Method for processing 8 shaped oil groove with numerical control boring mill

An 8-shaped, CNC machine tool technology, applied in metal processing equipment, milling machine equipment, manufacturing tools, etc., can solve problems such as low processing efficiency, uneven bottom plane of oil tank, potholes at arc transition, etc., to improve processing efficiency, Apparent mass change, consistent depth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

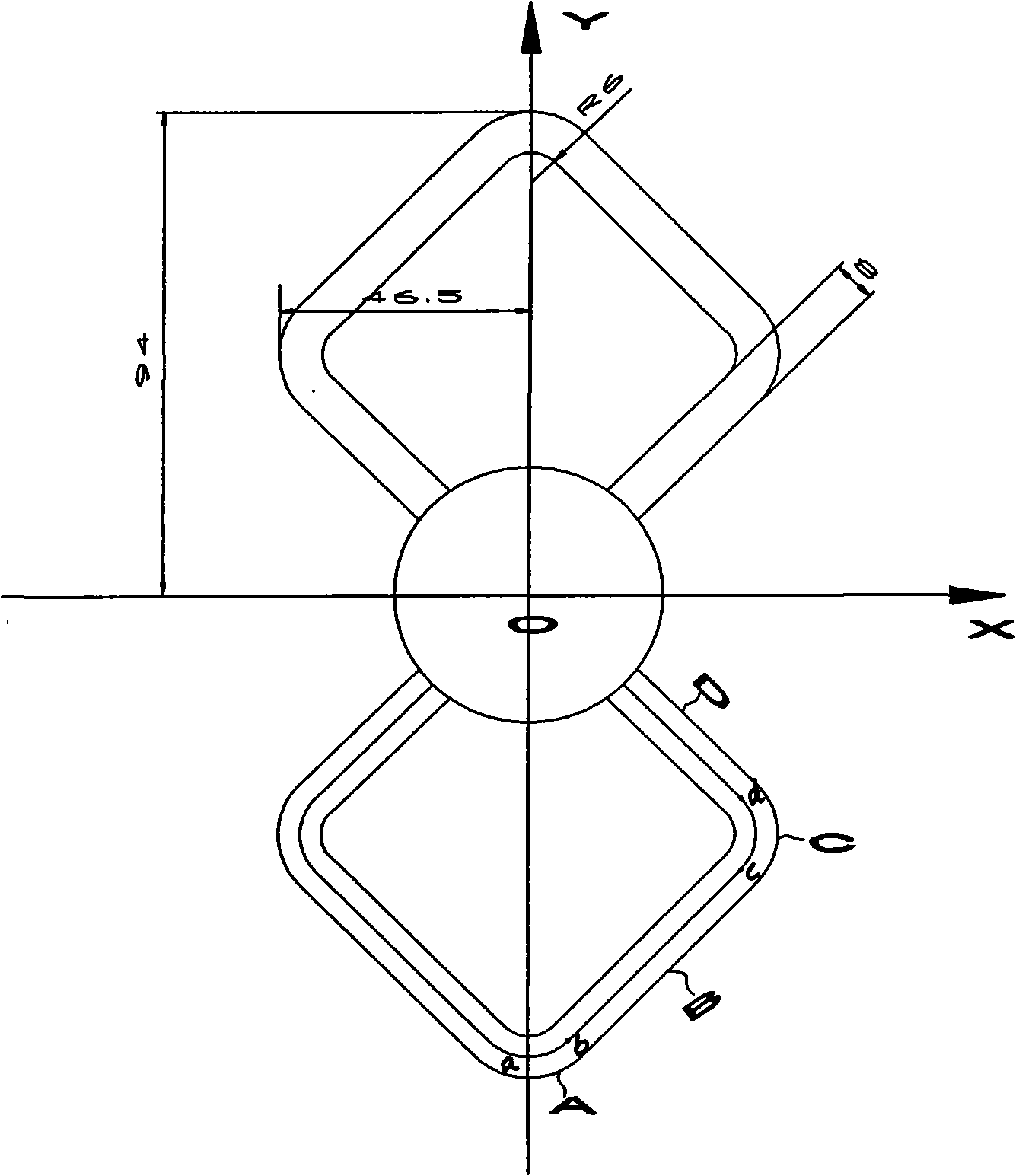

[0025] Such as figure 1 The 8-shaped oil groove is located on the inner surface of the bearing bush 1 (the bearing bush is half), and the direction is the same as the axial direction of the bearing bush. The 8-shaped oil tank is composed of two squares, has 8 straight segments, and there are 6 1 / 4 circular arcs between the straight segments.

