Mounting device for LED display screen and LED display screen

A technology for LED display screens and installation devices, which is applied in the direction of identification devices, instruments, etc., and can solve problems such as poor display effect, low flatness of the display surface, and large errors in the up and down directions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

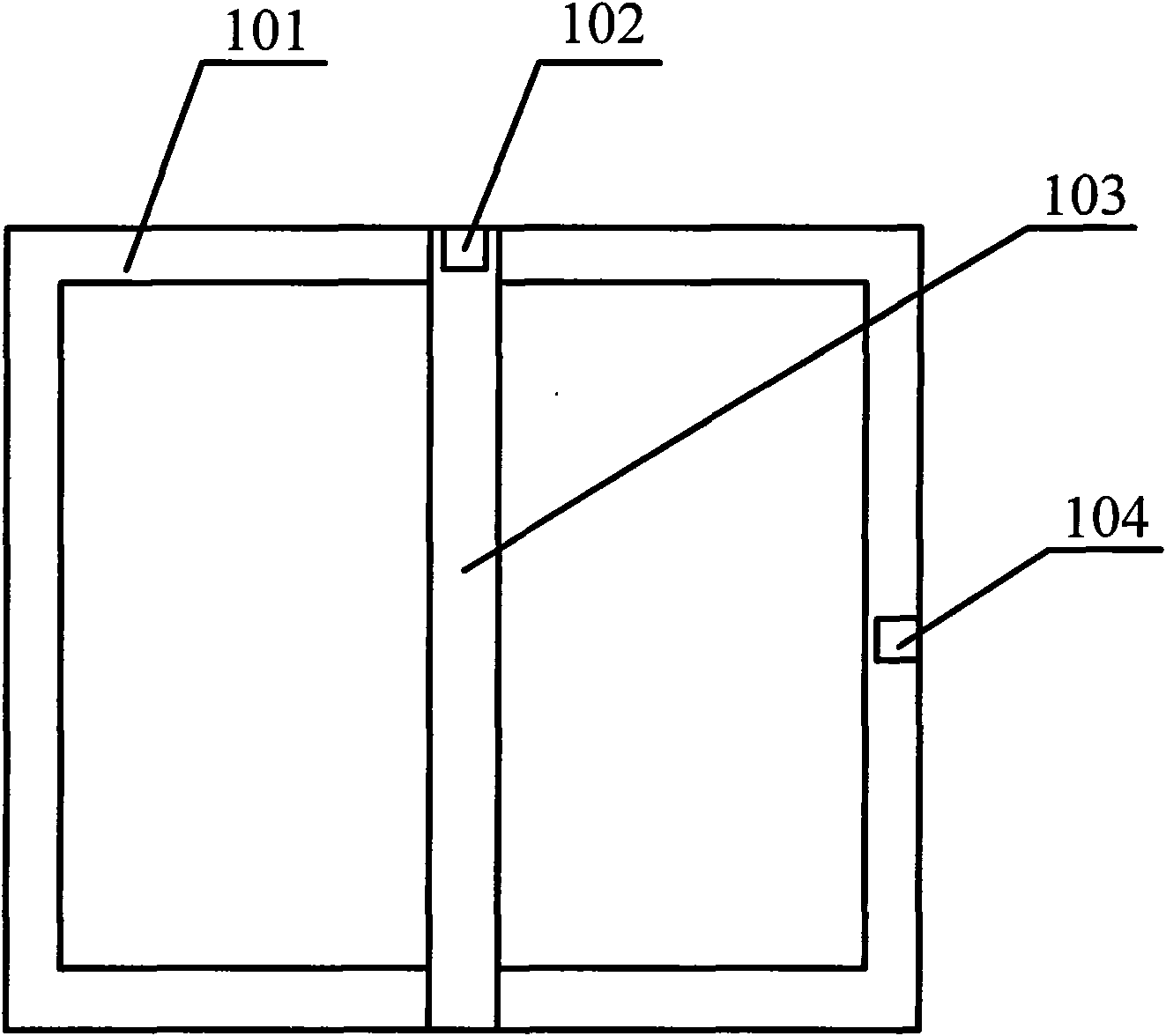

[0024] like figure 1 As shown, this embodiment provides an installation device for an LED display screen. The installation device includes a plastic frame 101 and one or more rigid support structures 103; A connecting unit 104, the first connecting unit 104 is used for fixedly connecting with the first connecting unit of other plastic frames; The connecting unit 102 is used for fixedly connecting with the second connecting unit of other rigid supporting structures.

[0025] The plastic frame 101 is injection molded from glass fiber polycarbonate plastic material. Polycarbonate is an engineering plastic with excellent performance. The mechanical properties and rigidity of polycarbonate can be improved by glass fiber reinforced polycarbonate, and the coefficient of linear expansion is greatly increased. Reduced, the dimensional stability is greatly improved, the molding shrinkage rate is significantly reduced, and at the same time, the defects of polycarbonate not resistant to ...

