Velocimeter assembling equipment

A technology for assembling equipment and tachometers, which is used in metal processing equipment, climate sustainability, and final product manufacturing. The difficulty of installation and the effect of improving the efficiency of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described in detail below through examples and in conjunction with the accompanying drawings.

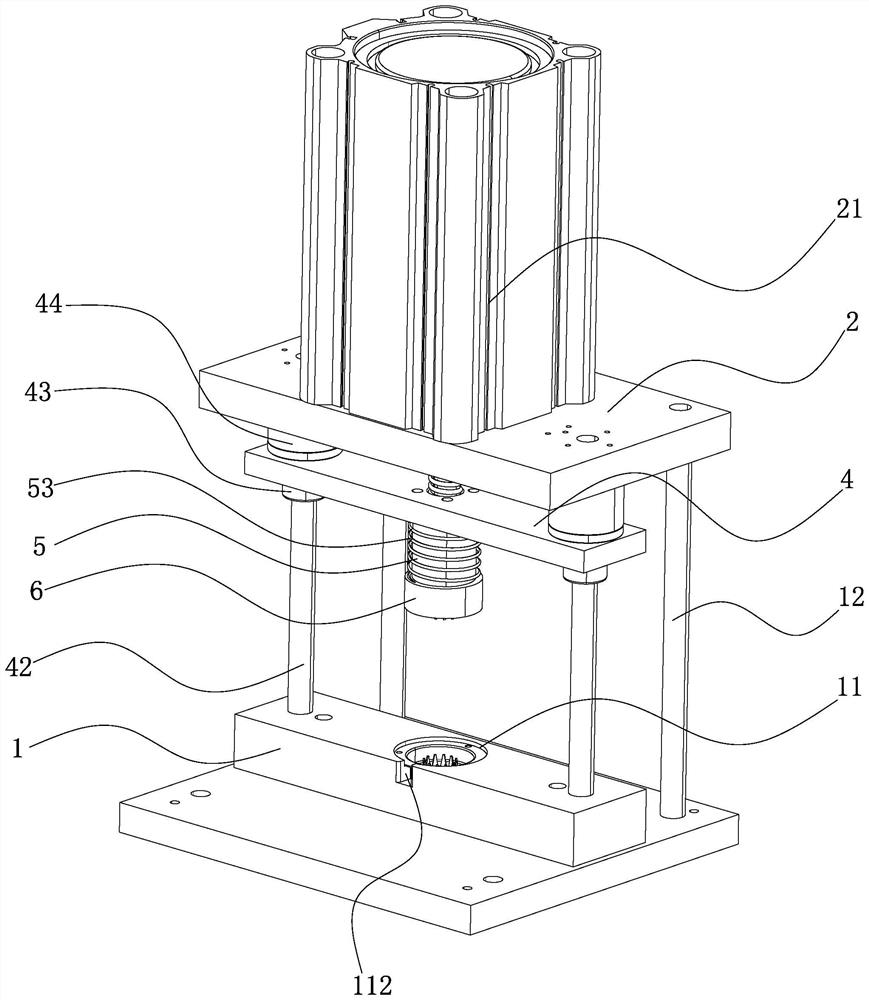

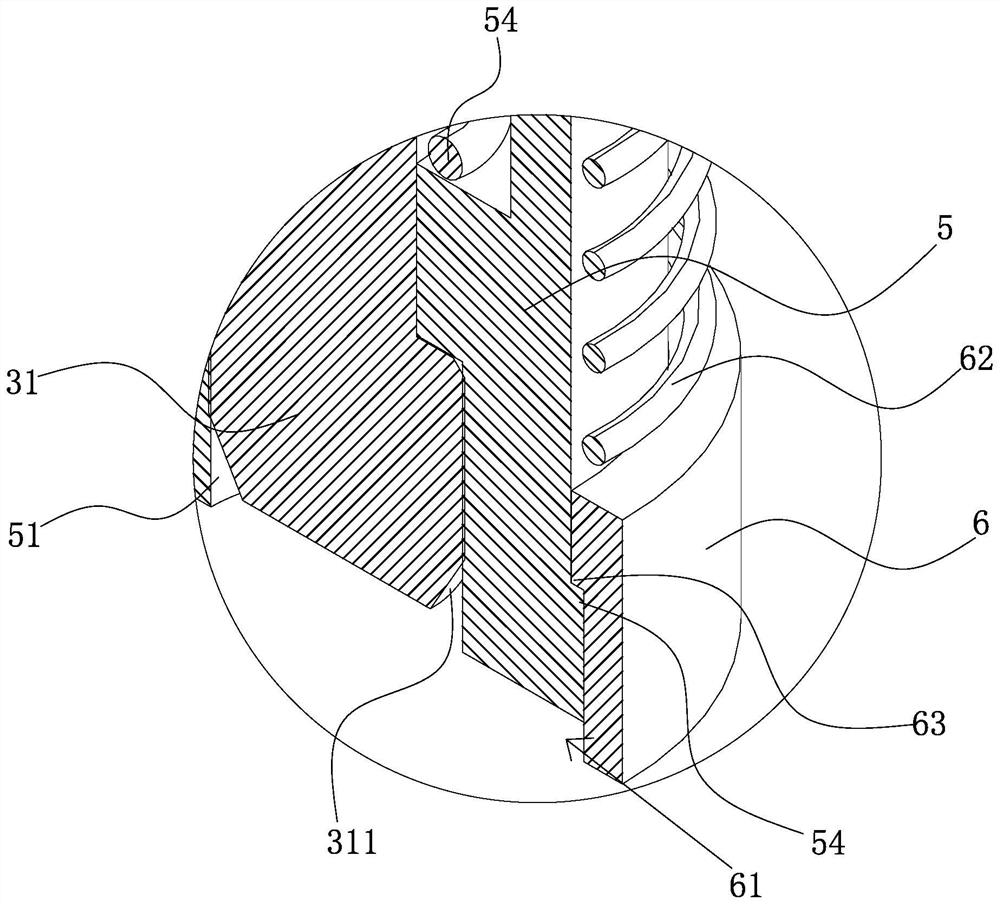

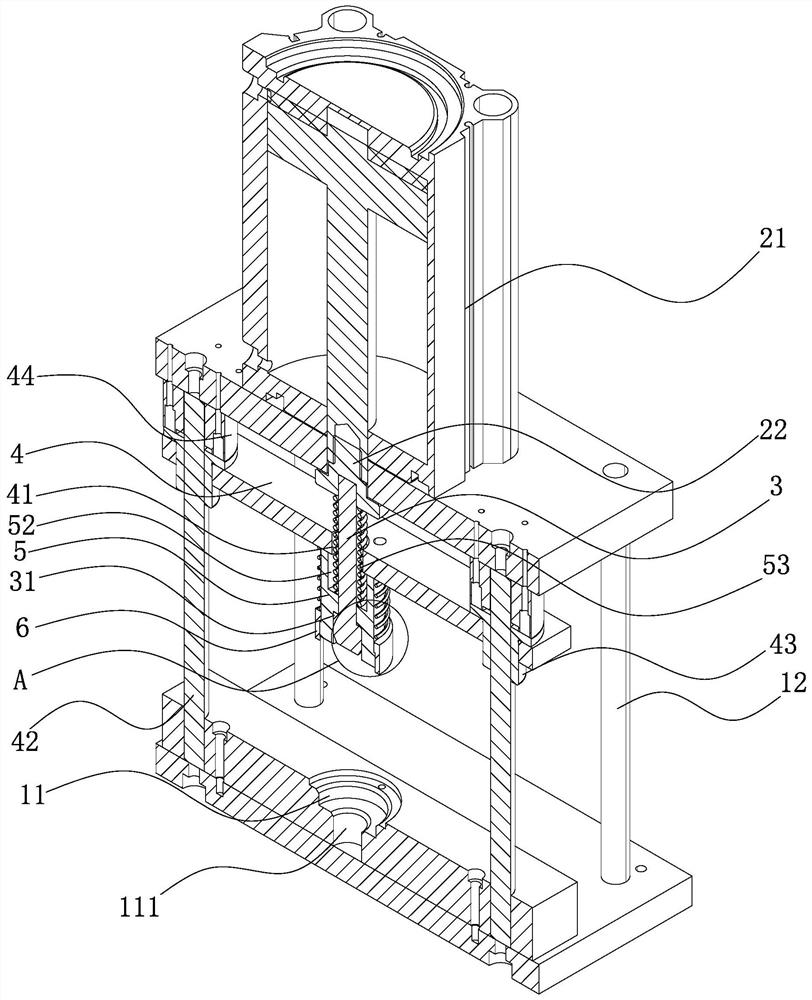

[0020] like Figure 1-2 As shown, a speed measuring device assembling equipment includes a base 1 and a top plate 2 arranged above the base 1, and a vertical pressure column 3 is arranged between the base 1 and the top plate 2 and can be moved up and down, and the bottom end of the pressure column 3 There is a pressure head 31, the top of the base 1 is corresponding to the lower part of the pressure column 3 and there is a positioning groove 11 for placing the lower pole claw workpiece of the speedometer. Plate 4, the outer circumference of the pressure column 3 is provided with a guide seat 5 connected with the bottom of the movable plate 4, and the outer wall of the guide seat 5 is provided with a clamping sleeve 6 that is used to clamp the upper pole claw workpiece of the speedometer and can move up and down,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com