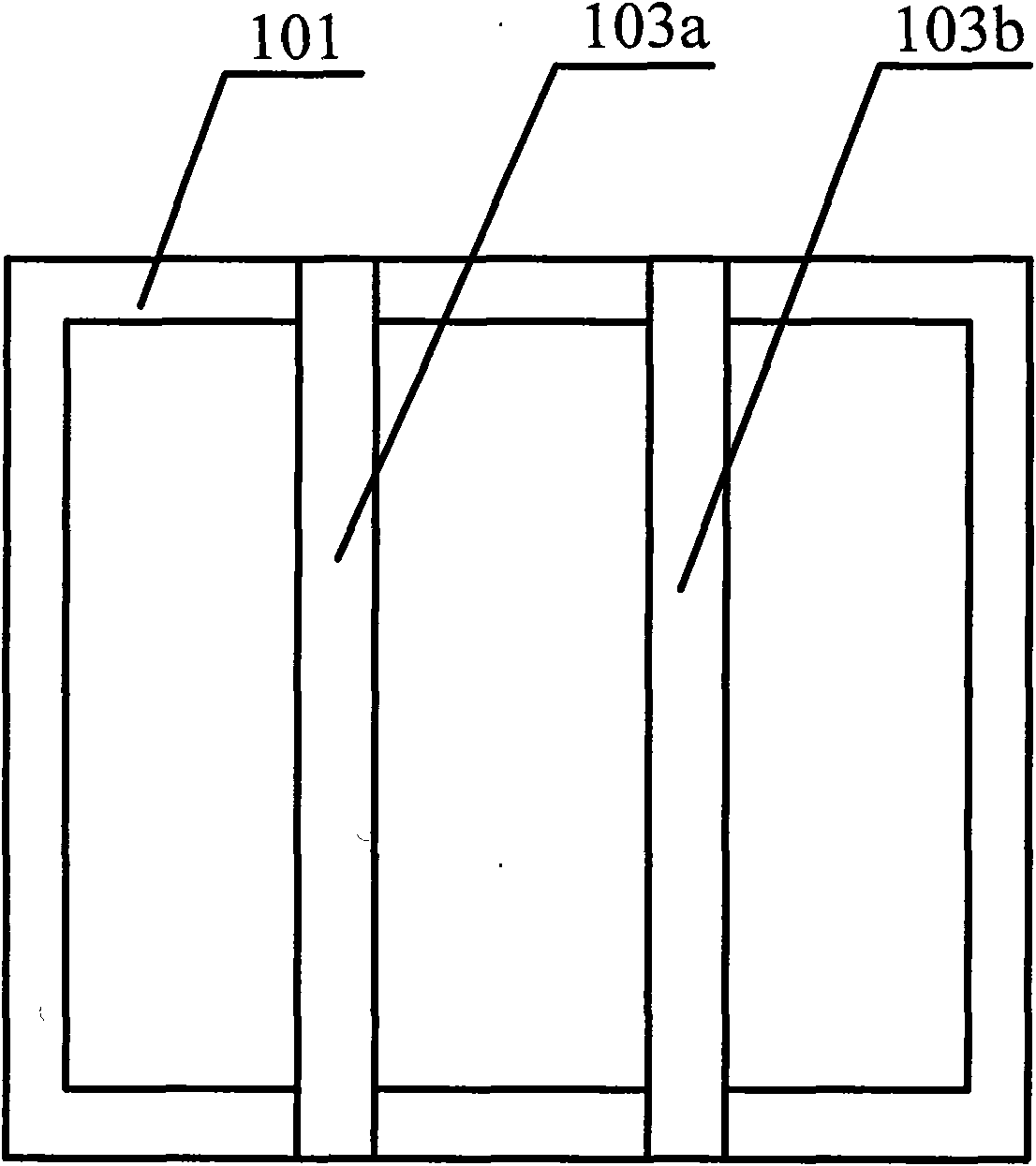

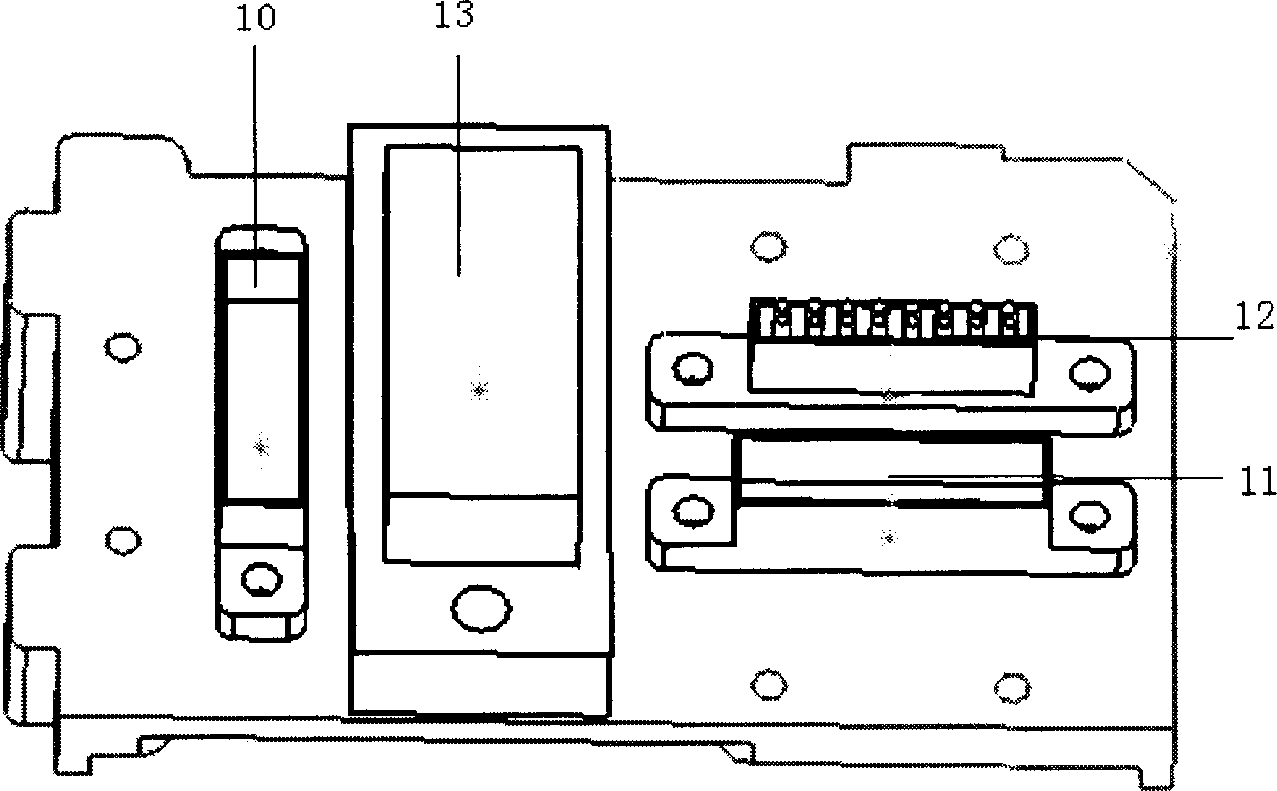

Board structure and electronic device

InactiveCN101273673AGuaranteed installation strengthMagnetic/electric field screeningCross-talk/noise/interference reductionEngineeringBoard structure

A board structure and an electronic device are provided in which a resin part that covers a plurality of electronic parts altogether has shielding characteristics and the mounting strength of the electronic parts mounted on the board can be secured. A board structure (10) comprises a board (11), a plurality of electronic parts (12) mounted along the board (11), and a resin part (13) covering each of the electronic parts (12) with resin (18) and adhering to the board (11). This board structure (10) further comprises a frame (15) surrounding the electronic parts (12) and adhering to the board (11) and a cover (17) closing an opening (16) of the frame (15). The resin (18) is placed inside the frame (15).

Owner:PANASONIC CORP

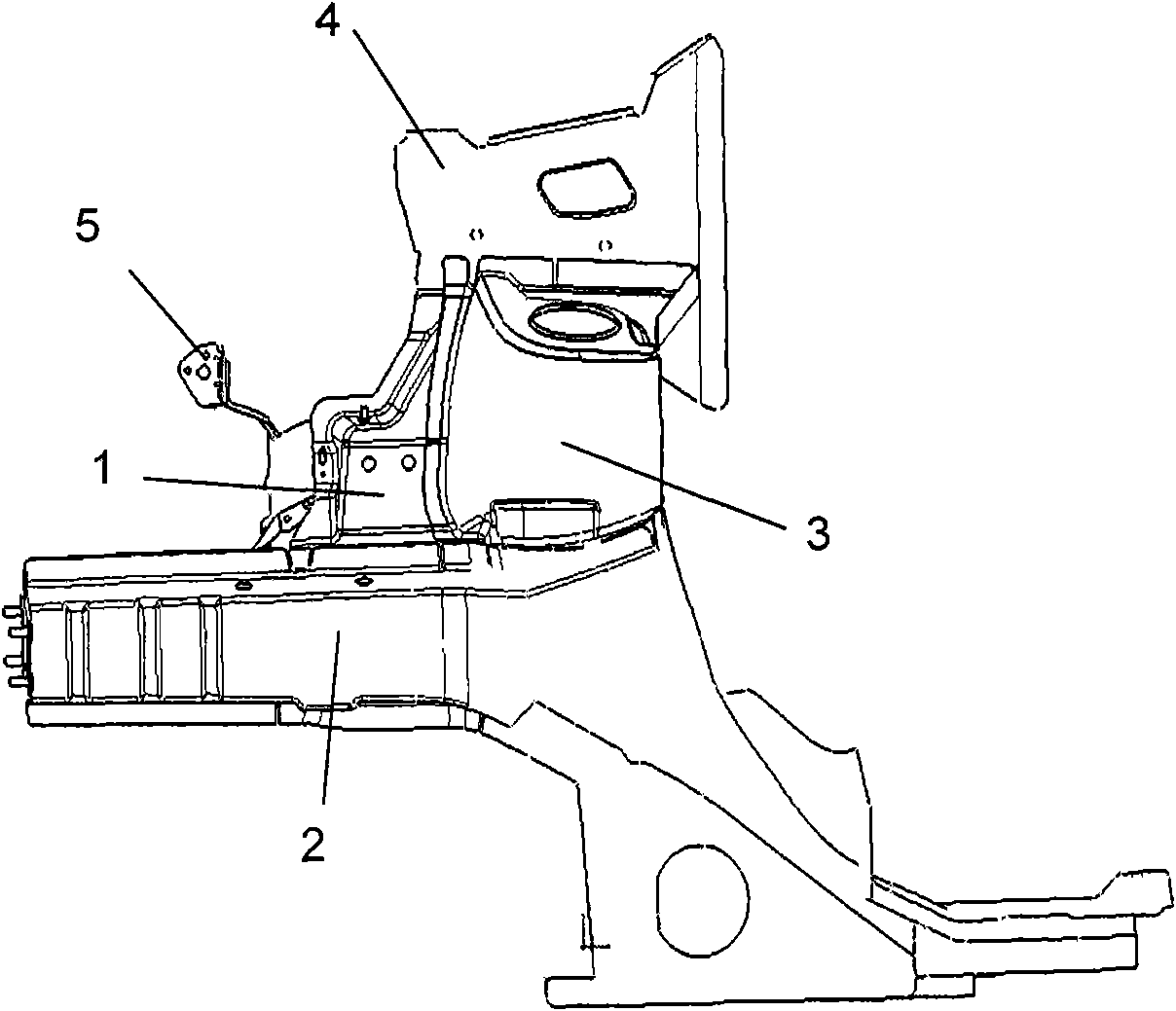

Front wheel cover side plate assembly for automobile

InactiveCN101863288AMeet the rigidityGuaranteed installation strengthSuperstructure subunitsMonocoque constructionsEngineeringFront edge

The invention discloses a front wheel cover side plate assembly for an automobile. The assembly comprises a front wheel cover side plate, a front longitudinal beam, a front shock absorber mounting plate, a connecting plate and a front fender mounting bracket which are arranged on the automobile body in a lateral symmetry way, wherein the front wheel cover side plate has a cavity structure with a top opening; the upper edge of the front longitudinal beam is fixedly connected to the lower end of the front wheel cover side plate; the front edge of the front shock absorber mounting plate is fixedly connected to the rear edge of the front wheel cover side plate; the connecting plate is fixedly connected with the upper end of the front wheel cover side plate and the upper end of the front shock absorber mounting plate respectively to form a closed cavity; the rear edge of the front fender mounting bracket is fixedly connected with the front edge of the front wheel cover side plate; and the lower end of the front fender mounting bracket is fixedly connected with the upper edge of the front longitudinal beam. The assembly not only rationally and effectively transfers the impact load from the front longitudinal beam to the rear part and the upper part of the automobile body during direct impact and biasing impact, but also ensures the installation strength, the accuracy and the NVH performance of the installation points on the left and the right suspension sides of an engine and the front fender mounting bracket.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

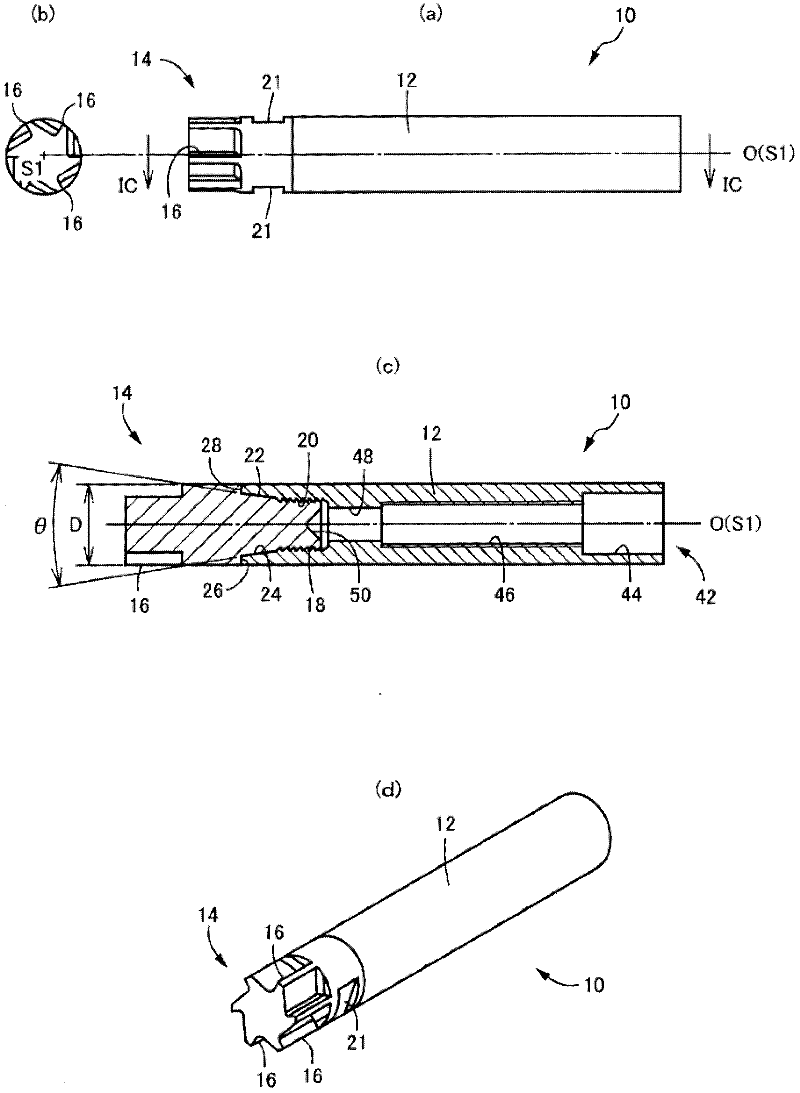

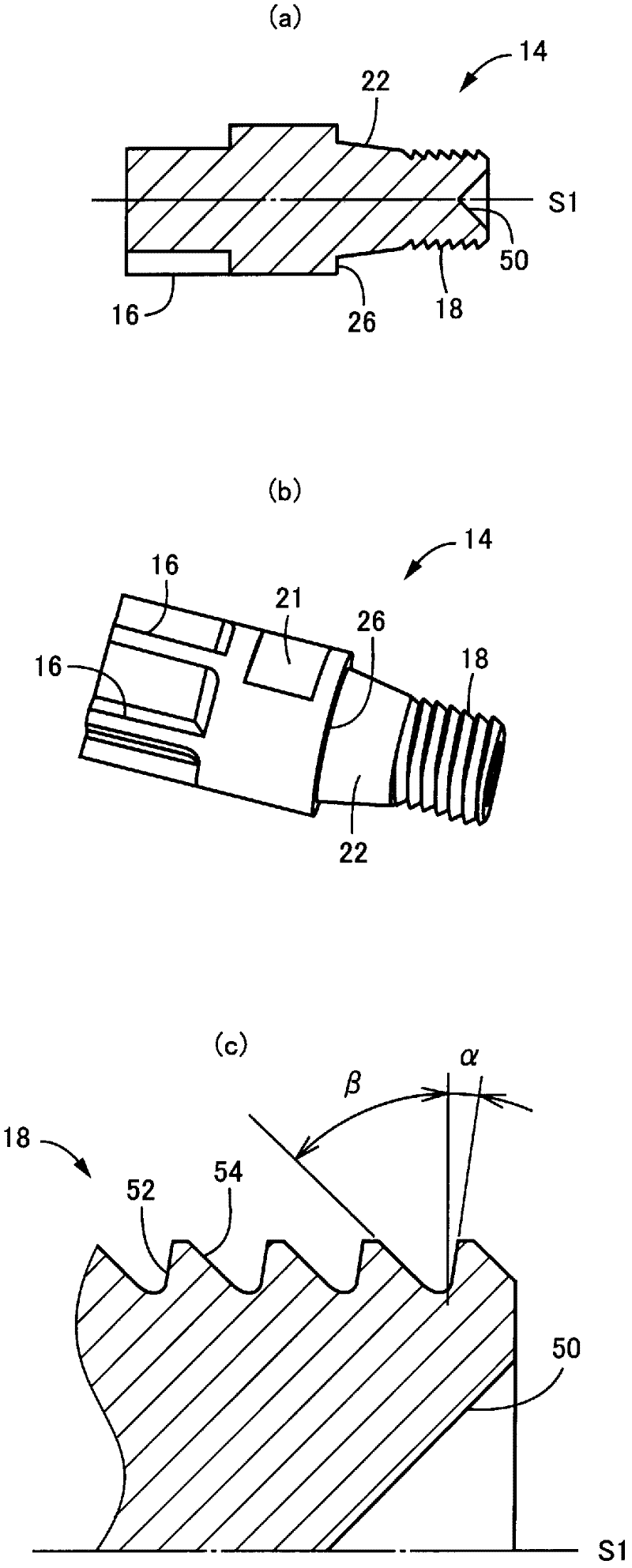

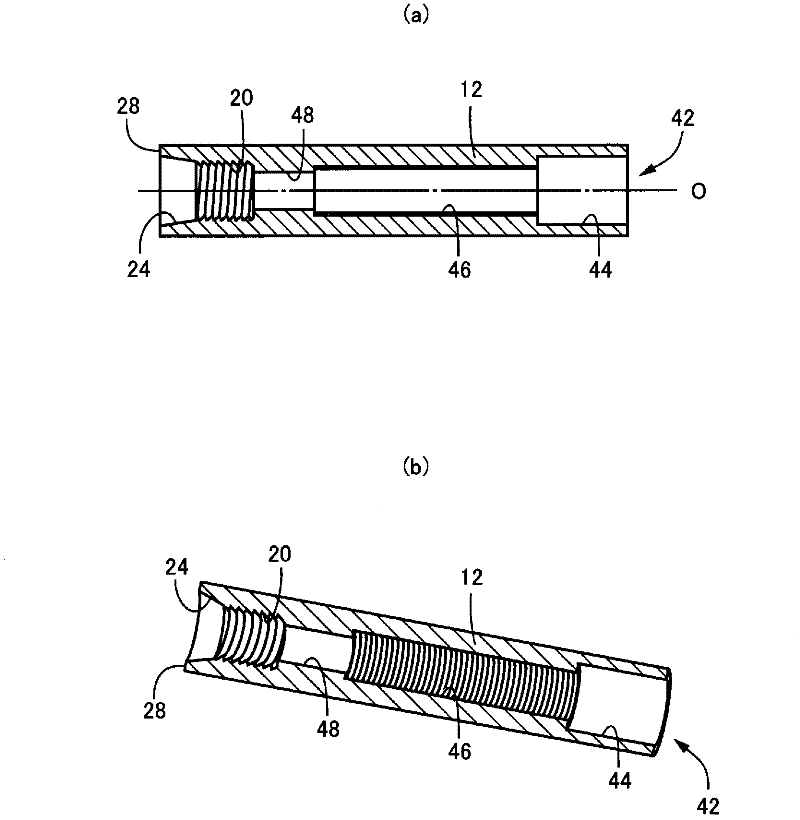

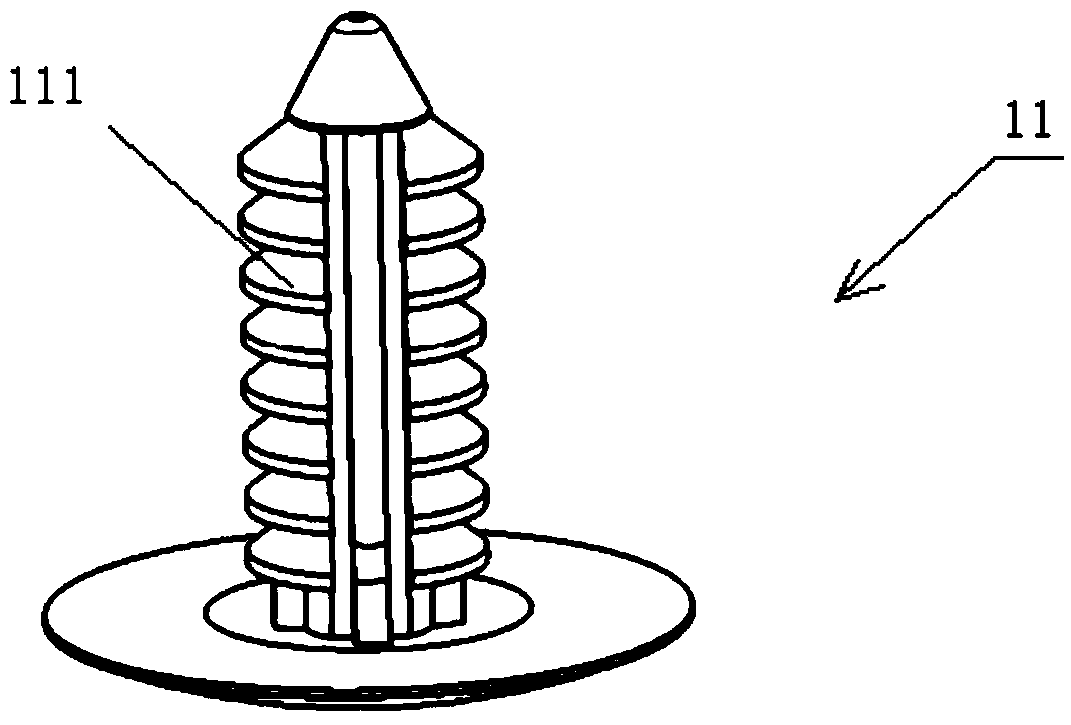

Machining head replacement type rotary tool, holder, and machining head

InactiveCN102458742AReduce the possibilityDeposition inhibitionTransportation and packagingMilling cuttersAbutmentEngineering

A machining head replaceable rotating tool having a fastening male screw and a fastening female screw disposed on respective shaft centers of one and the other of a machining head and a holder, the fastening male and female screws being threadably engaged with each other to concentrically and removably attach the machining head to a tip portion of the holder, the machining head and the holder being disposed with abutting surfaces abutted against each other in a fastened state when the fastening male and female screws are threadably engaged, the machining head replaceable rotating tool being integrally and rotationally driven via the holder in a tool rotation direction causing the fastening male and female screws to be fastened by a machining load to perform predetermined machining with the machining head, the abutment of the abutting surfaces preventing the fastening male and female screws from being further fastened by a machining load, the fastening male and female screws being saw-tooth buttress screws having a following flank angle [alpha] smaller than a leading flank angle [beta].

Owner:OSG

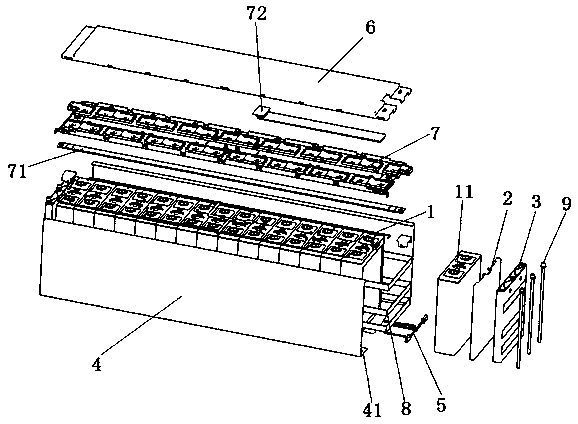

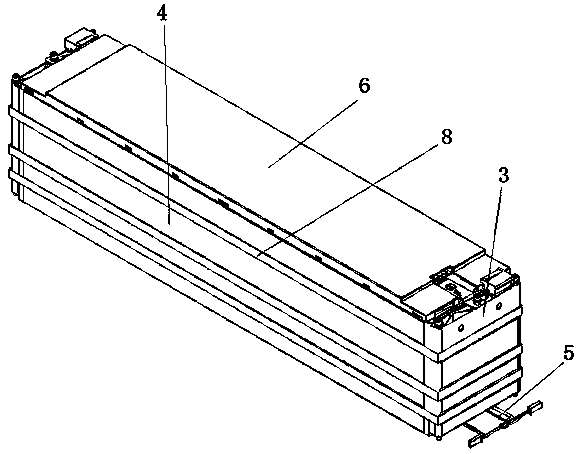

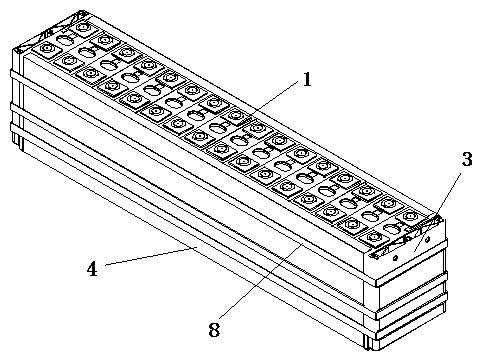

Battery module

InactiveCN108878702AReduce heat conduction lossLess assembly partsSecondary cellsCell component detailsPower batteryElectrical and Electronics engineering

The invention relates to the technical field of power batteries, in particular to a battery module. The battery module comprises a module framework and a battery pack which is arranged in the modularframework and formed by arranging single batteries and further comprises a temperature adjusting component for heating and / or cooling the battery pack; and an installation hole is formed in the bottomof the module framework, the bottom of the battery pack is exposed in the installation hole, and the temperature adjusting component is arranged in the installation hole and arranged on the bottom face of the battery pack in an attached mode. Due to the fact that the installation hole is formed in the bottom of the module framework, technical staff can directly arrange the temperature adjusting component in the installation hole in the attached mode; due to the fact that the module framework can support the battery pack, the technical staff do not need to arrange a bottom plate forming complete closure on the overall bottom face of the battery module; and due to the fact that the temperature adjusting component directly makes contact with the bottom of the battery pack, the heat conducting loss is reduced, assembly parts of the overall battery module are reduced, and therefore the battery module is lighter and good in heating or cooling effect.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG +1

