Frame structure for pure electric vehicle

A frame structure, pure electric vehicle technology, applied in the substructure, vehicle parts, transportation and packaging, etc., can solve the problems of low strength and rigidity of the frame, increased mass, deformation of the body, etc., to ensure the installation strength and overall Vehicle rigidity, improvement of torsion resistance performance, improvement of strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

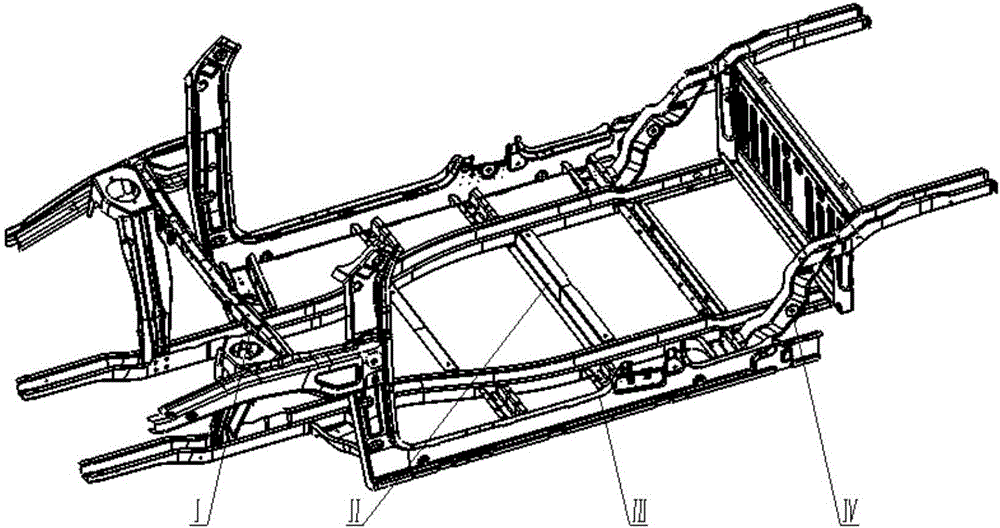

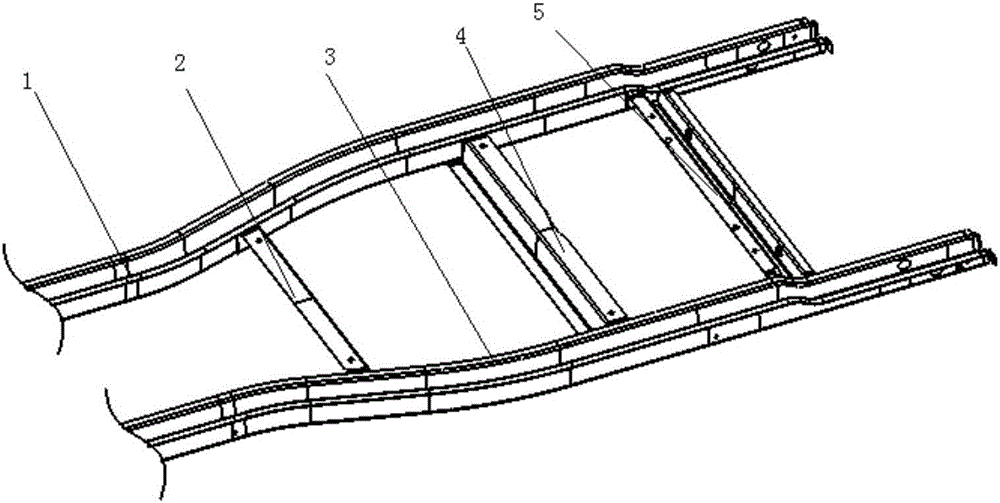

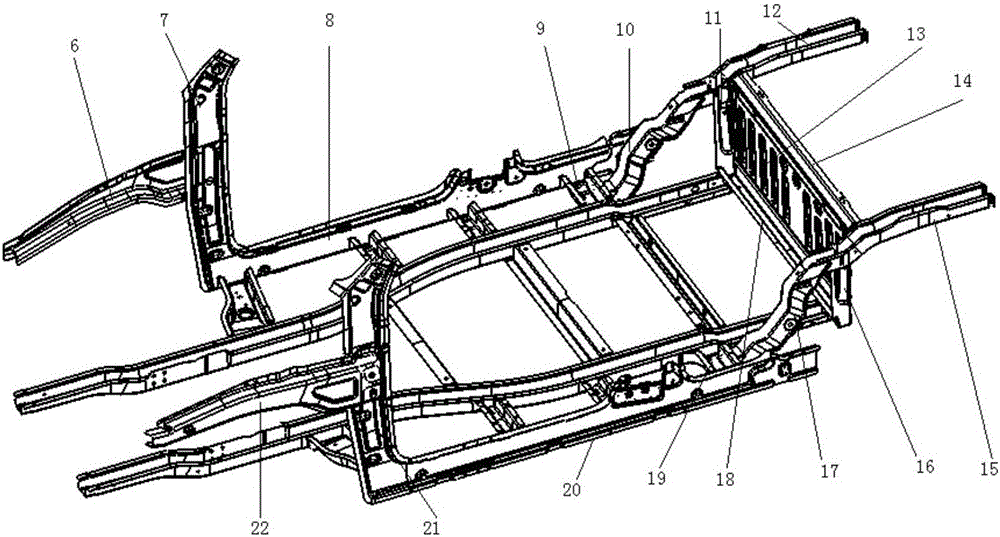

[0027] Such as figure 1 As shown, the main structure of the pure electric vehicle frame structure in this embodiment is composed of the front reinforcement structure I, the middle H-shaped structure II, the left / right beam structure III, and the rear battery compartment reinforcement structure IV, among which the middle H-shaped structure Ⅱ, such as figure 2 As shown, it includes middle beam one 2, middle beam two 4, middle beam three 5, left side beam 3 of frame and right side beam 1 of vehicle frame, left side beam 3 of vehicle frame and right side beam 1 of vehicle frame are through Longitudinal beams greatly improve the frame's ability to resist bending deformation and torsional deformation; image 3 As shown, a side beam 20, 8 on the left and right, together with the left and right side beams 3, 1 of the vehicle frame form a space structure of four longitudinal beams, wherein the left / right side beam structure III includes the left / right front cabin connecting beam 22 / 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com