A method for preparing high-density biomass briquettes

A technology for briquetting fuel and biomass, applied in the directions of biofuel, waste fuel, fuel, etc., can solve the problems of increased cost of biomass briquette fuel, unfavorable application promotion, huge equipment development cost, energy consumption cost and maintenance cost, etc. Difficulty in compression molding, strong operability, and the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

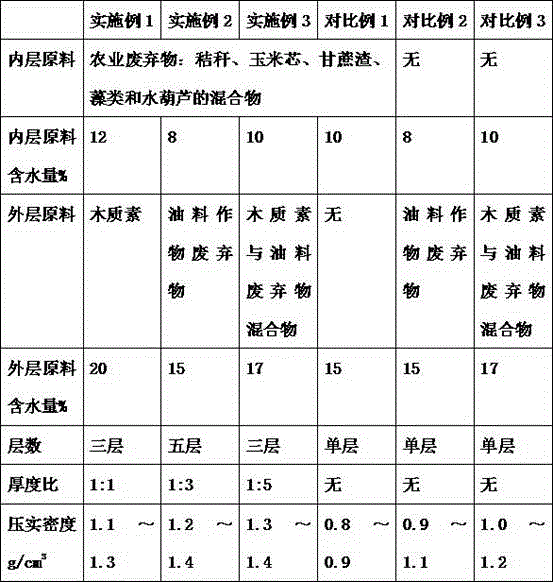

Examples

preparation example Construction

[0026] A method for preparing a high-density biomass briquette, wherein the high-density biomass briquette has a layered structure, comprising the steps of:

[0027] The first step, raw material pretreatment, respectively select agricultural waste as the inner layer raw material, and lignin and / or oil crop waste as the outer layer raw material. The agricultural waste includes straw, corn cob, bagasse, algae and water hyacinth The mixture of one or more of them, the lignin includes one or more of wood blocks, sawdust and bark, and the oil crop waste includes cottonseed, hempseed and tung tree One or more than one mixture, the inner layer raw material and the outer layer raw material are crushed, dried and sieved respectively, the mesh number of the outer layer raw material is 100-200 mesh, and the mesh number of the inner layer raw material is 10-60 mesh To obtain the inner layer raw material powder and the outer layer raw material powder to be processed;

[0028] The second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com