Patents

Literature

49results about How to "Reduce cavitation damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

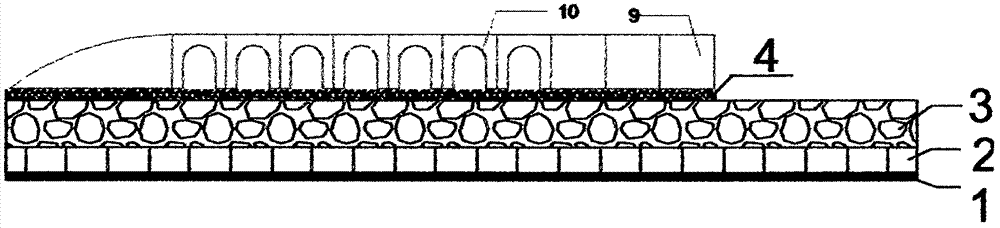

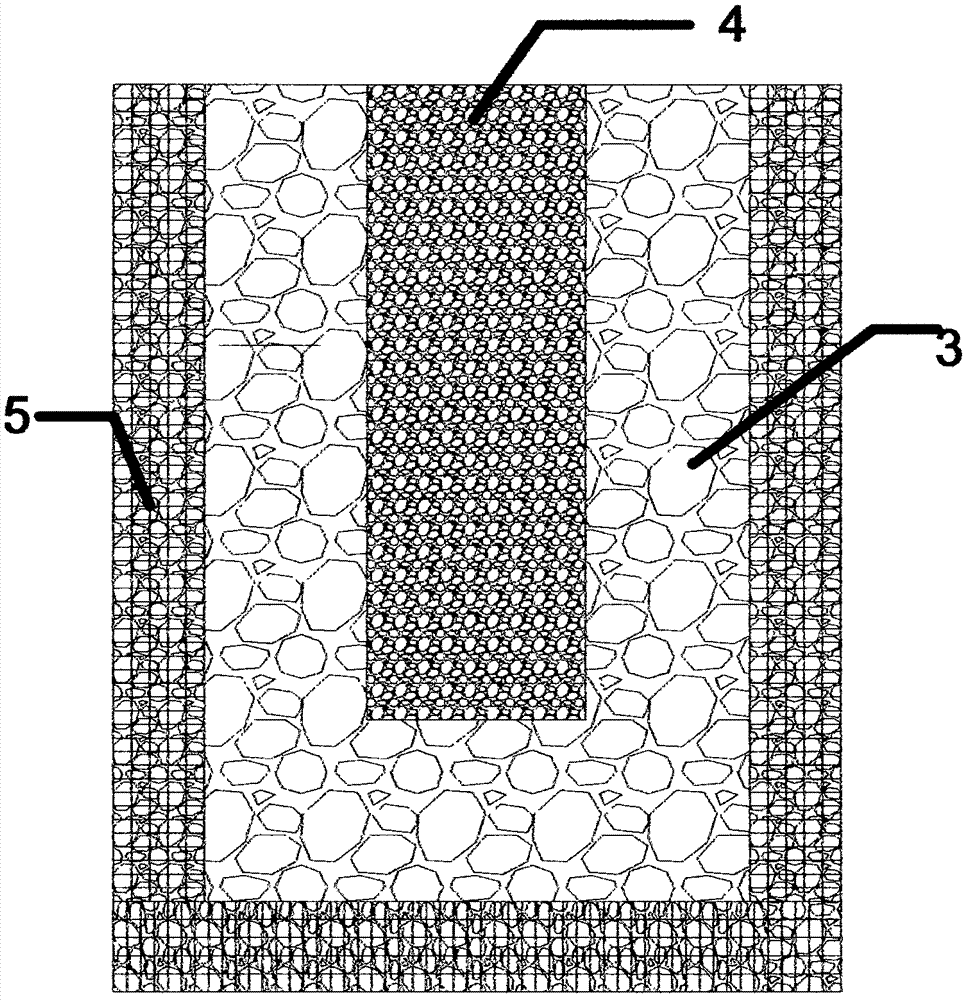

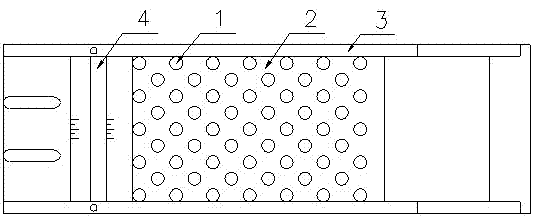

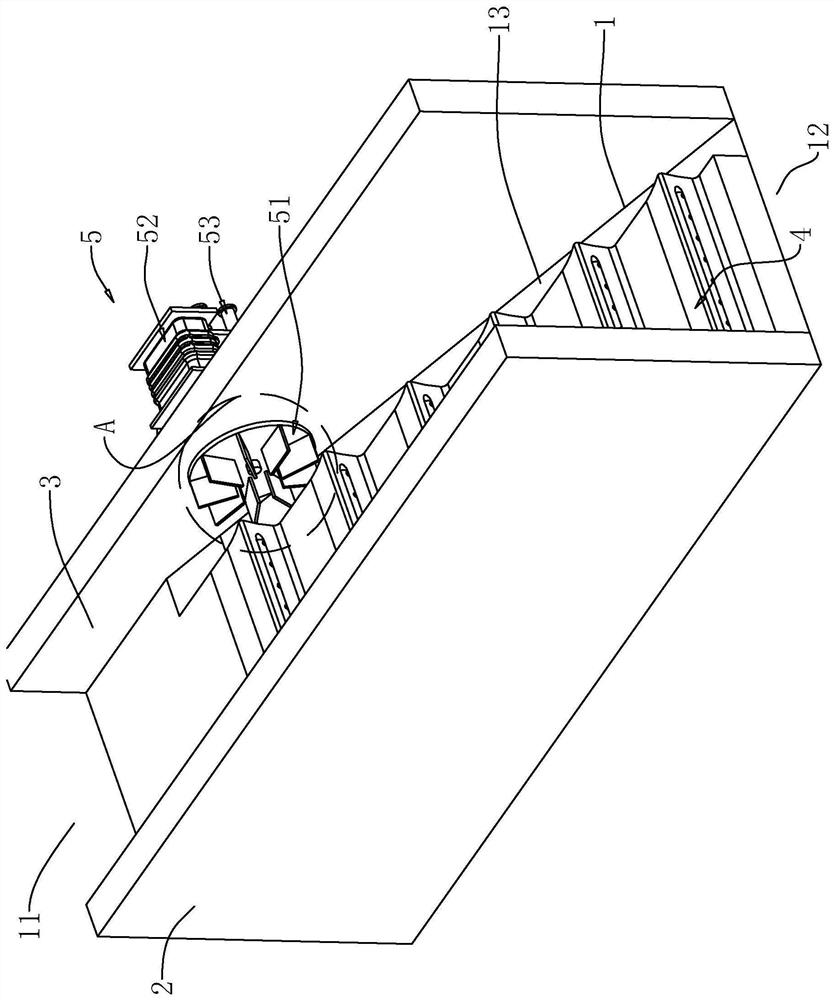

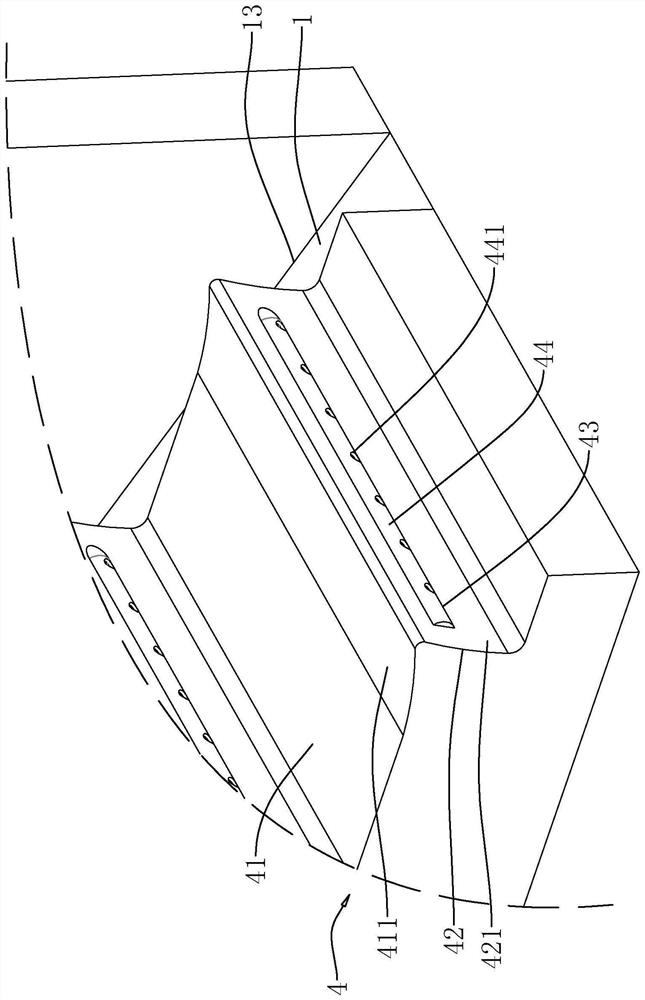

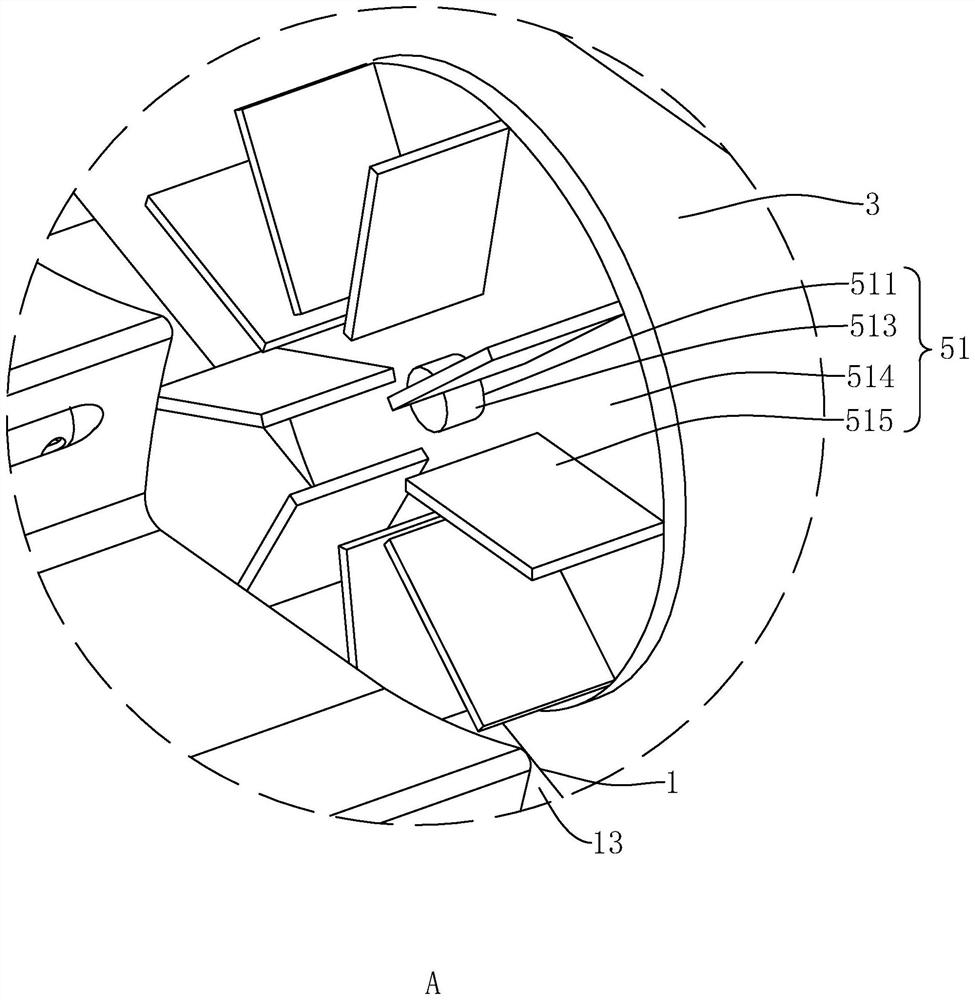

