Axial flow impeller machine design method and blade

A technology of impeller machinery and design method, which is applied in the direction of mechanical equipment, reaction engines, blade support elements, etc., and can solve the problems of poor cavitation resistance and low efficiency of axial flow impellers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

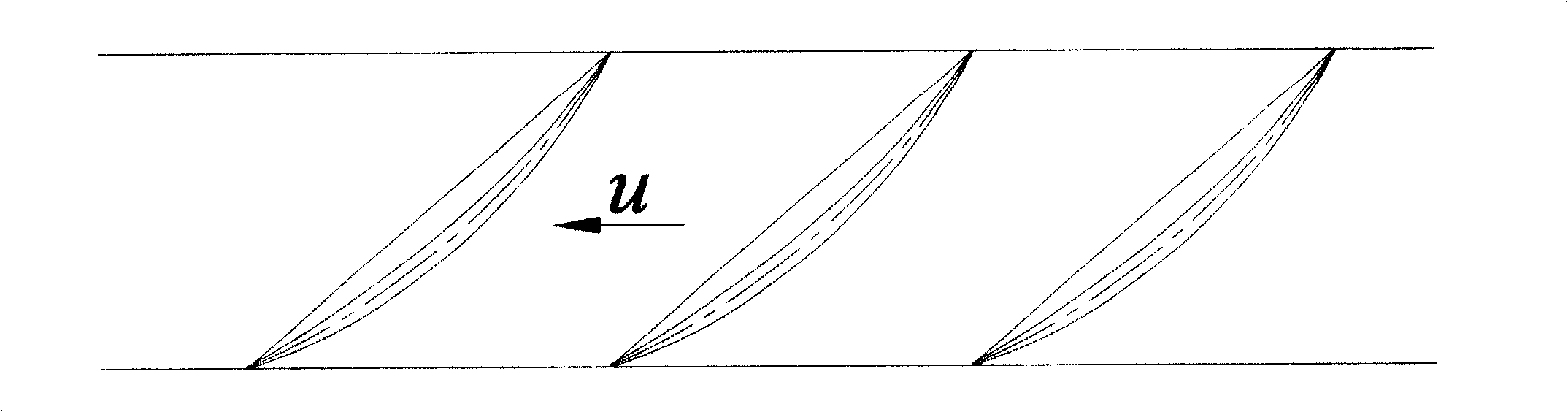

[0120] The details of the embodiments of the present invention will be described below by taking an axial-flow water pump as an example according to the accompanying drawings.

