Machining head replacement type rotary tool, holder, and machining head

A technology of rotary cutter and machining head, applied in the field of rotary cutter with replacement of machining head, can solve the problems of difficulty in obtaining sufficient installation strength, inability to disassemble, and flank welding, etc., and achieves easy screwing and loosening, easy disassembly, and welding inhibition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

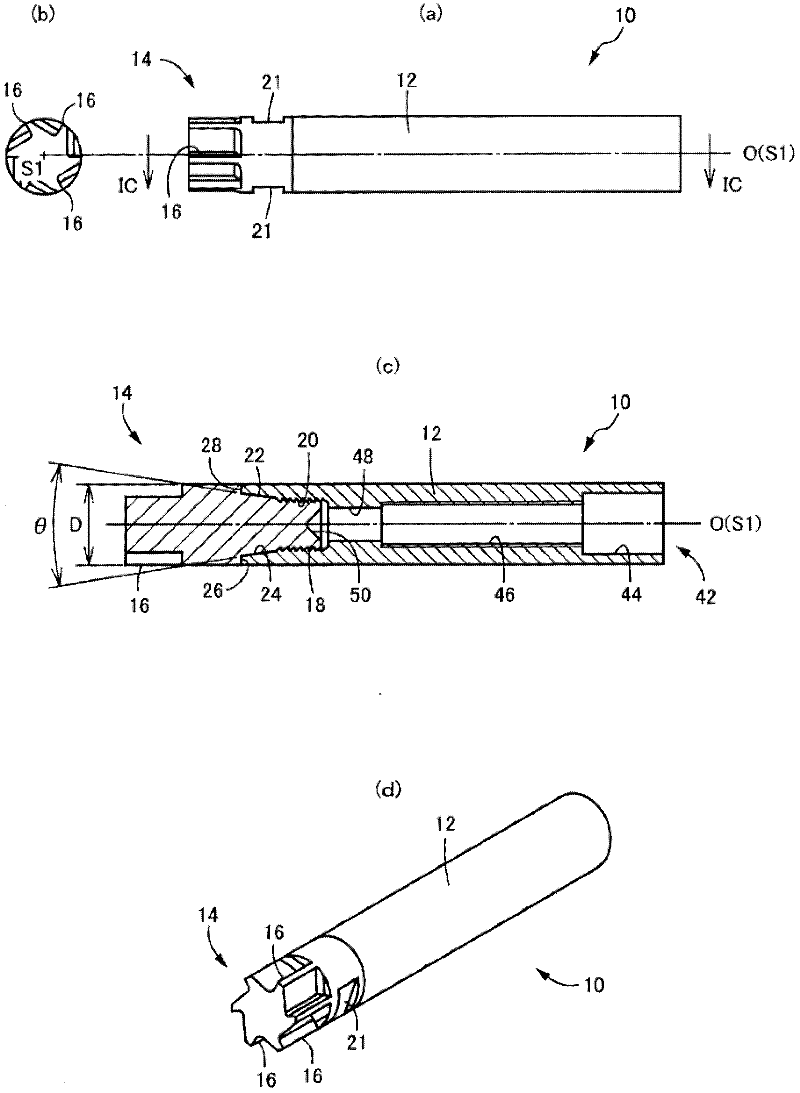

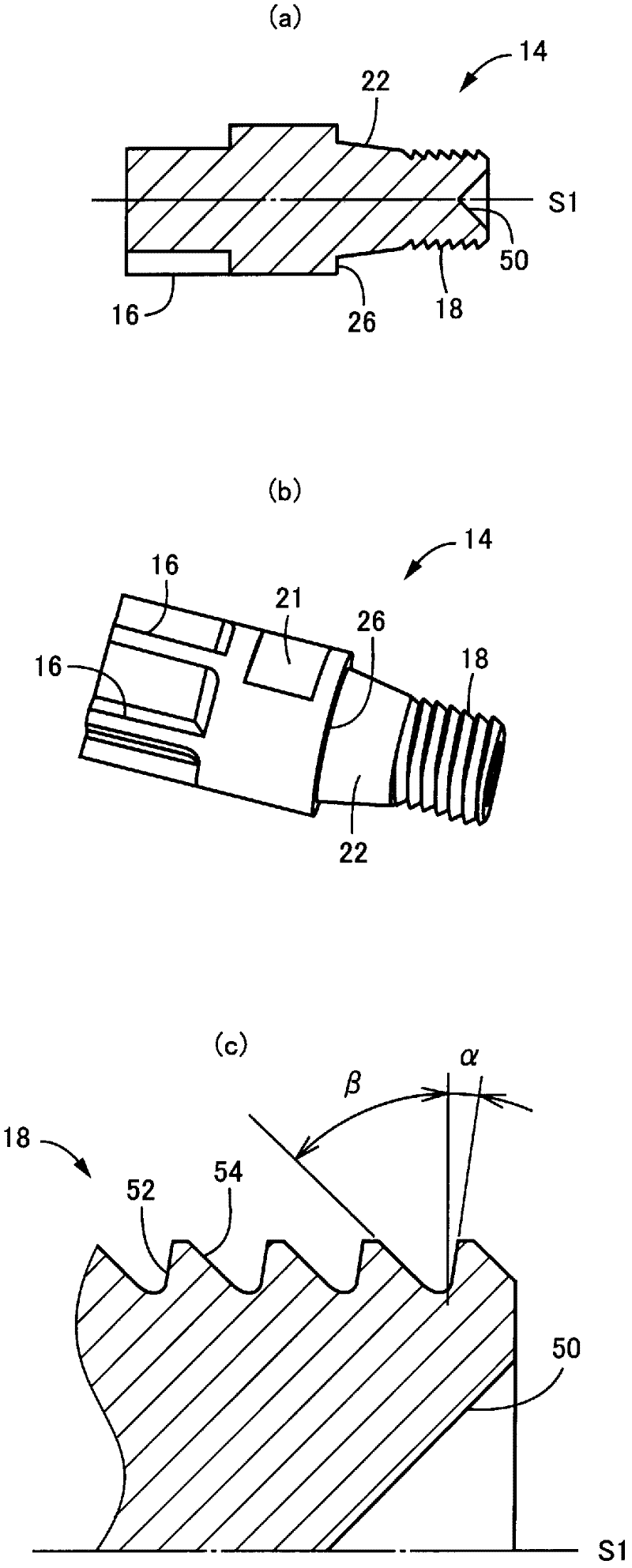

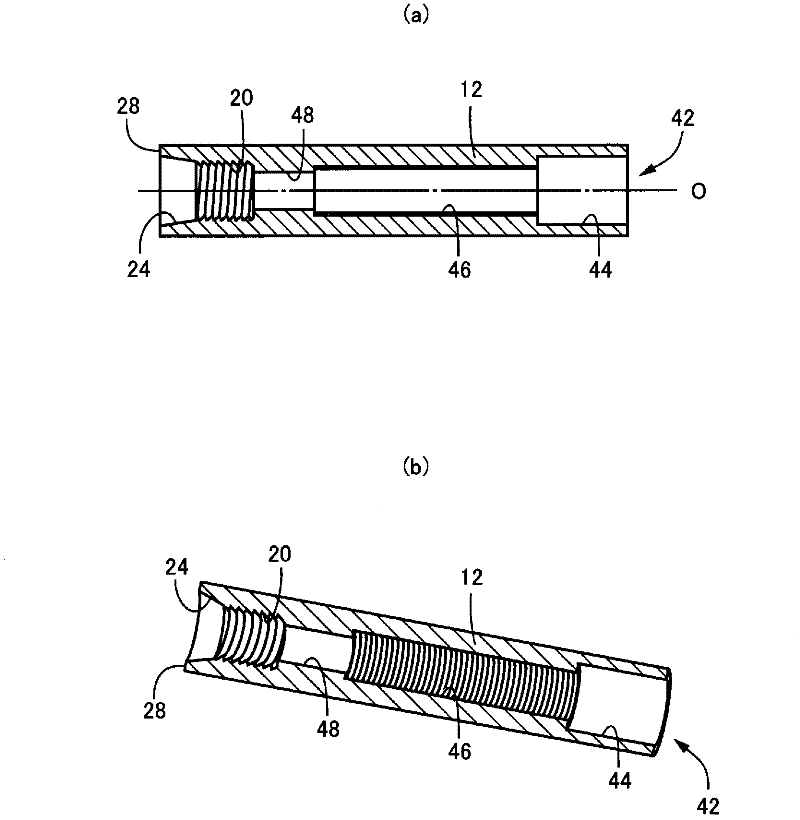

[0037] figure 1 It is a figure which shows the machining head replaceable rotary cutter 10 which concerns on one embodiment of this invention, figure 1 (a) is a front view viewed from a direction perpendicular to the axis O, figure 1 (b) is a bottom view seen from the front end side, figure 1 (c) is figure 1 IC-IC line sectional view in (a), figure 1 (d) is a perspective view. The machining head replaceable rotary tool 10 is a milling tool, and has a cylindrical shank 12 and a machining head 14 . The shank 12 is equivalent to the tool holder, and is made of relatively cheap high-speed tool steel, while the machining head 14 is made of cemented carbide, and is provided with six peripheral cutting edges 16, and is coated with a hard coating such as a compound coating as needed. The cutting edge diameter D of the peripheral cutting edge 16 is 12 mm in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com