Assembly component and assembly method for crankshaft timing gear

A timing gear and assembly component technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult pressing, poor assembly stability, low accuracy, etc., to improve assembly stability and accuracy, reduce The effect of pressing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

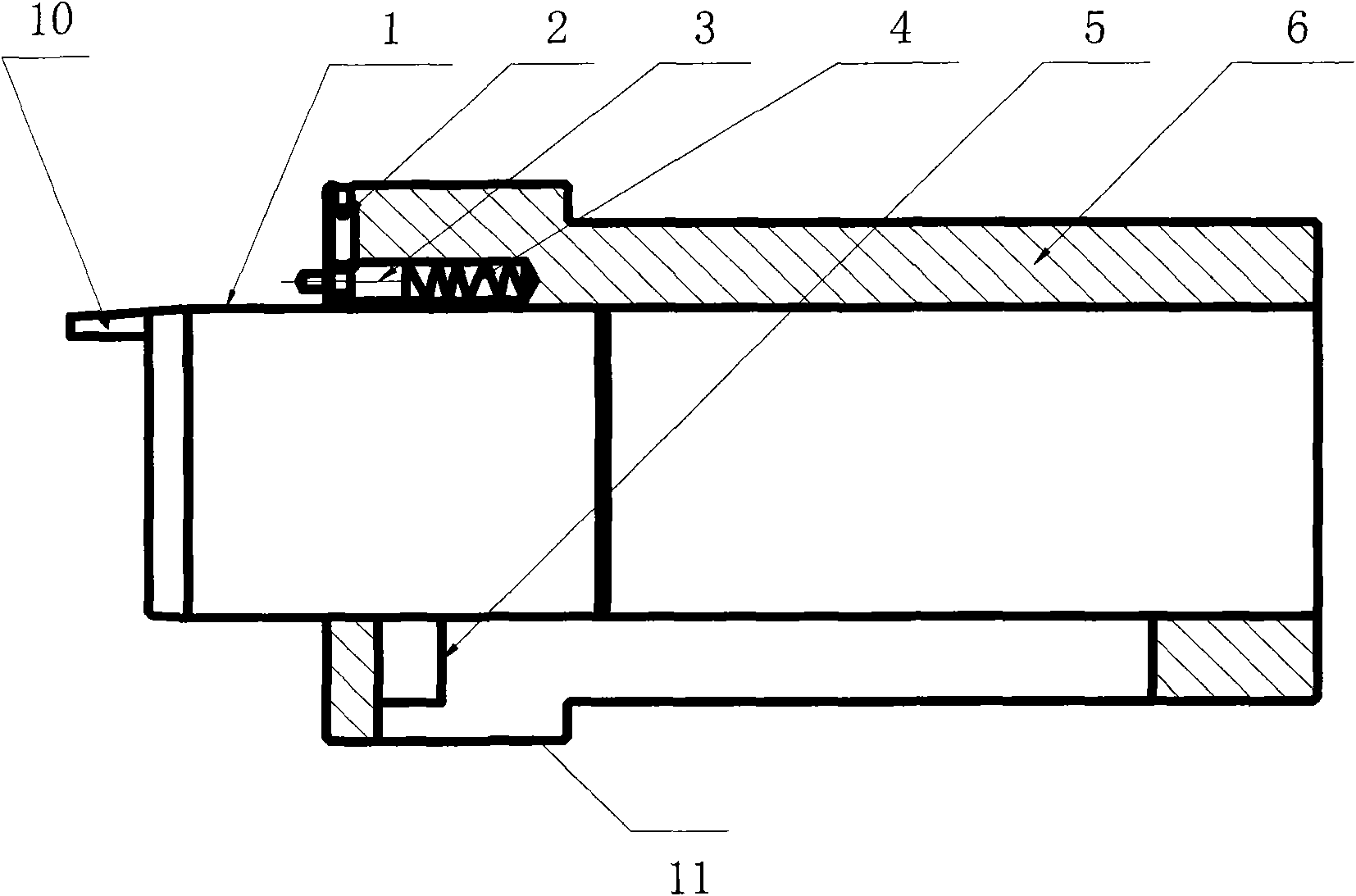

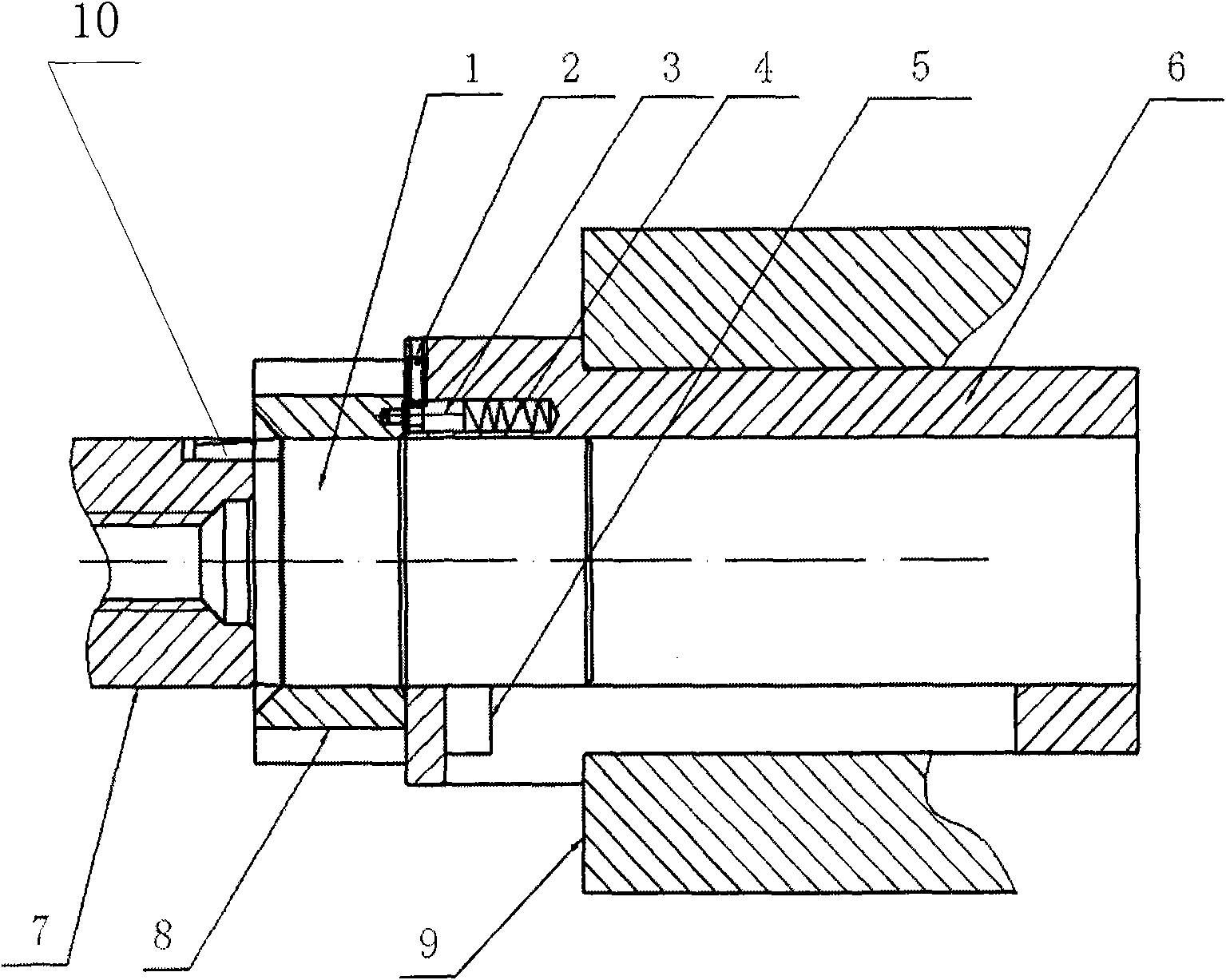

[0032] According to an embodiment of the present invention, a crankshaft timing gear assembly assembly is provided. Such as figure 1 and figure 2 As shown, this embodiment includes a guide shaft 1 and a guide sleeve 6 , wherein the guide sleeve 6 can be axially slidably fitted on the guide shaft 1 .

[0033] In this embodiment, on the guide shaft 1, a positioning key 10 can be provided at the end away from the guide sleeve 6, and the positioning key 10 is located at the bottom of the guide shaft; The pin 5 is located on the side of the guide shaft 1 and is used to limit the relative position between the guide shaft 1 and the guide sleeve 6 . On the guide sleeve 6, a positioning pin 3 may be provided at an end away from the guide shaft 1, and the positioning pin 3 is parallel to the guide shaft 1 and close to the guide shaft 1; a shoulder structure 11 is provided at an end close to the positioning pin 3, The shoulder structure 11 is arranged on the periphery of the guide sl...