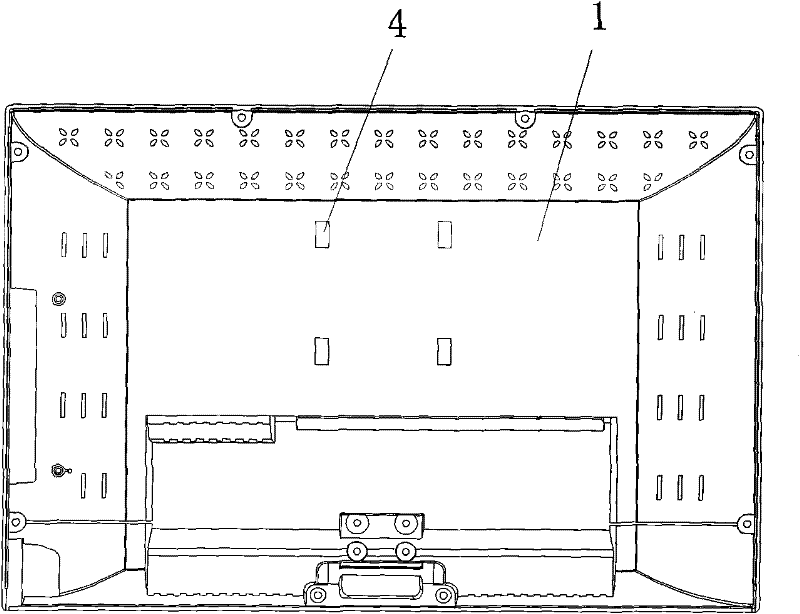

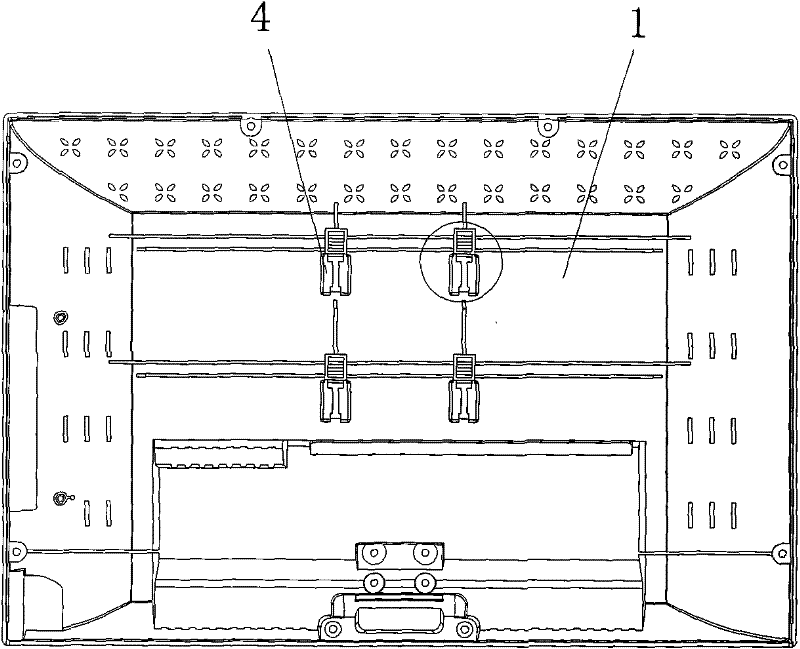

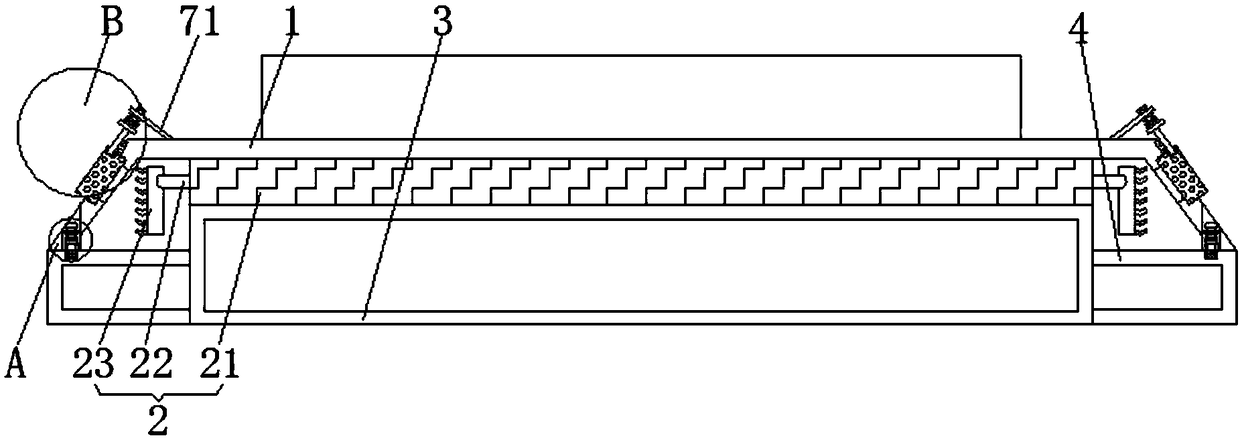

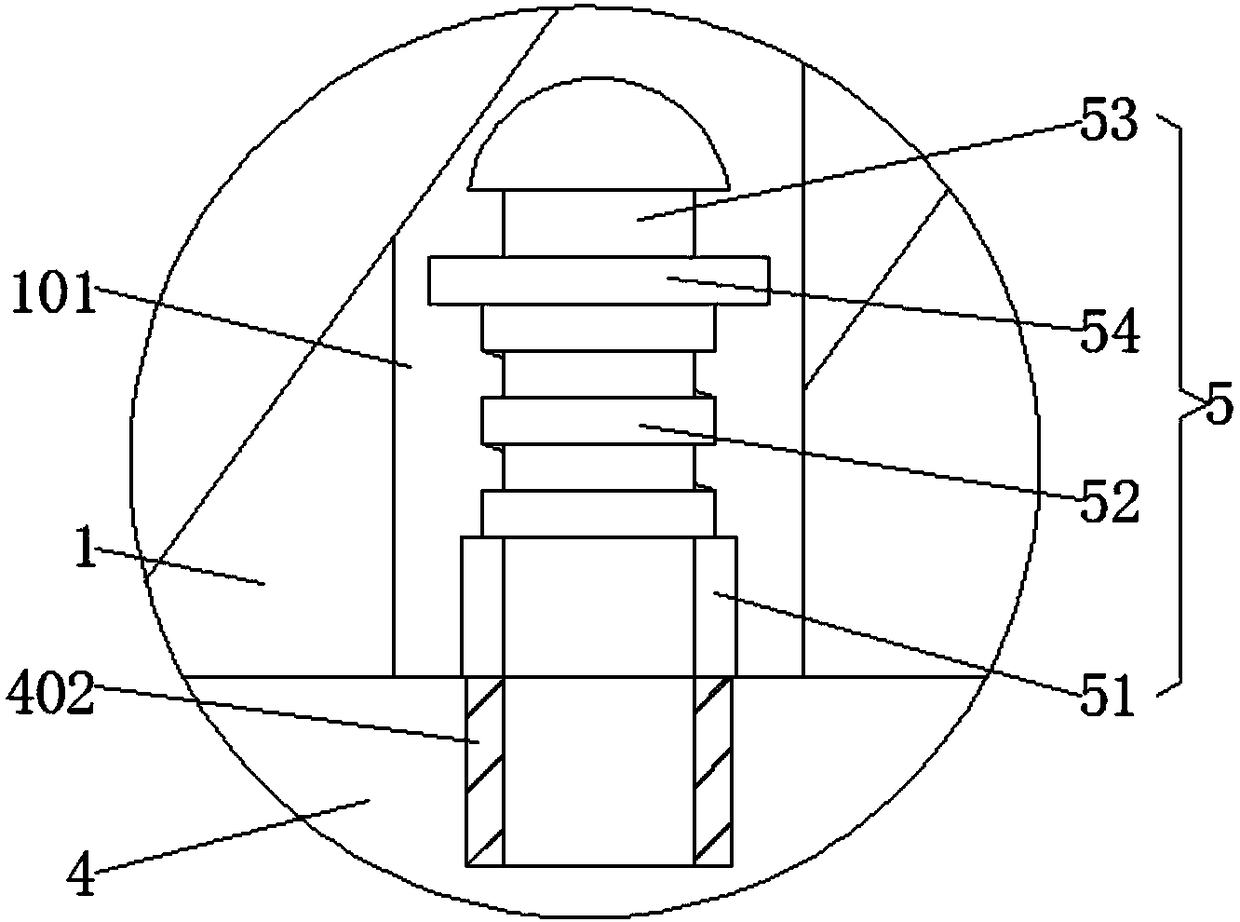

Wall hanging device for flat panel televisions

InactiveCN102478146AReduce processing laborReduce the cost of the whole machineTelevision system detailsMachine supportsEngineeringStructural engineering

The invention discloses a wall hanging device for flat panel televisions; the wall hanging device comprises a rear housing (1) of the flat panel television and a wall hanging plate (2) which is fixed with a wall; at least two hangers (3) are outwards extended out from the wall hanging plate; and hanging holes (4) which correspond to the hangers in number are arranged in a corresponding position of the rear housing. Compared with the prior art, the wall hanging device has the advantages that eight hardware parts are saved under the condition that the installation intensity is ensured, the number of workers for processing materials and production lines is reduced, and the cost of the whole machine is reduced; and the wall hanging device can be widely applied to the panel televisions with the sizes below 26 inches.

Owner:KONKA GROUP

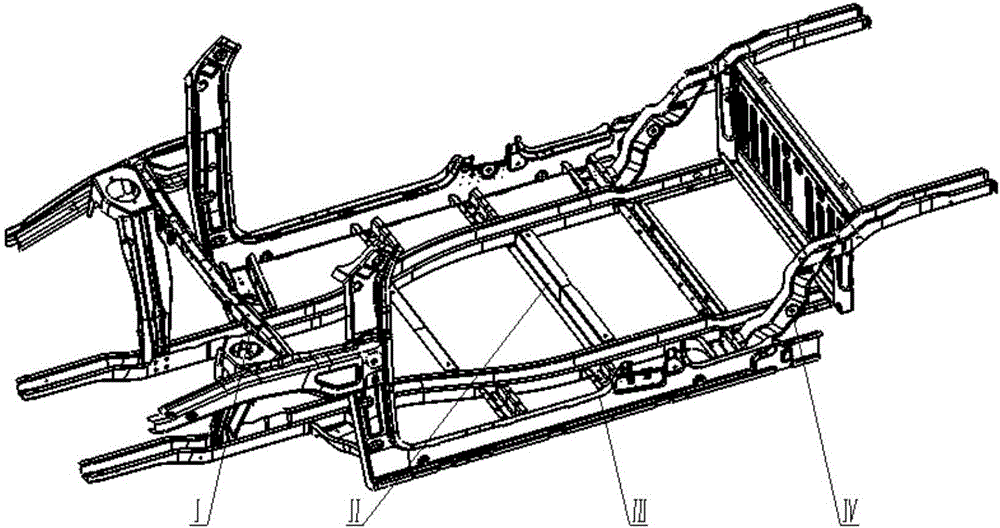

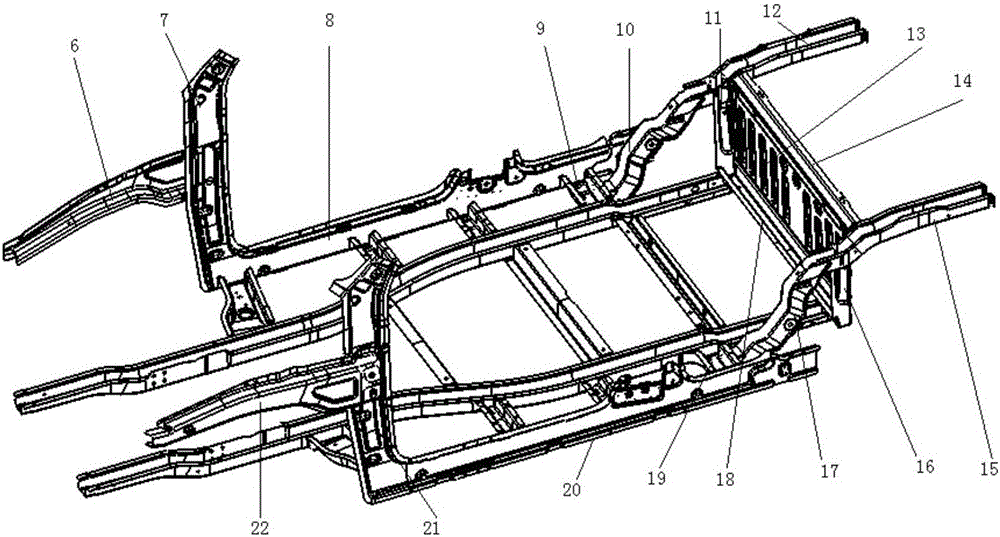

Frame structure for pure electric vehicle

The invention discloses a frame structure for a pure electric vehicle. The frame structure adopts a four longitudinal beam space structure, and consists of a middle-through-type H-type structure formed by double frame longitudinal beams and cross beams, side beam structures on the two sides of the frame, a front strengthening structure and a back battery cabin strengthening structure together. The middle H-type structure can ensure the rigidity of the whole vehicle body structure, and can effectively improve the torsion resistance of the frame; the front strengthening structure and the back battery cabin strengthening structure can effectively improve the safety of front collision and back collision, relieve deformation of a driving cabin when in collision, and provide safety protection for passengers at the greatest extent. Compared with the traditional frame structure, according to the technical scheme, the safety of front collision, side collision and back collision can be effectively improved, meanwhile the torsion resistance of the frame structure can be effectively improved, the mounting strength and the finished vehicle rigidity of a chassis system can be ensured, and the properties of the driving smoothness, the controllability, the trafficability and the like are all considered.

Owner:烟台宏瑞汽车有限责任公司

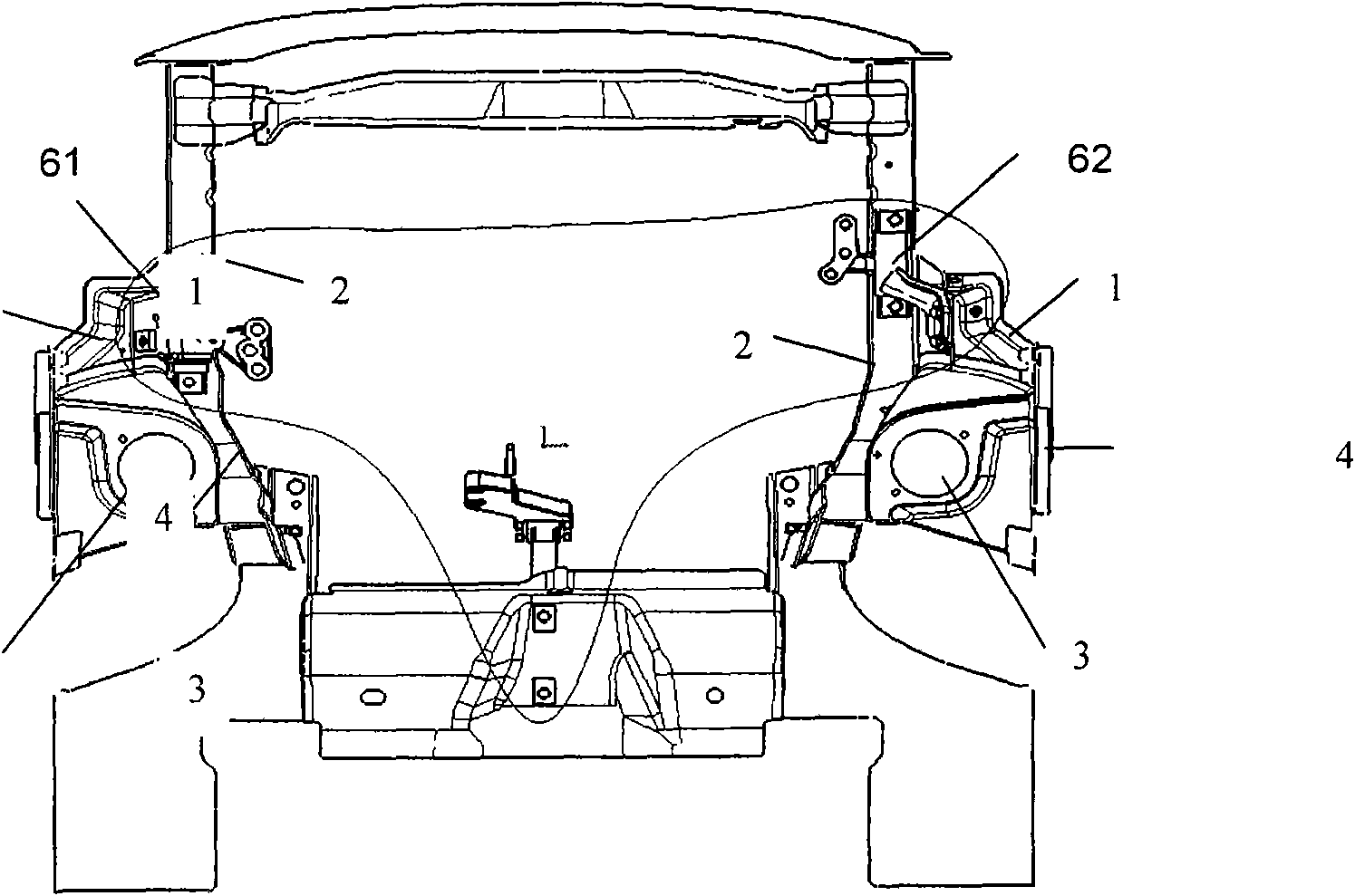

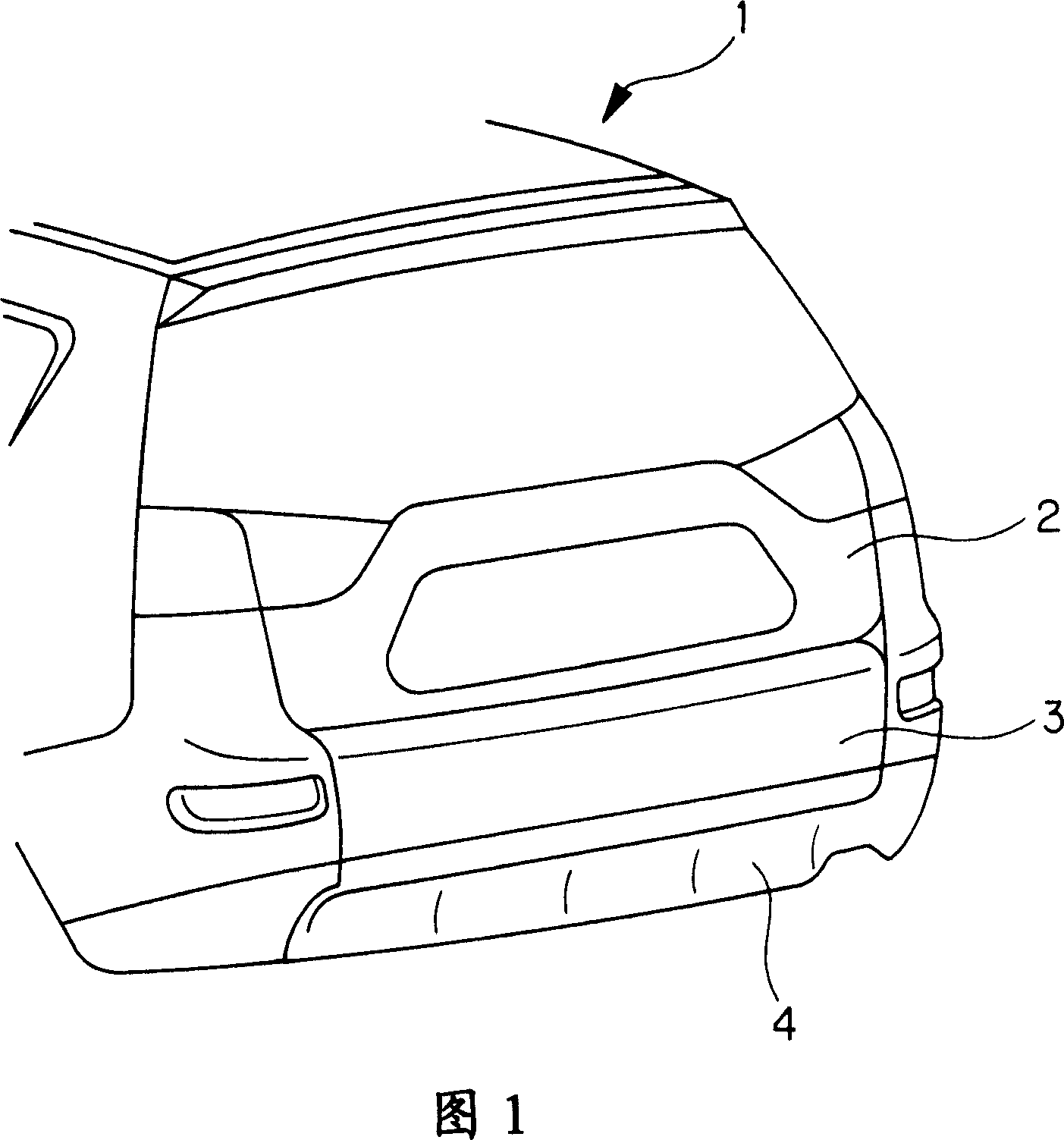

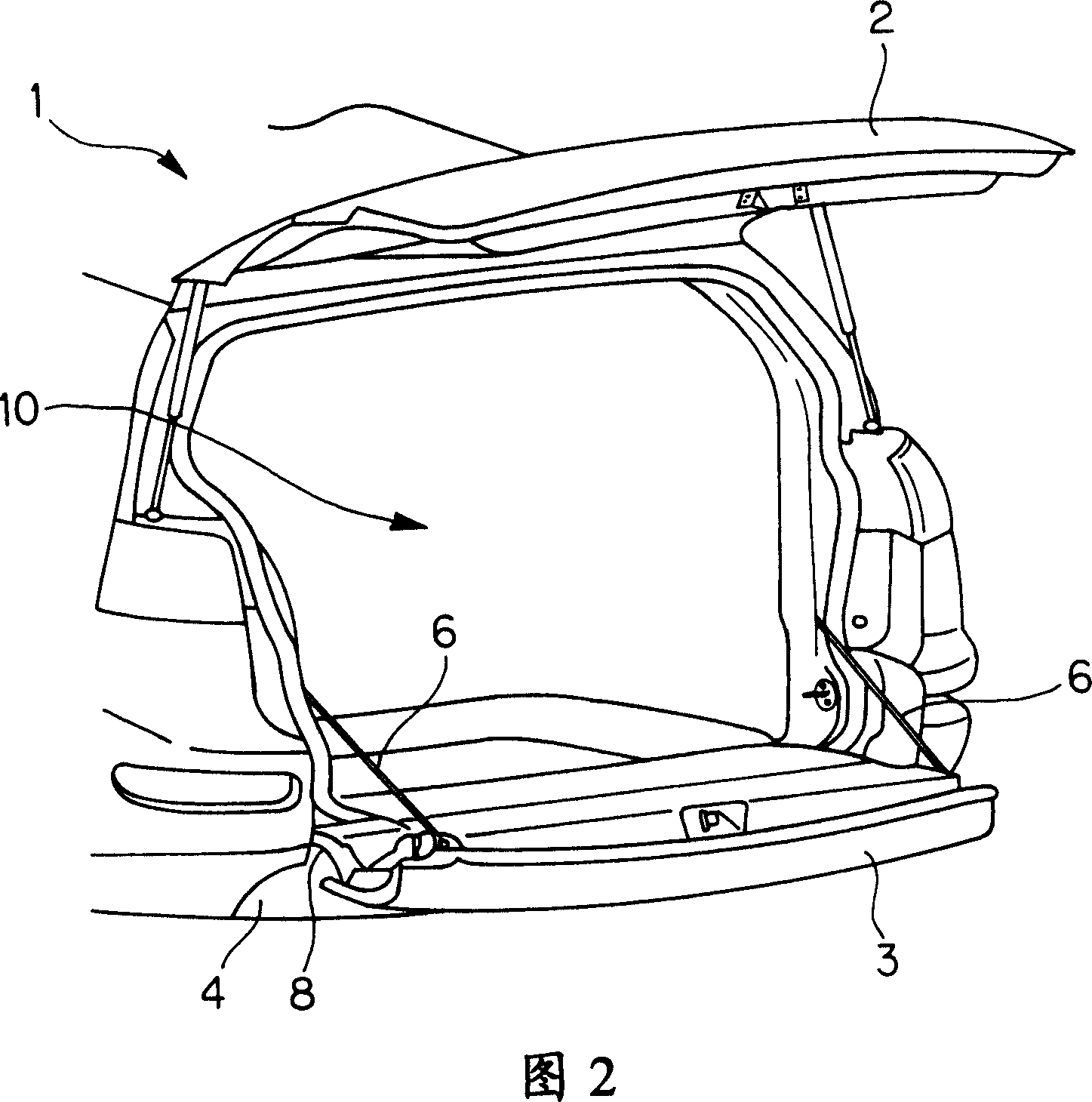

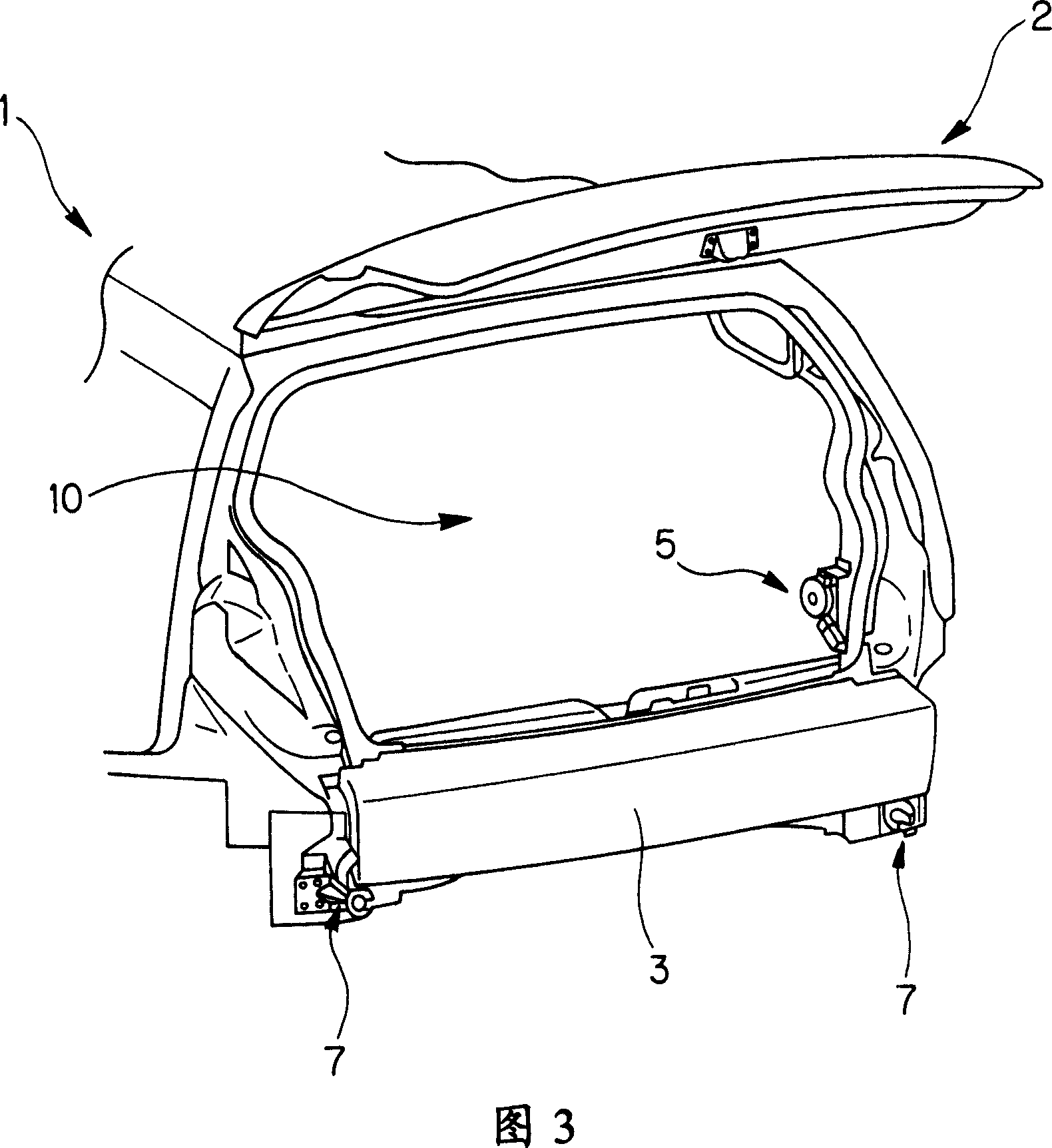

Opening and closing apparatus of vehicle

InactiveCN1932227AIncreased Design FreedomGuaranteed large openingMan-operated mechanismDoor/window applicationsEngineeringClosed state

The invention discloses an opening and closing device for a car, comprising: an opening and closing member for opening and closing an opening of a car body; a lower hinge for pivotally supporting the opening and closing member from below; and a cover member , arranged under the opening and closing member placed in the closed state, for covering the pivot support portion of the lower hinge from behind, wherein, when the opening and closing member is in the open state, the pivotally supported by the pivot support portion The pivoting part spans the covering part, the opening and closing part is located behind the covering part, and the highest position of the pivoting part is not higher than the upper surface of the opening and closing part.

