Installing structure of inner waterproof holding strip fixing supports of vehicle door

A technology for fixing brackets and waterproof clamping strips, which is applied to superstructures, superstructure subassemblies, sealing devices, etc. It can solve the limitations of door trim shape and molding process, reduce the installation accuracy of fixing brackets, and affect the installation of inner waterproof clamping strips Precision and other issues, to achieve the effect of convenient assembly, simple structure, and reliable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail:

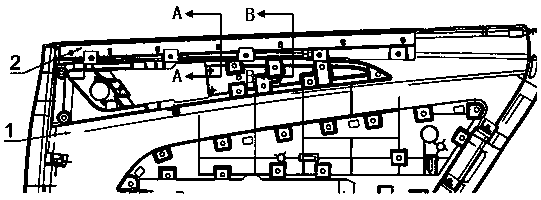

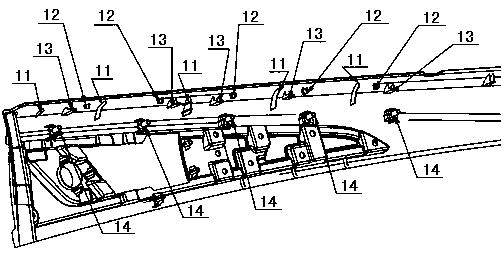

[0018] like figure 1 The installation structure of the fixing bracket of the waterproof clip strip in the vehicle door shown, including the door trim panel 1 and the fixing bracket 2 installed on the door trim panel 1, refer to figure 2 , five first limit pins 11 , five second limit pins 12 and five third limit pins 13 are arranged at intervals on the inner surface of the upper edge of the door trim panel 1 .

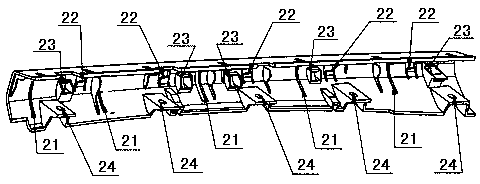

[0019] see image 3 , 4 , the fixing bracket 2 is provided with five first limit holes 21 corresponding to the positions of the first limit pins 11 , five second limit holes corresponding to the positions of the second limit pins 12 , and a third positioning pin The five third limit holes 23 corresponding to the 13 position are provided with elastic clips 22 in the second limit holes. Only one end of the elastic clips 22 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com