Vacuum pump motor output shaft installation device

An installation device and output shaft technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of large shaft runout, scratches on the surface of the output shaft, reducing the pass rate of press fitting, etc. The effect of reducing the probability of beating, reducing production costs, and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

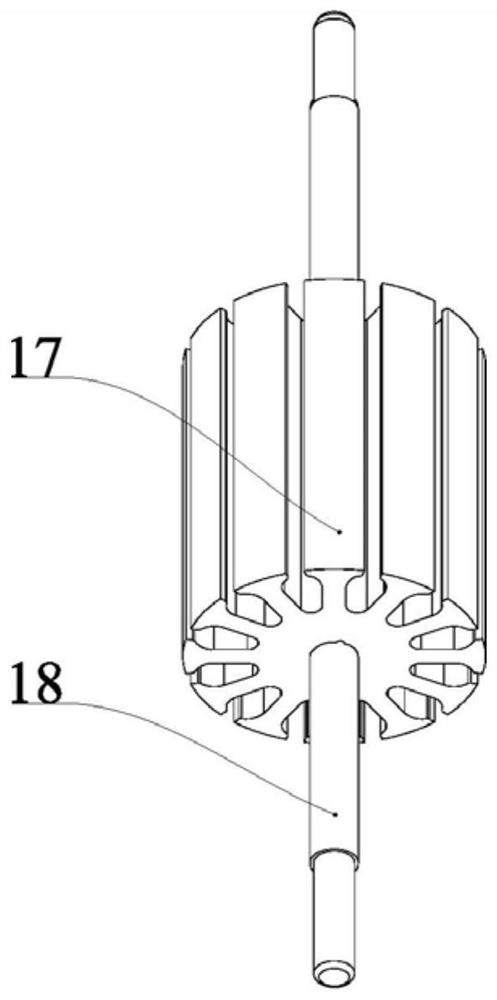

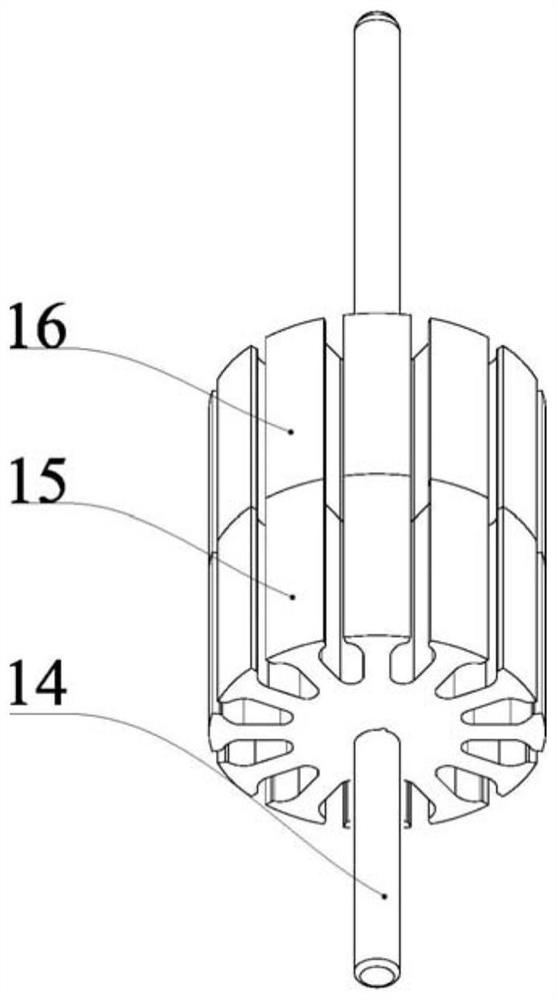

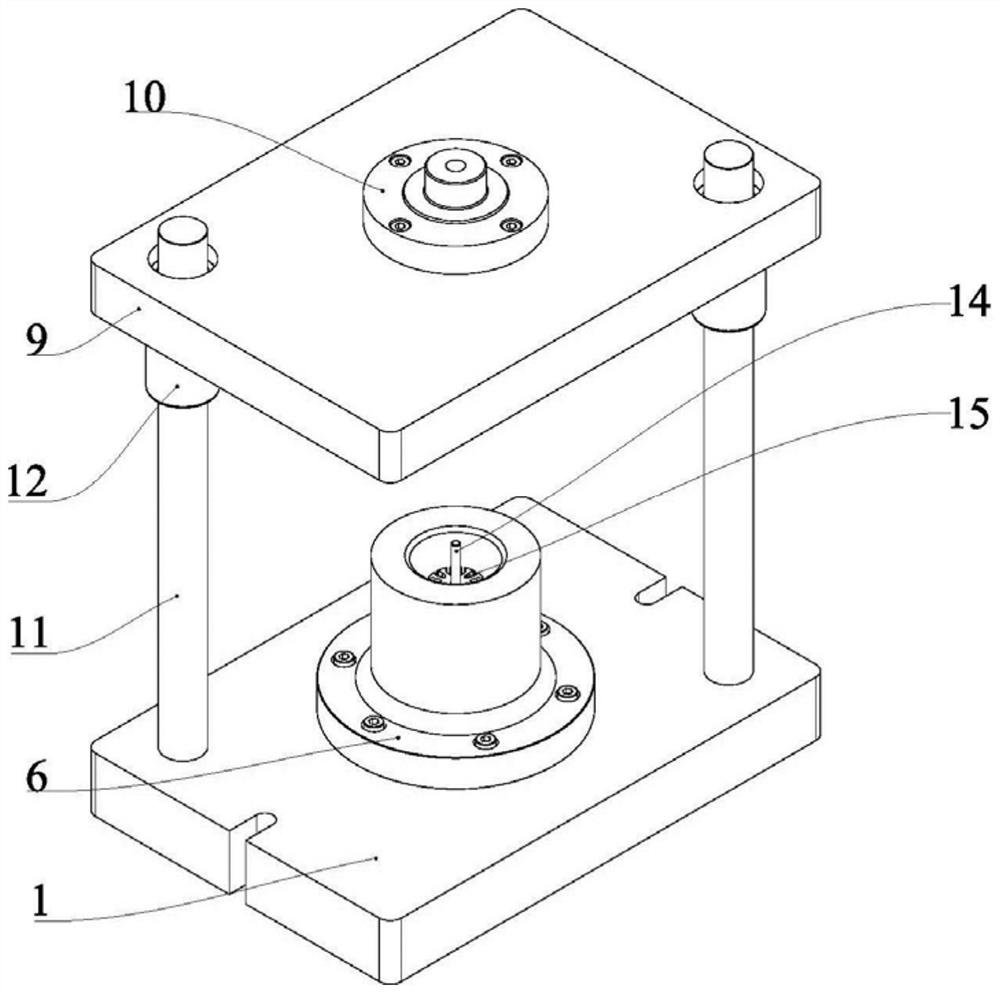

[0031] Embodiment one is basically as Figure 2 to Figure 5 Shown: combined Figure 3 to Figure 4 , the vacuum pump motor output shaft installation device, including the lower mold base 1, the flange plate 6, the guide post 11, the guide sleeve 12, the upper mold base 9, the floating mold handle 10 and the pressure head 7, and the flange plate 6 is fixedly connected to the lower mold base 1, the guide post 11 connects the upper die base 9 and the lower die base 1, the upper die base 9 can move up and down along the guide post 11, the guide sleeve 12 fits on the guide post 11, and the guide sleeve 12 is located between the upper die base 9 and the lower die base 1. Between the lower mold bases 1 , the lower surface of the upper mold base 9 is fixedly connected with the indenter 7 , and the upper surface of the upper mold base 9 is connected with the floating mold handle 10 .

[0032] combine Figure 5 , the flange 6 is provided with a cavity for lamination forming, the pressu...

Embodiment 2

[0040] Embodiment two is basically as Image 6 As shown: Embodiment 2 is based on Embodiment 1. The difference is that the shaft mounting seat 5 is slidably connected in the cavity of the flange 6, and the ejector rod 19, the first wedge rod 20, and the second wedge rod 21 are added. And the third wedge bar 22.