Owner:MITSUBISHI MOTORS CORP +1

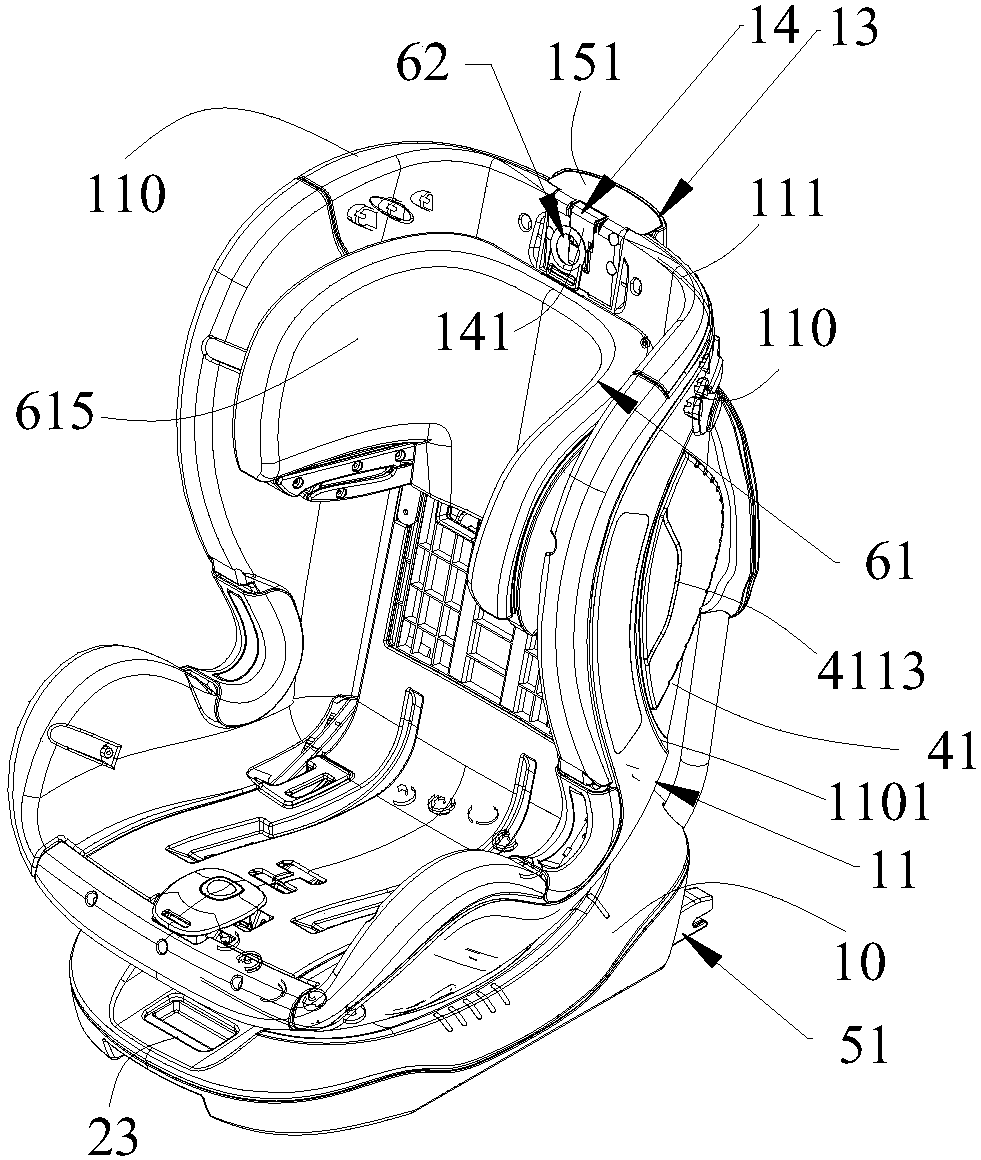

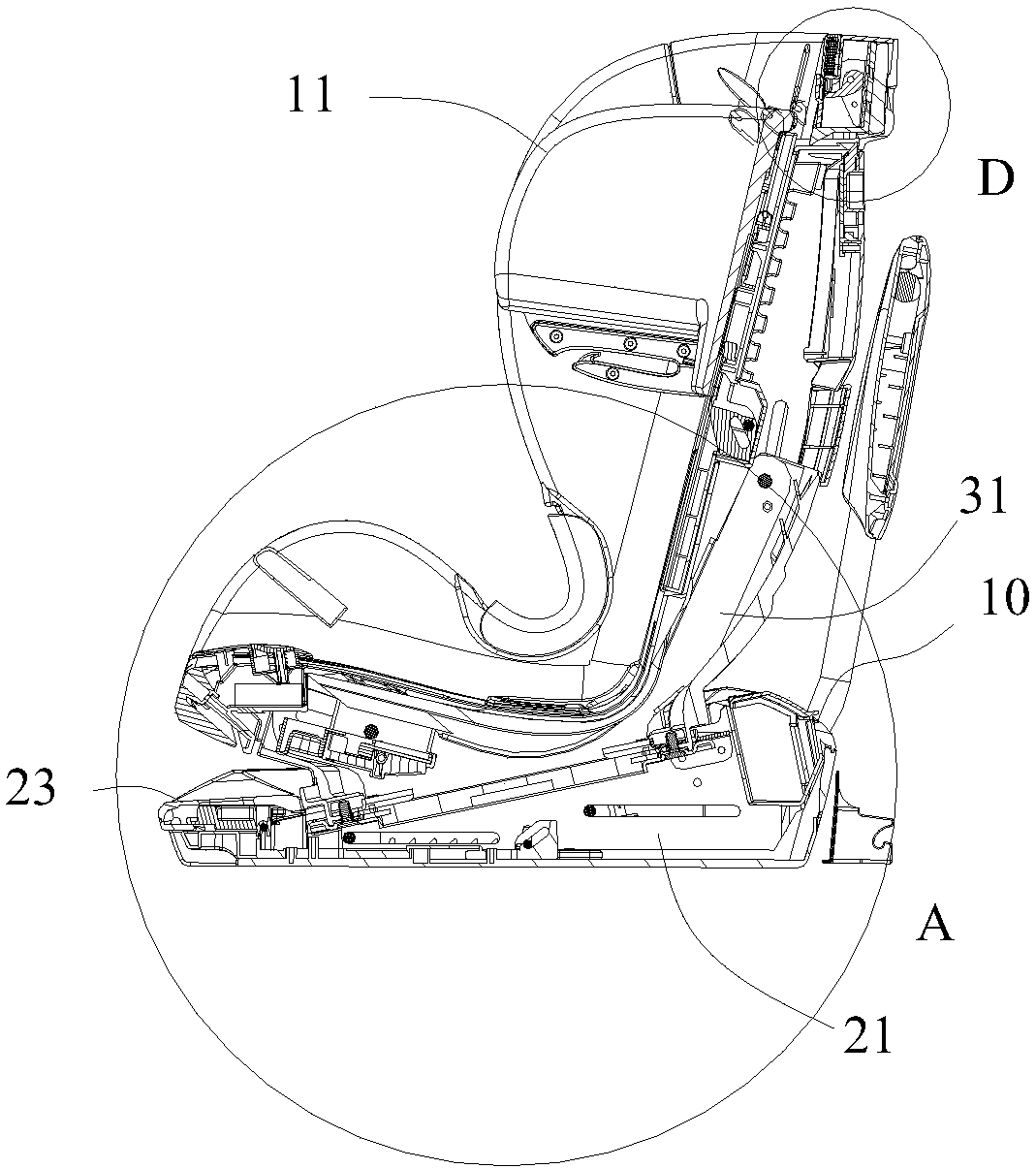

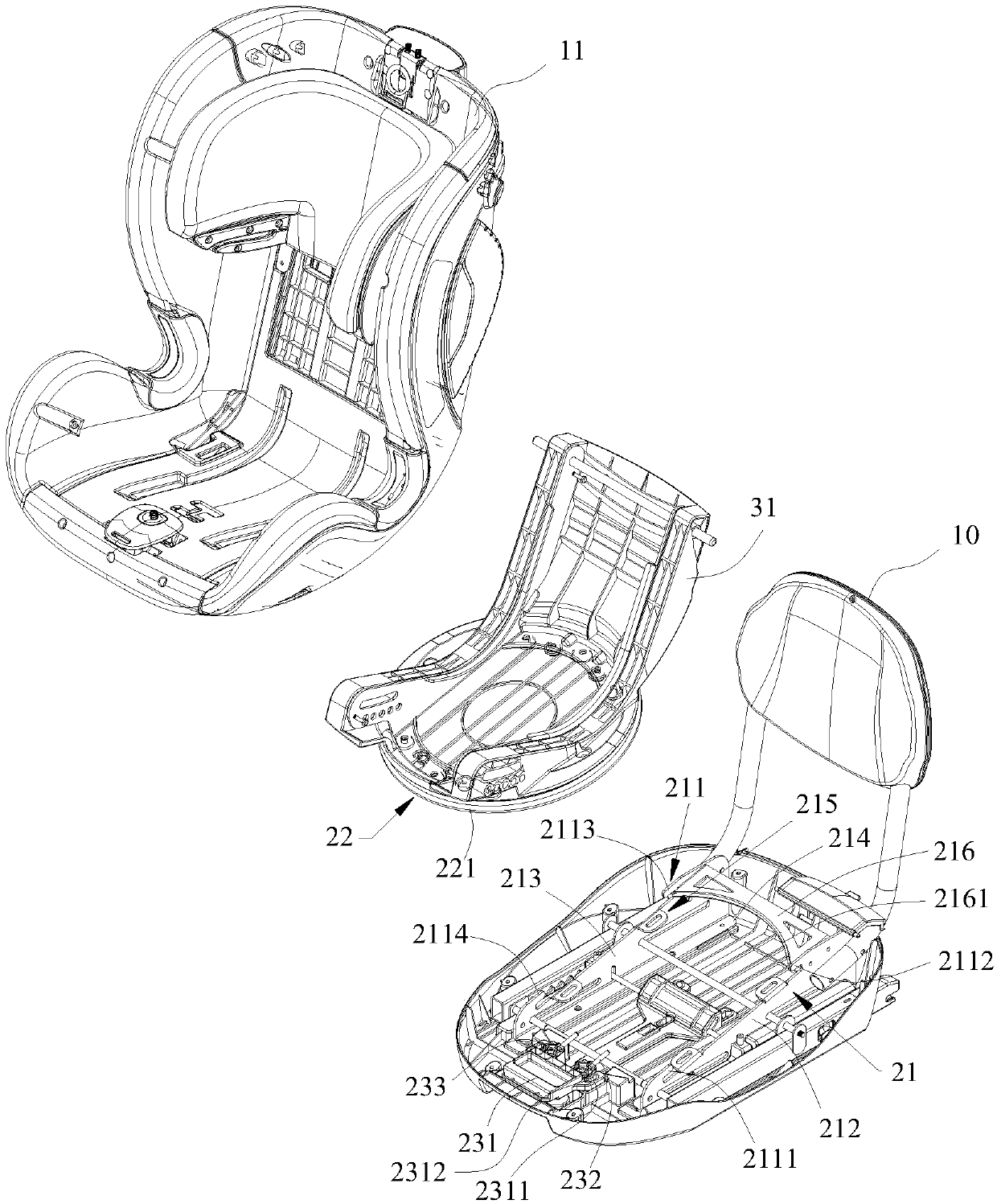

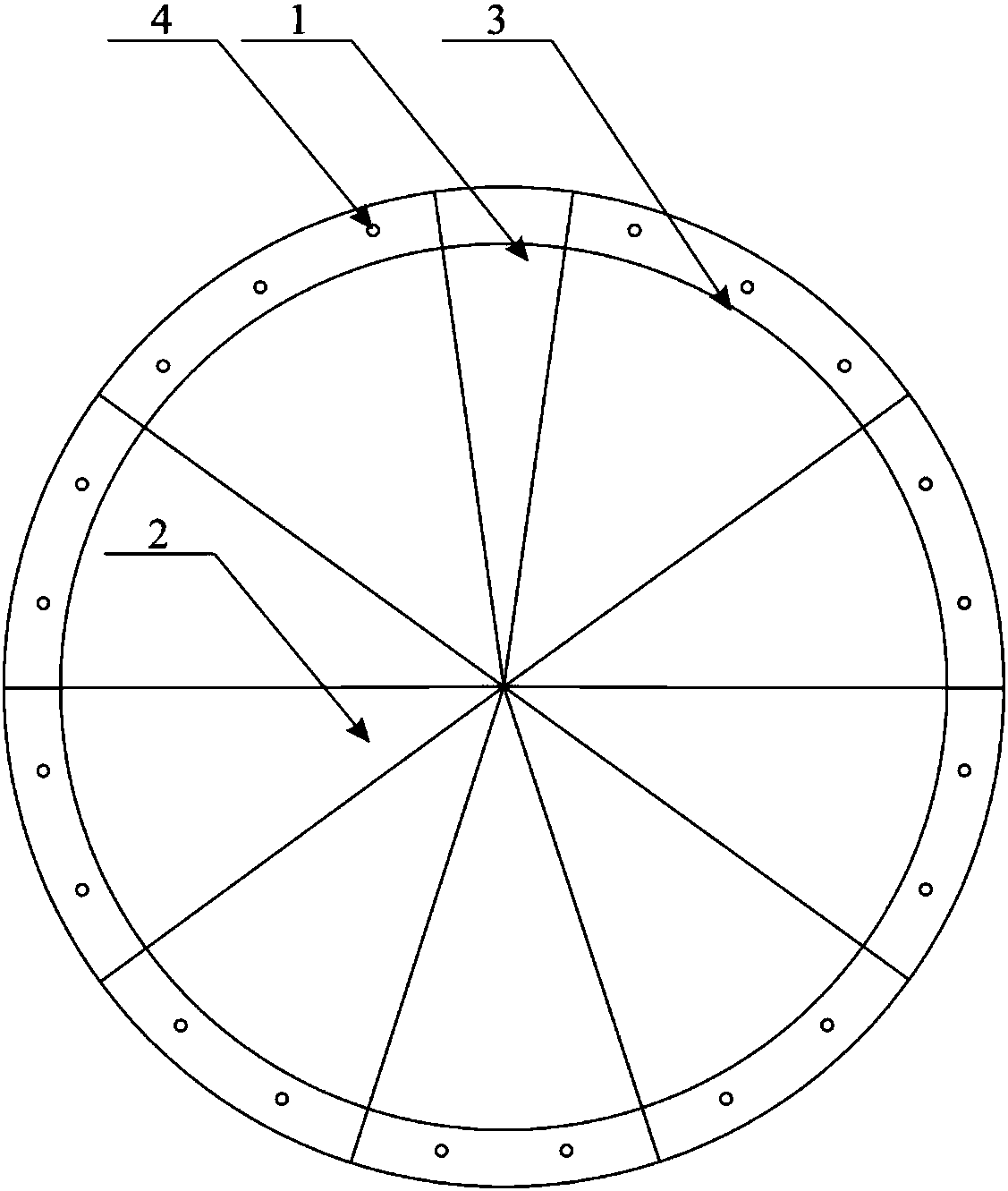

Child restraint system

PendingCN107839556ALow rotational resistanceGuaranteed installation strengthChild seatsLocking mechanismEngineering

The invention discloses a child restraint system. The child restraint system comprises a base and a seat, a turntable bracket is fixed to the base, the bottom of the seat is provided with a turntablematched with the turntable bracket, and the turntable bracket is provided with at least three jaws each of which is pressed against the edge of the turntable to define the position of the turntable; the turntable is provided with a pitch adjustment frame, the seat is mounted on the pitch adjustment frame, a matched angle locking mechanism is arranged between the pitch adjustment frame and the sea,and the pitch adjustment frame comprises a bottom holder and two supporting plates arranged side by side on the bottom holder; in the movement path, for adjusting the pitch angle, of the seat, one ends of the two supporting plates are provided with first guiding rods and the other ends of the two supporting plates are provided with second guiding grooves; the seat is provided with first guiding grooves matched with the first guiding rods and second guiding rods matched with the second guiding grooves; the guiding rods move along the corresponding guiding grooves to guide the seat to adjust the pitch angle.

Owner:ZHEJIANG CH BABY

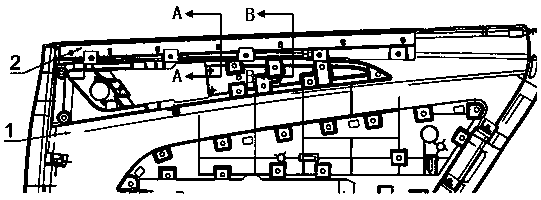

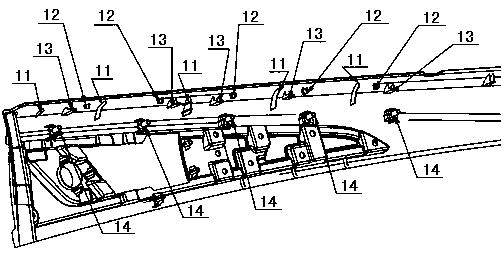

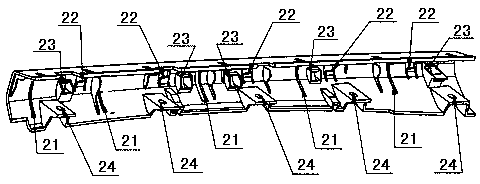

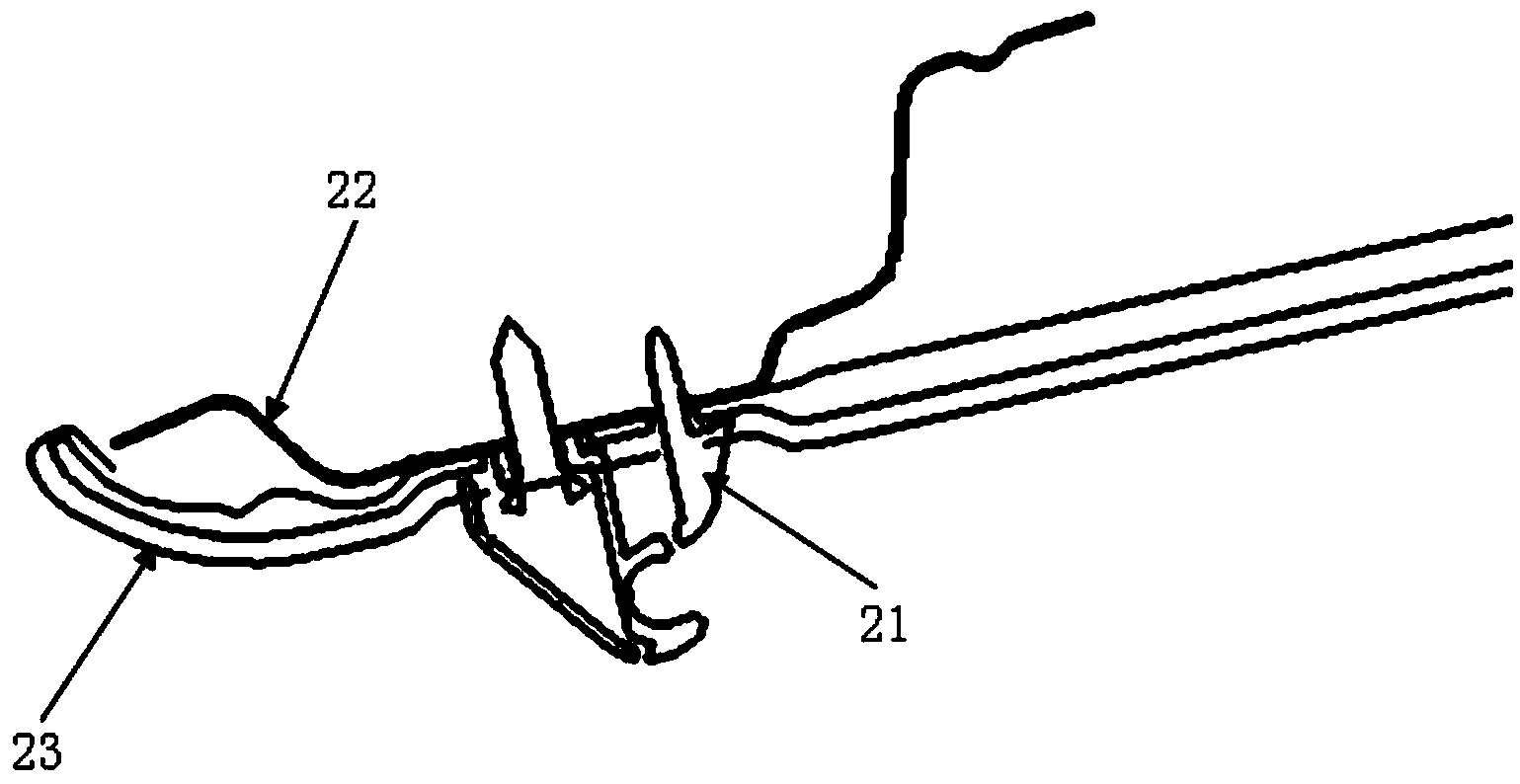

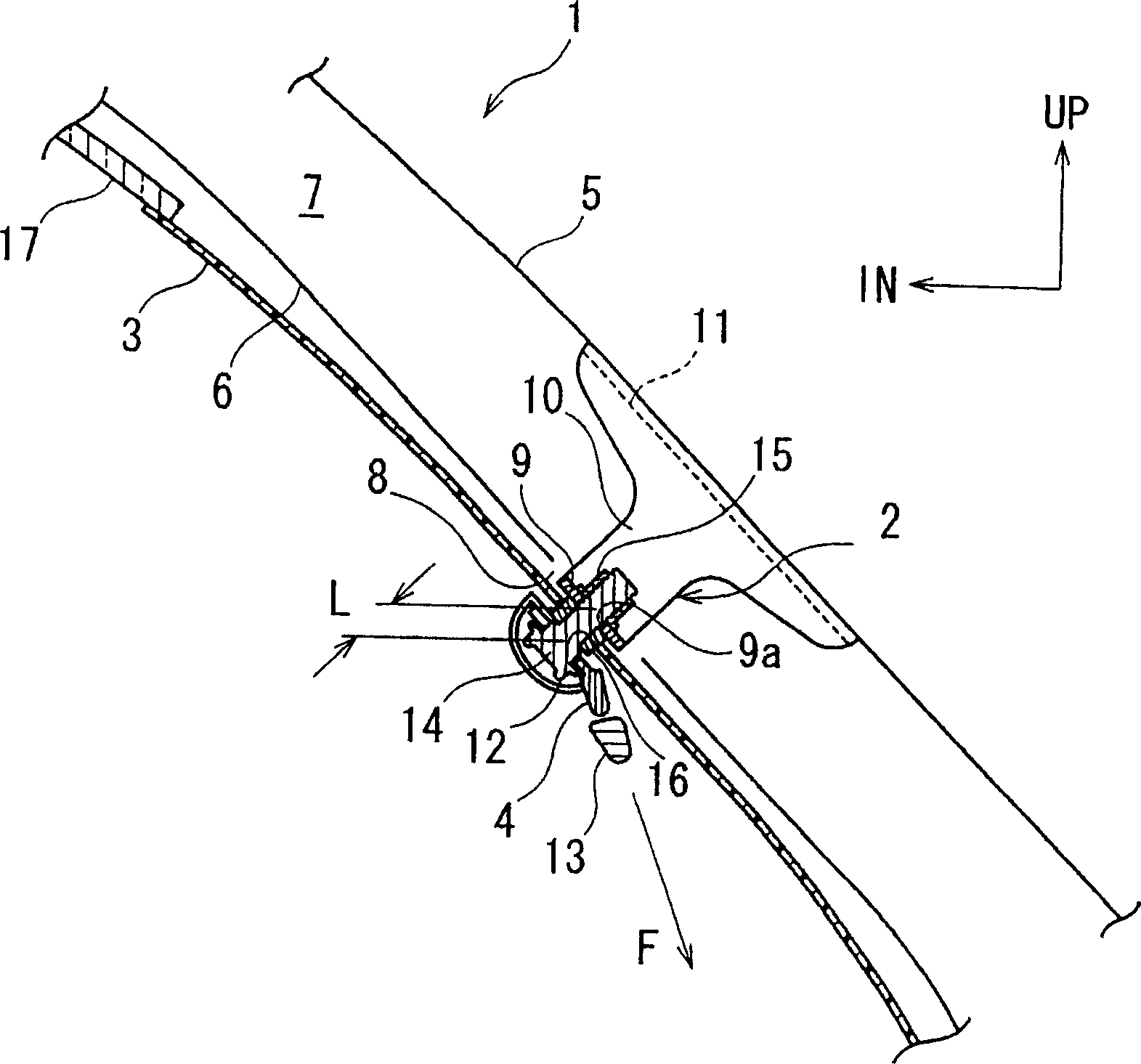

Installing structure of inner waterproof holding strip fixing supports of vehicle door

ActiveCN103863075AGuaranteed installation accuracyGuaranteed installation strengthEngine sealsSuperstructure subunitsEngineeringElectrical and Electronics engineering

