Installation fastening structure of vehicle overhead antenna

A technology for fastening structures and vehicle roofs, which is applied to antenna supports/installation devices, antennas, antenna components and other directions, and can solve the problems of adding nuts and antenna assembly assembly, complicated installation of overhead antennas, and difficult installation and fixation. To achieve the effect of easy installation and fixation, improve assembly stability, and simplify installation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A specific embodiment will be described in detail below in conjunction with the accompanying drawings.

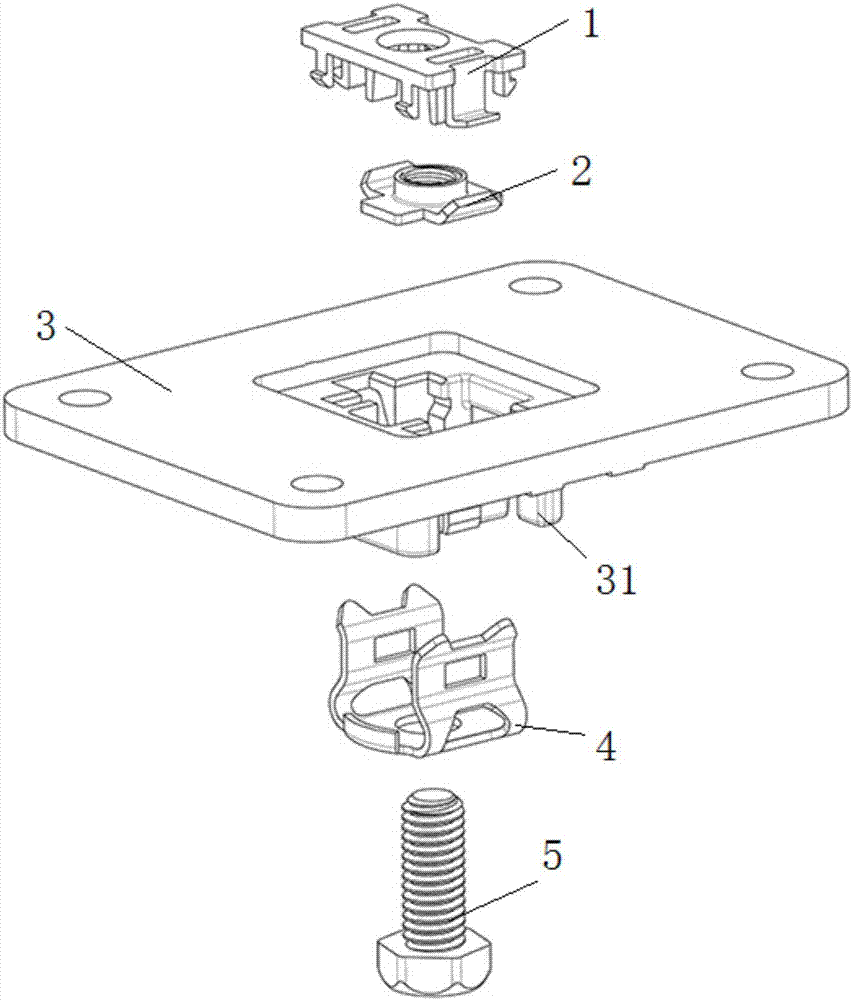

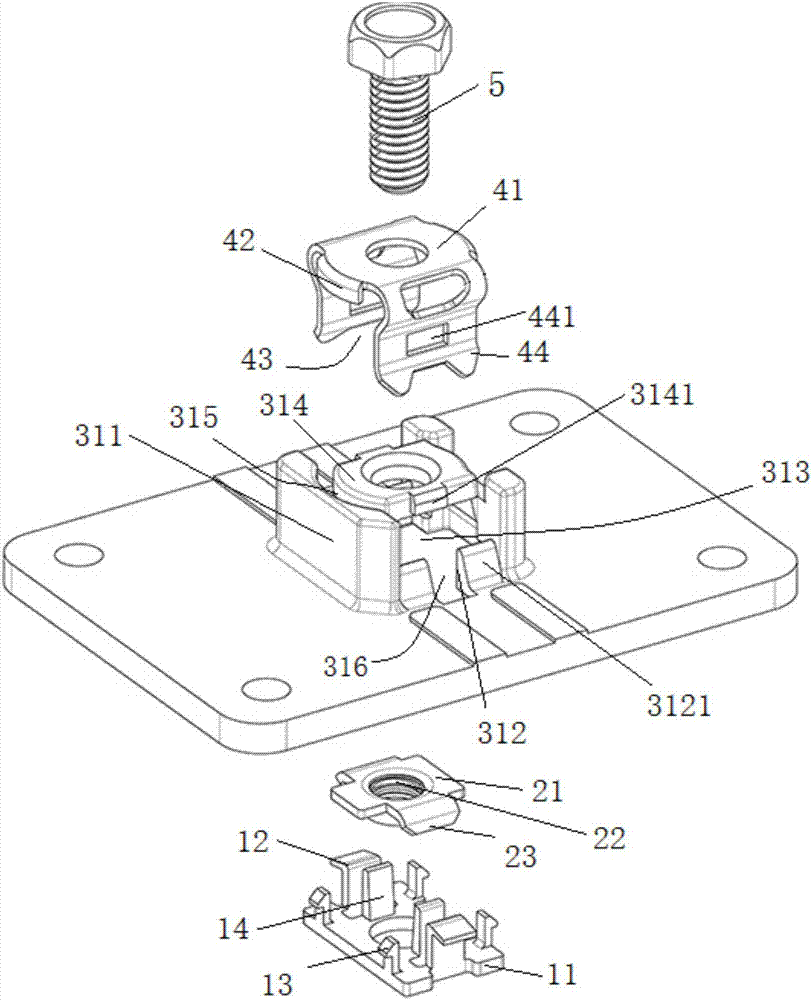

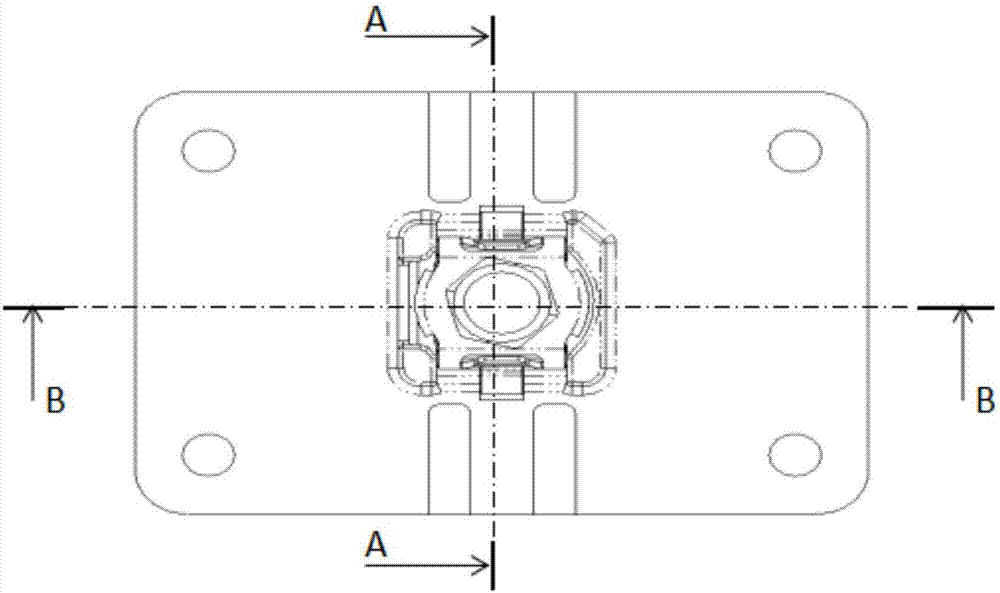

[0023] Please refer to figure 1 and figure 2 , a mounting and fastening structure for a vehicle overhead antenna, used for mounting the antenna in a mounting hole of a vehicle sheet metal, the mounting and fastening structure includes a buckle 1, a threaded support gasket 2, an antenna base 3, a catch Piece 4 and Bolt 5:

[0024] The buckle 1 includes a connecting bottom plate 11 , on which a through hole adapted to the bolt 5 is arranged; a plurality of hooks 13 and a plurality of support columns 14 are arranged on the lower surface of the connecting bottom plate 11 . In this embodiment, a hook 12 is provided at both ends of the connecting base 11 , two hooks 13 are provided at both sides, and two support columns 14 are provided at the middle.

[0025] The threaded support gasket 2 includes a threaded support gasket part 21 and a push top 23. The middle part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com