Automatic assembly device for starter one-way device

An assembly device and one-way device technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of poor workpiece quality, high work intensity, low assembly accuracy, etc., achieve low manufacturing cost, convenient on-site operation, The effect of improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

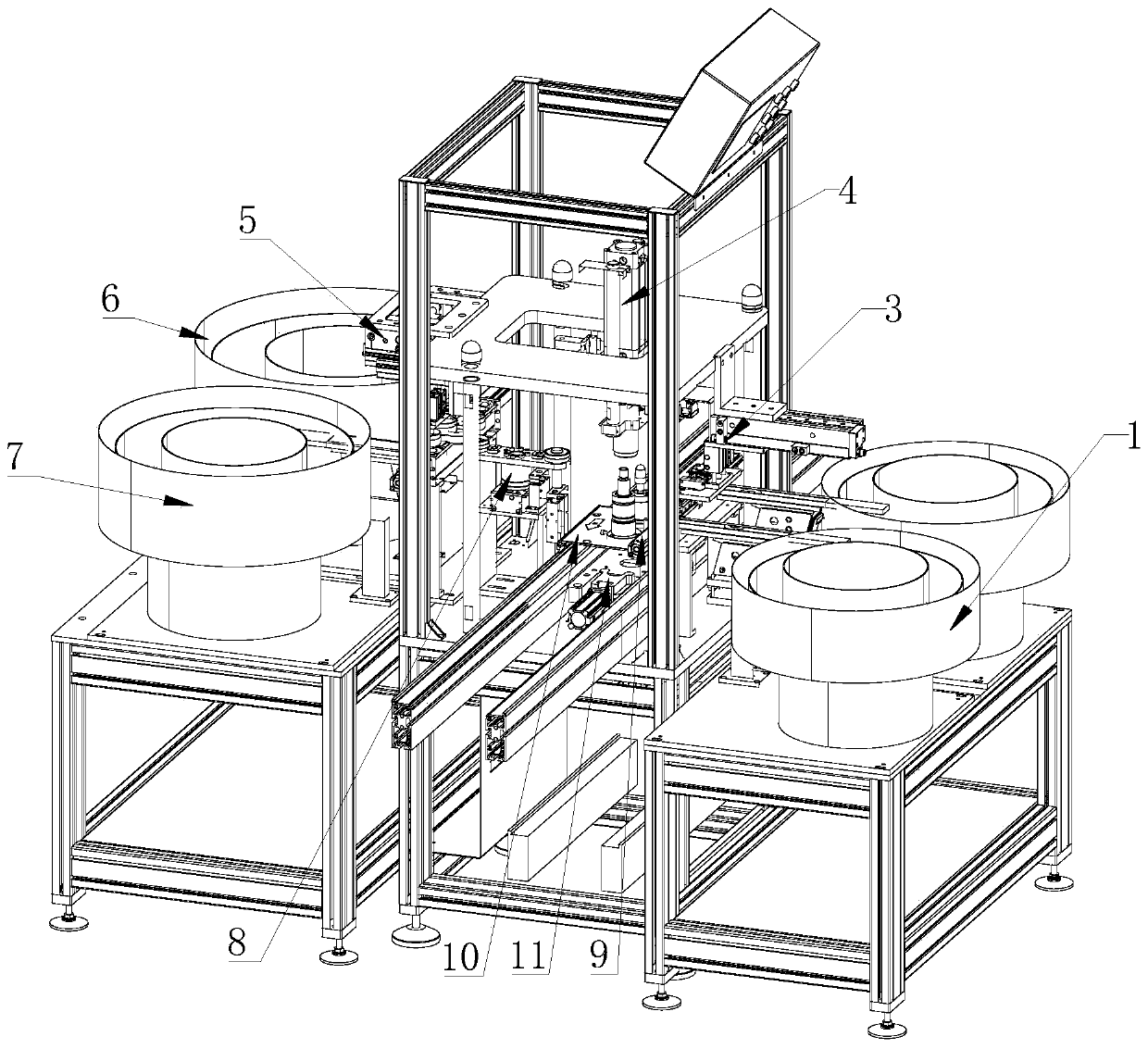

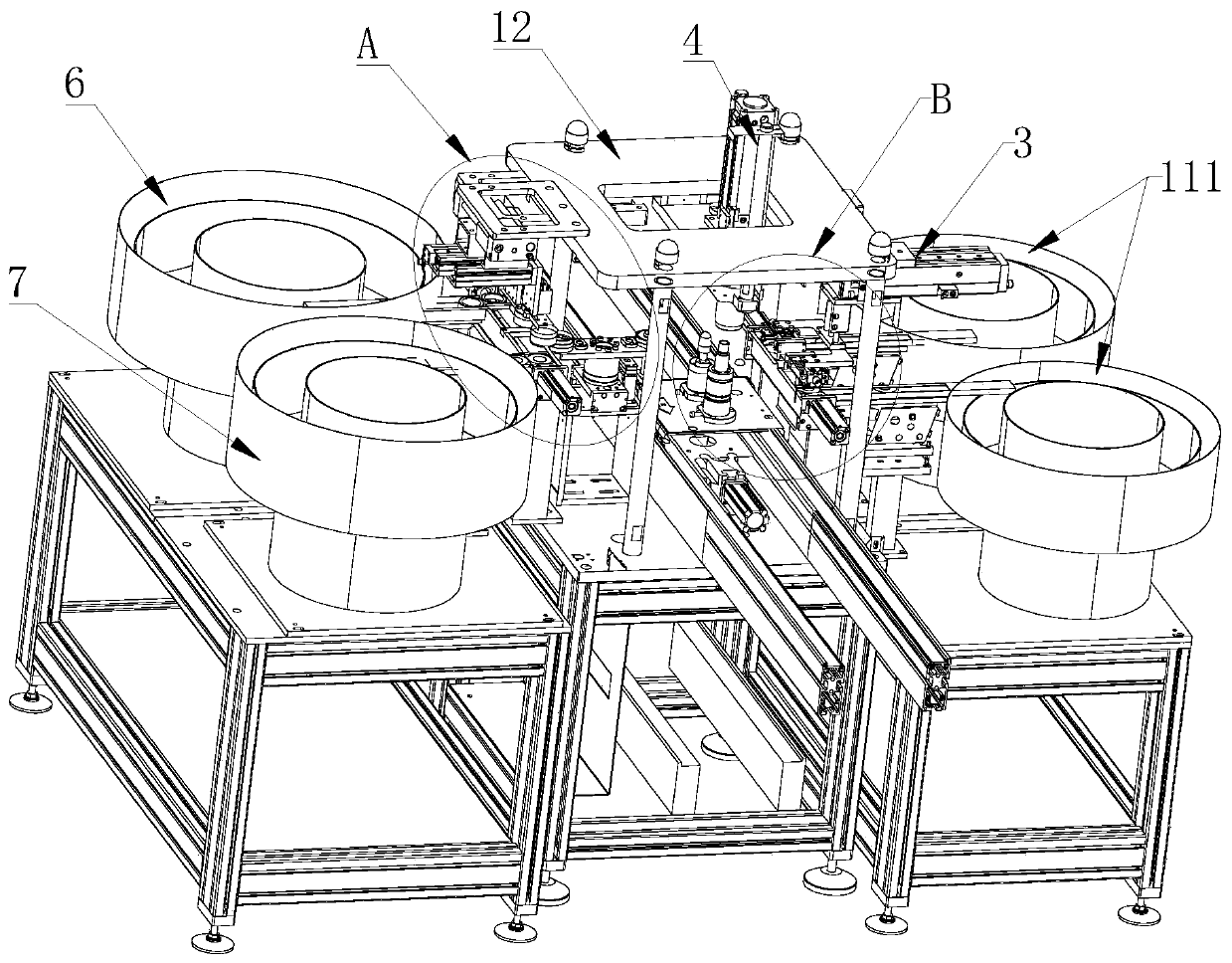

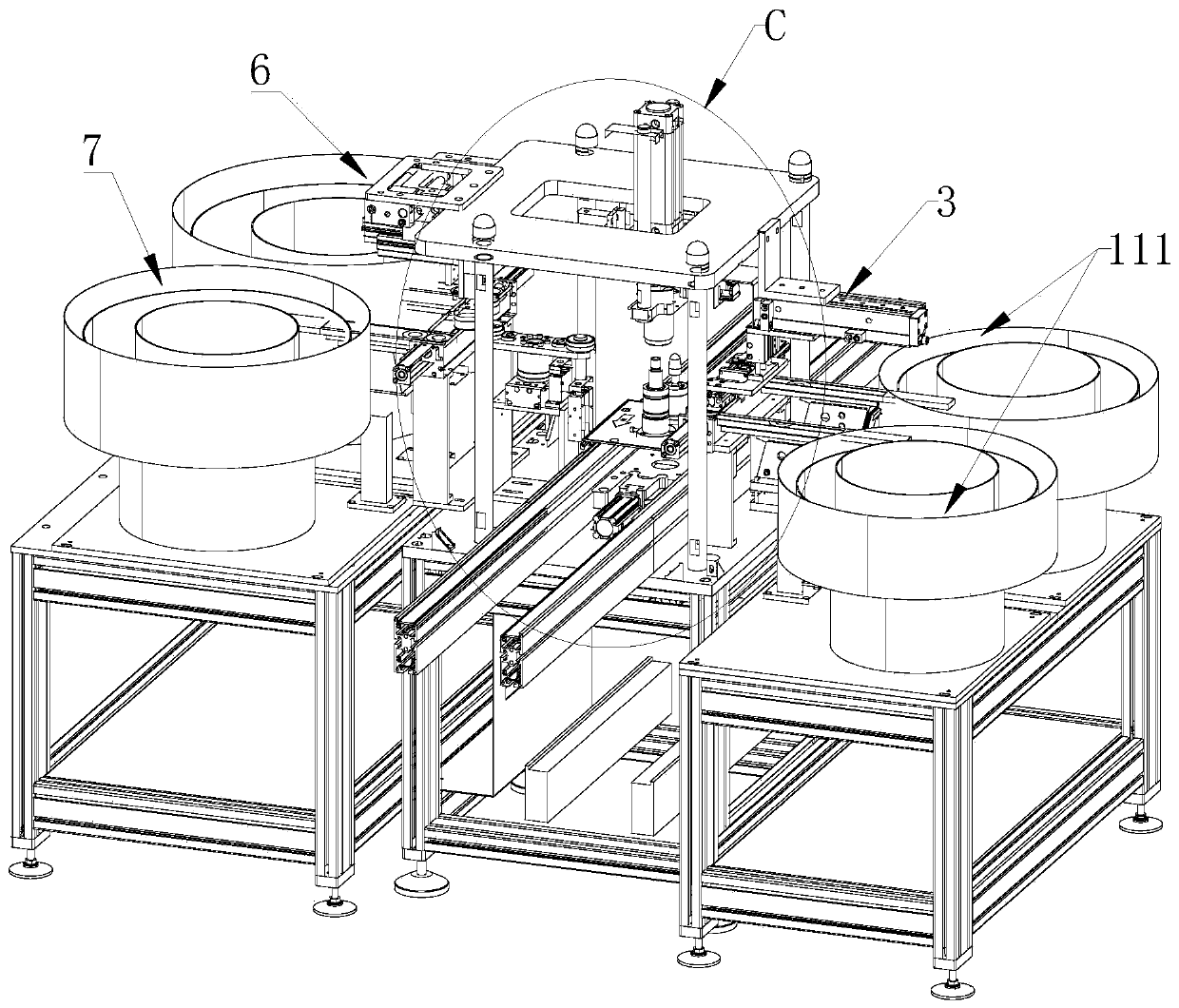

[0025] Such as Figure 1-7 As shown, the present invention relates to an automatic assembly device for starter checker 101, including a first assembly mechanism integrated on the frame for assembling the semicircular gasket 112, for assembling the full circular gasket 71 and the cover 61 The second assembly mechanism, the operating mechanism for transferring and positioning the assembly plate 10 fixed with the one-way device 101 and the automatic control center for controlling the operation of each component;

[0026] The first assembly mechanism includes a semicircular pad 112 discharging mechanism 1, a first displacement mechanism 9 and a semicircular pad 112 assembly manipulator;

[0027] The second assembly mechanism includes a full-circle pad 71 discharge mechanism, a cover 61 discharge mechanism, a second displacement mechanism 9, a grabbing mechanism, a moving rotation mechanism 8 and a press-fit mechanism 4;

[0028] The operating mechanism includes a transmission mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com