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

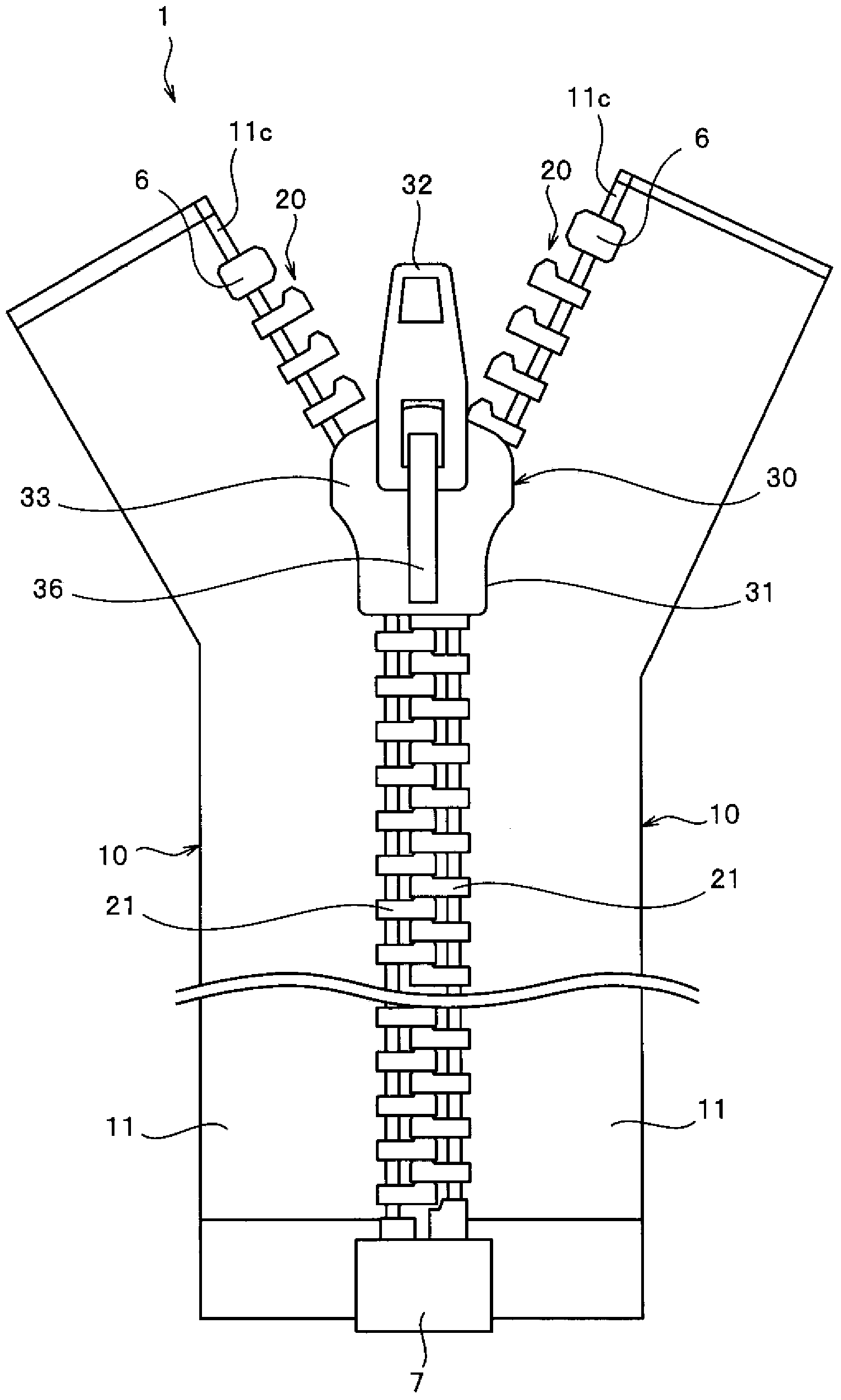

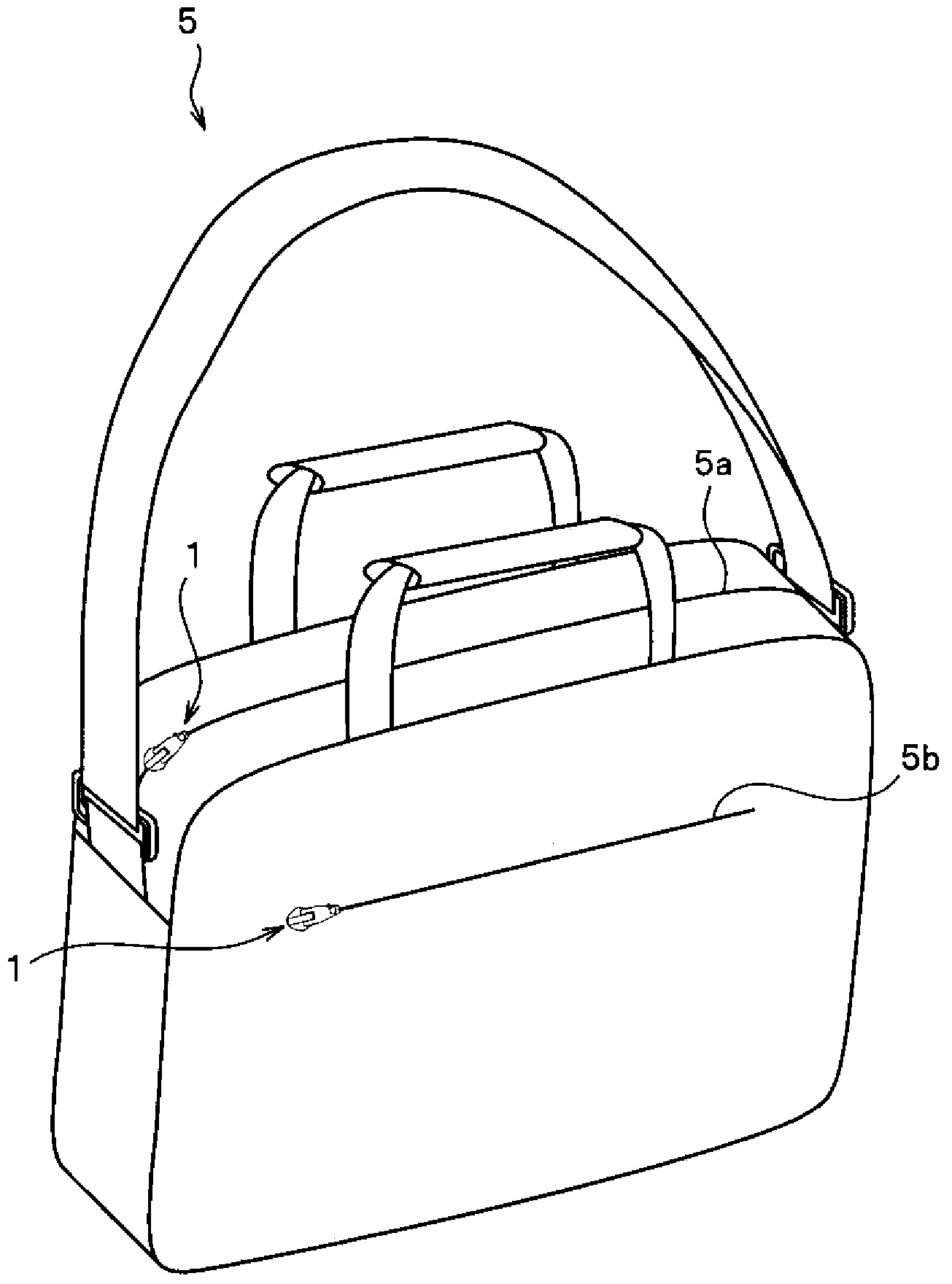

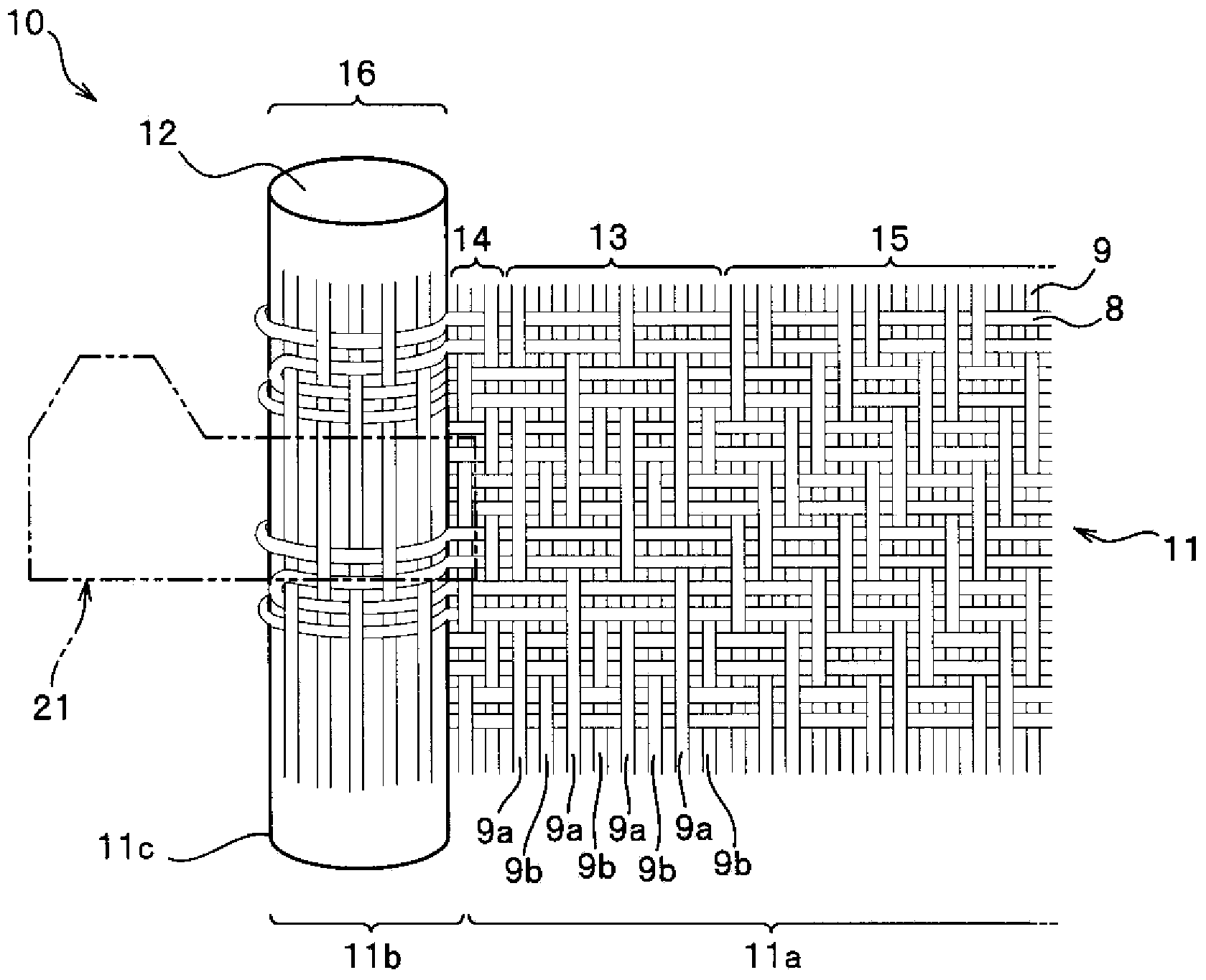

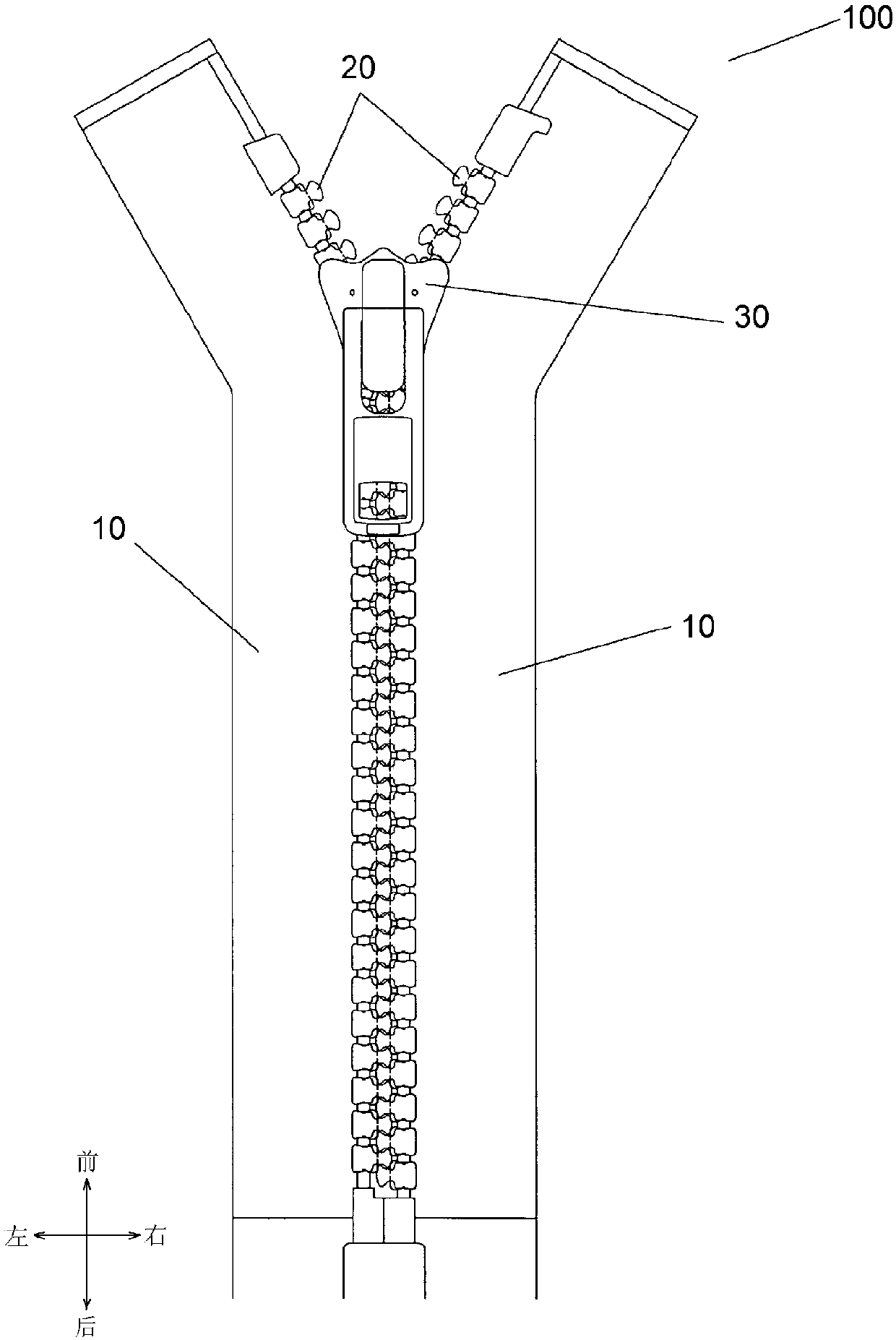

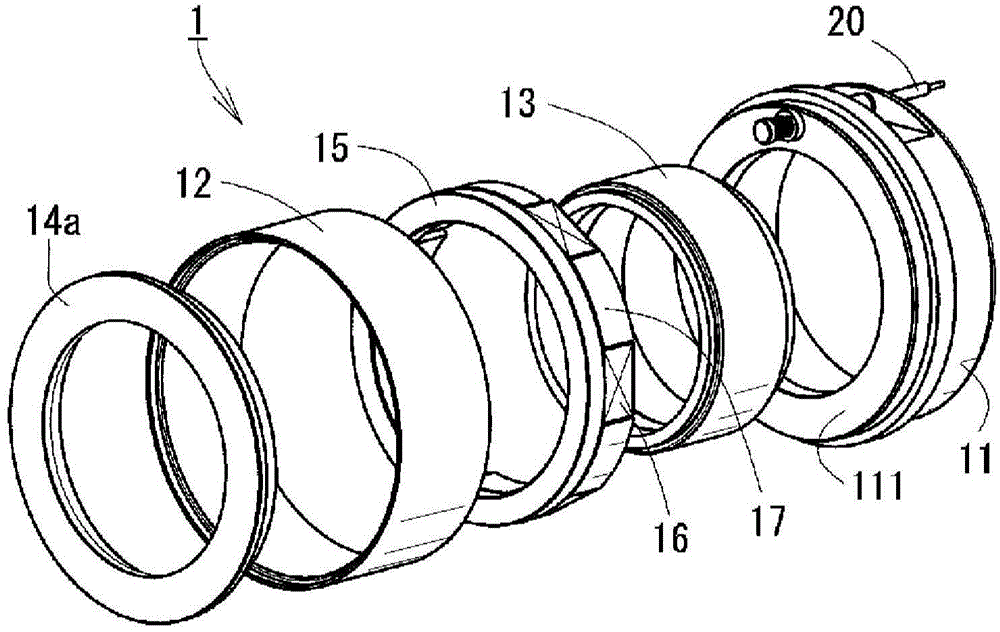

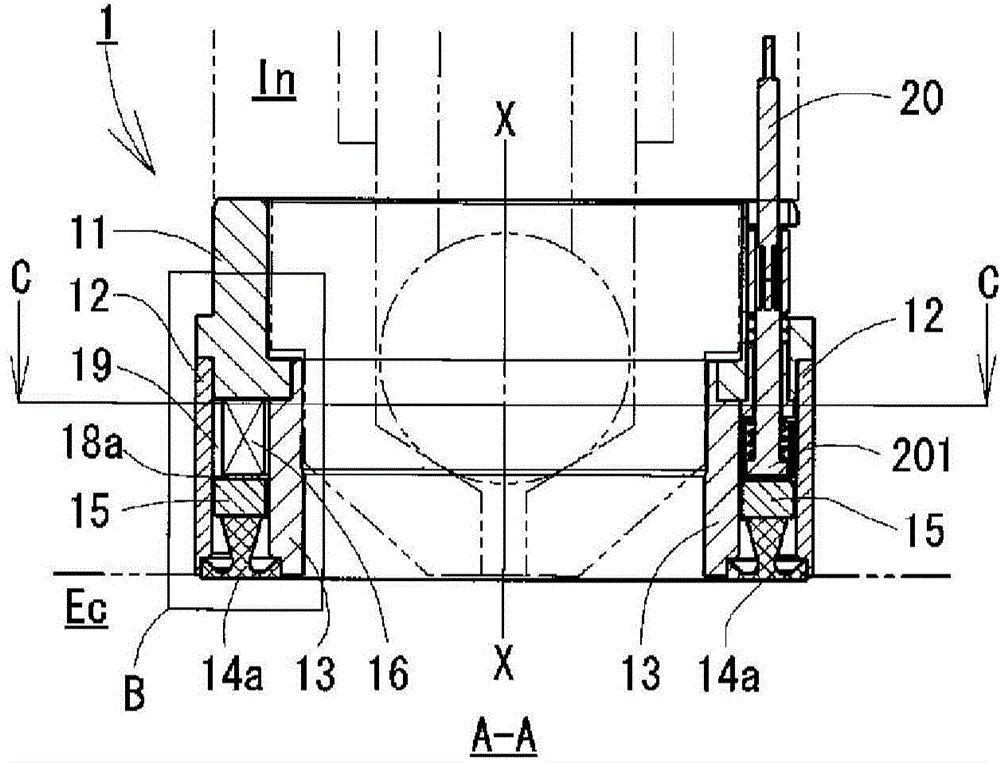

Slide fastener and hidden slide fastener

ActiveCN103917125ANot easy to reachSuppresses undesirable situations such as breakageSlide fastenersWoven fabricsFastenerWeft yarn

This slide fastener (1, 2) is configured such that a fastener tape (11, 17, 18, 19, 41) comprises a single-ply woven structure and has a double-ply woven region (13, 13a, 43) formed along the longitudinal direction of the tape, the double-ply woven region (13, 13a, 43) comprising a double-ply woven structure. An inner single-ply woven region (14, 14a, 14b, 44) and an outer single-ply woven region (15, 45), which have a single-ply woven structure, are formed on the tape inner edge side and tape outer edge side of the double-ply woven region (13, 13a, 43). As a result of the configuration, weft yarns (9) arranged in the double-ply woven region (13, 13a, 43) are less likely to be cut even if the fastener tape (11, 17, 18, 19, 41) makes contact with ridge line sections (34c, 64a) on the lower wing plate side of a slider (30, 60) when the slider (30, 60) is slid, and consequently the lifetime of the slide fastener (1, 2) is extended.

Owner:YKK CORP

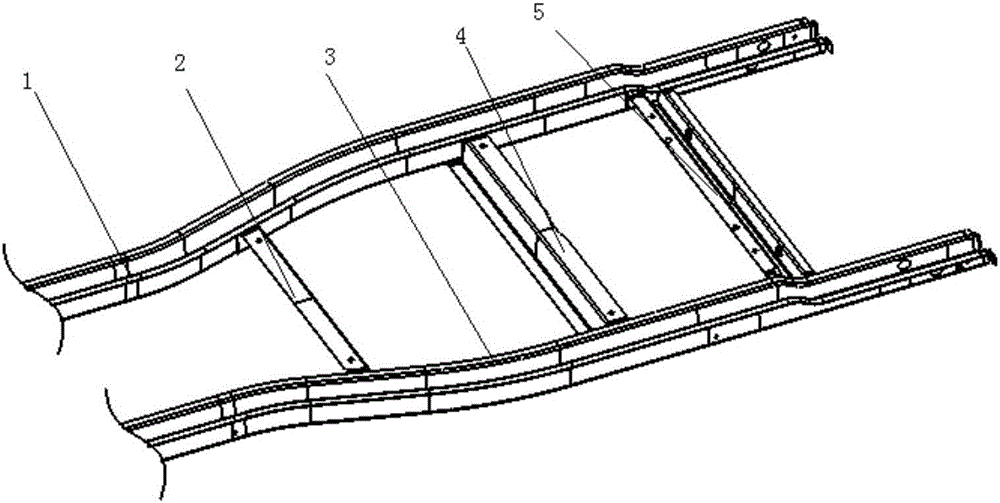

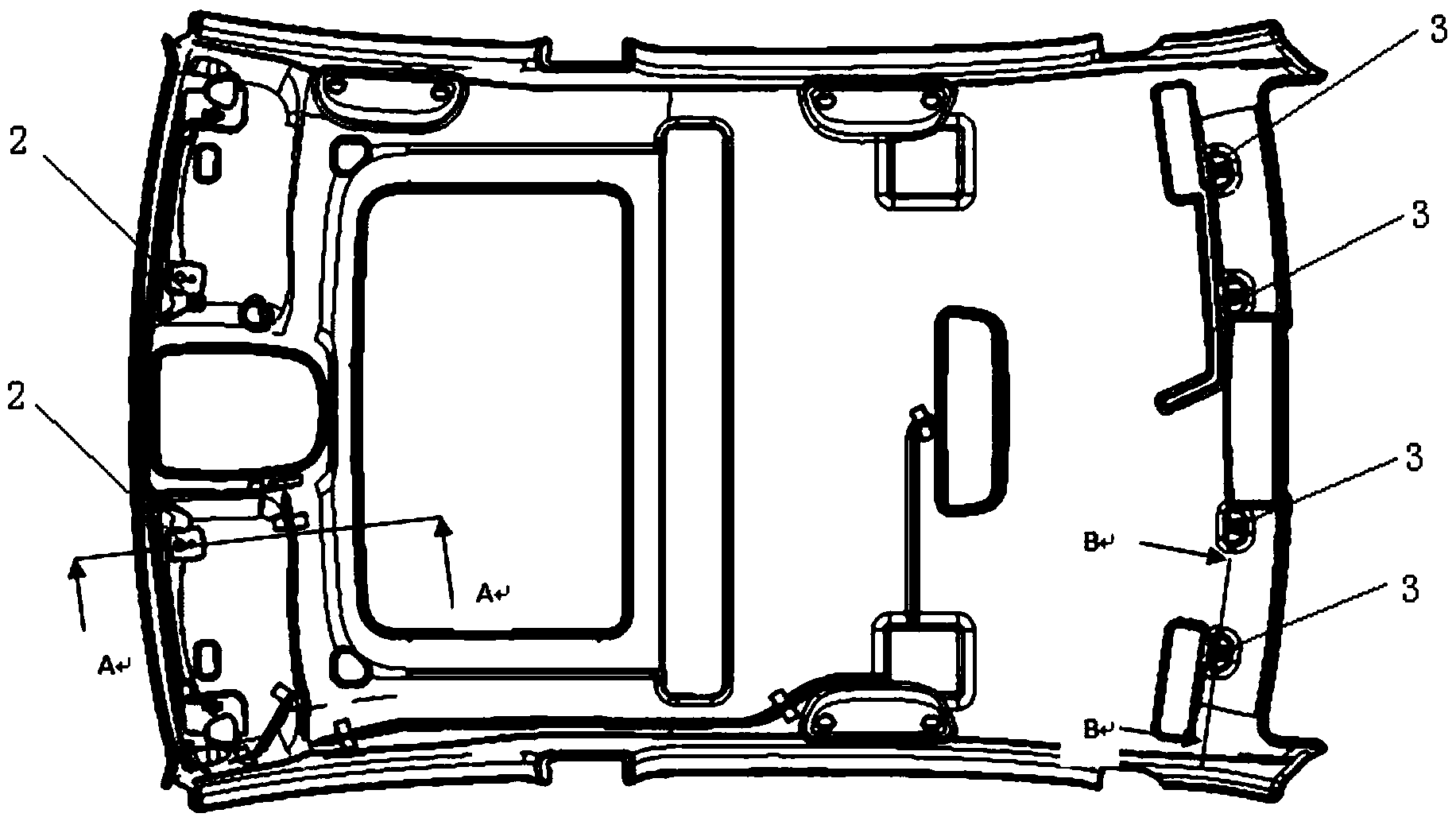

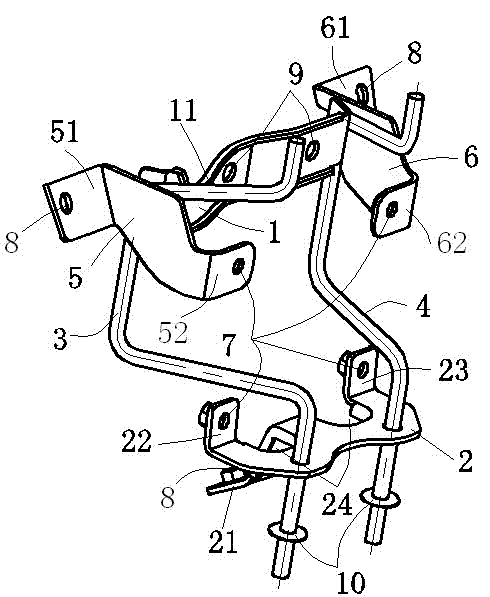

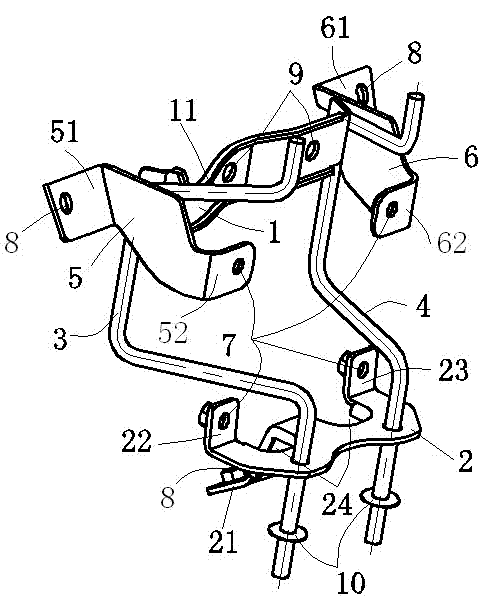

Automobile and roof mounting structure thereof

ActiveCN104175974AGuaranteed reliabilityGuaranteed installation strengthSuperstructure subunitsArchitectural engineeringMetal sheet

The invention discloses an automobile and a roof mounting structure thereof. The roof mounting structure comprises positioning parts and fixing parts. The positioning parts are sun shield auxiliary supports fastened in first mounting holes arranged in a front beam metal sheet and a roof. The fixing parts are arranged between the roof and rear beam metal sheet; each fixing part comprises a base and a steel fastener mounted on the base, the steel fastener is fastened in a second mounting hole arranged in the rear beam metal sheet. Therefore, the roof mounting structure allows the roof to be firmly mounted and accurately positioned; the fixing parts disposed between the roof and the rear beam metal sheet are avoided being exposed; the steel fasteners are hidden in the roof, so that scratch between the steel fasteners and other parts or passengers is avoided, and mounting quality of the roof is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

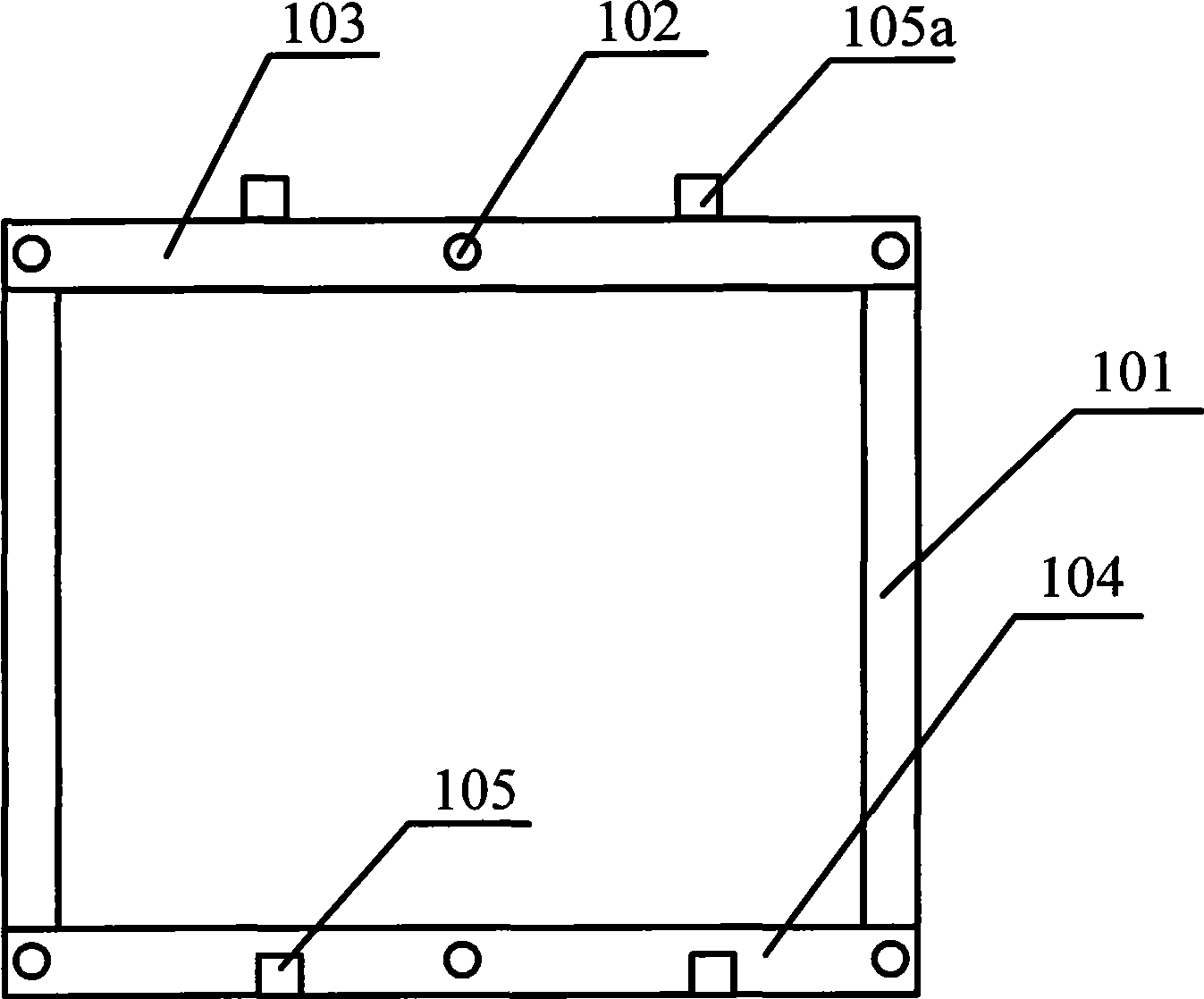

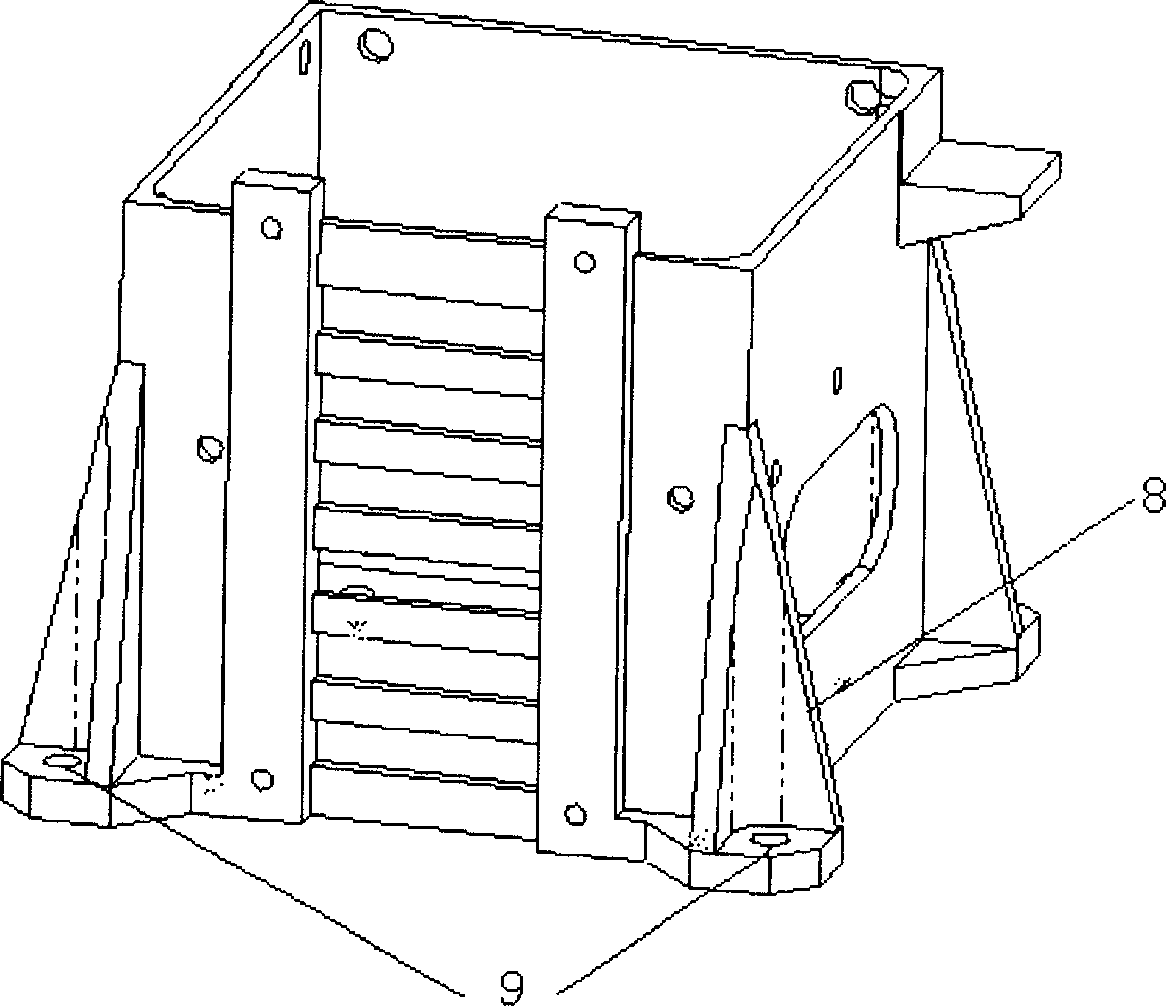

Mounting device for LED display screen and LED display screen

The invention discloses a mounting device for an LED display screen as well as an LED display screen. The mounting device comprises a plastic frame and at least one rigid supporting structure, wherein at least one side of the plastic frame is provided with at least one first connecting unit for being fixedly connected with first connecting units of other plastic frames; the rigid supporting structure is at least fixed with two lateral edges of the plastic frame, and provided with a second connecting unit for being connected with second connecting units of other rigid supporting structures. The mounting device ensures that the LED display screen is flexibly mounted, the assembly accuracy of the LED display screen is high, the flatness of a display surface of the LED display screen is high, and the LED display screen is more convenient to move or transport.