Embodiment 2

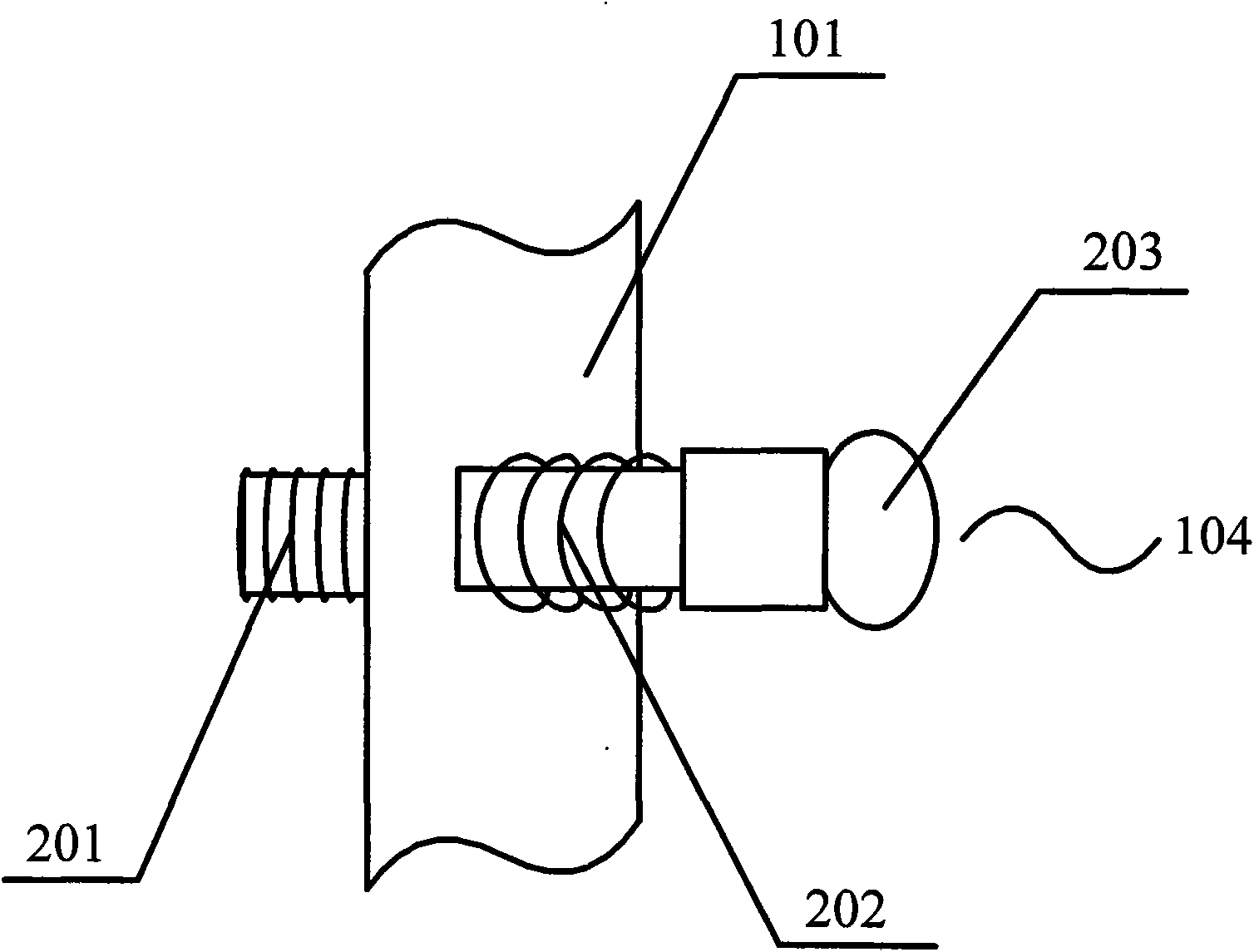

[0034] like figure 2 As shown, on the basis of the above examples, the first connection unit 104 is configured as a pinned connection piece, and the pinned connection piece is adapted to the pinned connection positions set by other first connection units, for example, In this embodiment, one side of the plastic frame 101 is provided with a pinned connector, and the plastic frame connected with the plastic frame 101 is provided with a corresponding pinned connection position, and the two plastic frames pass through the matched pins. The connecting piece and the pinned connection position are fixedly pinned to each other.

[0035] In order to further maintain the stability of the two plastic frames when they are connected to each other, the installation errors of the two plastic frames in the front and rear and up and down directions are small, the installation accuracy of the LED screen body is high, and the display surface after the LED display screen is installed has high flat...

