Installing structure for LED display screen and the LED display screen

A technology of LED display and installation structure, applied in the direction of identification devices, instruments, etc., can solve the problems of inconvenient moving and transportation, difficult installation, etc., and achieve the effect of convenient moving or transportation, fast and stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

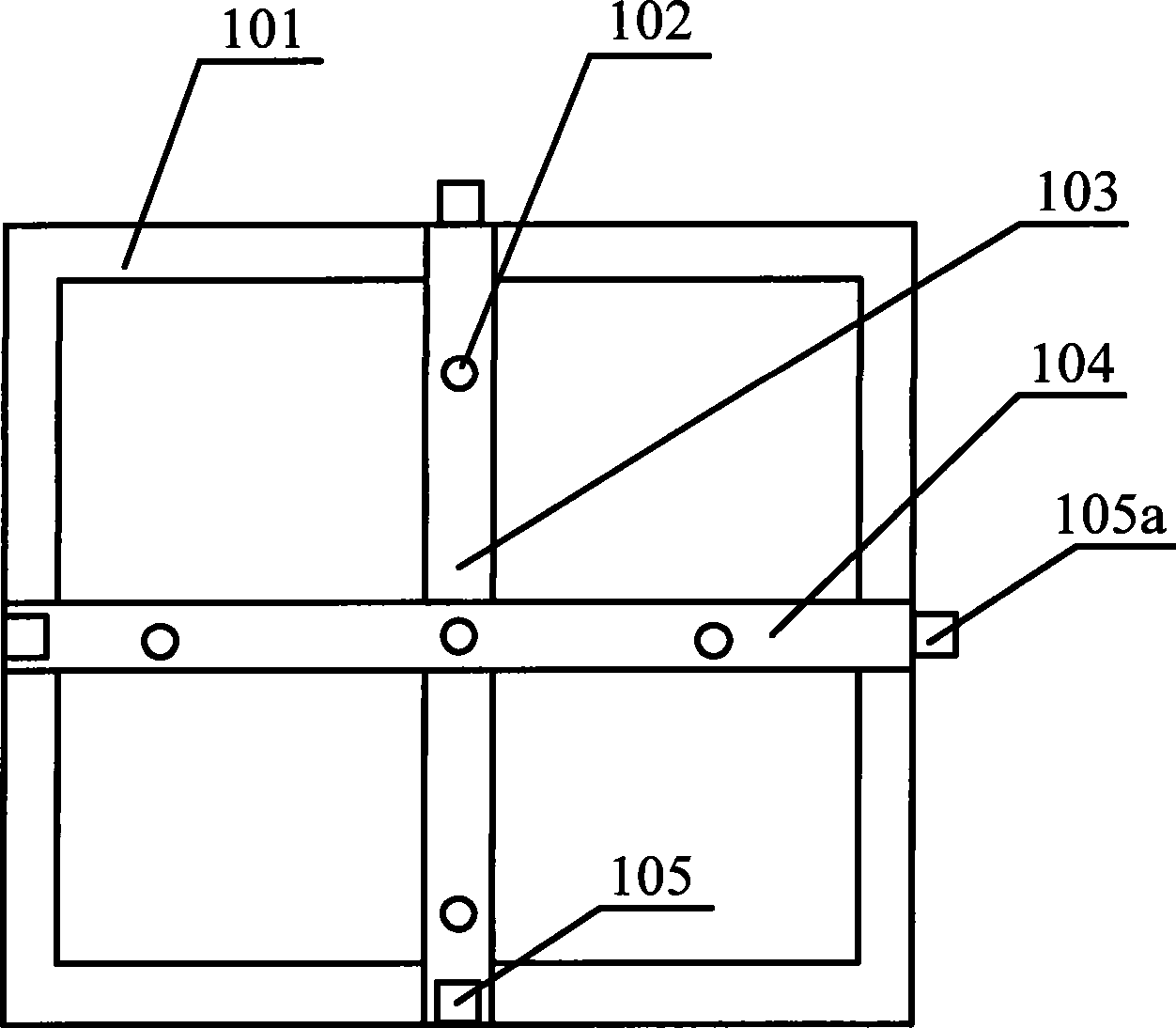

[0023] Such as figure 1 As shown, the present embodiment provides a mounting structure for LED display screens, the mounting structure includes a rigid support structure and a plastic frame 101, a connection structure 105 is also set on the rigid support structure; the rigid support The structure includes a rigid support bar 103 and a rigid support bar 104, and these two rigid support bars form a rigid support plane; on the rigid support bar 103 and the rigid support bar 104, one or more fixing positions 102 are respectively provided for fixing at least An external LED display module is used to form an LED display screen.