Owner:幸琳

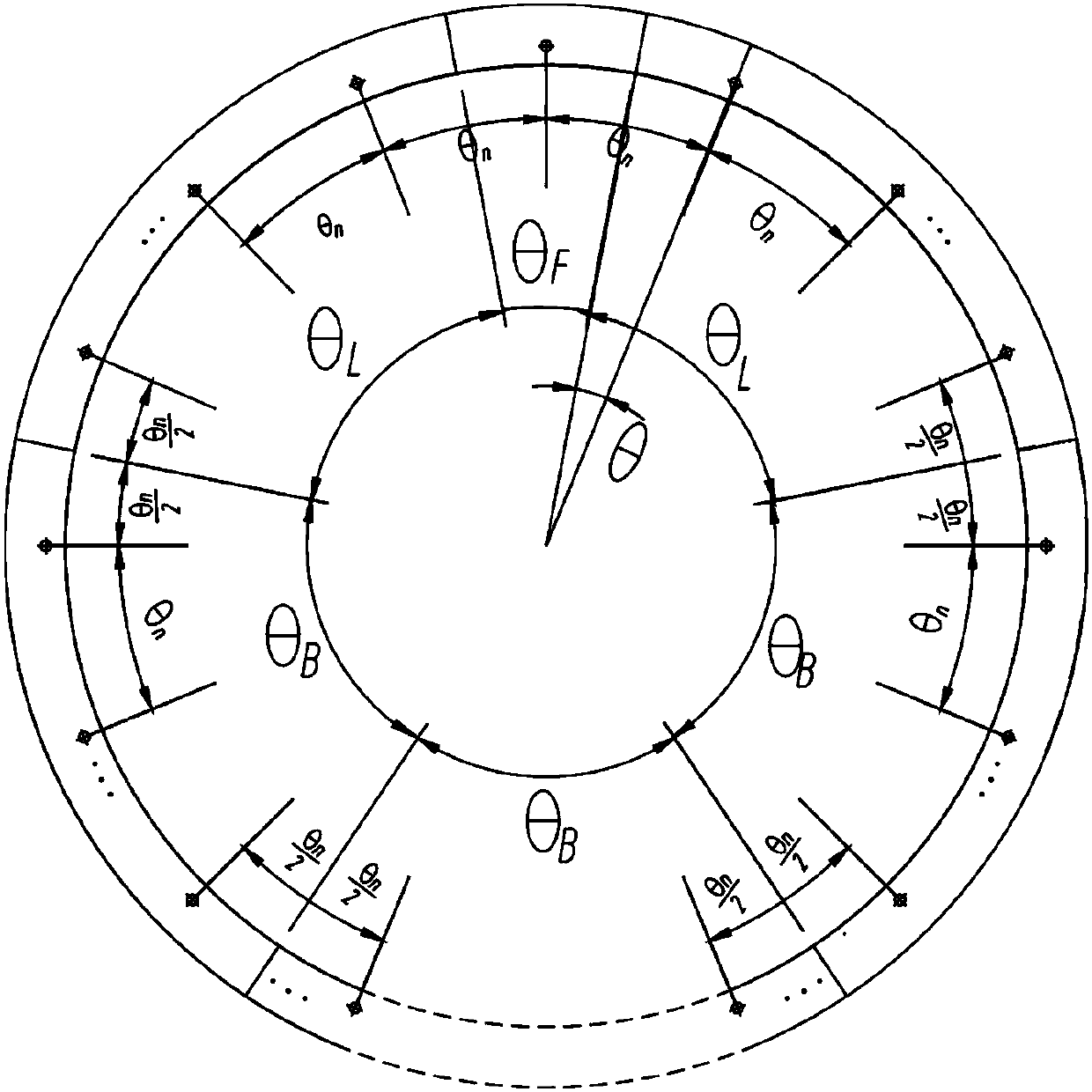

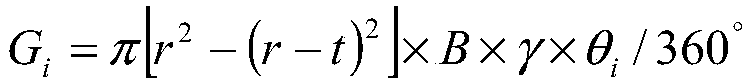

Shield tunnel lining ring and blocking method

ActiveCN107762530AImprove structural strengthOptimize material usageUnderground chambersTunnel liningEngineeringShield tunneling

The invention discloses a shield tunnel lining ring and a blocking method. The shield tunnel lining ring is composed by splicing seven standard segments connected in sequence, two adjoining segments connected with the two outer sides of the standard segments correspondingly and a capping segment between the two adjoining segments. The lining ring is provided with longitudinal bolts in the longitudinal direction. The blocking method of the shield tunnel lining ring includes the steps that according to the maximum segment lifting weight of a shield tunneling machine, the number of the standard segments in the lining ring is determined, the number of the longitudinal bolts is chosen according to the number of the standard segments, the distribution scheme of the longitudinal bolts in each segment of the lining ring and the circle center angle value and weight corresponding to each segment are calculated, and the lifting ability of the shield tunneling machine is verified. The shield tunnel lining ring is suitable for a shield tunnel with the diameter of 12 m, and the blocking method of the shield tunnel lining ring can be suitable for blocking of the tunnel segments of any diameter soas to optimize segment design.

Owner:SOUTHWEST JIAOTONG UNIV

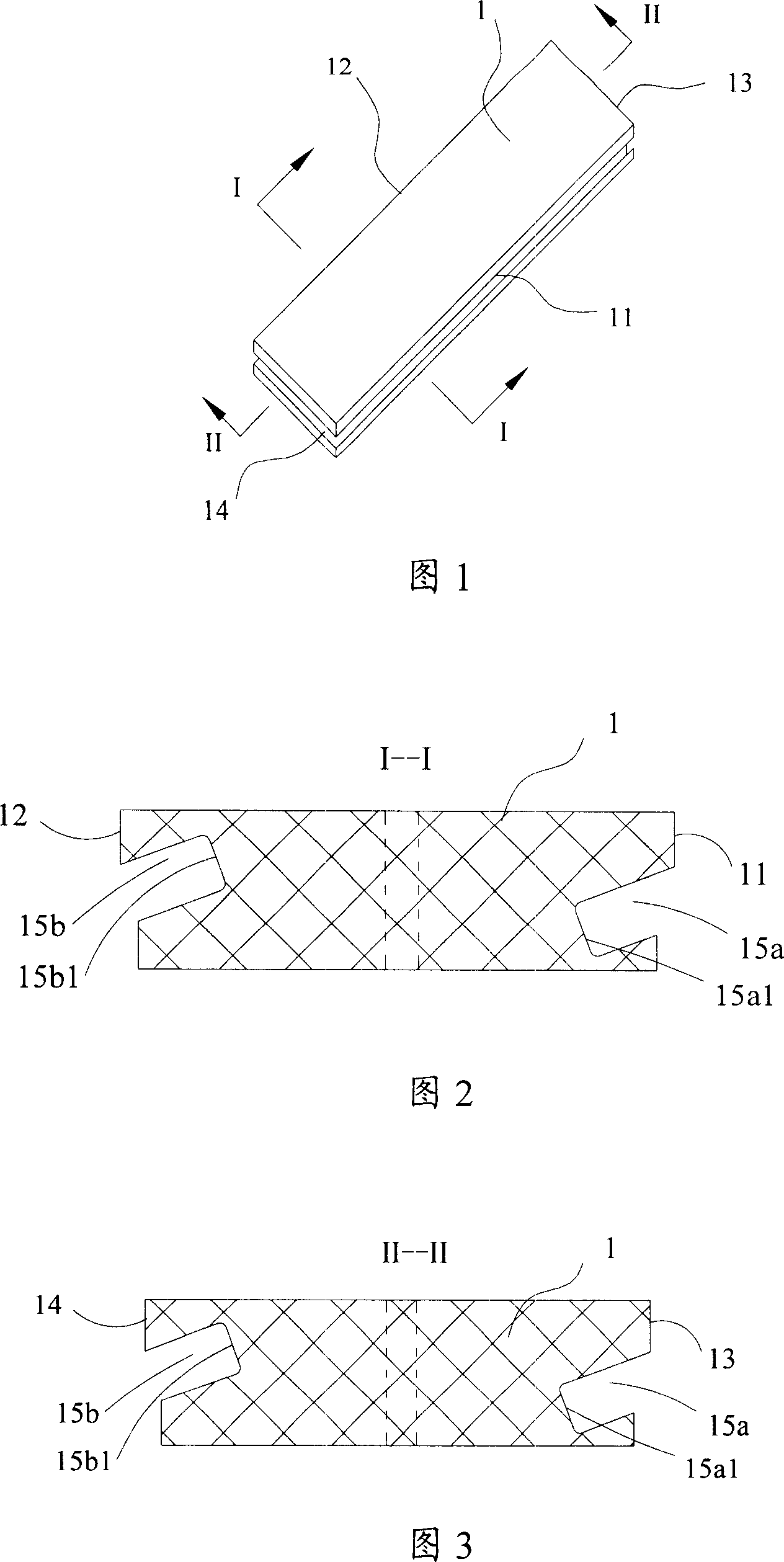

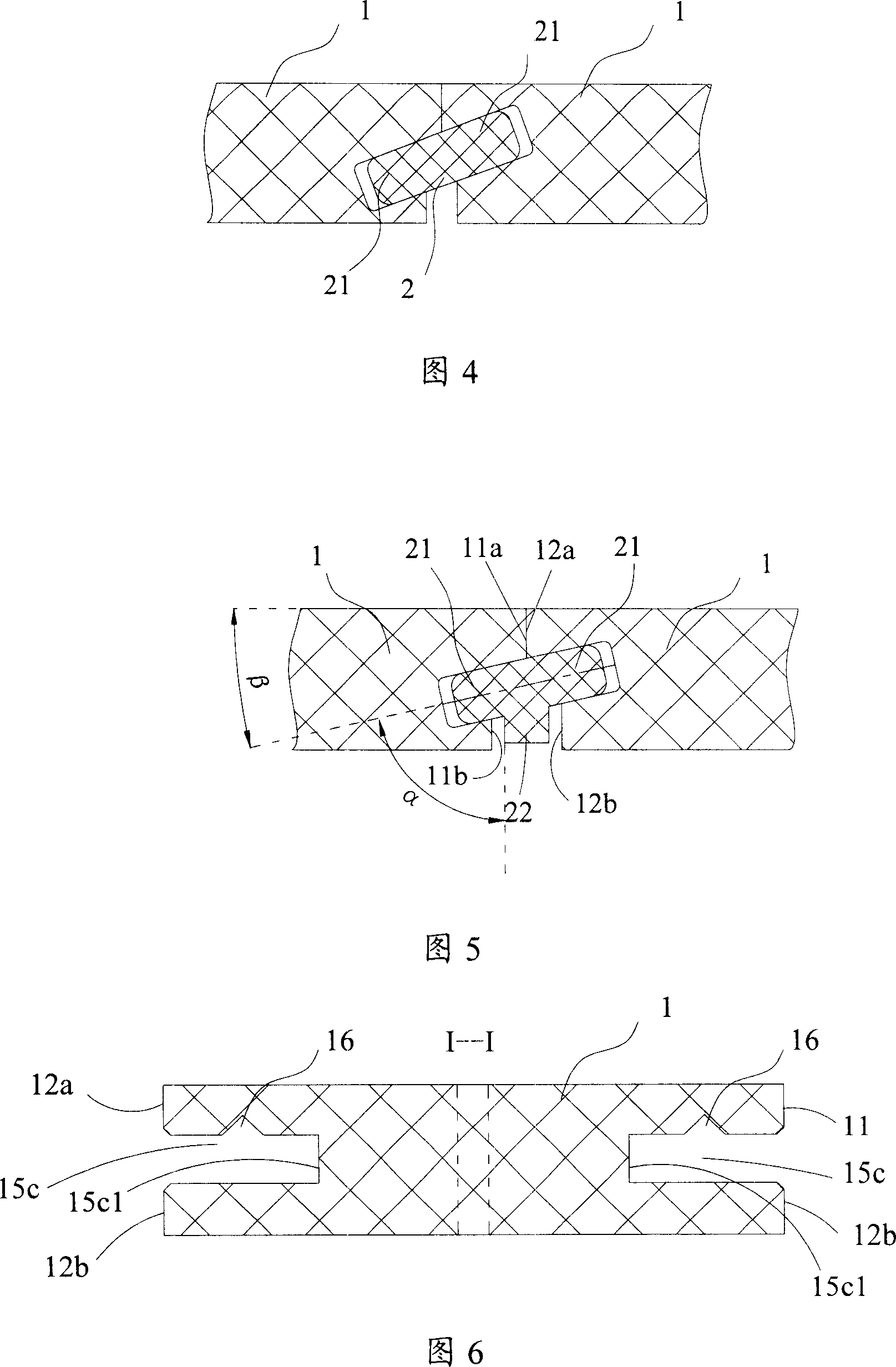

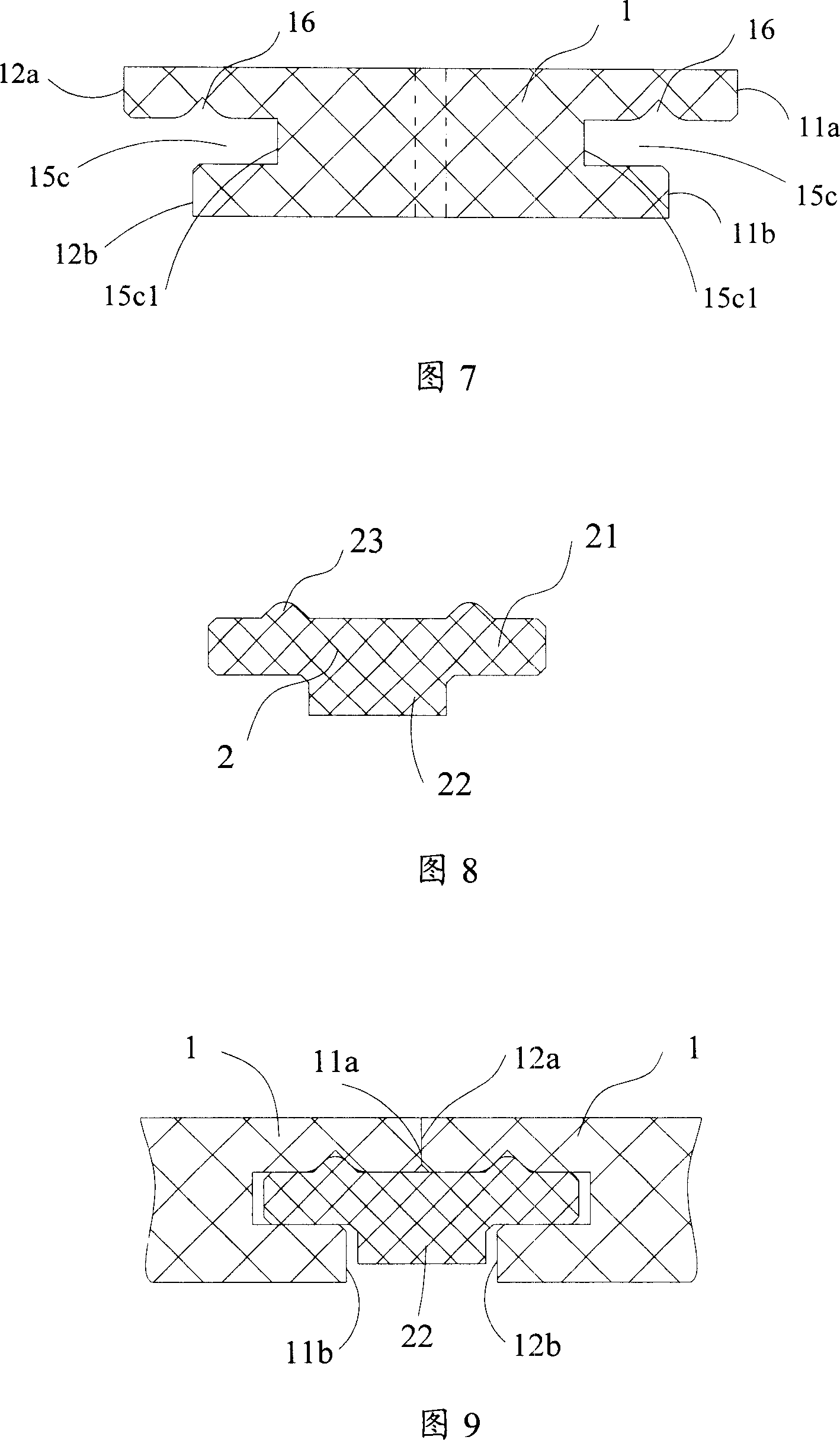

Floor board block and floor board connector thereof

InactiveCN100999953ASimple structureGuaranteed installation strengthFlooringEngineeringUltimate tensile strength

Owner:刘向飞

Light assembling structure for optical fiber gyro-space application

InactiveCN1888821AReduce volumeIncrease heat conduction areaSagnac effect gyrometersAttitude controlHeat resistance

Optical fiber peg-top space applied light combination structure has a perpendicular configuration reality and its side faces are vertical with the underside. The outside of two side faces and the inside of underside are the fixing plane to three peg-tops. The rest side faces use to fix the electrical source box and cube mirror. The three peg-tops are perpendicular setting, and the peg-top of x axis and y axis is fixed on the outside of the reality side faces, the peg-top of z axis is fixed on the inside of the reality underside. Their fixing surfaces contact completely to increase the heat exchange area of the peg-top to reduce the heat resistance effectively. The three joining pieces connecting with peg-tops fix on one joining piece plane and put the three joining piece planes into one to connect with the jack of the reality connecting with system. The three peg-tops can debug alone and this is fit for fixing and maintenance the optical fiber peg-top. It is suitable for the gesture controlling of the space aerocraft with small volume, light weight, little heat resistance, high reliability security, well diathermancy.

