Non-aqueous system internal-combustion engine cooling liquid

An internal combustion engine and coolant technology, applied in the chemical industry, can solve the problems of less propylene glycol resource, high consumption, high price, etc., and achieve the effect of good pumpability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

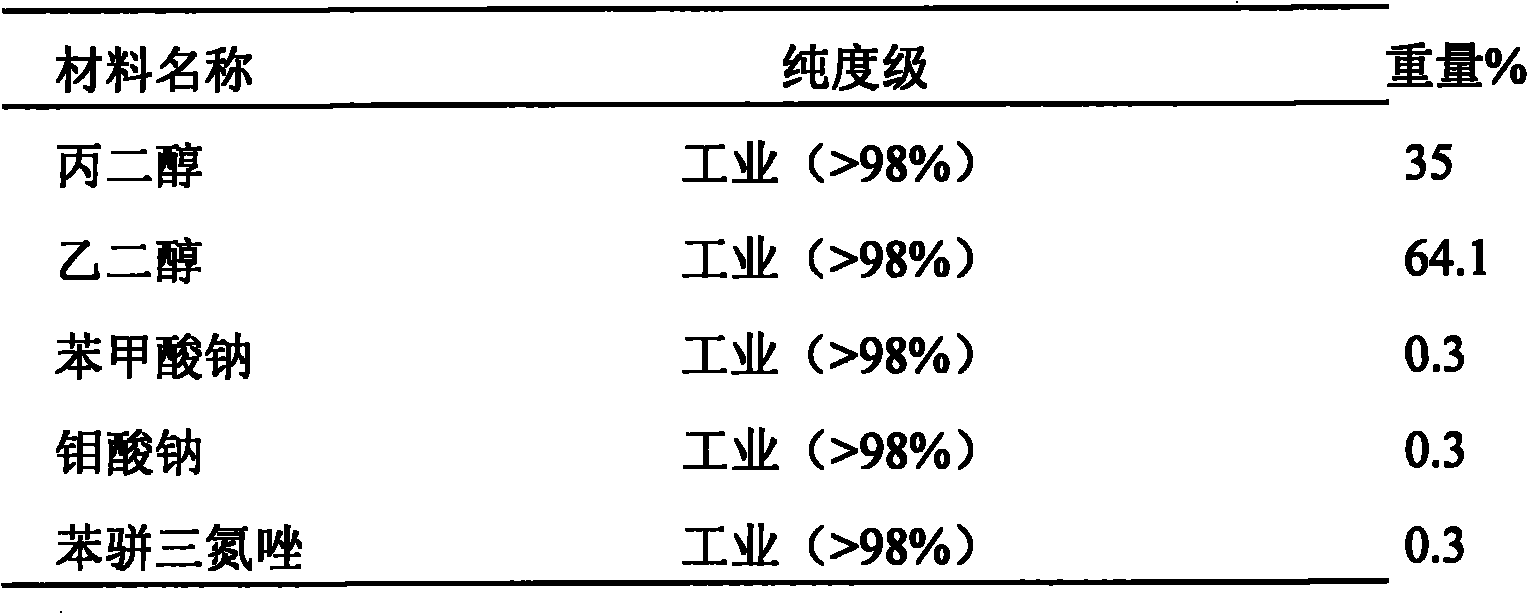

[0024] One of the formulations of a non-aqueous internal combustion engine coolant of the present invention

[0025]