[0041] The ejector rod 19 is fixedly connected to the bottom of the upper die base 9, and a cavity is opened in the lower die base 1, and the first wedge rod 20, the second wedge rod 21 and the third wedge rod 22 are slidably connected in the cavity, and the ejector rod 19 is used for When the first wedge rod 20 is pushed, the first wedge rod 20 meshes with the second wedge rod 21, the left side of the second wedge rod 21 meshes with the third wedge rod 22, and the top end of the third wedge rod 22 abuts against the plug 3, A first spring is connected between the first wedge rod 20 and the cavity wall, and a second spring is connected between the second wedge rod 21 ...

Embodiment 3

[0043] Embodiment three such as Image 6 As shown: Embodiment 3 is based on Embodiment 2. The difference is that the coaxial installation mechanism of the mounting seat 28 includes a sliding seat 23 installed on the frame, and the sliding seat 23 is fixedly connected with a support rod 26. Have threaded hole, threaded hole internal thread is connected with locating rod 29, is also slidably connected with motor 32 mounting table 31 on the frame, has the positioning hole for locating rod 29 insertion in the motor 32 mounting table 31, and slide seat 23 inner rotation Connected with driving screw rod 25, on the support rod 26 slidingly connected with positioning frame 27, driving screw rod 25 is threadedly connected with positioning frame 27, is fixedly connected with the first cylinder 33 and the second cylinder 34 on the frame, the output shaft of the first cylinder 33 14 is fixedly connected with the sliding seat 23, and the output shaft 14 of the second air cylinder 34 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com