[0024] Moreover, a connection structure is also provided on the rigid support structure for connecting with connection structures of other rigid support structures. The connection structure can be any connection structure capable of fixing the two rigid support structures to each other, and can be respectively arranged at the ends of the rigid support bar ...

Embodiment 2

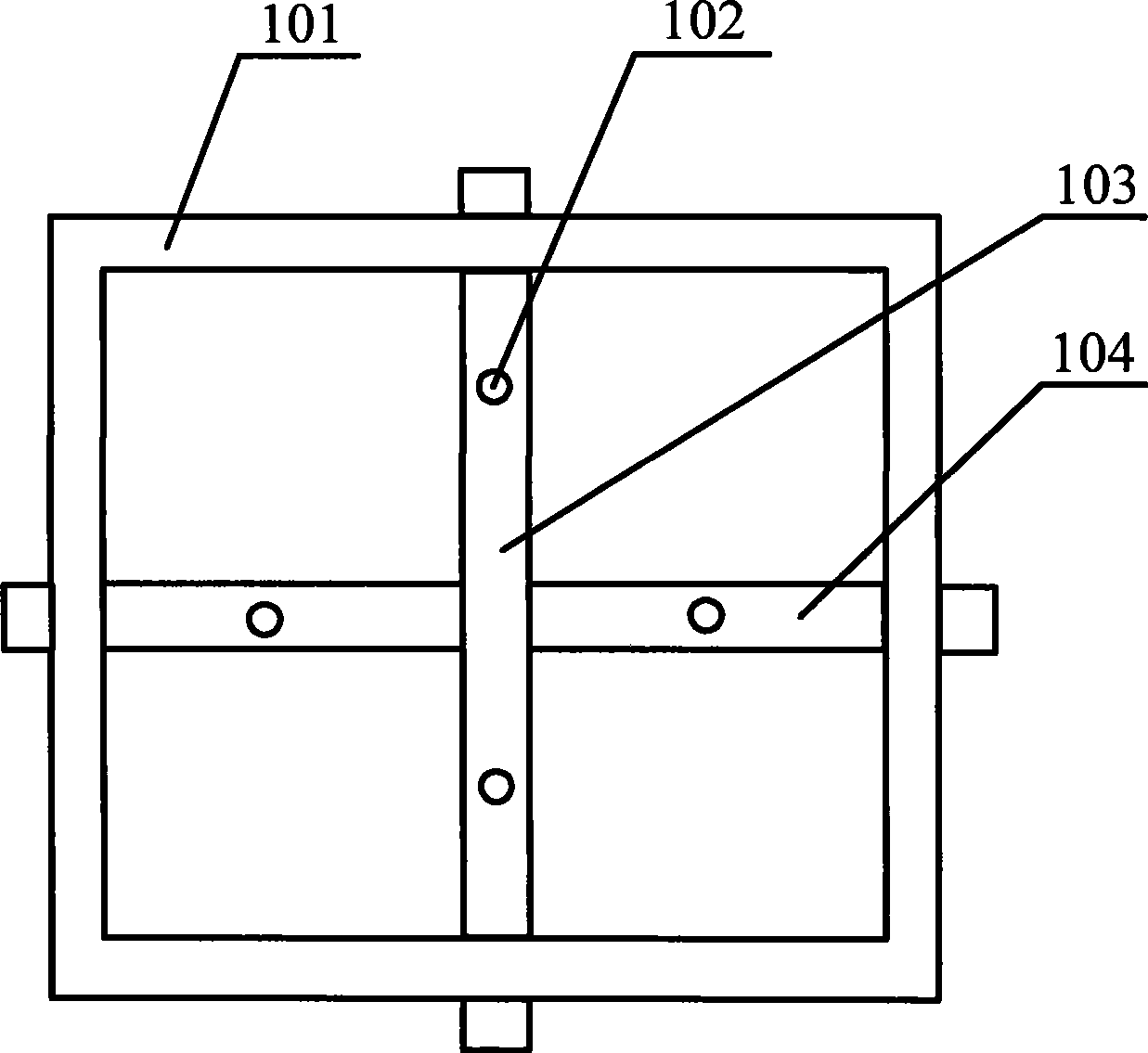

[0036] Such as figure 2As shown, similar to the above examples, this embodiment provides an installation structure for LED display screens, the installation structure includes a rigid support structure and a plastic frame 101, and a connection structure is also provided on the rigid support structure 105; the rigid support structure includes a rigid support bar 103 and a rigid support bar 104, and these two rigid support bars form a rigid support plane; the rigid support bar 103 and the rigid support bar 104 are respectively provided with one or more fixing positions 102, used for fixing at least one external LED display module to form an LED display screen.

[0037] Among them, such as figure 2 As shown, the plastic frame 101 is fixed on the rigid support plane formed by the rigid support bar 103 and the rigid support bar 104 , and is located on the same side of each fixing position 102 .

