Multifunction full automatic once shaping stone material fringe machine

A fully automatic and multi-functional technology, applied in the field of special equipment for processing stone slab stripes, can solve the problems of pattern docking shape, unsatisfactory pattern uniformity, low efficacy, high labor cost, etc., to achieve multiple functions, reduce production costs, and equipment durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

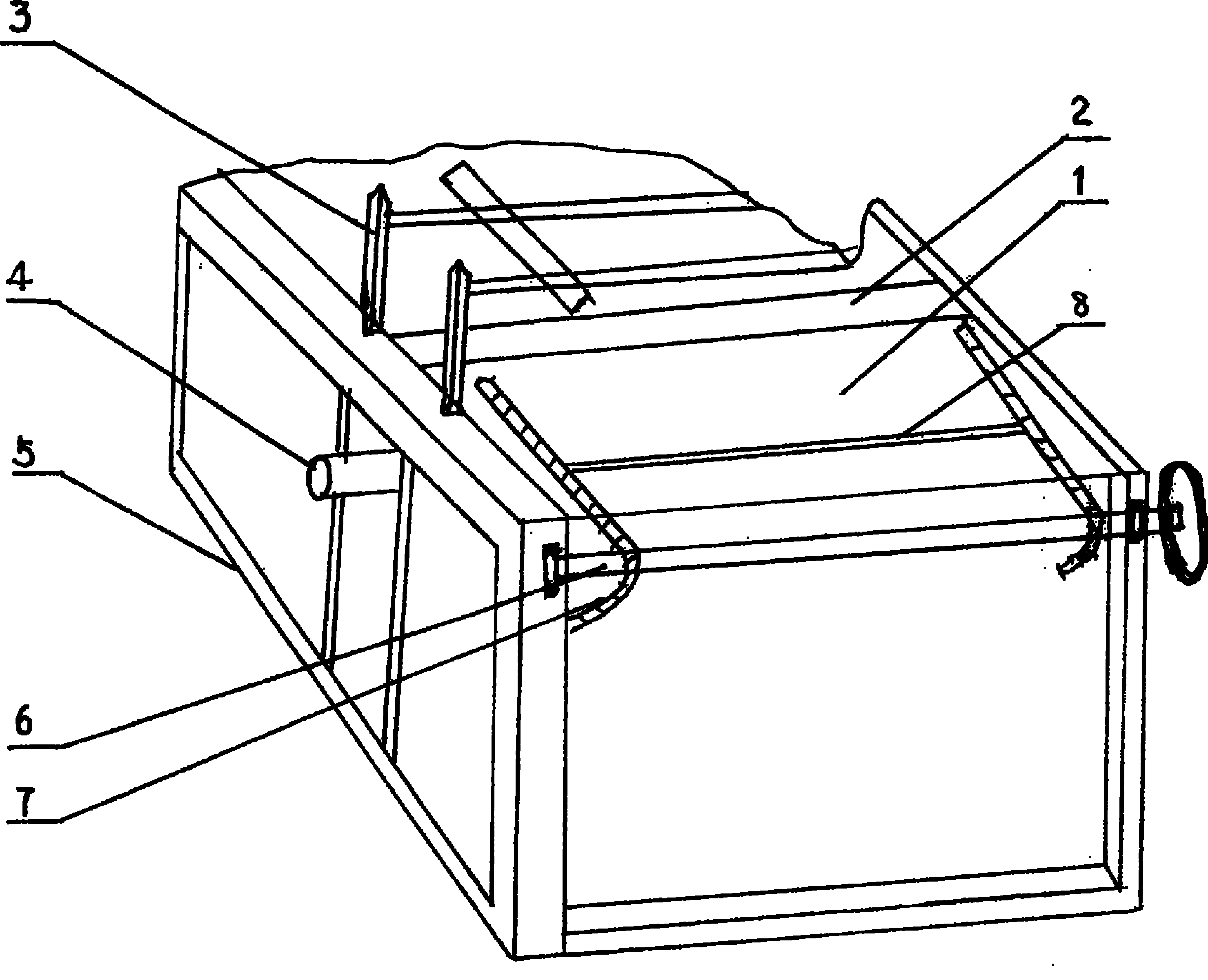

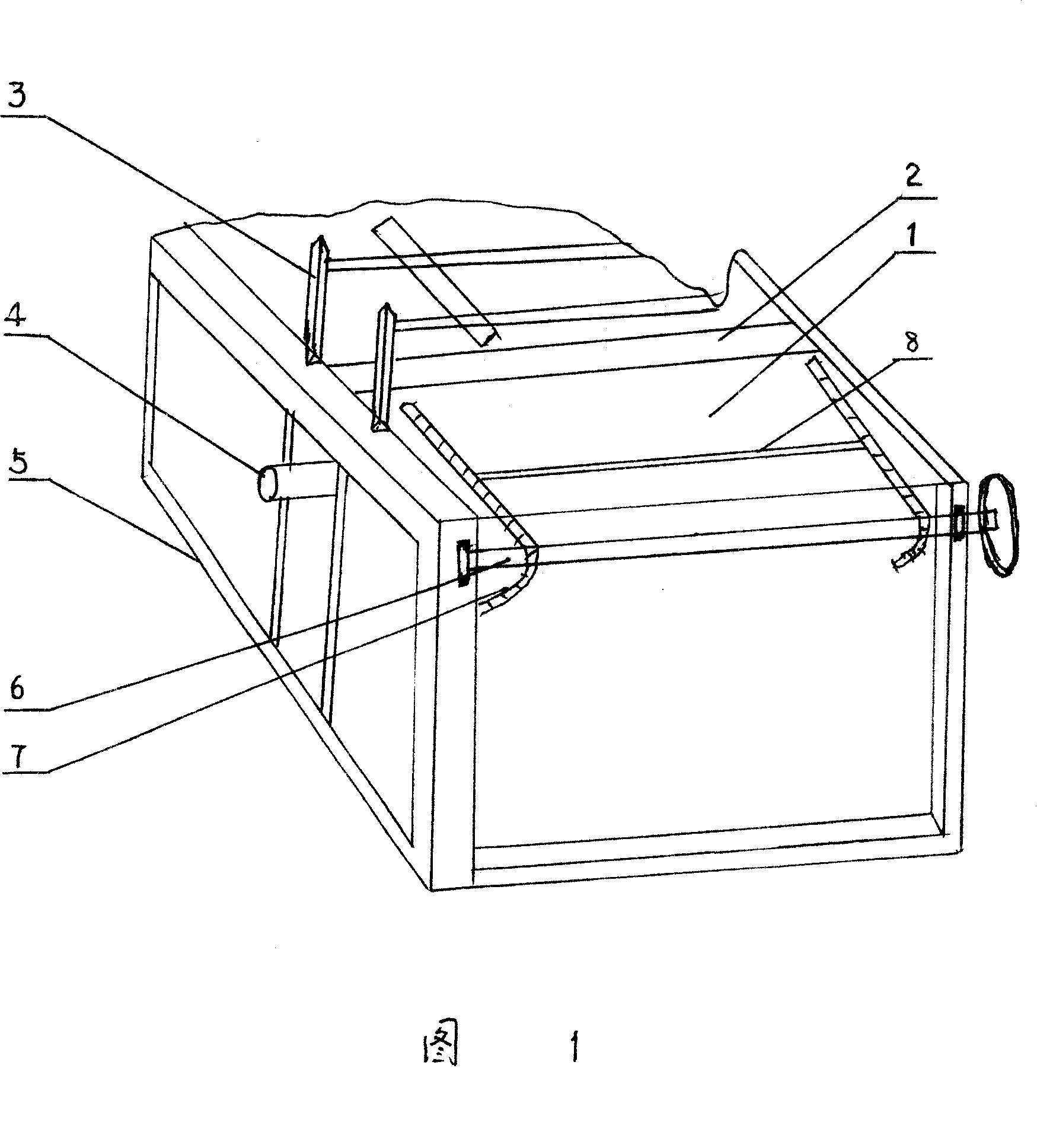