Embodiment 3

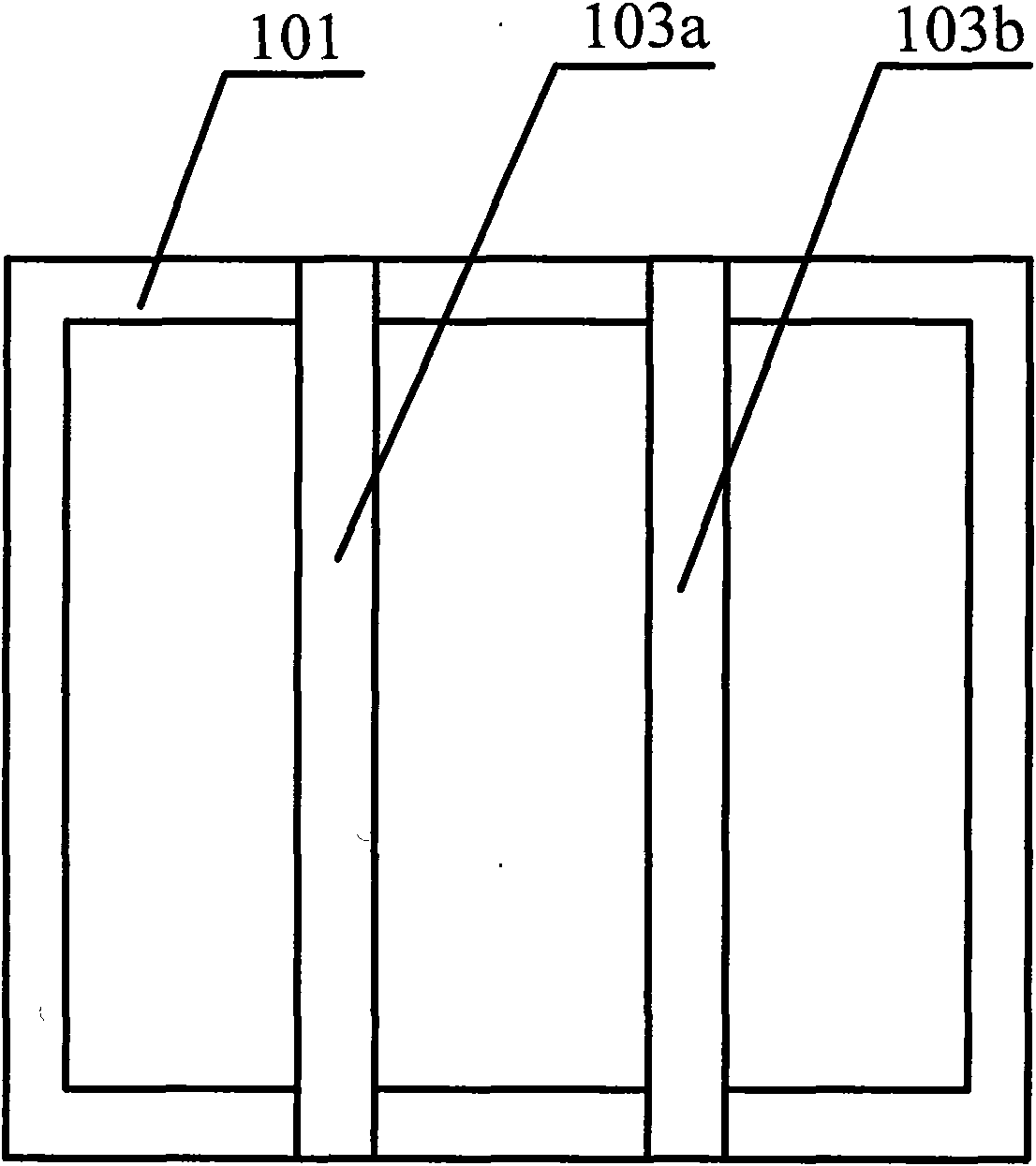

[0038] like image 3 As shown, on the basis of the above examples, the rigid support structure includes two or more rigid support bars, for example, including a rigid support bar 103a and a rigid support bar 103b, two rigid support bars, a rigid support bar 103a and a rigid support bar The strips 103b play a role in bearing, fixing and maintaining the shape of the plastic frame 101 .

[0039] Moreover, the rigid support bars 103a and the rigid support bars 103b are arranged in parallel, and the arrangement of the support bars arranged in parallel is simple and beautiful; in addition, the rigid support bars can also be arranged crosswise.

[0040] In addition, the rigid support bars 103a and the rigid support bars 103b have a balanced mass relative to the plastic frame 101, that is, the rigid support bars 103a and the rigid support bars 103b are evenly arranged in the middle of the plastic frame 101, and at least the same as the plastic frame. The two sides of the 101 are fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com