Three-dimensional metal-based Printed Circuit Board (PCB) assembly structure, corresponding light-emitting lamp and manufacturing method

A technology for PCB circuit boards and metal-based circuit boards, which is applied in three-dimensional rigid printed circuit boards, printed circuit manufacturing, and structural connection of printed circuits. ability, limit the design and manufacture of light-emitting lamps, etc., to achieve the effect of facilitating mass mechanized production, improving assembly stability and mechanical strength, and convenient and fast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

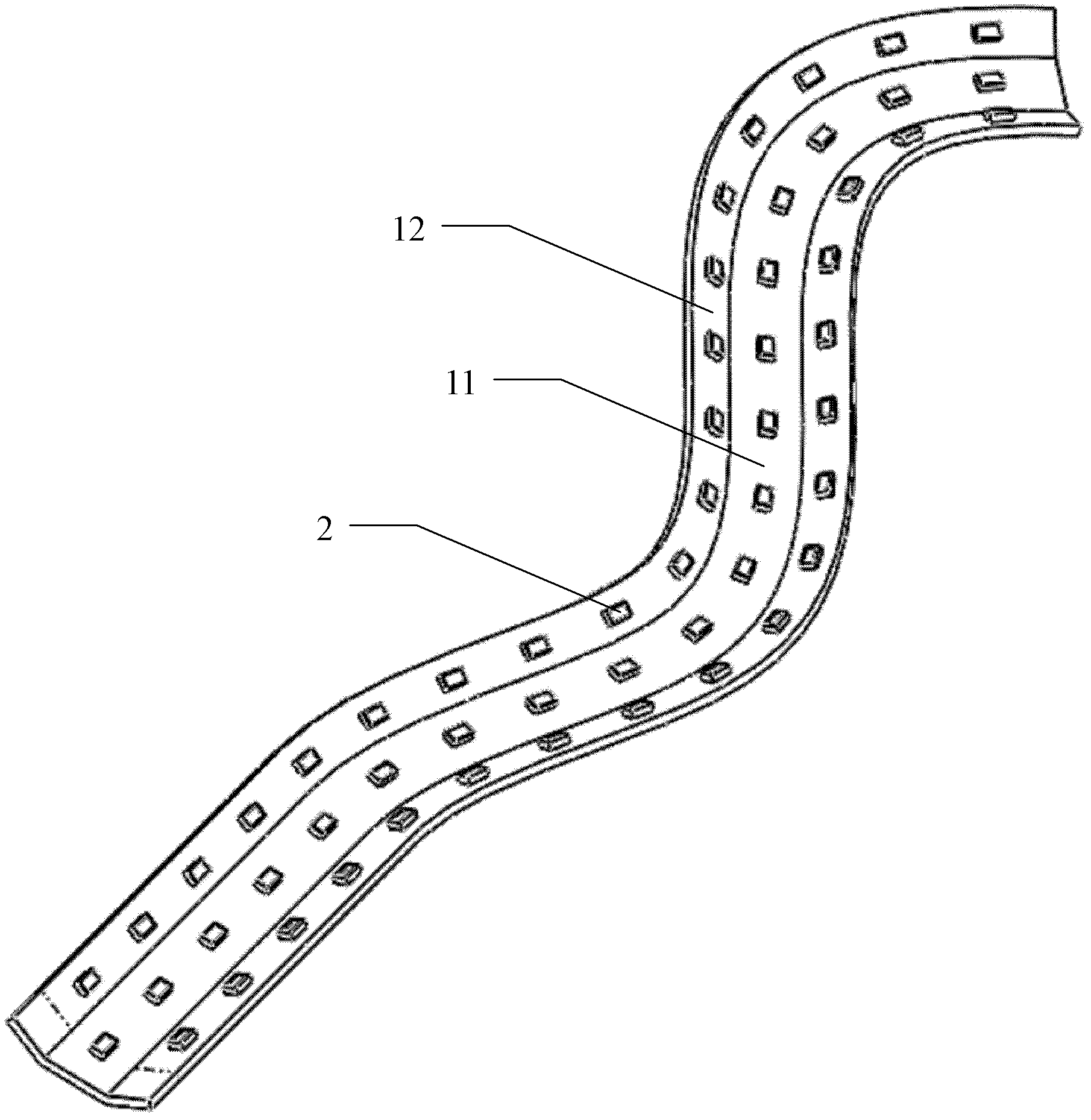

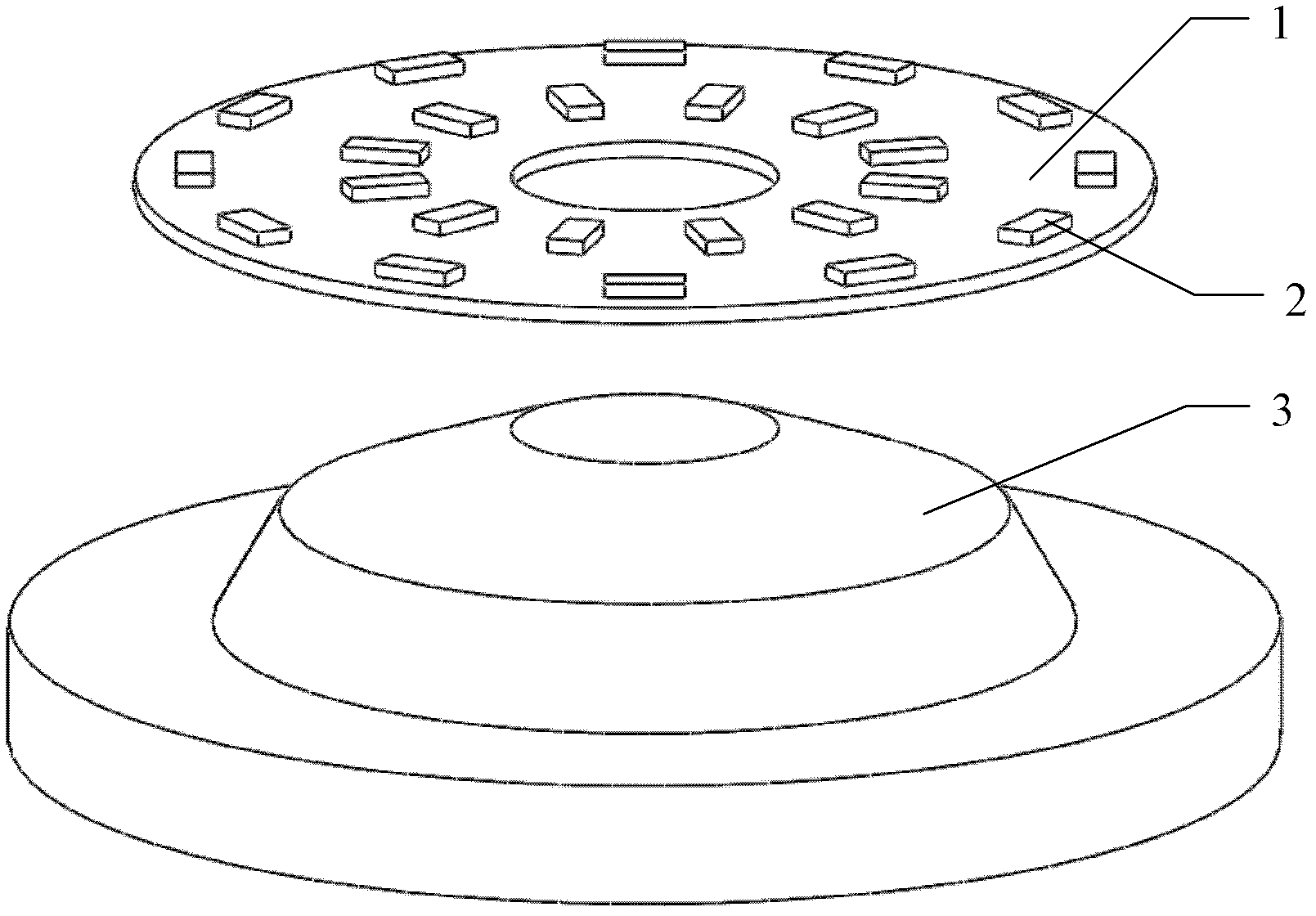

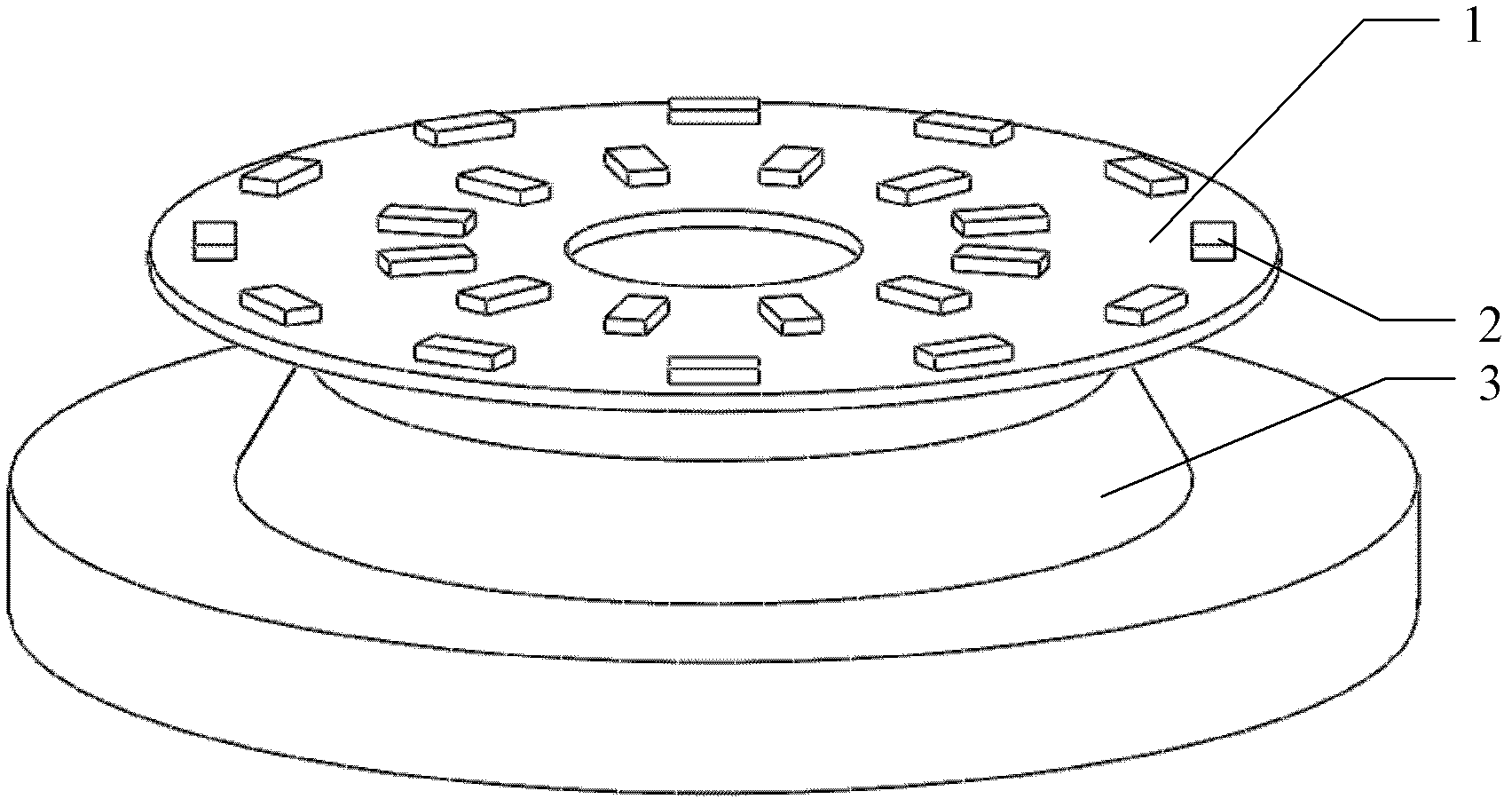

[0040] see figure 1As shown, the three-dimensional metal-based PCB circuit board assembly structure in the light-emitting lamp, wherein the assembly structure consists of a single continuous metal-based circuit board 1 and several light-emitting elements 2 arranged on the upper surface of the metal-based circuit board 1 Each light-emitting element 2 mentioned above is connected to the metal-based circuit board 1, and the parts of the metal-based circuit board 1 with the light-emitting elements 2 are not on the same plane or on the same continuous curved surface, and the metal The base circuit board 1 has a three-dimensional structure.

[0041] Among them, the metal-based circuit board includes:

[0042] (1) Metal-based circuit mother block 11, in which the various parts with light-emitting elements 2 can be on the same plane or on the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com