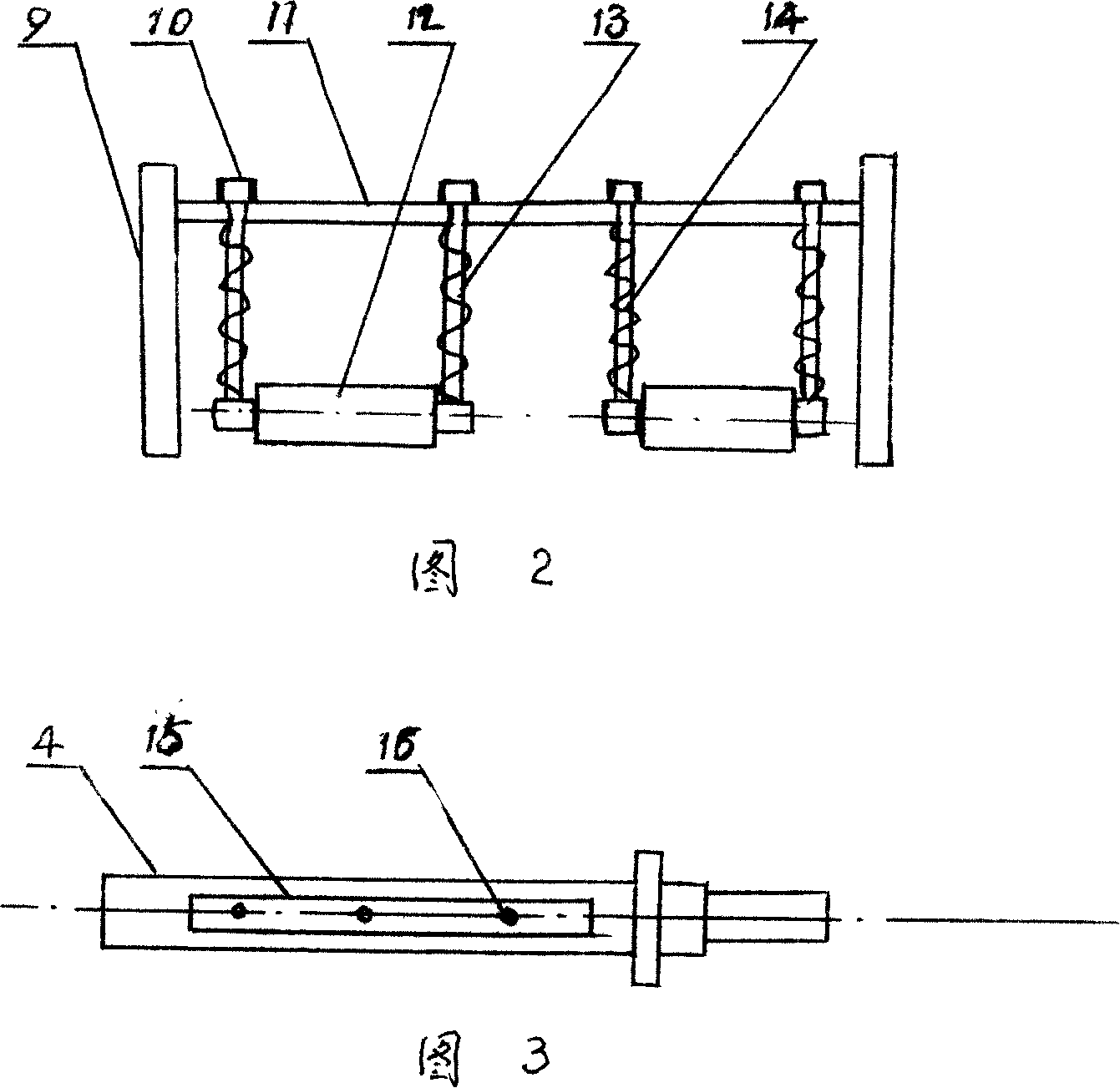

[0012] As shown in Figures 1-3, in the embodiment of the present invention, the frame 5 is made of channel steel. The workbench 1 is fixed on the upper end surface of the frame 5 . The front and rear ends of the frame 5 are respectively equipped with sprocket shafts 6 through bearing mechanisms. Two chains 7 cooperating with the sprocket shaft 6 arranged on the left and right sides of the work surface 1 are respectively connected with the left and right sides of the sheet material frame 8 for conveying the sheet materials. A main shaft 4 is arranged below the worktable 1, and multiple sets of saw blades are mounted on the main shaft 4 through fixing keys 15. At the corresponding position directly above the main shaft 4 , a planing slot 2 is provided on the worktable 1 , and the upper end of the saw blade goes deep into the planing slot 2 . A floating pressing mechanism 3 is installed above the planing slot 2 .

[0013] The conveying motor drives the sprocket shaft 6 to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com