Discharge chute

A chute and bottom plate technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as erosion damage and cavitation damage, reduce energy dissipation and anti-scouring pressure, increase frictional resistance, and improve turbulent kinetic energy Effect of Dissipation Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

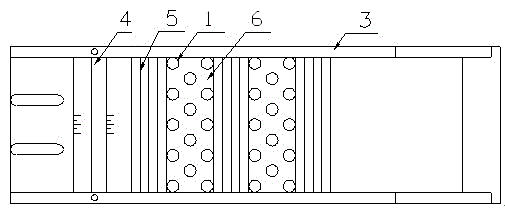

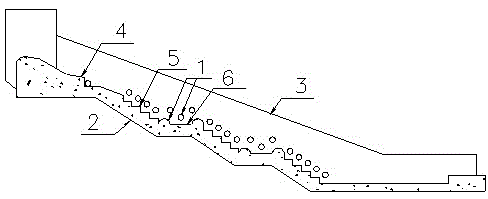

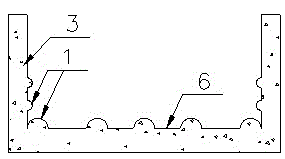

[0013] Such as Figure 1-Figure 3 As shown, an embodiment of the present invention includes a base plate 2 and side walls 3 on both sides of the base plate. The base plate 2 includes several sections of stepped base plates 5 and several sections of smooth base plates 6. The stepped base plates 5 and the smooth base plates 6 are arranged at intervals. And / or the side wall 3 is provided with several protrusions 1; the protrusions 1 are hemispherical or streamlined, the height of the protrusions 1 is 0.5m-2.0m, and the protrusions 1 are arranged in a staggered manner; the gradient of the stepped floor 5 is 5-60 0 ; The aeration and corrosion reduction facility 4 is connected to the upstream end of the bottom plate 2 .

[0014] The size of the protrusion 1 should be determined according to the hydraulic conditions of the chute. When a hemispherical protrusion is used, the ratio of the hemispherical height to the diameter of the bottom circle can be controlled between 1:2 and 1:8; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com