Owner:BEIHANG UNIV

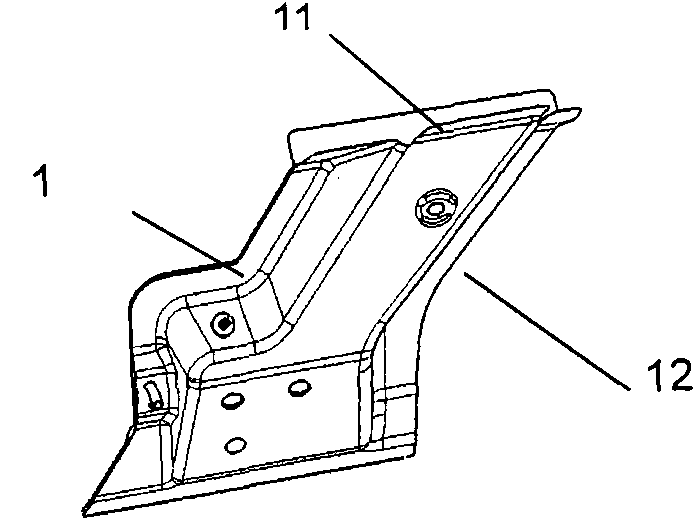

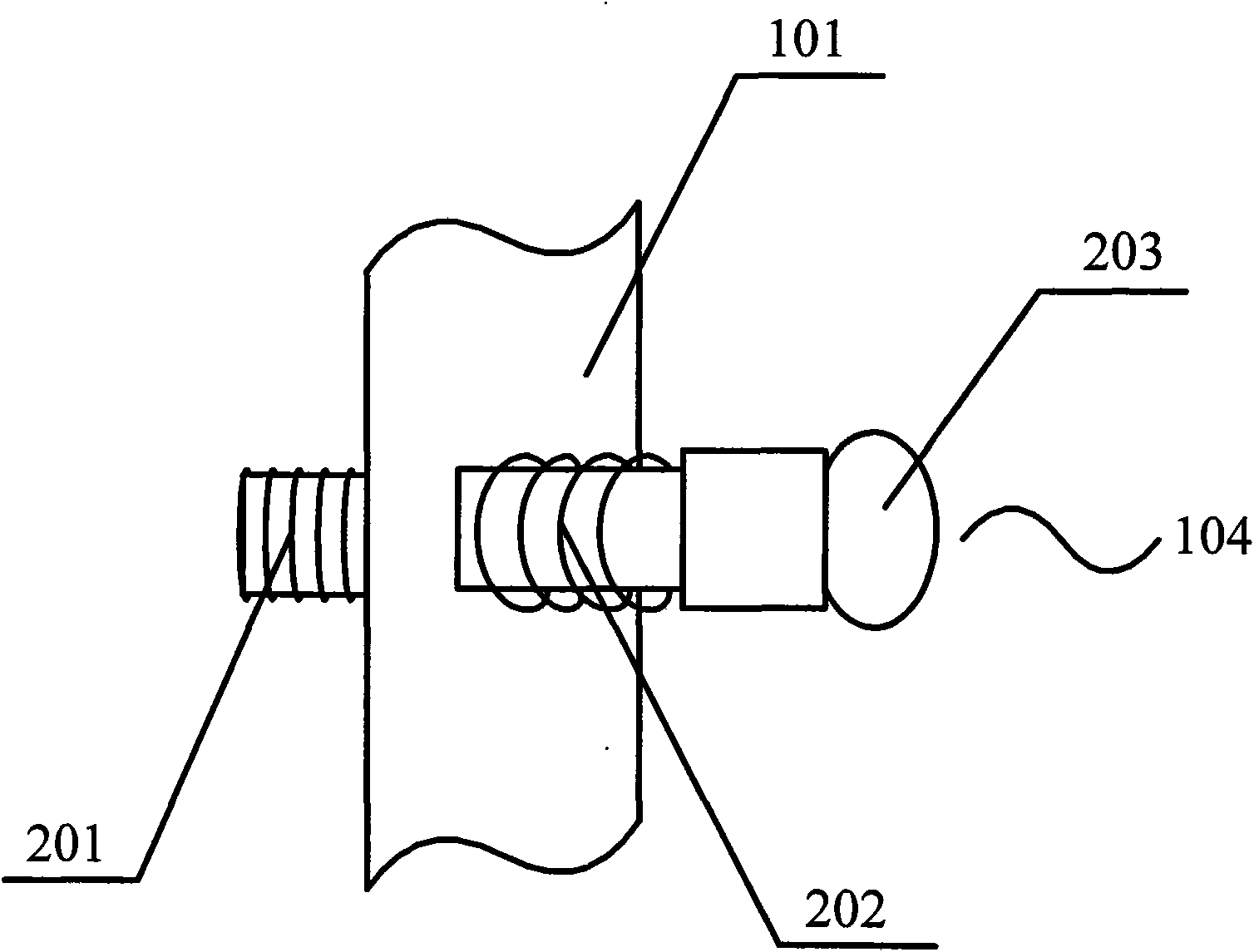

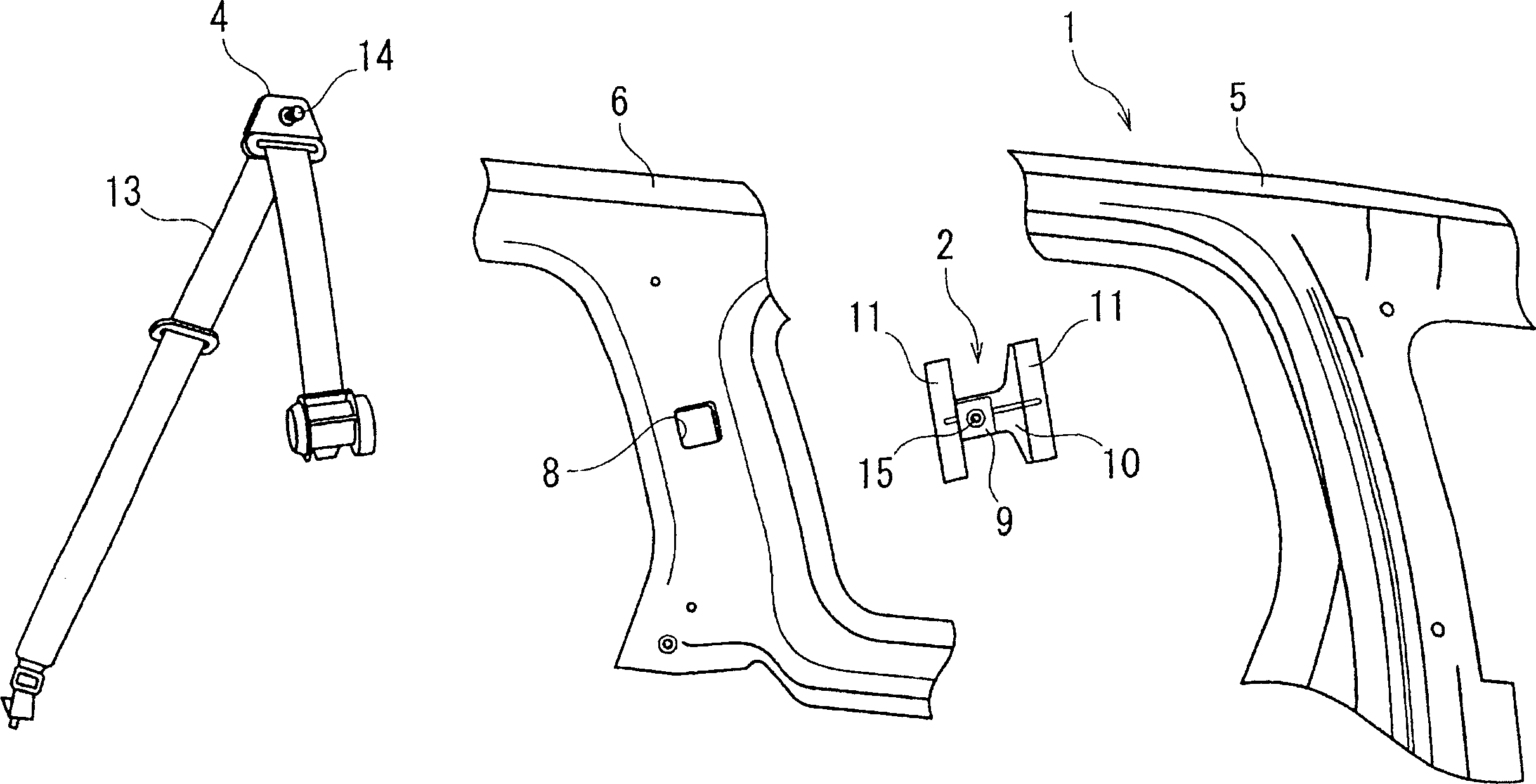

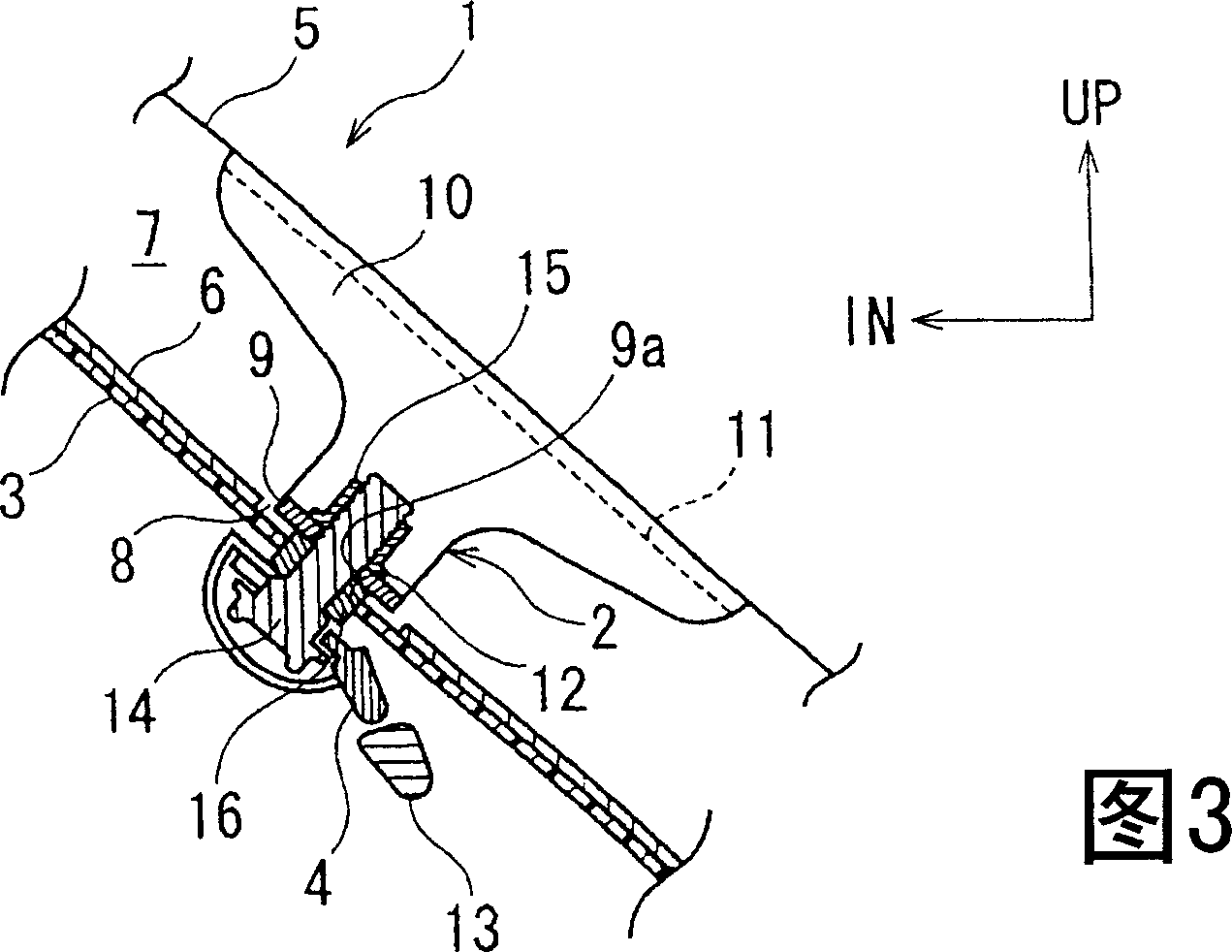

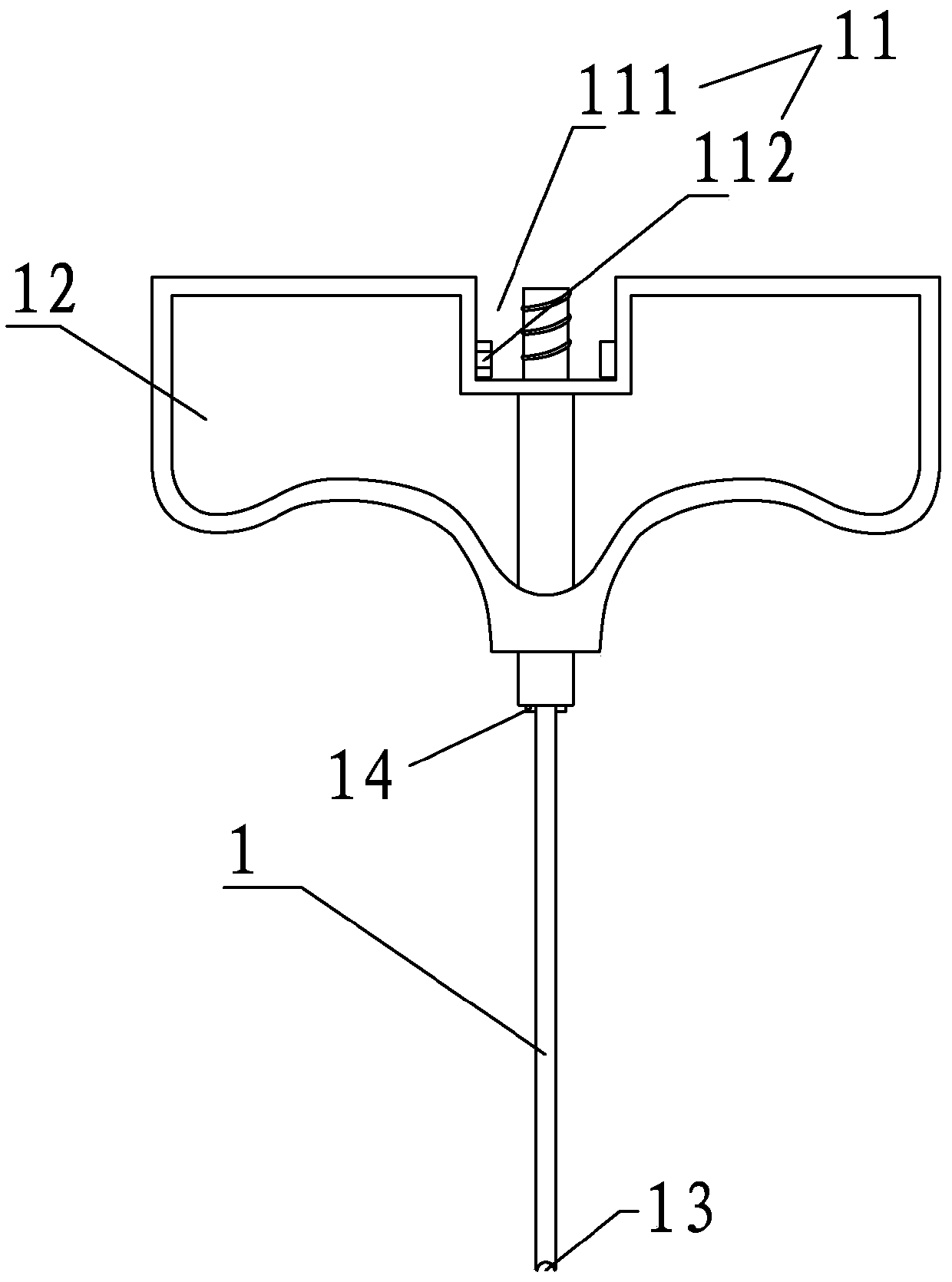

Mount structure of safety belt fixing element

ActiveCN1765664AGuaranteed installation strengthCushion the shockBelt anchoring devicesEngineeringBelt safety

The present invention provides an installation structure of a seat belt fastener, which not only ensures the installation strength of the seat belt fastener, but also alleviates the impact caused by the deformation of the inner liner. Wherein, the pillar (1) has an outer liner (5) and an inner liner (6), and the outer liner (5) and the inner liner (6) form a closed space (7). An opening (8) is formed in the inner liner (6). The reinforcing member (2) has an engaging portion (11) and a fixing member supporting portion (9). The joining portion (11) is joined to the vehicle inner side of the outer liner (5) in the closed space (7). The vehicle inner surface of the fastener support portion (9) protrudes from the opening portion (8) of the inner liner (6). The decorative cover (3) has a mounting hole (12), and is provided on the vehicle inner side of the inner liner (6). The seat belt anchor (4) is arranged on the vehicle inner side of the trim cover (3), and is installed on the anchor supporting part (9) of the reinforcement (2) through the fixing bolt (14) inserted through the installation hole (12).

Owner:ISUZU MOTORS LTD

Combined motorcycle headlamp bracket

InactiveCN102514655ATowards clarityGuaranteed installation strengthOptical signalHeadlampArchitectural engineering

The invention discloses a combined motorcycle headlamp bracket. The combined motorcycle headlamp bracket comprises an upper bending plate, a lower bending plate, a left main connecting rod, a right connecting rod, a left bending plate and a right bending plate; wherein the upper bending plate and the lower bending plate are separated in vertical direction, and the upper bending plate is located in front of the lower bending plate; the left bending plate and the right bending plate are arranged on the left and the right sides of the upper bending plate in mirror symmetry; the middle of the left bending plate is welded with the upper bending plate via the left main connecting rod; the middle of the right bending plate is welded with the upper bending plate via the middle of the right main connecting rod; the lower end of the left main connecting rod and the lower end of the right main connecting rod are backwards bent and then upwards bent so as to vertically penetrate the rear part of the lower bending plate; and the upper end of the left main connecting rod and the upper end of the right main connecting rod are backwards bent and then upwards bent. Four front steering lamp bracketmounting holes, three air deflector mounting holes and two instrument bracket mounting holes are arranged at the combined bracket so that a front steering lamp bracket, an air deflector and an instrument bracket can be mounted together.

Owner:力帆科技(集团)股份有限公司

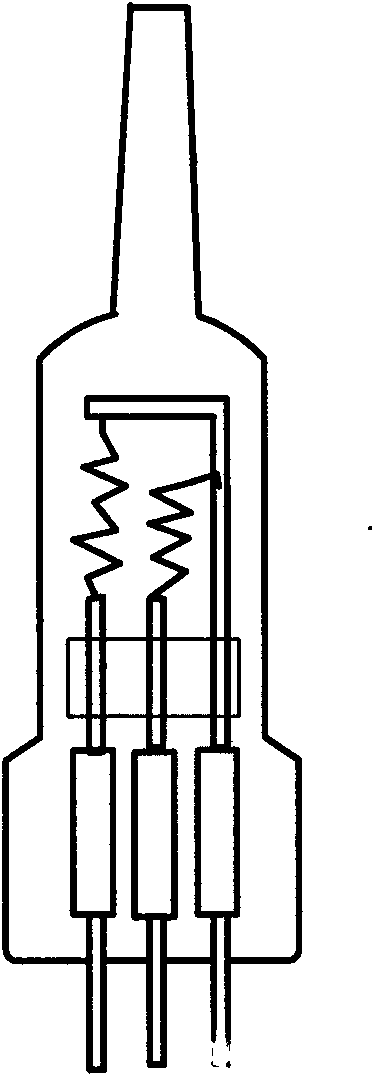

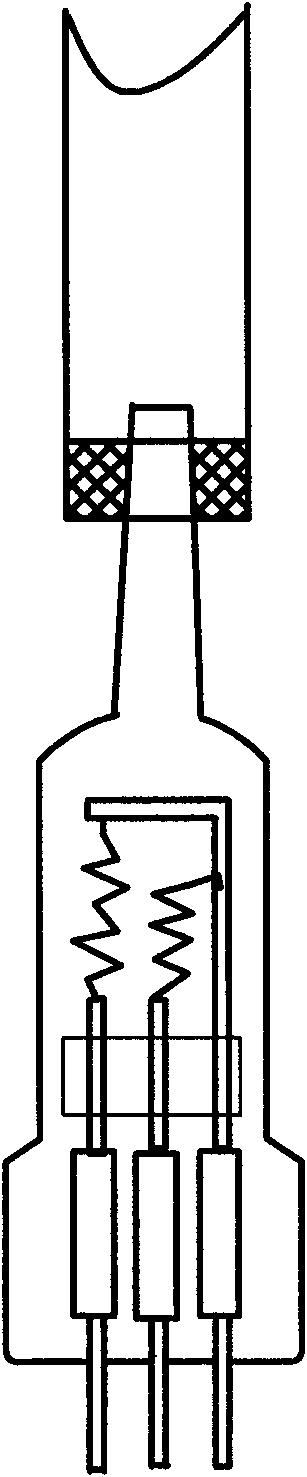

Process for producing enclosed halogen tungsten automobile headlight

InactiveCN101599416AEasy to make electrical contactsGuaranteed installation strengthElectrical apparatusHalogenHydrogen

The invention discloses a process for producing an enclosed halogen tungsten automobile headlight, which comprises the following steps: (1) carrying out racking; (2) carrying out buttwelding, namely melting and butting two ends of a copper pin and a molybdenum pin through power supplying to form a copper-molybdenum pin; (3) carrying out spot welding of molybdenum plates, namely respectively performing spot welding between the one end of each of three molybdenum plates and each of three molybdenum rods on a light stand, and between the other ends of the three molybdenum plates and three copper-molybdenum pins; (4) after completing the manufacture of a wick and a glass bulb, carrying out press seal, and reserving an air exhaust rod at the upper end of the glass bulb; (5) performing hydrogen brightening and air exhausting, namely completing the hydrogen brightening and air exhausting on a round exhaust machine together; (6) bending the copper-molybdenum pins after stable power-on burn-in detection; and (7) after completing manufacturing a lamp base, carrying out focusing assembly, carrying out surface covering, displacing gas in an inner cavity of the halogen tungsten automobile headlight, carrying out leak detection process, and carrying out finished production inspection after the leak detection process. The process can reduce rejection rate, has simple and convenient operation and high work efficiency.

Owner:舒建江

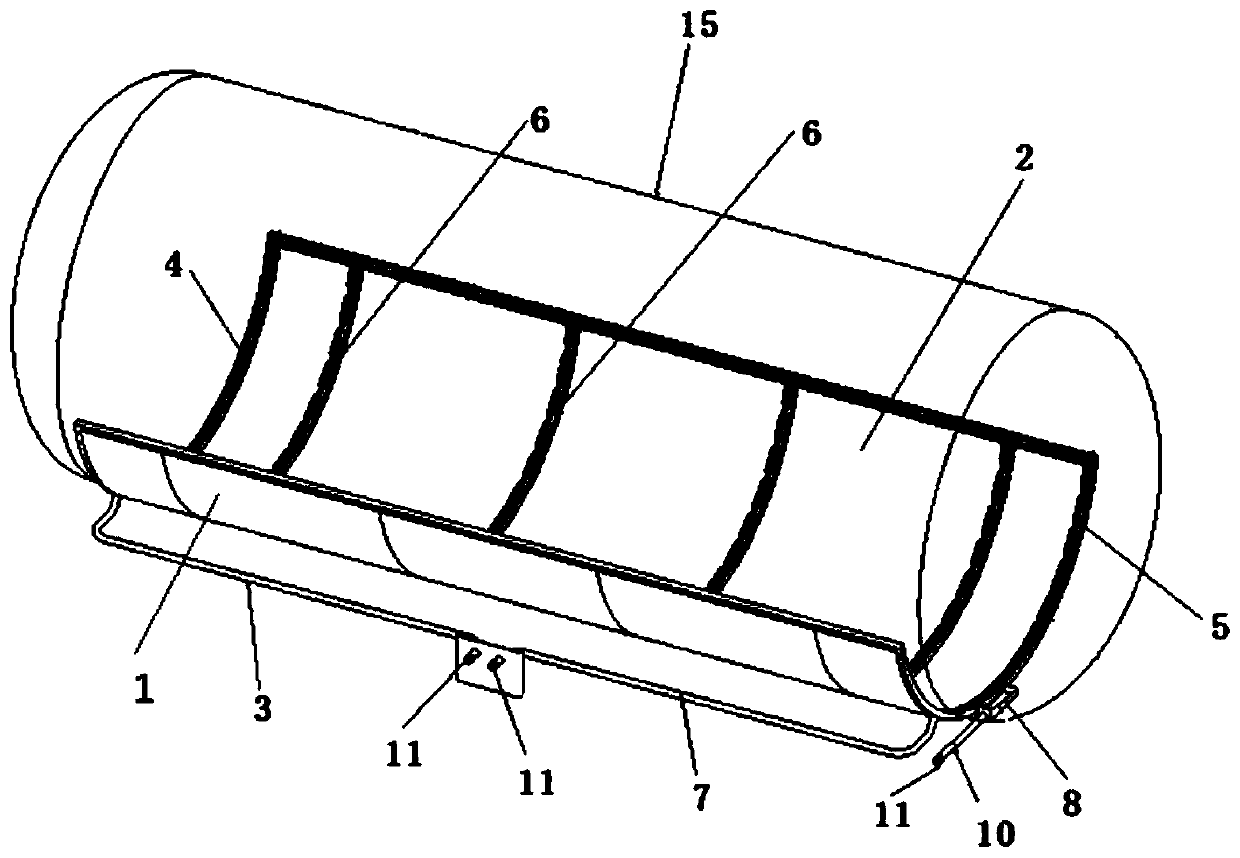

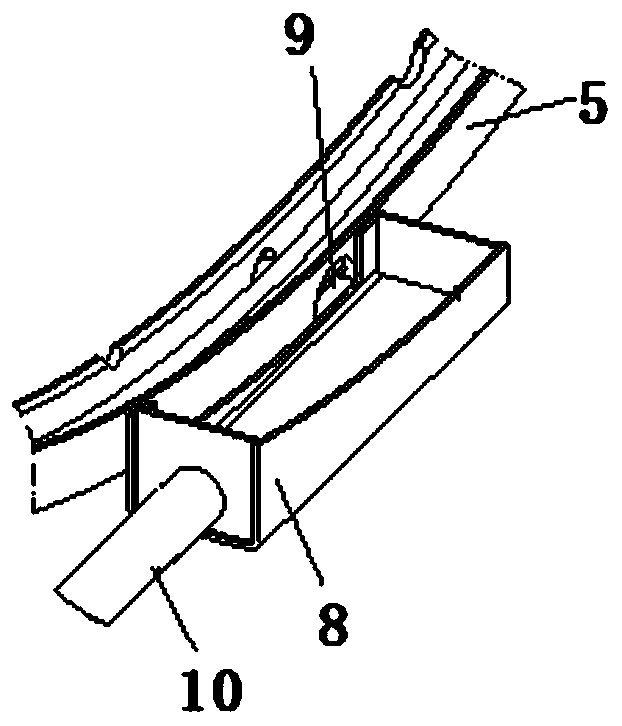

Tank container steam heating device

PendingCN110844373AHeating evenlyRealize closed loopLarge containersTank wagonsEngineeringHeat balance

The invention belongs to a container steam heating device. In order to solve the technical problem that an extra-tank heating system of a tank container in the prior art is low in heating efficiency and insufficient in heating balance degree, and condensed water generated by a heating pipeline in a low-temperature environment is poor in circulation, a tank container steam heating device is provided. The tank container steam heating device comprises an arc-shaped shell and an arc-shaped heating cover plate, the shell is arranged outside the heating cover plate in a sleeving mode, a cavity is formed between the shell and the heating cover plate, a steam inlet channel, a steam outlet channel and a plurality of cavity partition plates are arranged in the cavity in the circumferential direction, the plurality of cavity partition plates are located between the steam inlet channel and the steam outlet channel to divide the cavity into a plurality of heating areas which sequentially communicate with one another, steam passing holes and condensed water passing holes are formed in the inner side of the steam inlet channel, steam passing holes and condensed water passing holes are formed in the cavity partition plates, steam passing holes and condensed water passing holes are formed in the inner side of the steam outlet channel, and condensed water discharge ports are formed in the outerside of the steam outlet channel.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

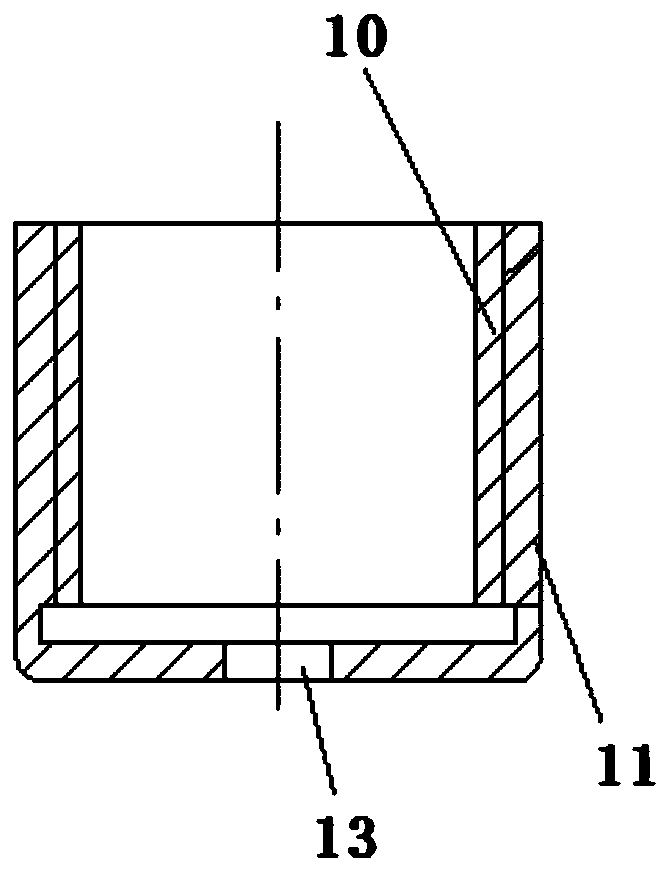

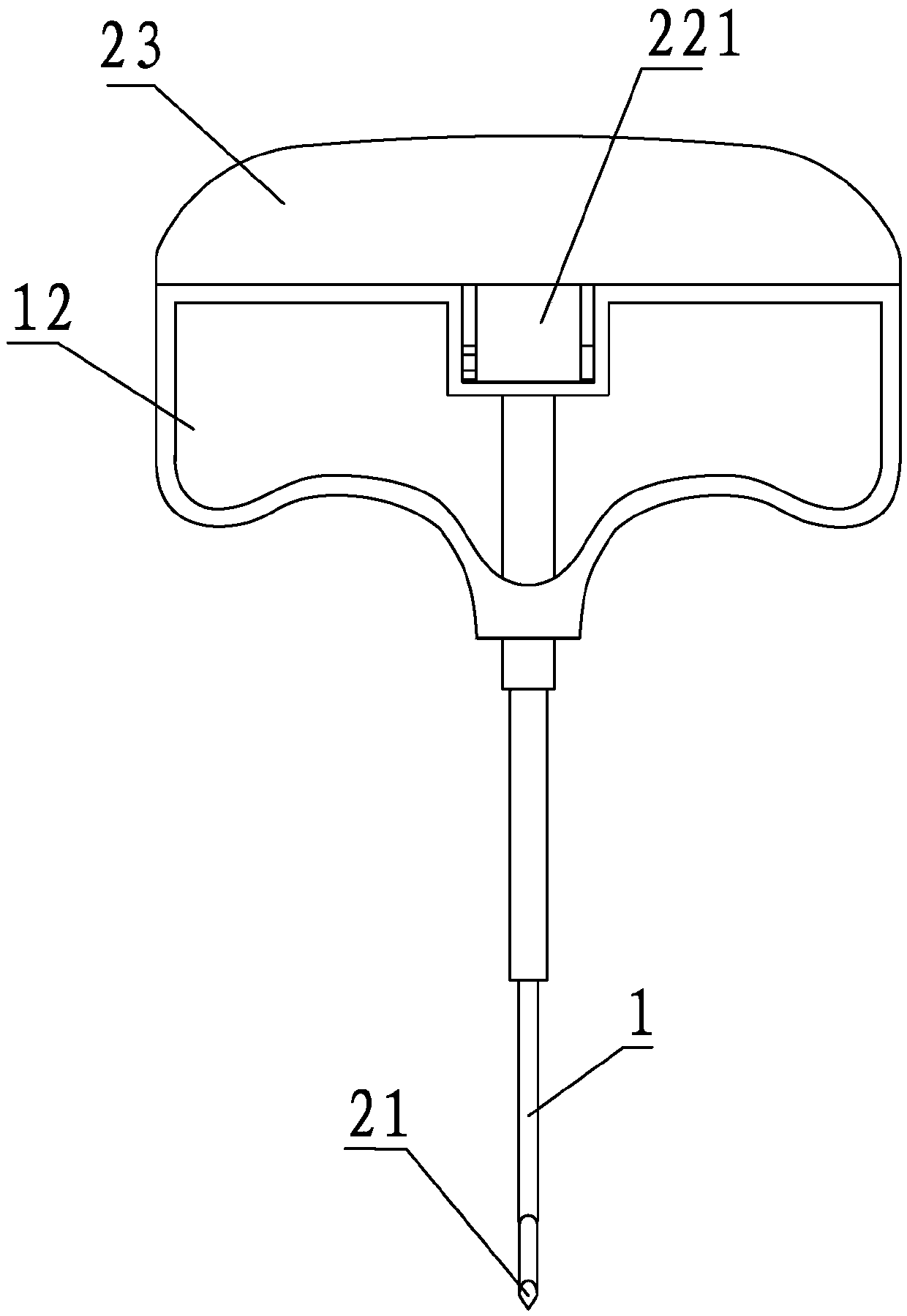

Bone marrow puncture needle

ActiveCN105496469AShorten the timeAvoid deviations in piercing directionSurgical needlesVaccination/ovulation diagnosticsBiomedical engineeringBone marrow

The invention provides a bone marrow puncture needle, which comprises a needle sleeve, a needle core and a limiting sleeve, wherein a puncture part is arranged at the head end of the needle core; matched first connection part and second connection part are arranged on the needle core and the needle sleeve respectively; the needle core and the needle sleeve are connected with each other through the first connection part and the second connection part along the length direction of the needle core; the needle sleeve sleeves the outside of the needle core and the puncture part is exposed; the limiting sleeve comprises a through hole which corresponds to the needle core in size along the longitudinal direction; a groove which is communicated with the through hole is formed in the outer surface of the limiting part along the longitudinal direction; the limiting sleeve sleeves the outside of the needle core through the groove and the through hole; two ends of the limiting sleeve are propped against the needle sleeve and the needle core respectively; and the puncture part moves back and forth along the length direction of the needle core and is accommodated into the needle sleeve. According to the bone marrow puncture needle, the limiting sleeve can be installed without taking out the needle core after puncture is ended, so that the puncture sampling time is shortened; and deviation in the puncture direction due to the fact that the needle core is taken out and is inserted again after the limiting sleeve is installed is also avoided.