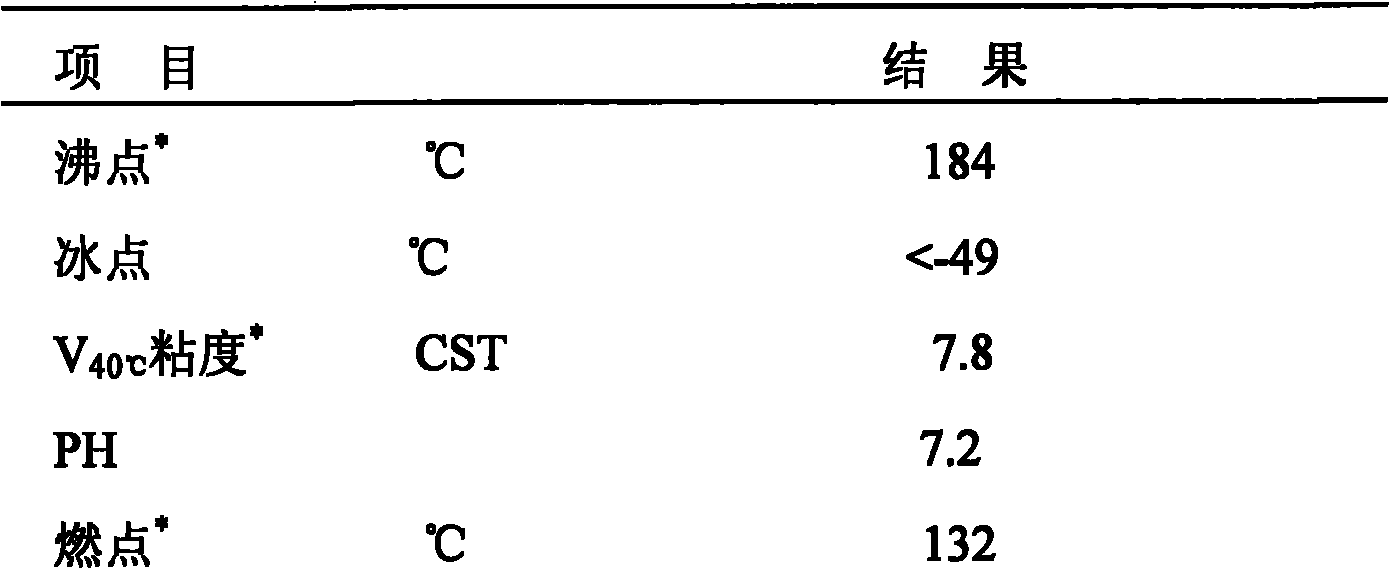

[0026] Physical and chemical data

[0027]

[0028] Effect

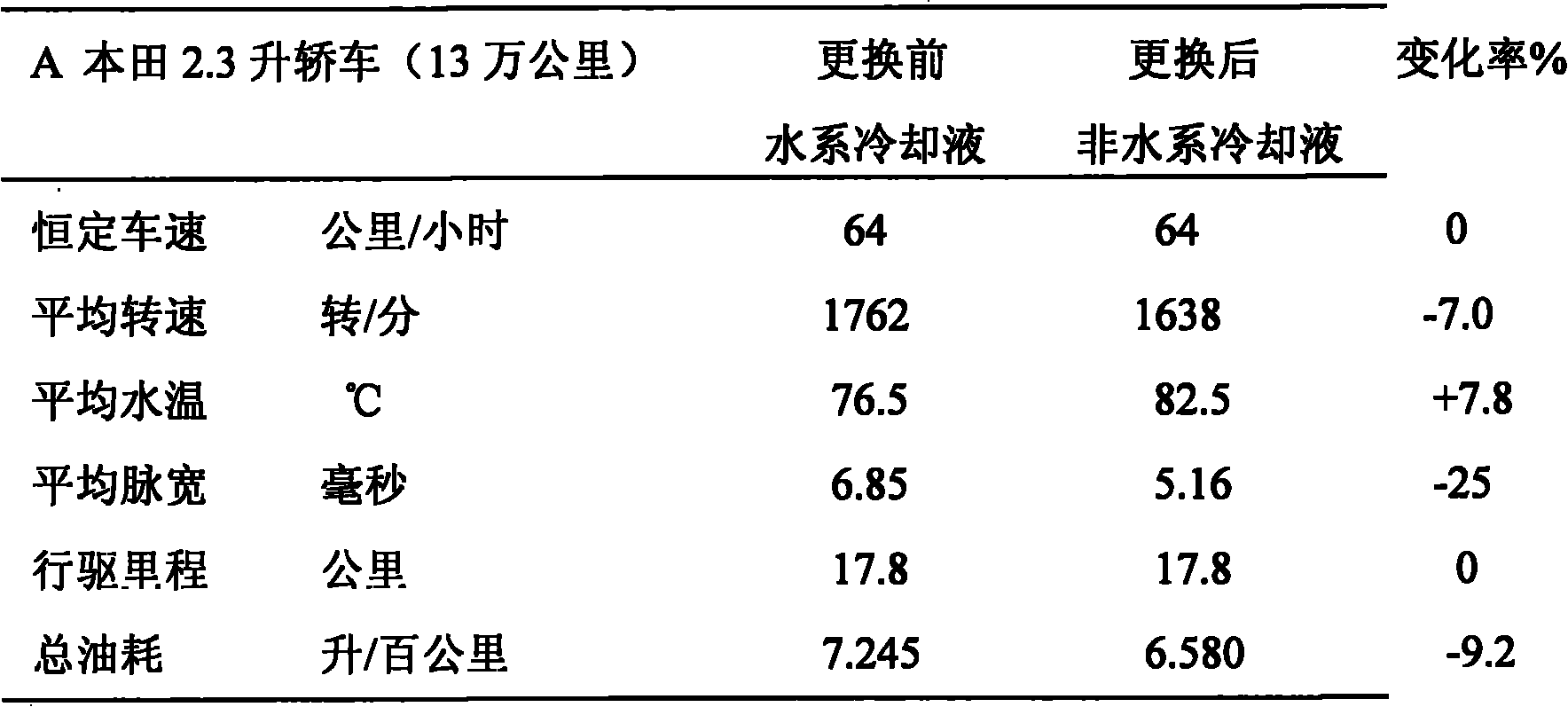

[0029] ①Constant speed and fixed route driving test (average of 4 times)

[0030]

[0031] Result: 8% fuel saving

[0032] ②Gas emission test (idling speed)

[0033]

[0034] The result: significantly lower exhaust emissions

[0035] ③ Fuel consumption test (idling speed)

[0036]

[0037] Result: The fuel consumption is significantly reduced by the pulse width

[0038] ④Long-term use status

[0039] The two cars A and B have been driving for one year from July 2007 to mid-August 2008. Car A has driven 20,000 kilometers in total, and car B has driven 40,000 kilometers in total. It has experienced various driving conditions such as high temperature in summer, low temperature in winter, urban traffic and high-speed roads, and has achieved good results. Compared with water-based c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com