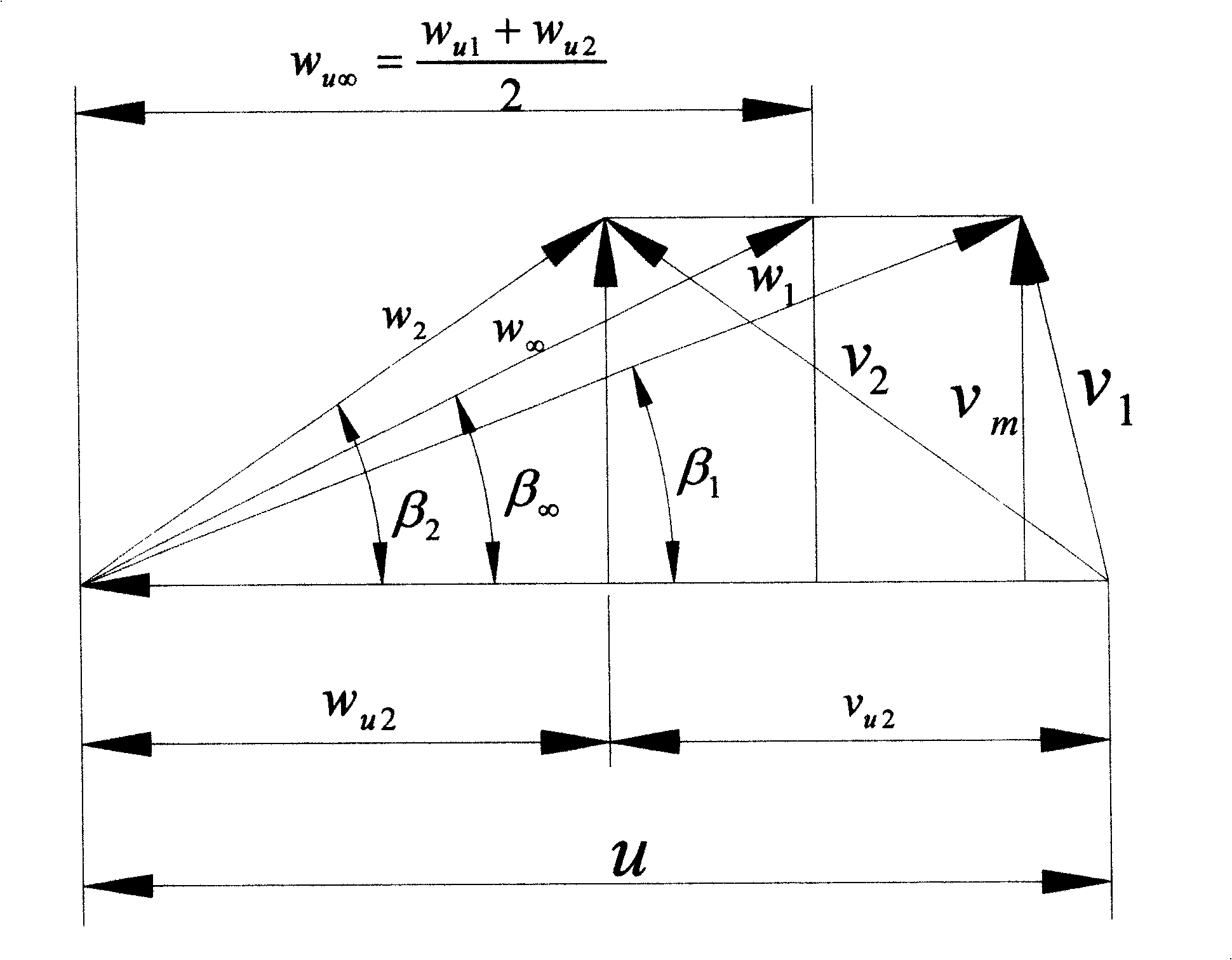

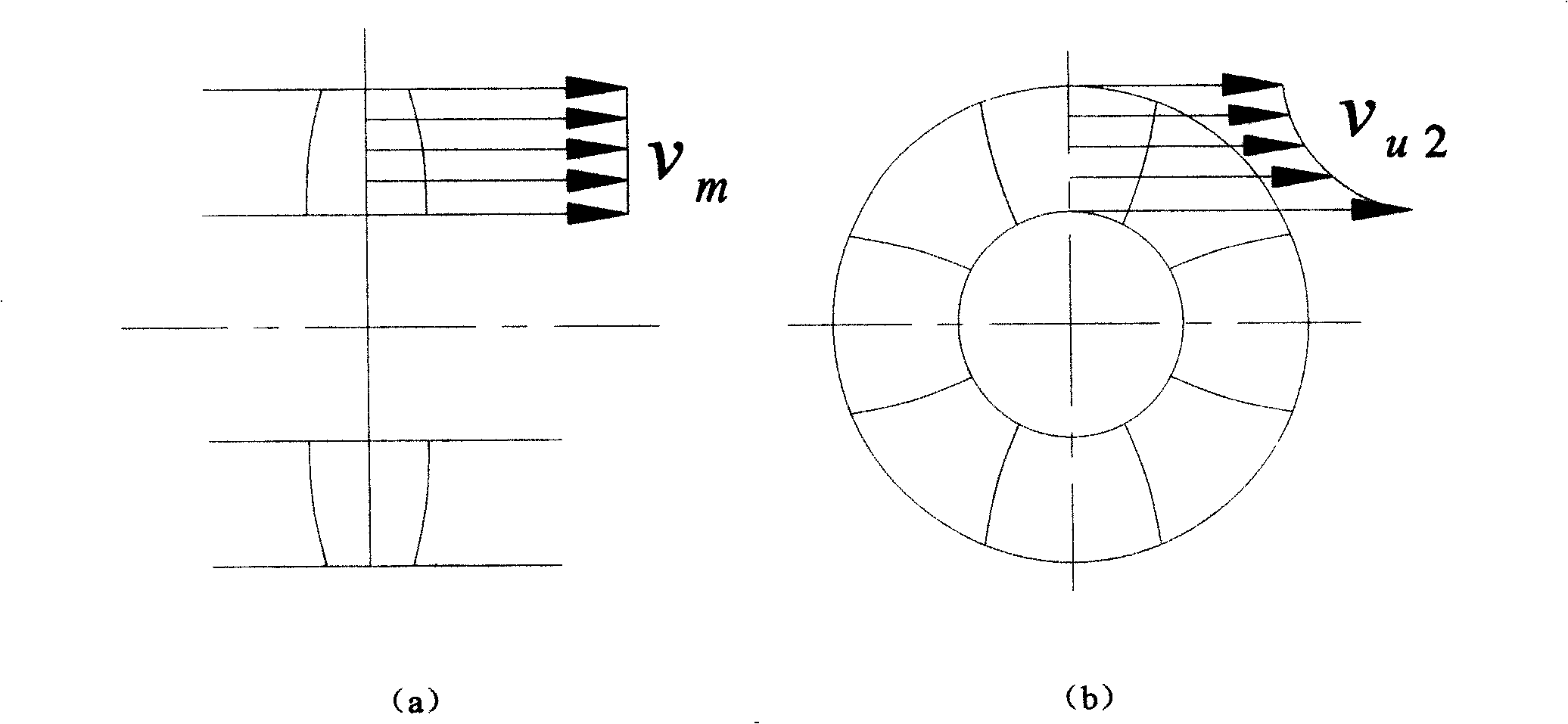

[0121] The inventor of the present invention believes that the closer the assumed flow model is to the actual flow field, the higher the efficiency of the axial-flow turbomachinery designed using this flow model will be. Therefore, the flow model of the present invention is assumed as follows: (1) fluid is ideal incompressible fluid; (2) fluid particle flows on the cylindrical surface taking impeller axis as center line; (3) rotating speed, torque of impeller machinery , flow, etc. do not change with time; (4) the flow is axisymmetric; (5) the circumferential component v at the blade outlet u2 and shaft speed v m2 Linearly distributed along the radial direction of the blade, and the circumferential component and axial surface velocity at the hub side are small, while the circumferential component and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com