Owner:孙龙

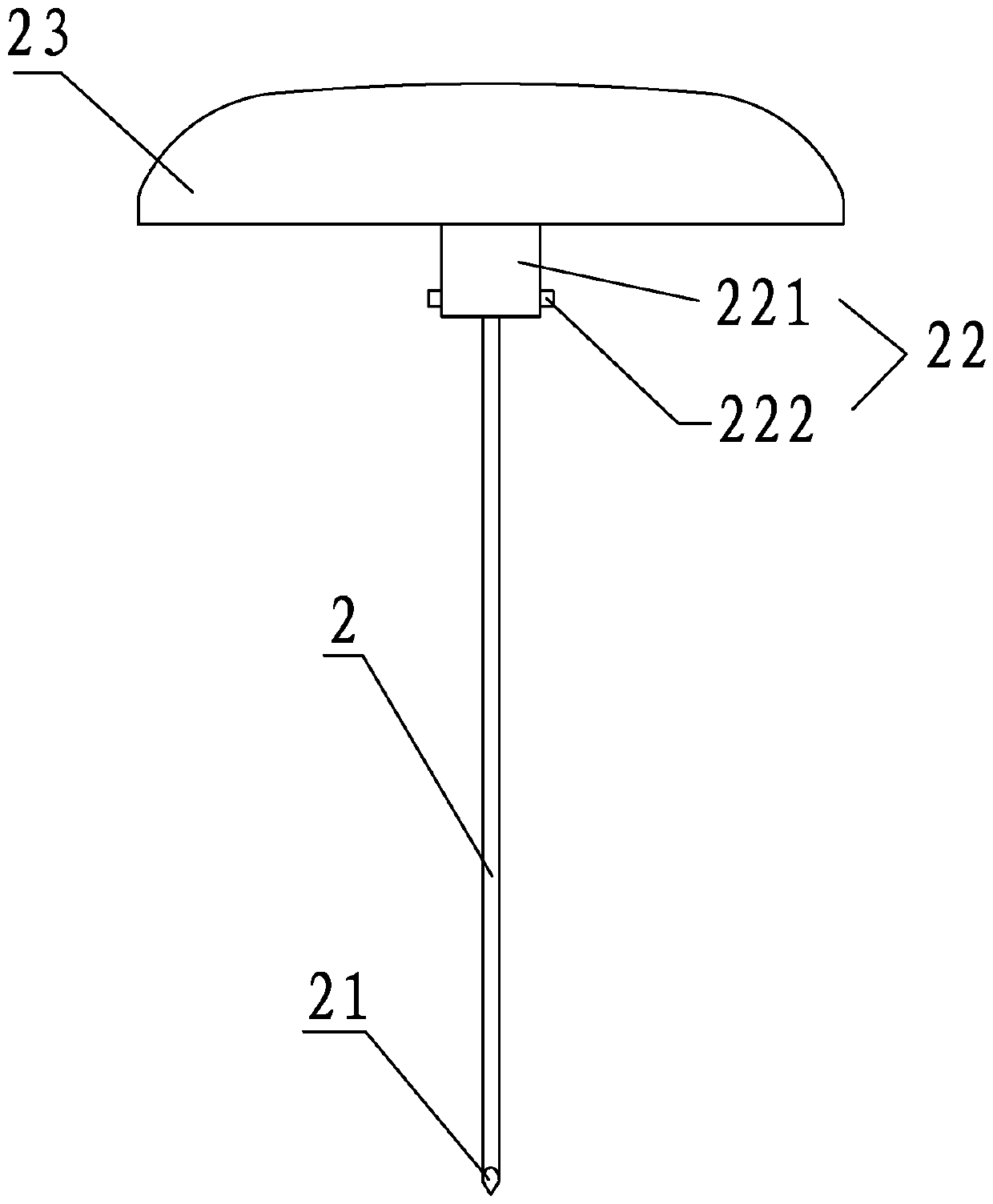

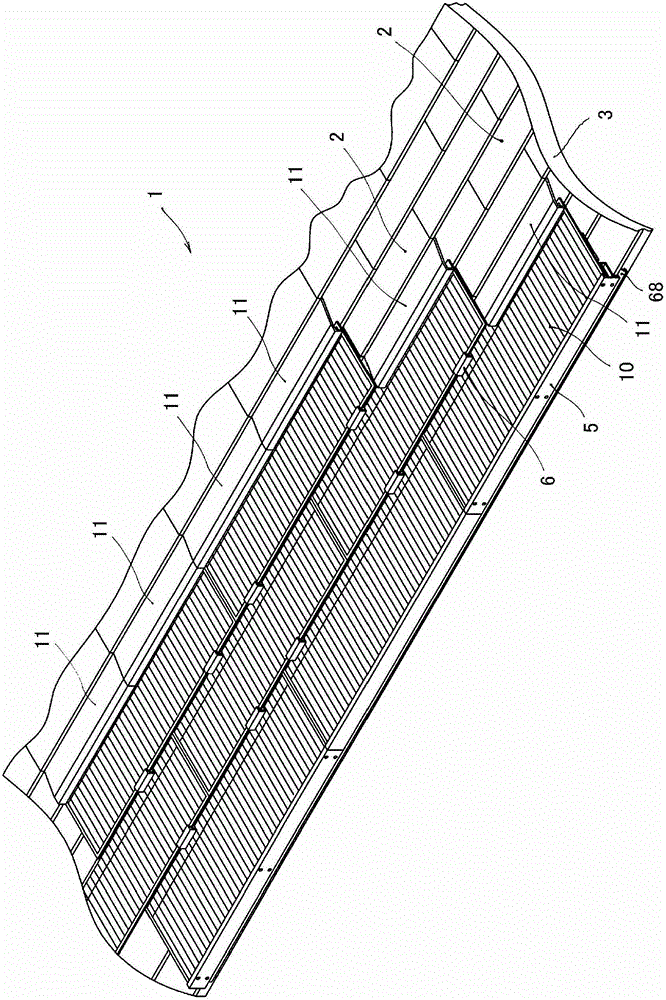

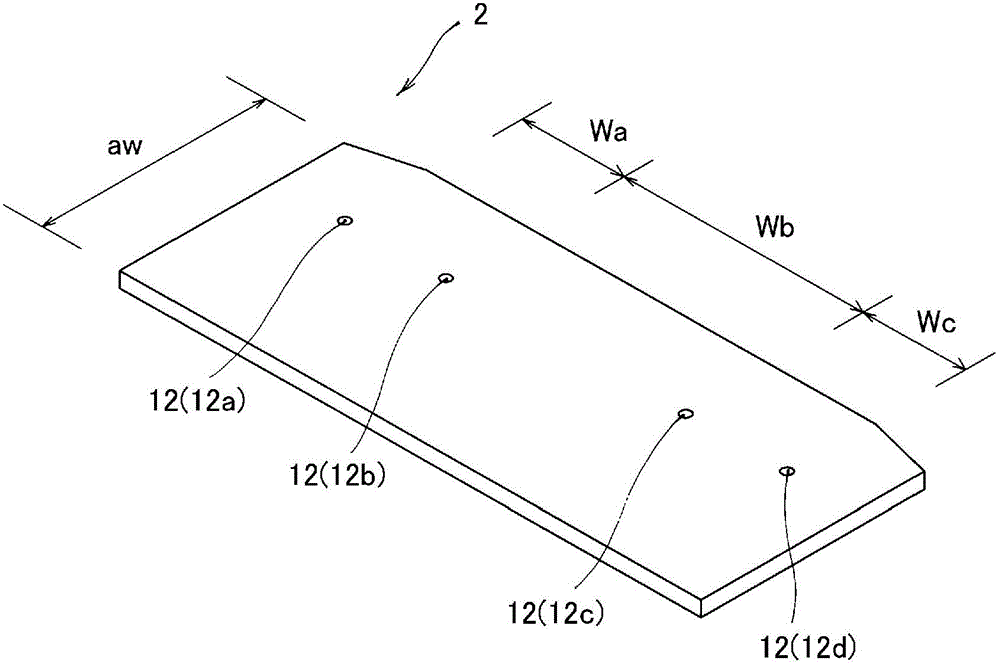

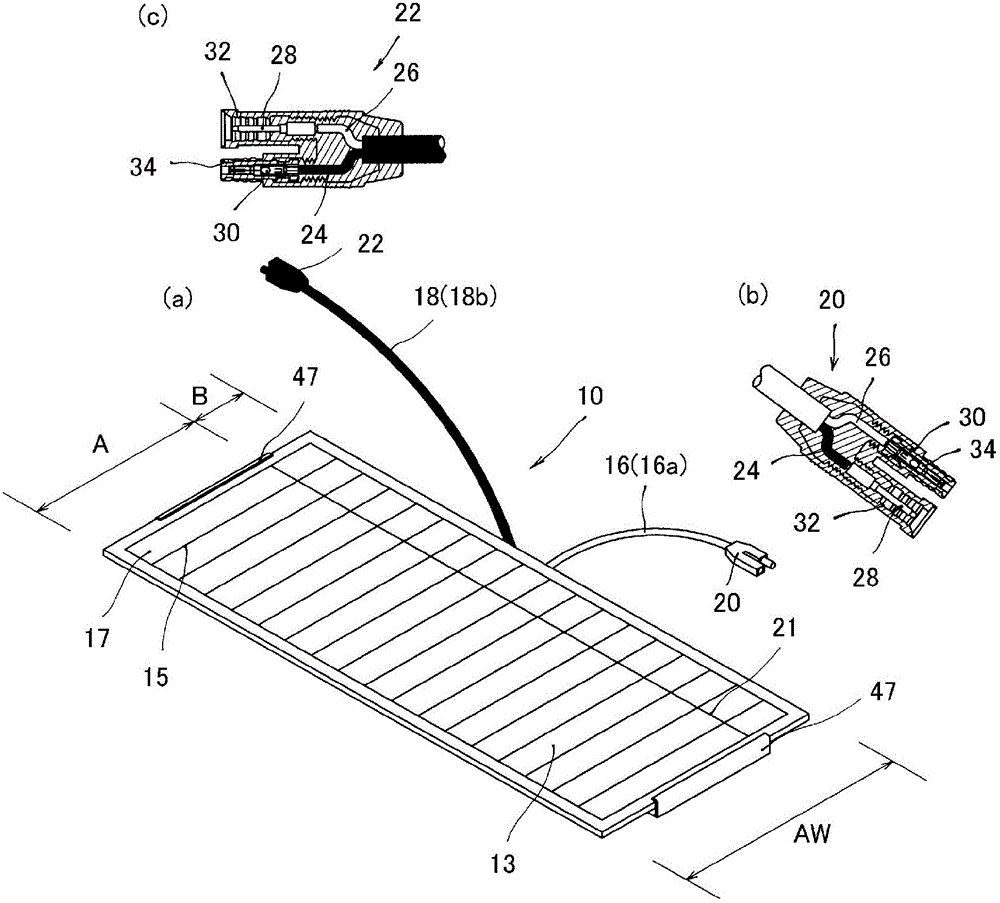

Roof structure, fixture for solar cell module, and method for installing solar cell module

ActiveCN102753769ADoes not generate settingsEffective installationPhotovoltaic supportsRoof covering using slabs/sheetsRoof tileEngineering

Provided is development of a roof structure which has high lining performance and no concern of a roof leak, and which is capable of maintaining a certain level of installation strength even if one slate roof tile is damaged. A solar cell module (10) is installed on a basic roof structure (3) shingled with slate roof tiles (roof member) (2) via an eaves mounting bracket (eaves fixture) (5) and a middle mounting bracket (fixture) (6). The middle mounting bracket (6) is attached to the end section of a ''specific roof member,'' and a lower plate member (72) is disposed between the ''specific roof member'' and a ''lower side roof member.'' Screws or the like are inserted into a hole (100) of the lower plate member (72) and affixed, and the ''specific roof member'' is mounted on the ''lower side roof member'' into which the screws are inserted, thus preventing rainwater from entering a mounting hole (12). An upper plate member (73) overlaps the ''specific roof member,'' and clamping elements (117) (118, 119) are inserted into the mounting hole (12). The ''upper side roof member'' is mounted on the ''specific roof member,'' thus also preventing rainwater from entering the mounting hole (12).

Owner:KANEKA CORP

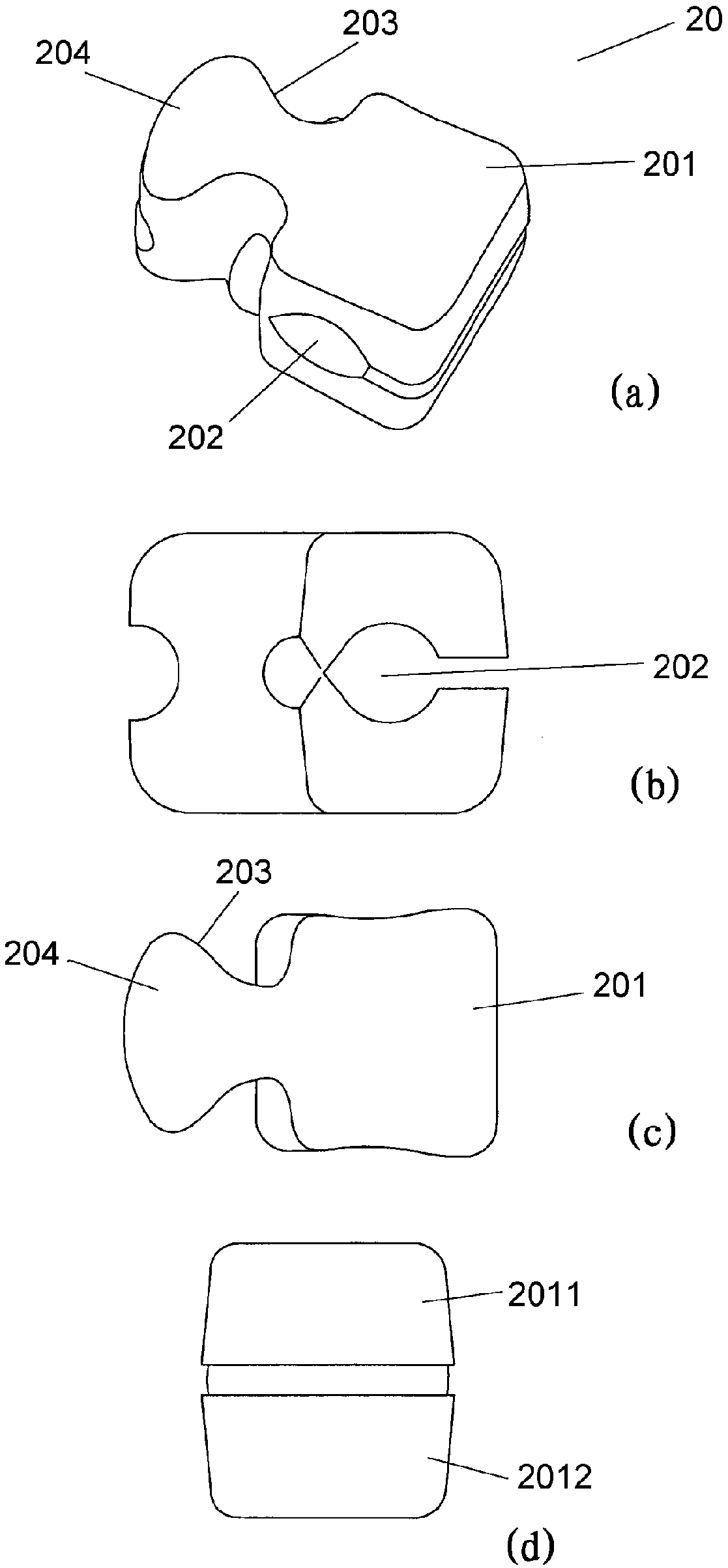

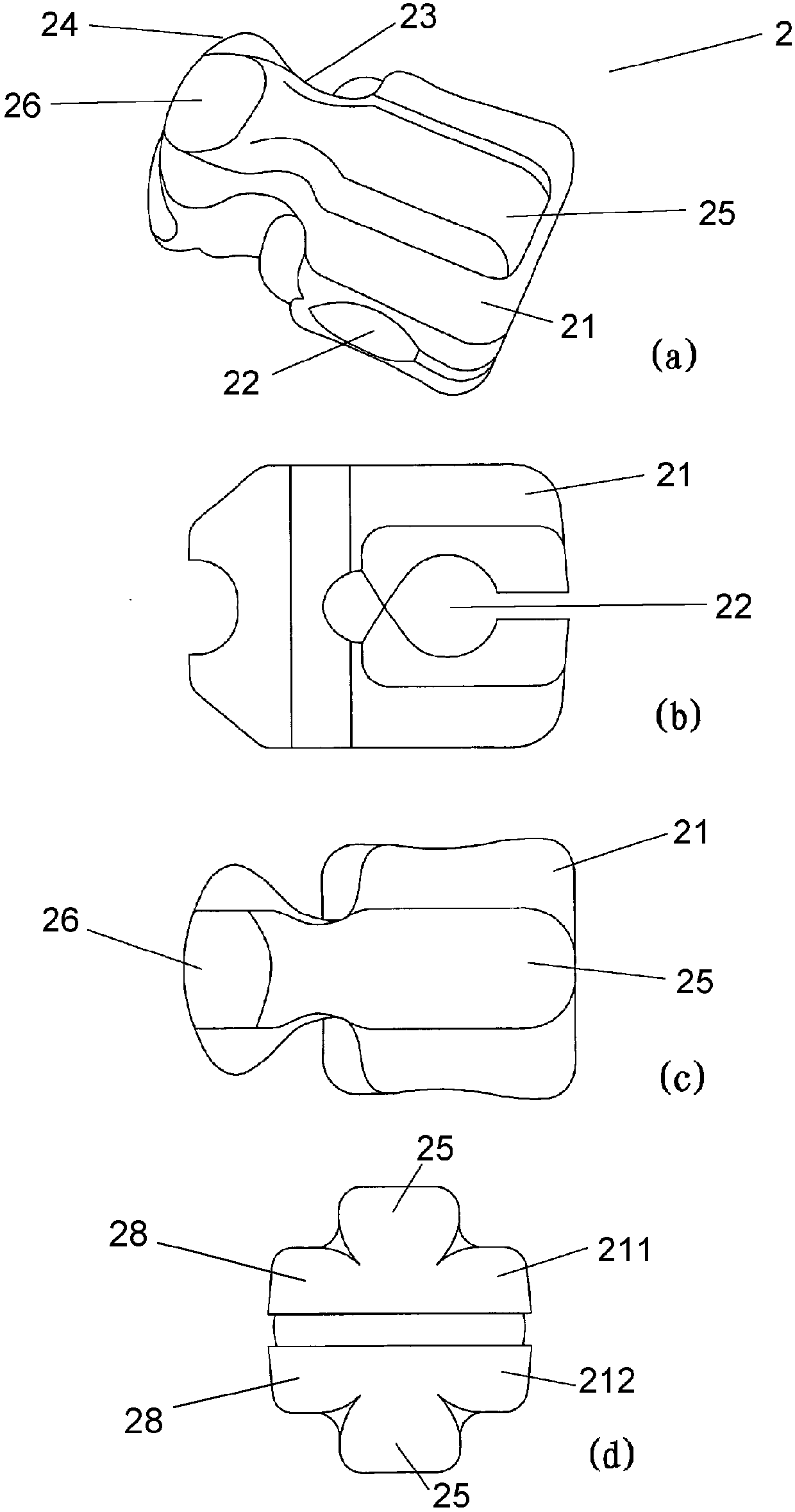

Chain tooth, chain strap and zipper

The invention provides a chain tooth, a chain strap and a zipper. The chain tooth and a strap are arranged together to form the chain strap, and the chain tooth comprises a body part, a mounting part,a neck part and a head part. The body part and the head part are connected through the neck part, the mounting part is used for mounting of the strap, the body part comprises an upper body part and alower body part, and at least one of the upper body part and the lower body part comprises a protruding part and a base part. The protruding part extends out of the base part, is located in the middle in the front-back direction and extends in the left-right direction. Furthermore, an inclined part inclined downwards in the left-right direction is formed on at least one side, in the vertical direction, of the head part, and convex parts extending in the front-back direction are formed on the two sides of the protruding part. According to the chain tooth, the chain strap and the zipper, weightreduction can be achieved, and strength and use reliability can be guaranteed.

Owner:YKK CORP

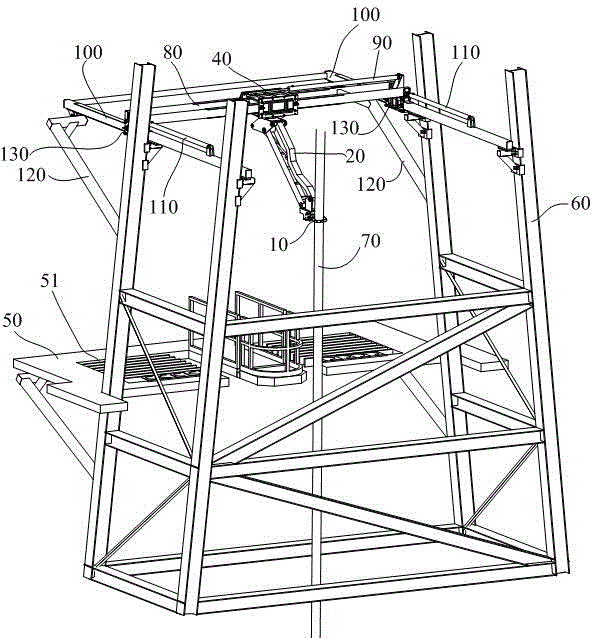

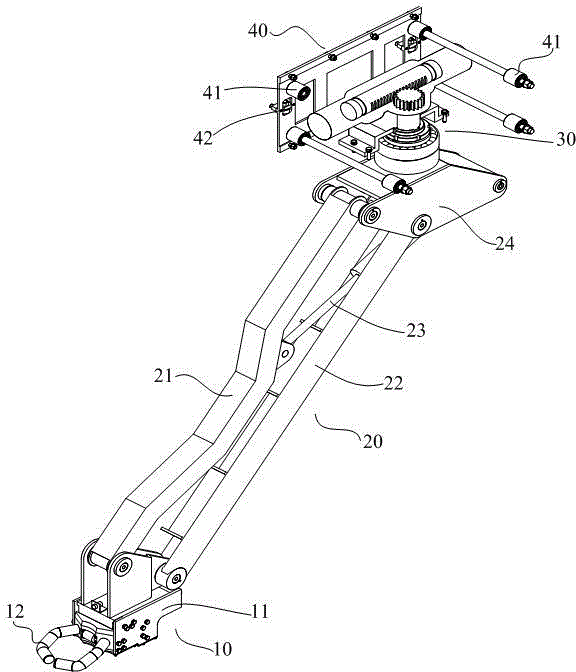

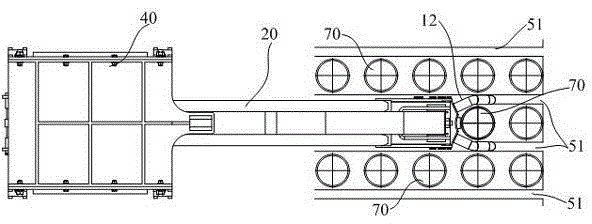

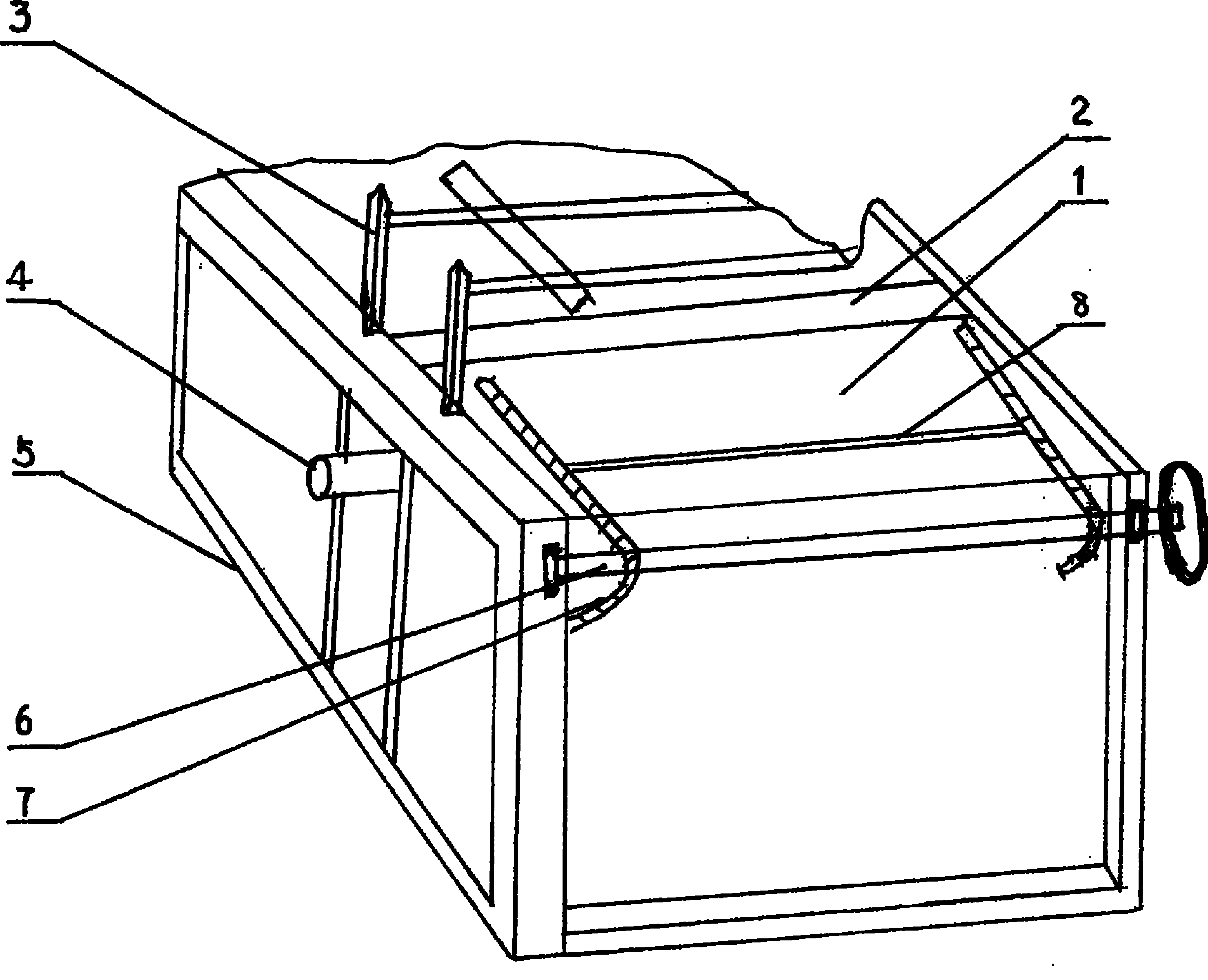

Oil rig racking platform string discharge manipulator

InactiveCN104895514AEasy to insertEasy to take outProgramme-controlled manipulatorDrilling rodsDischarge efficiencyManipulator

The invention provides an oil rig racking platform string discharge manipulator which comprises a manipulator body, a manipulator arm, a swing mechanism and a mounting seat, wherein the manipulator arm is hinged at the lower end of the manipulator arm, the upper end of the manipulator arm is connected with the swing mechanism, and the swing mechanism is arranged on the mounting seat. The manipulator body comprises a connecting seat, two manipulator fingers and a manipulator open-close driving mechanism, wherein each manipulator finger comprises multiple linear finger segments and arc joint segments which connect each of two adjacent linear finger segments, and the opening and closing of the manipulator body is realized by the manipulator open-close driving mechanism which drives the manipulator fingers to overturn. Each finger of the manipulator body is of a structure connected by the linear finger segments and the arc joint segments at intervals so as to be bent more smoothly. Therefore, when the manipulator open-close driving mechanism drives the manipulator body to overturn downwards and overturn till the manipulator body is in the opening state, the finger portion cannot expand outwards, the overall width cannot be enlarged, the fingers can be inserted and taken out of the arranged string conveniently, the discharge efficiency of the string is improved, and the discharge density cannot be reduced.