[0038] For example, if figure 2 As shown, a quadrilateral rigid support plane ca...

Embodiment 3

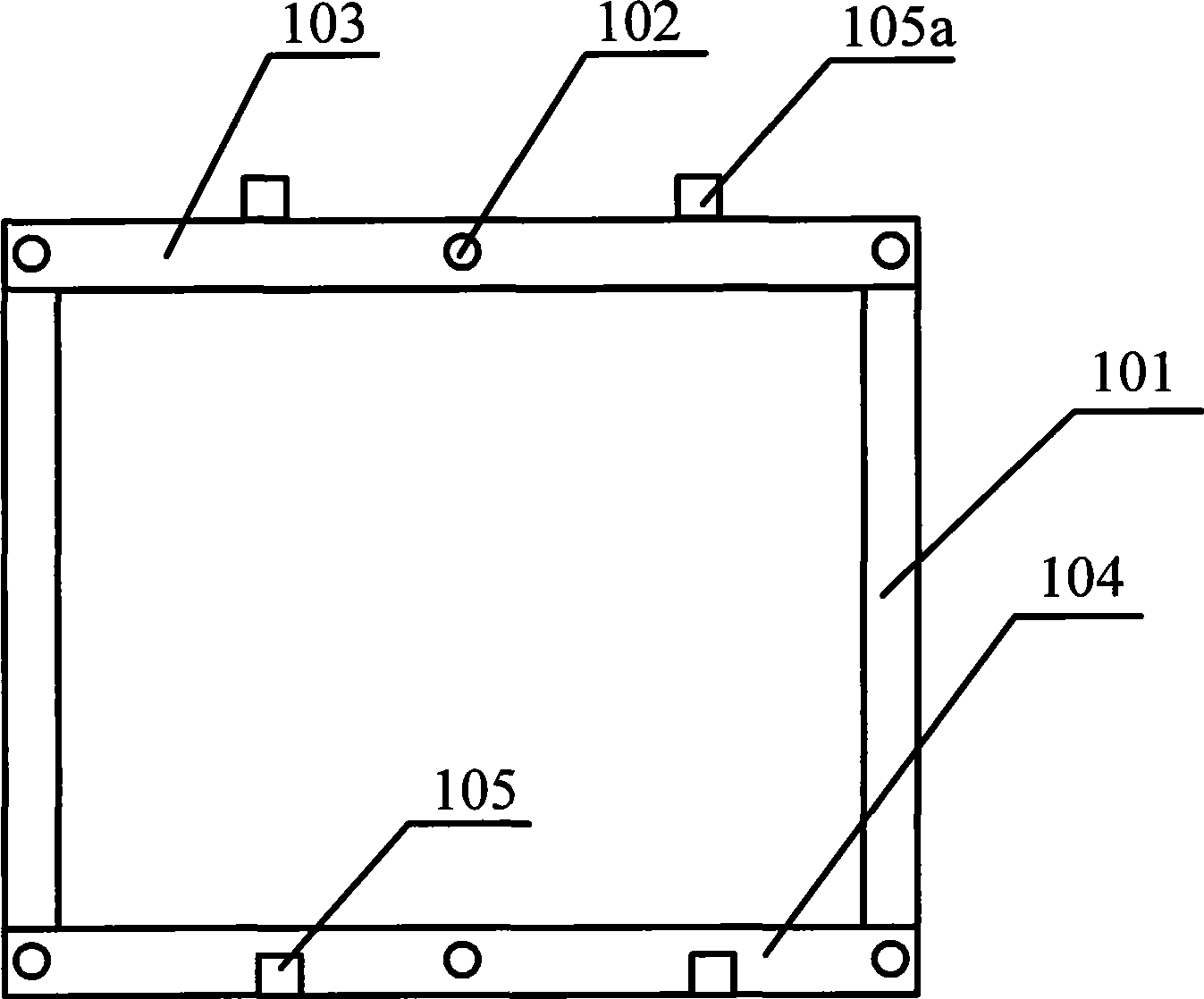

[0040] Such as image 3 As shown, similar to the above examples, this embodiment provides an installation structure for LED display screens, the installation structure includes a rigid support structure and a plastic frame 101, and a connection structure is also provided on the rigid support structure 105; the rigid support structure includes a rigid support bar 103 and a rigid support bar 104, and these two rigid support bars form a rigid support plane; the rigid support bar 103 and the rigid support bar 104 are respectively provided with one or more fixing positions 102, used for fixing at least one external LED display module to form an LED display screen.

[0041] In this embodiment, the rigid support bar 103 and the rigid support bar 104 are arranged parallel to each other, and the rigid support bar 103 and the rigid support bar 104 can be respectively arranged on the top and bottom of the plastic frame 101, so that the plastic frame 101 is integrated The top is relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com