Automated assembling machine for solenoid coil

An electromagnetic coil and assembly machine technology, applied in the field of machinery, can solve the problem that the conveying direction of the magnetic core is not easy to ensure the magnetic core, etc., and achieve the effects of high practical value, high assembly stability, and high degree of automatic vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

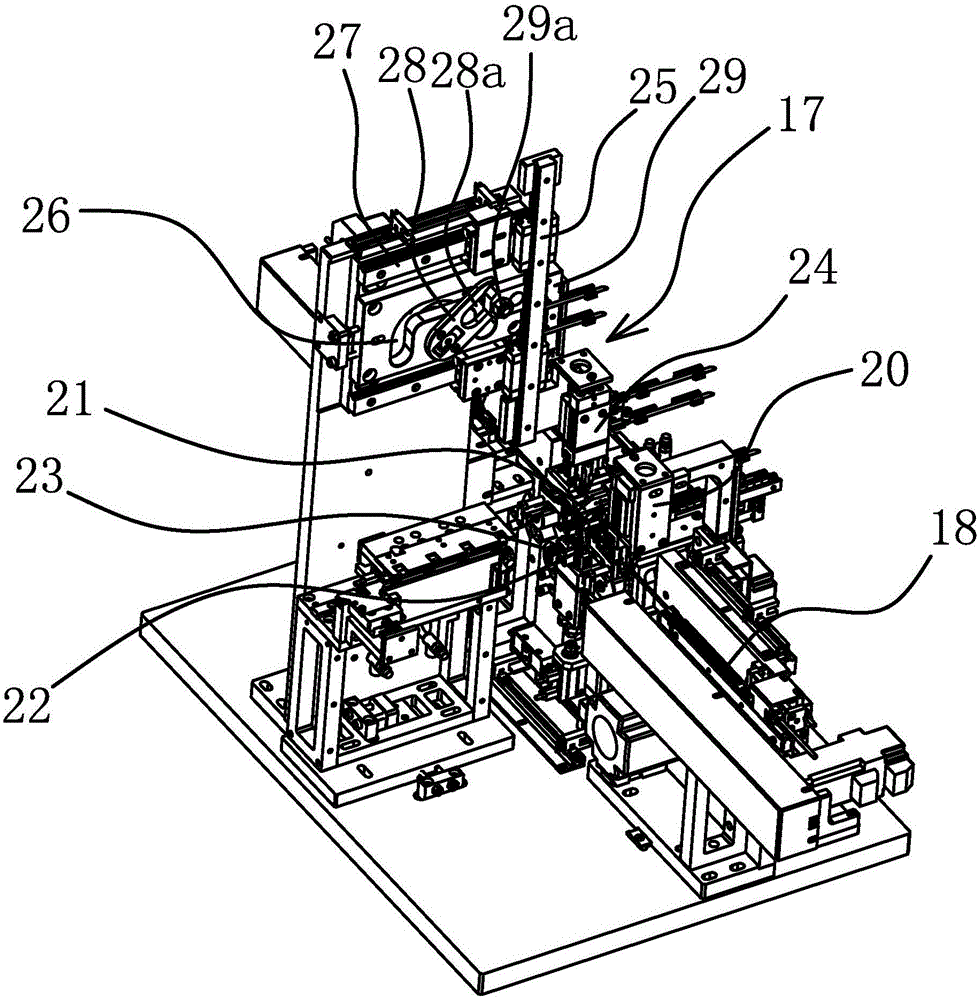

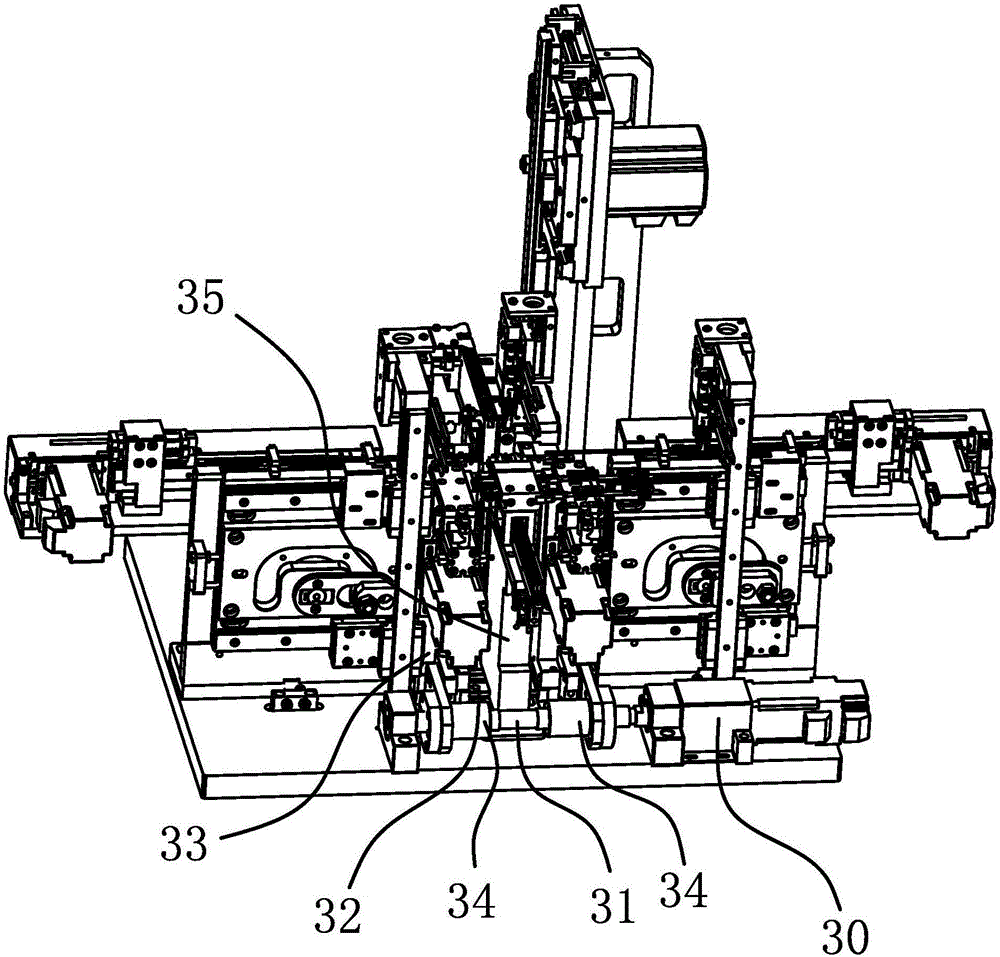

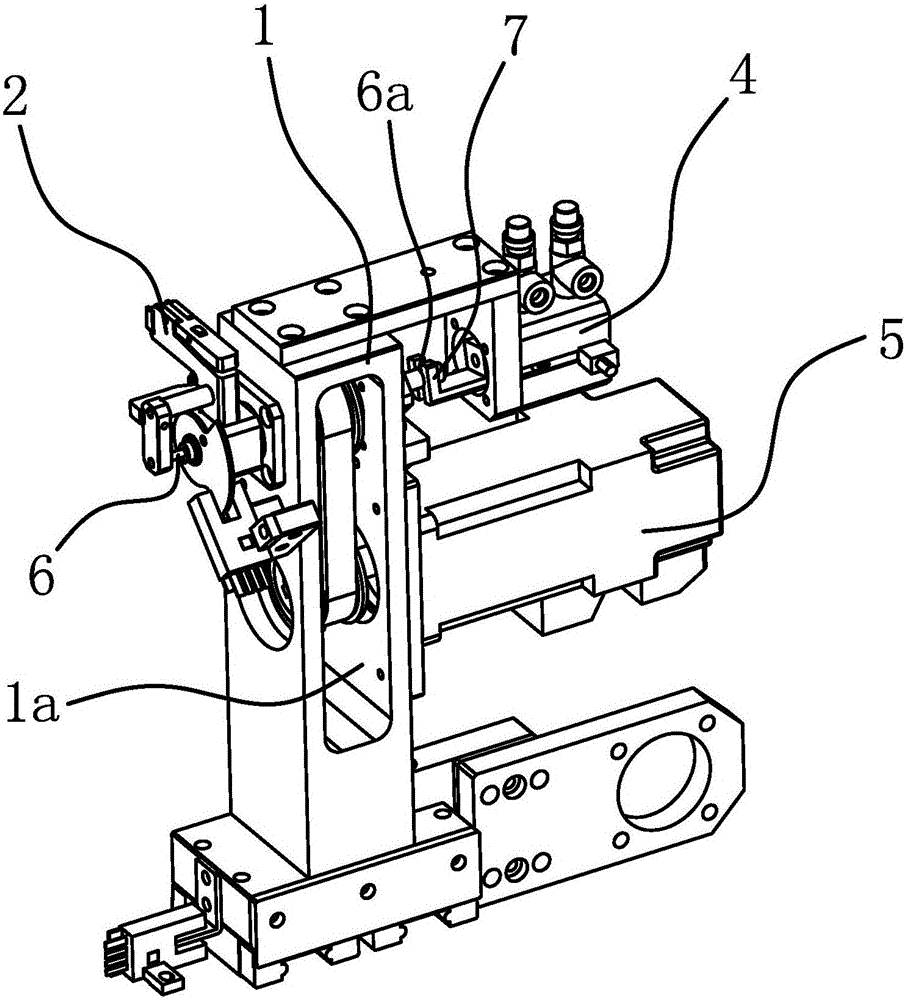

[0043] Such as figure 1 As shown, the automatic electromagnetic coil assembly machine includes a bracket 35, the bracket 35 has an assembly for assembling the electromagnetic coil, and the upper part of the assembly has a manipulator 17 for conveying the coil. The left and right sides of the accessories have clamping parts 2 for transporting magnetic cores, and the support 35 also has a storage tank 18 for storing magnetic cores. There is also a gap between the storage tank 18 and the clamping parts. There is a conveying member 20 and the conveying member 20 can transport the magnetic core at the storage tank to the clamping member 2 in an orderly manner. The above-mentioned clamping member 2, the storage tank 18 and the conveying member 20 form a magnetic core conveying unit. The number of magnetic core conveying units is two and symmetrically arranged on both sides of the assembly. The above two clamping parts 2 are connected through a synchronous driving mechanism and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com