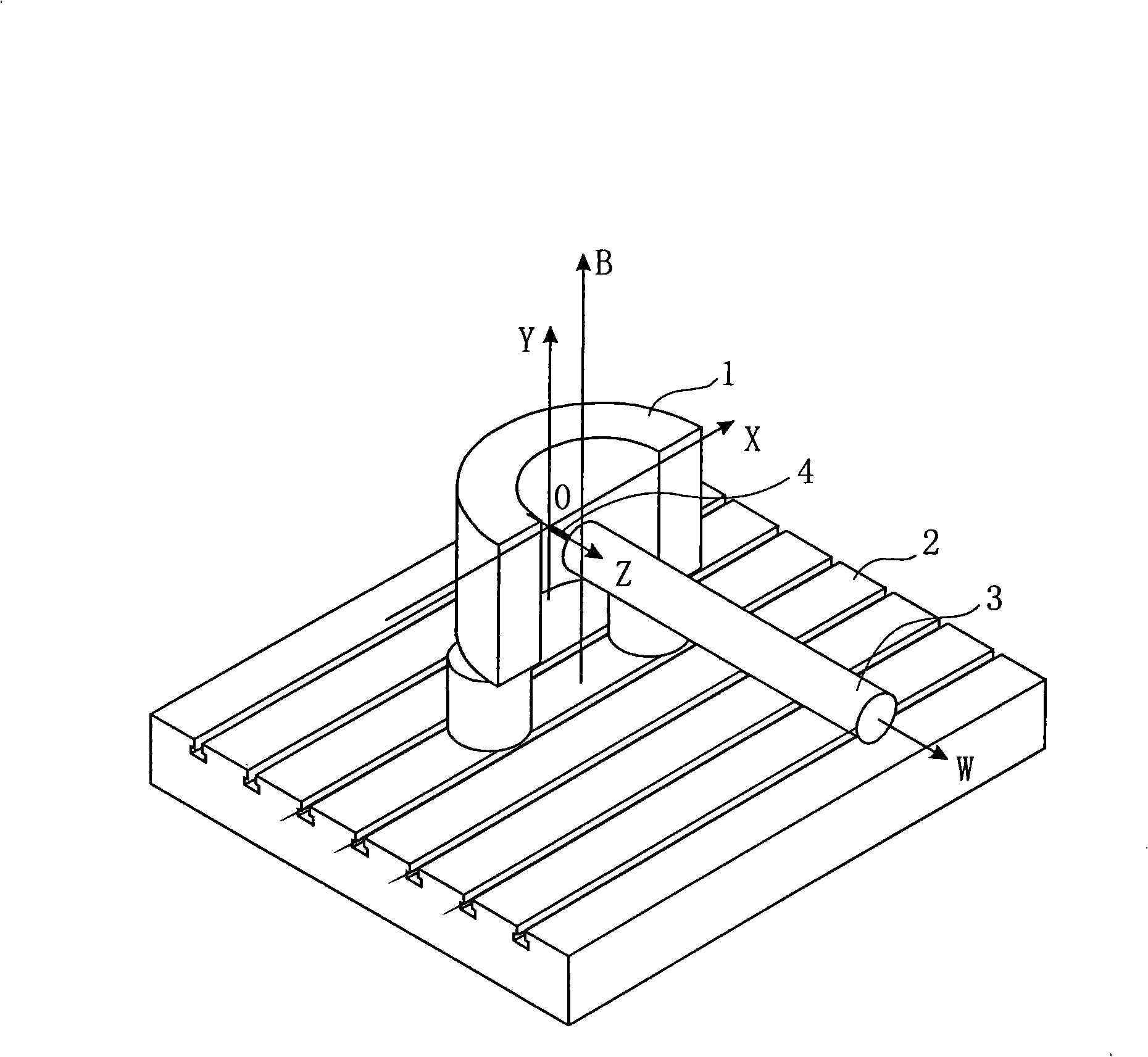

[0026] Such as figure 2 As shown, the bearing bush 1 is placed vertically on the turntable 2 of the CNC boring machine, and the inner surface of the bearing bush is adjusted to be concentric with the turntable 2 (same rotation center), so that the bearing bush 1 can rotate coaxially with the turntable 2.

[0027] In order to ensure the feasibility and convenience of CNC boring machine processing the 8-shaped oil tank with circular arc, the 8-shaped oil tank takes the center point O of the 8-shaped oil tank as the origin to establish a coordinate system XOYZ, and the 8-shaped oil tank in the coordinate plane XOY The center point O is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com