Owner:QINGDAO JIERUI IND CONTROL TECH CO LTD

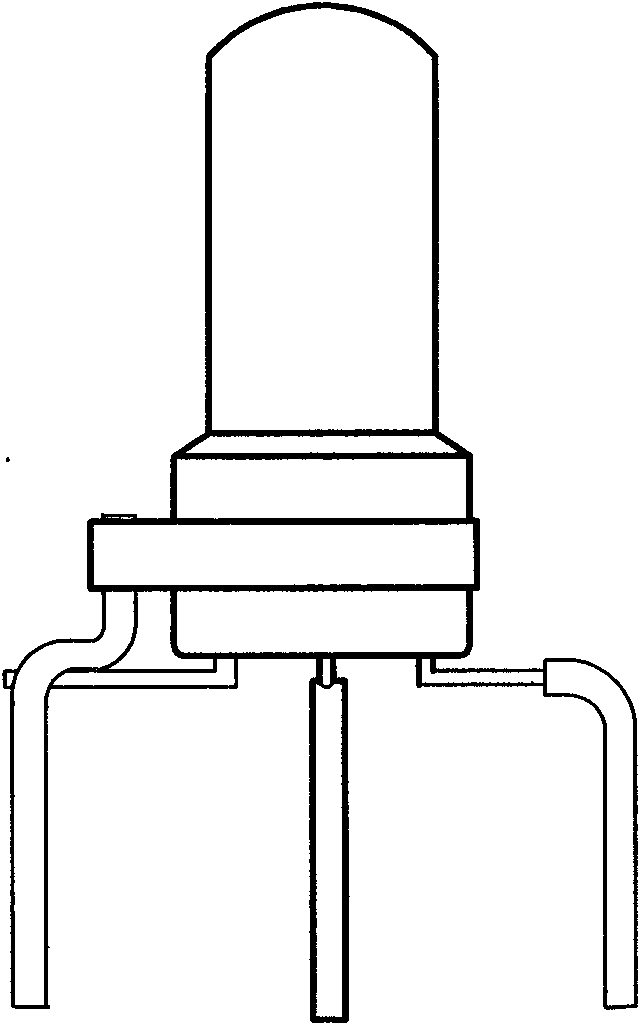

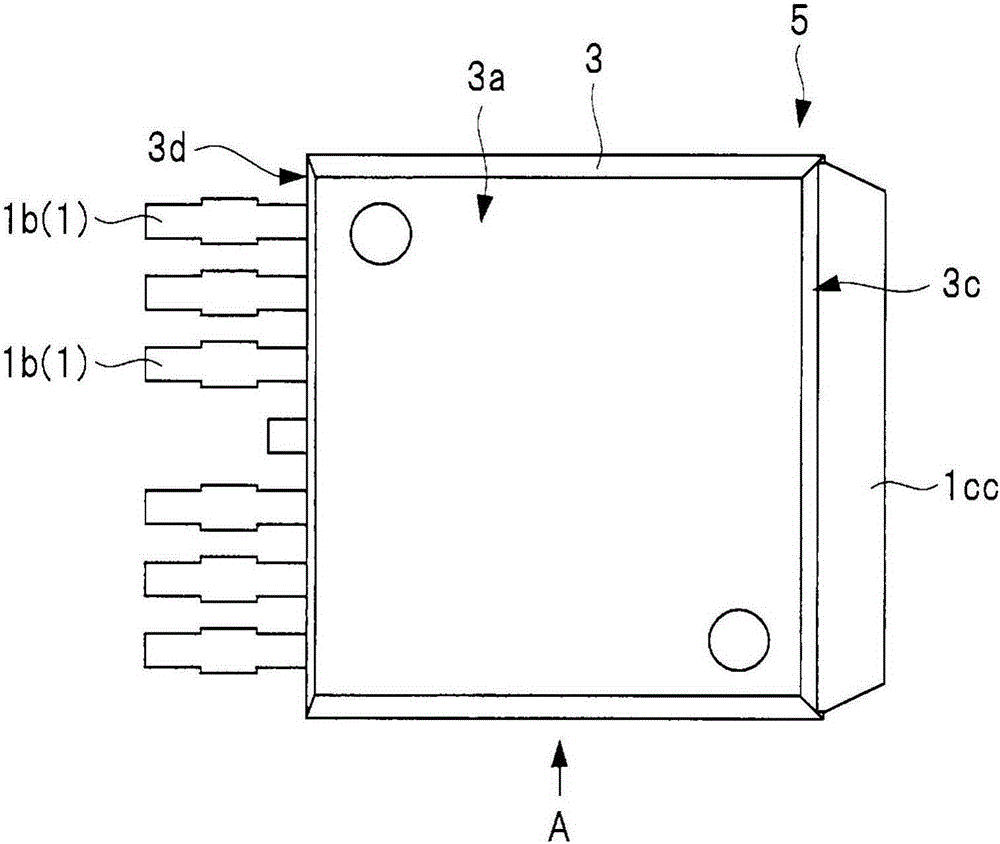

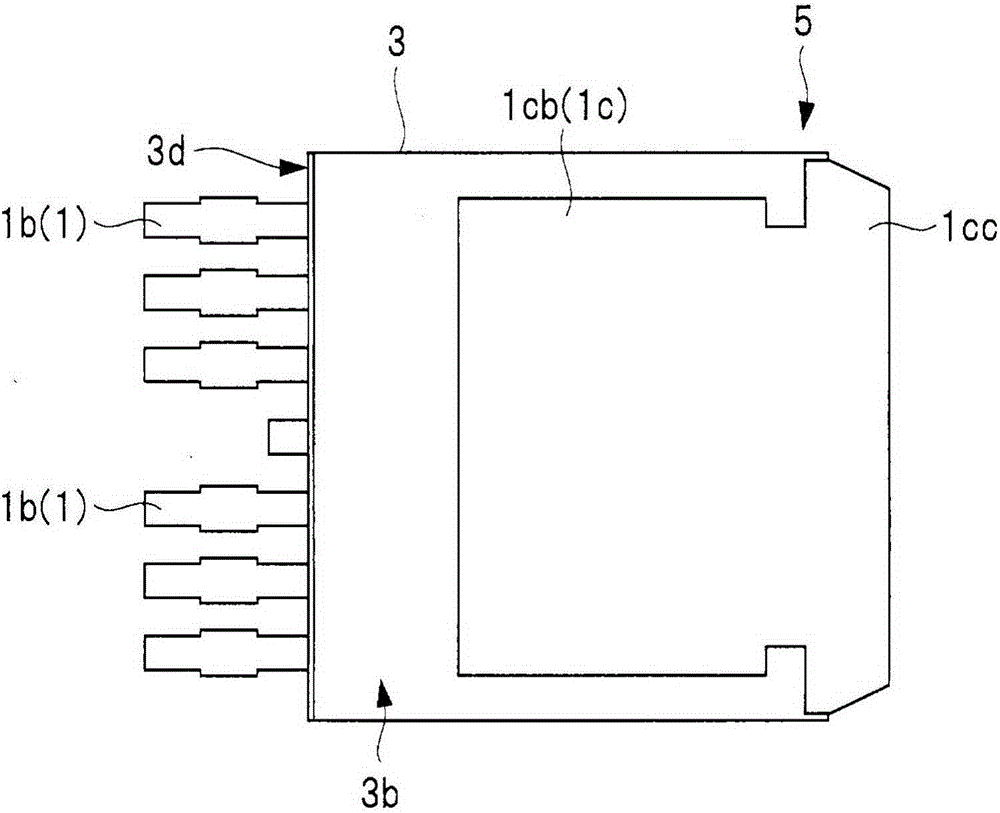

Semiconductor device

InactiveCN105470227AGuaranteed installation strengthReduced installation areaSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

A semiconductor device is disclosed in the invention to reduce a mounting area while securing a mounting strength of a semiconductor device, a power transistor includes a chip mounting portion, a semiconductor chip, a plurality of leads, and a sealing body. An outer lead portion in each of the plurality of leads includes a first portion protruding from a second side surface of the sealing body in a first direction, a second portion extending in a second direction intersecting with the first direction, and a third portion extending in a third direction intersecting with the second direction. Furthermore, a length of the third portion in the third direction of the outer lead portion is shorter than a length of the first portion in the first direction.

Owner:RENESAS ELECTRONICS CORP

Display device for novel media operation

InactiveCN108167599AEasy maintenanceThe connection is firmly fixedTelevision system detailsColor television detailsLiquid-crystal displayDisplay device

The invention discloses a display device for novel media operation. The display device for the novel media operation comprises a first shell, wherein a heat dissipation mechanism is fixedly installedon the inside wall of the shell; a liquid crystal display is arranged on one side of the heat dissipation mechanism, and a second shell is arranged on the front side of the first shell; first threadedholes are all formed in the four corners of the second shell, and fastening mechanisms are arranged between pass grooves and the first threaded holes; and filter screens are both arranged on the twosides of the outside surface of the first shell, one side of each filter screen stretches out to the inner portion of the first shell, and a clamping groove is formed in the other side of each filterscreen. Locking mechanisms are both fixedly arranged on the other two sides of the outside surface of the first shell, second threaded holes are formed in the middle portion of the lower surface of the first shell, and a disassembly mechanism is arranged on the lower side of the first shell. The display device for the novel media operation has the advantages that the numbers of bolts are reduced by arranging the fastening mechanisms in the four corners, the second shell is convenient to disassemble from the first shell, and then the liquid crystal display is convenient to maintain.

Owner:沈漪澜

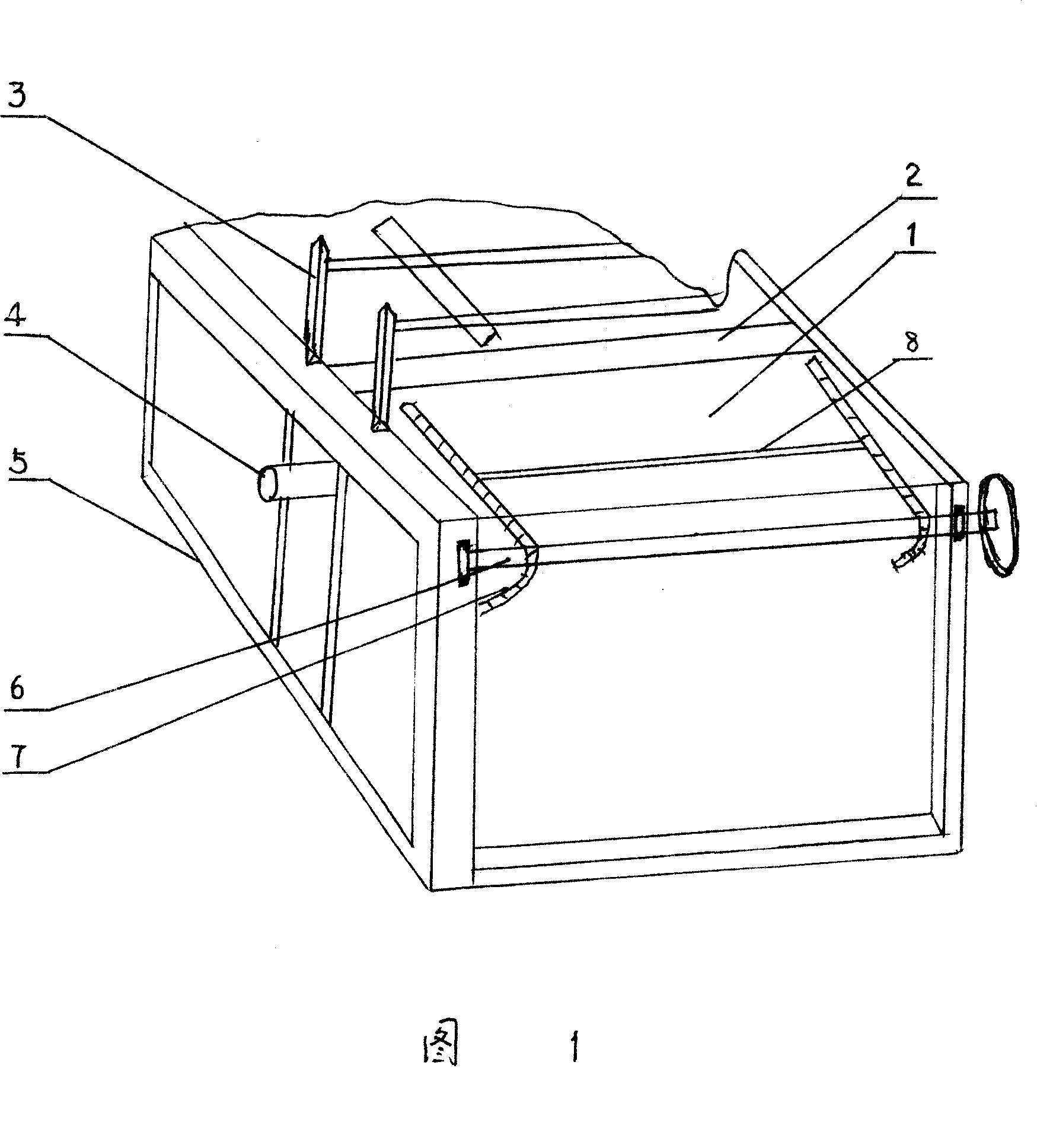

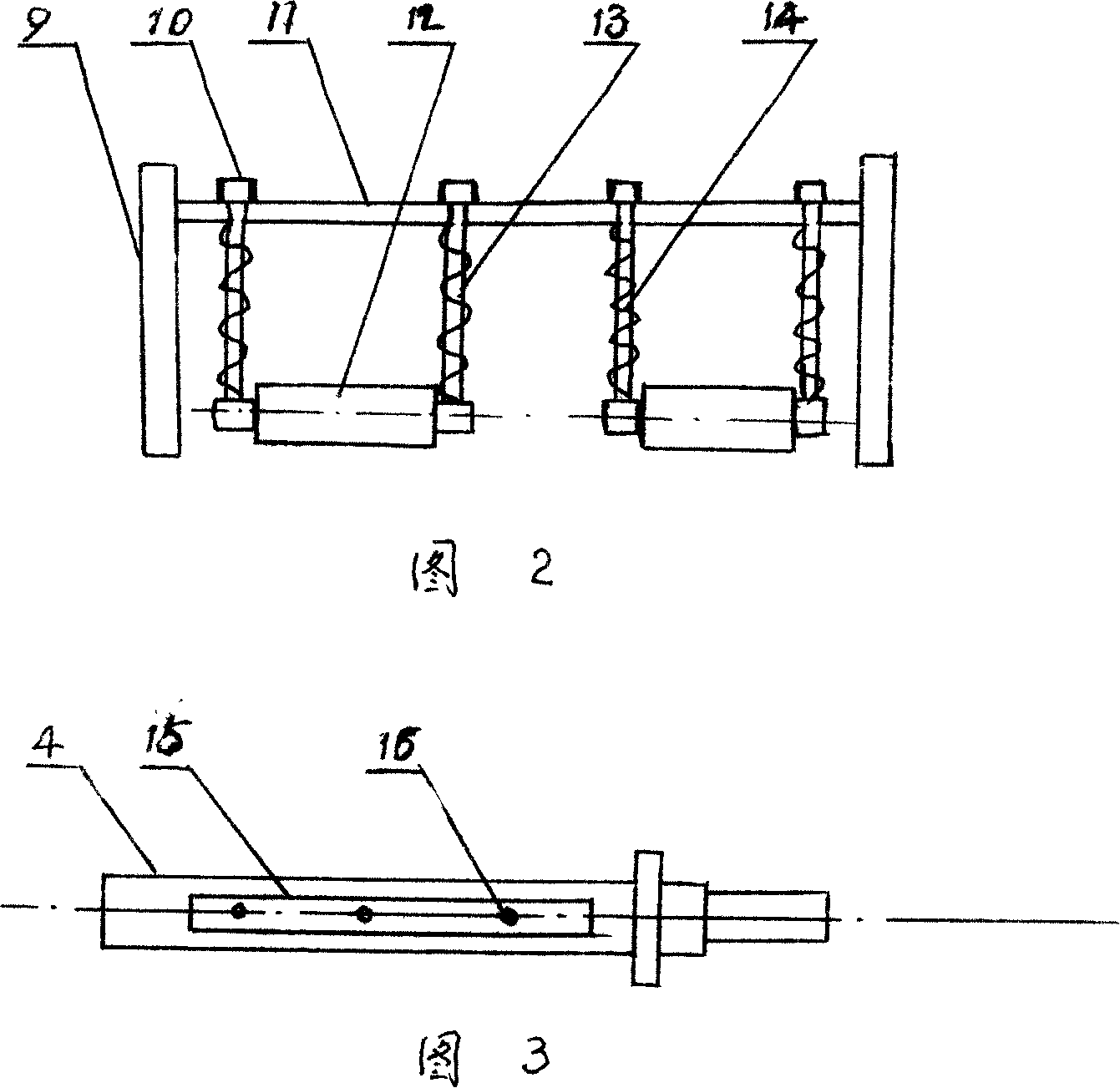

Multifunction full automatic once shaping stone material fringe machine

InactiveCN100999114BConsistent depthConsistent widthStone-like material working toolsSprocketEngineering

Owner:季永君

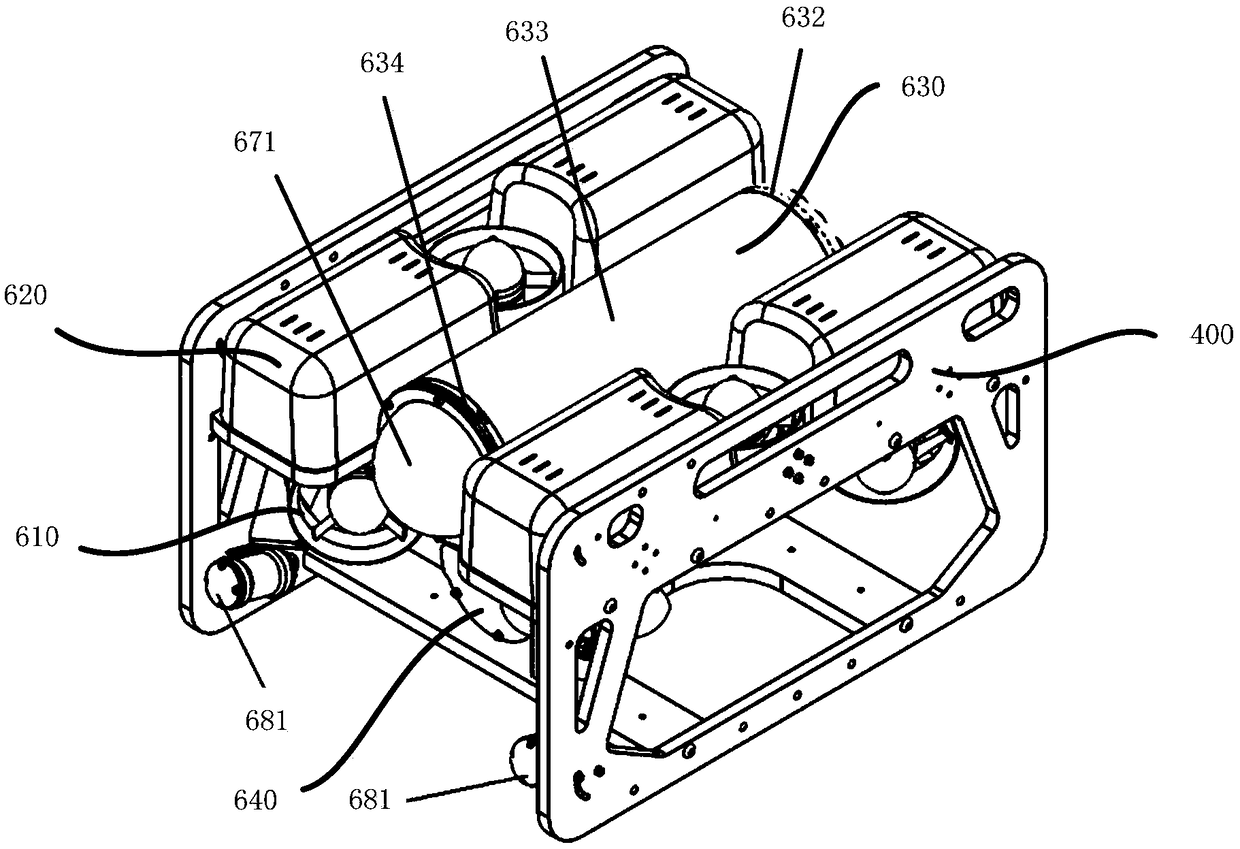

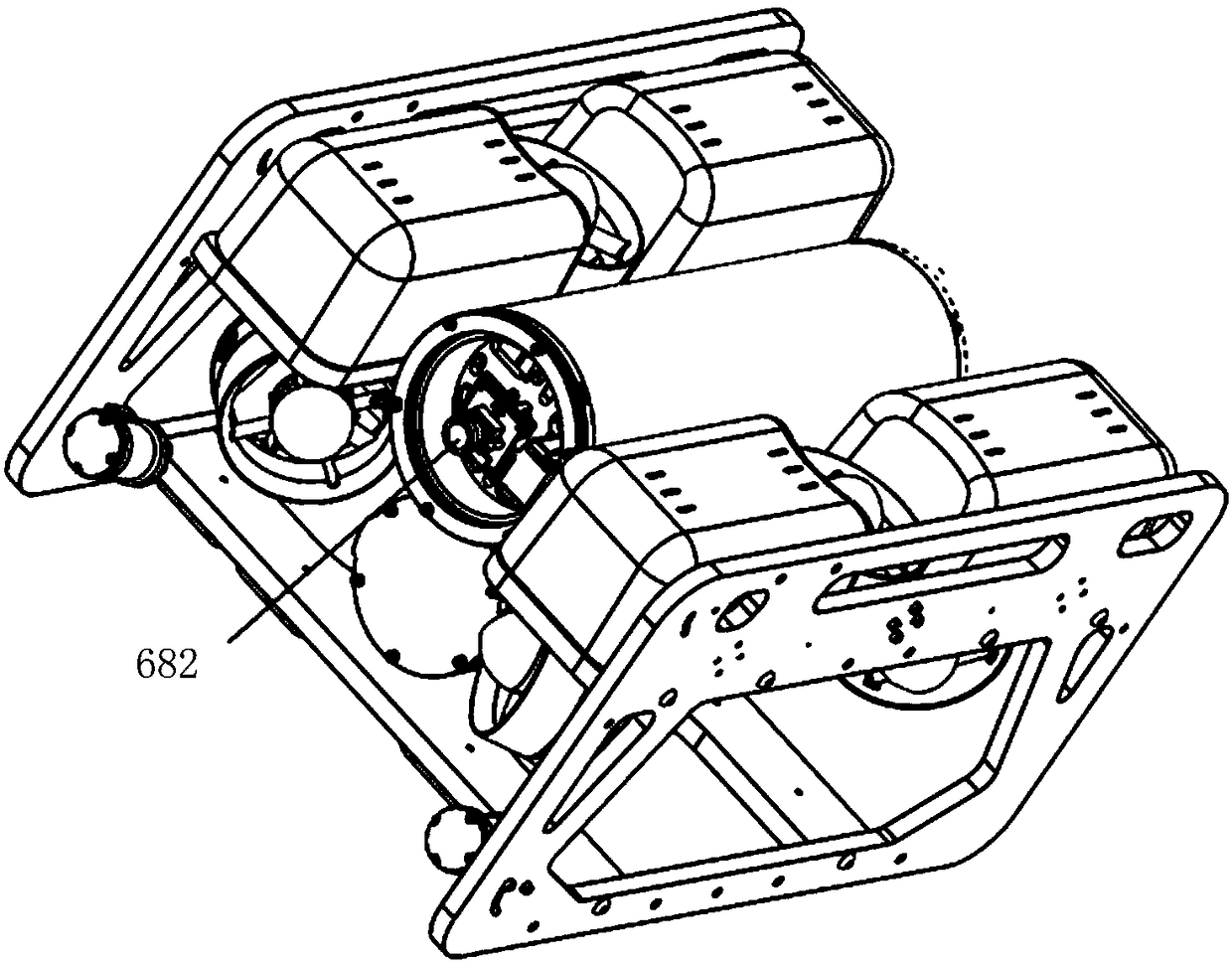

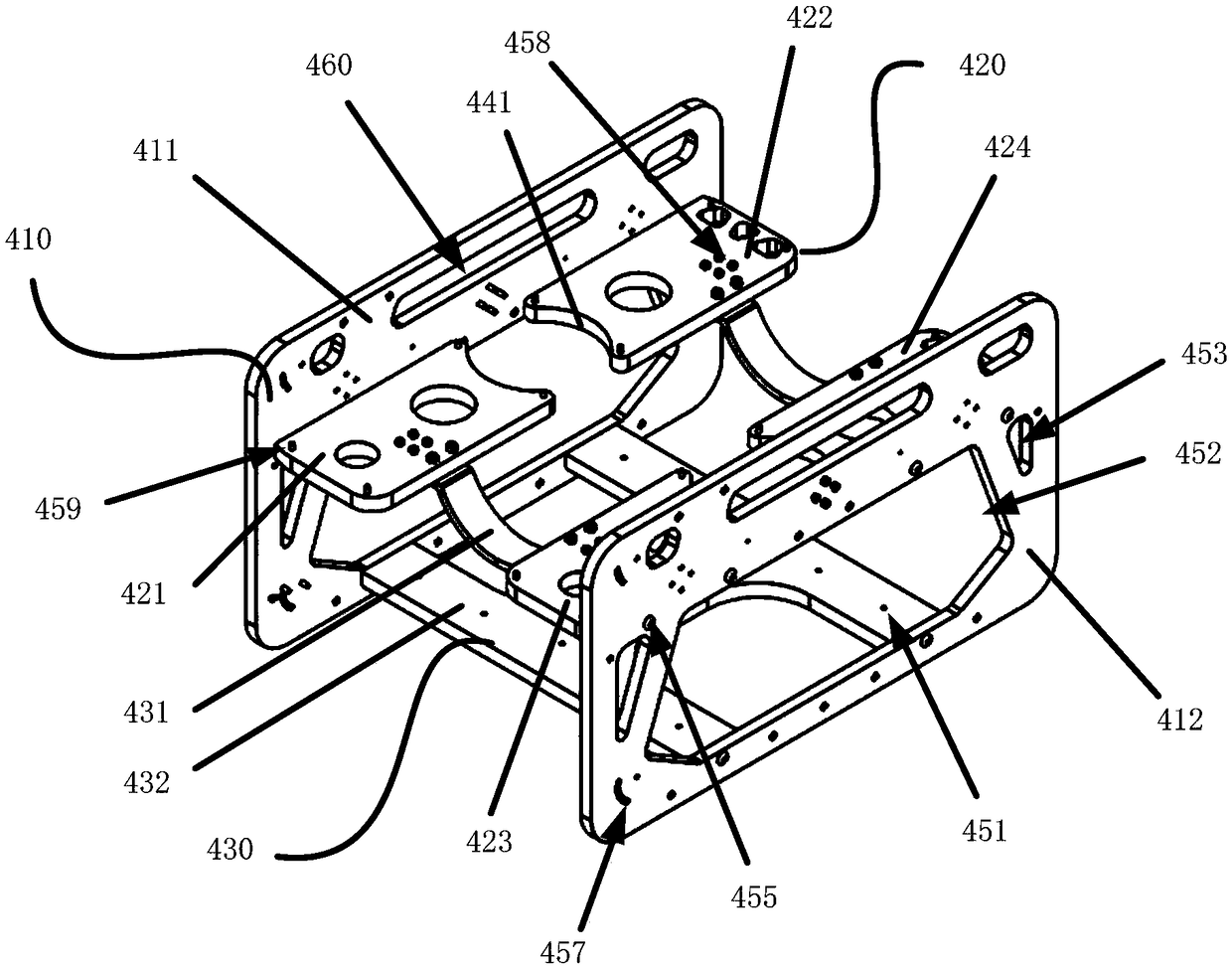

Underwater reconnaissance robot

PendingCN108860526ASuitable for remote observationQuick assemblyUnderwater equipmentSonarRear quarter

The invention provides an underwater reconnaissance robot. The underwater reconnaissance robot comprises a framework assembly, a propeller module, a buoyancy part module, an electronic cabin module, abattery module and a functional part module, wherein the propeller module, the buoyancy part module, the electronic cabin module and the battery module are detachably mounted on the framework assembly; the framework assembly comprises a side plate structure, a supporting plate structure and a bridge connection structure; the side plate structure comprises two side plates including a left side plate and a right side plate; the bridge connection structure is directly or indirectly connected onto the side plates; the supporting plate structure comprises two supporting plates including a left supporting plate and a right supporting plate; the left supporting plate and the right supporting plate are fixedly mounted on the left side plate and the right side plate respectively; the functional part module comprises any one or more structures mounted on the framework assembly and / or the electronic cabin module: a searchlight, a camera and a sonar. According to the underwater reconnaissance robot provided by the invention, the camera and the multi-beam sonar are loaded, and the searchlight and a sapphire glass cover are matched, so that the underwater reconnaissance robot is suitable for remote observation under muddy water and an observation distance can reach 100m or more.

Owner:上海查湃智能科技有限公司

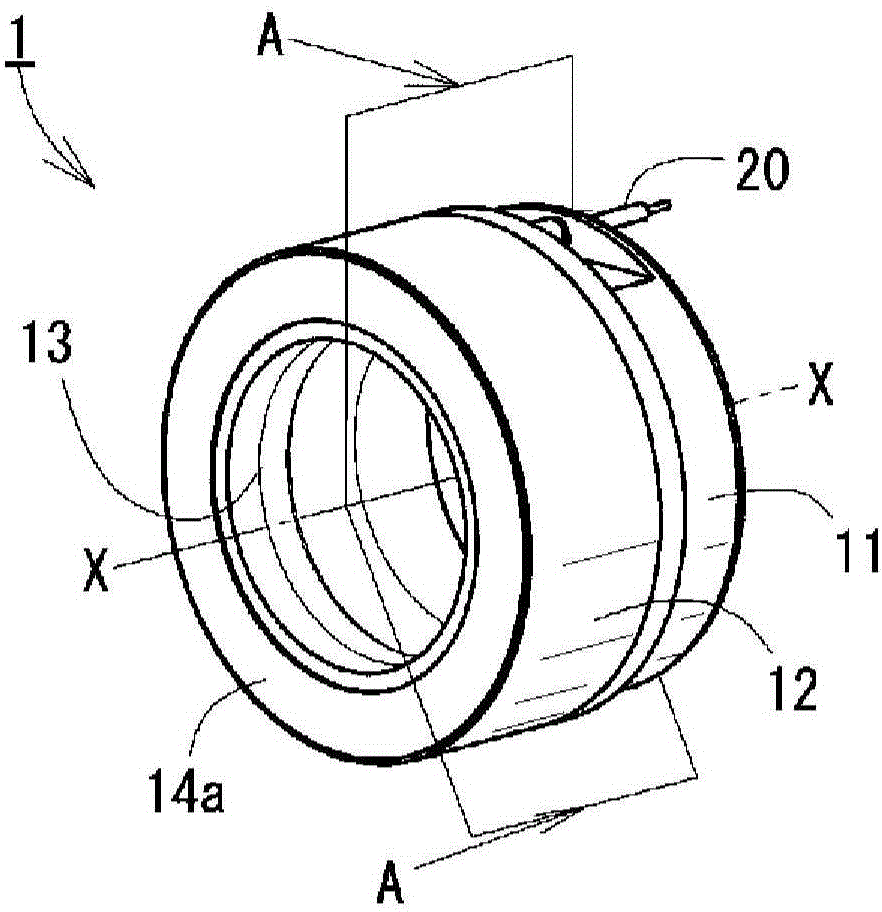

Combustion pressure sensor

InactiveCN104583744AAccurate measurementRigid influenceInternal-combustion engine testingRapid change measurementCombustion chamberPressure transmission

A combustion pressure sensor comprising a ring-shaped cylinder body is mounted to the front end outer peripheral section of a function component mounted to the combustion chamber of an engine and detects the combustion pressure in the combustion chamber. The cylinder body has a sealed space formed between an outer cylinder member and an inner cylinder member, which are coaxial with each other, and one side of the sealed space is sealed with a ring-shaped diaphragm and the other side of the sealed space is sealed with a ring-shaped support member. The diaphragm has, on the combustion chamber side, a ring-shaped pressure receiving section which receives pressure from the outside, and diaphragm also has, on the back surface side, a ring-shaped transmission section. A pressure transmission member and a pressure detection element are provided in the sealed space. The transmission section of the diaphragm, the pressure transmission member, the pressure detection element, and the support member are sequentially in close contact with each other.

Owner:CITIZEN FINEDEVICE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com