Embodiment 2

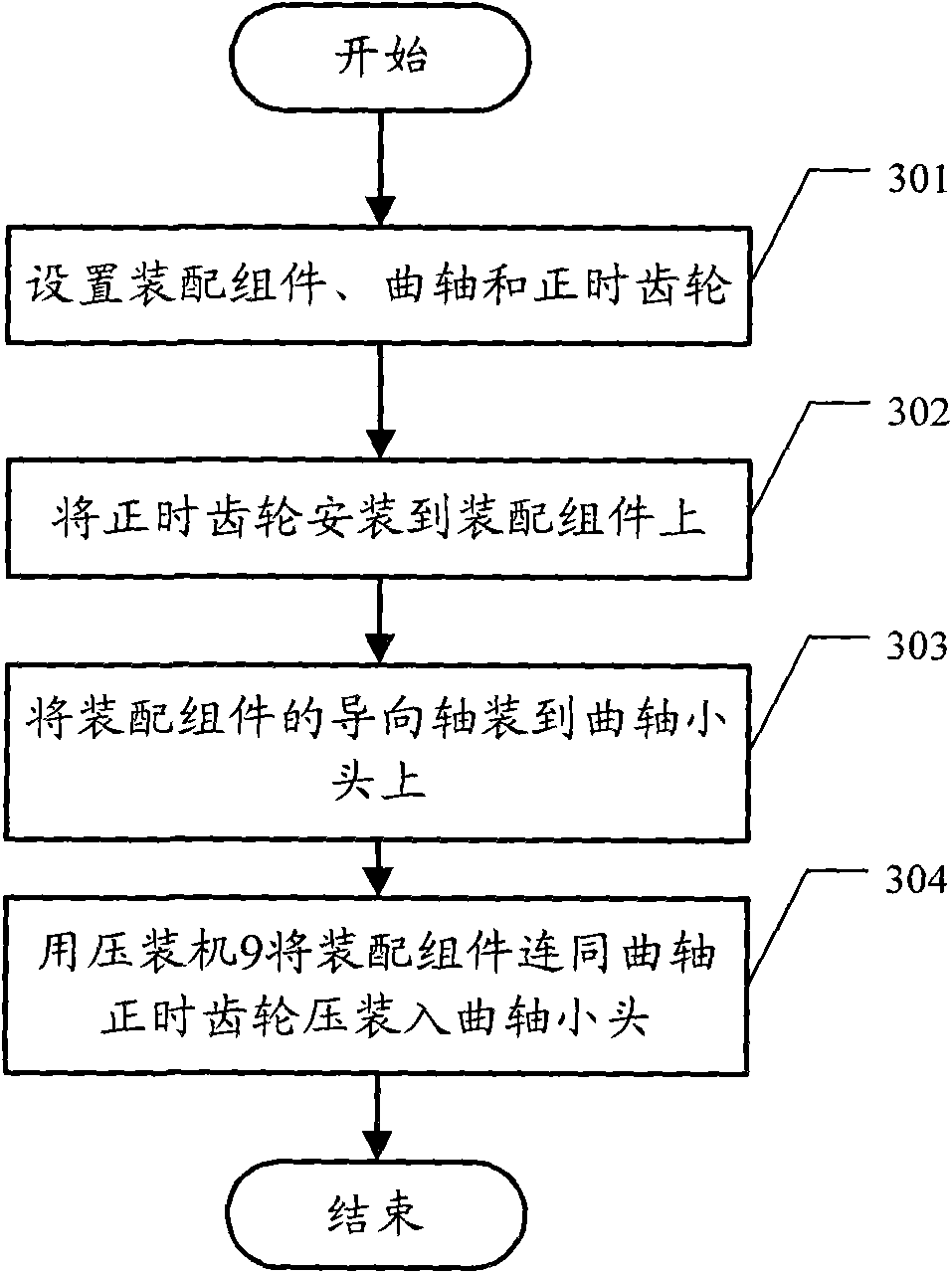

[0038] According to an embodiment of the present invention, a crankshaft timing gear assembly method is provided. Such as Figure 1-Figure 3 As shown, this embodiment includes:

[0039] Step 301: Set the assembly components, and set the crankshaft and timing gear 8 accordingly according to the assembly components; specifically:

[0040]The assembly assembly, that is, the crankshaft timing gear assembly assembly includes a guide shaft 1 and a guide sleeve 6 sleeved on the guide shaft 1 in an axial sliding manner, wherein a raised positioning key is provided at the end of the guide shaft 1 away from the guide sleeve 6 10. The positioning key 10 is located at the bottom of the guide shaft 1. The positioning key 10 can be used to fix the relative position between the assembly assembly and the small end of the crankshaft 7; Position pin 5 can be used to limit the relative position between guide shaft 1 and guide sleeve 6; An end near guide key 10 is provided with guide pin 3 at g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com