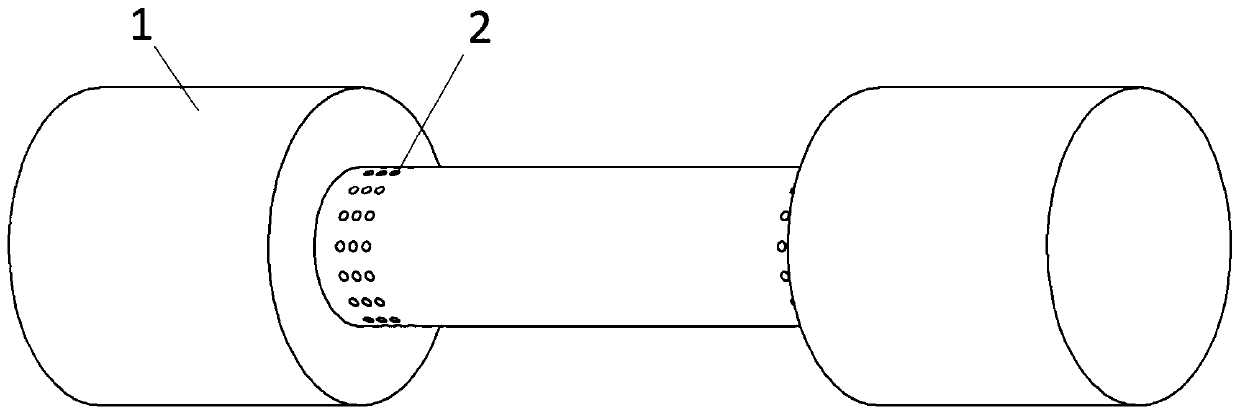

Ecological environmental-protection permeable spur dike structure

PendingCN107119626AReduce shockSmooth and convenient construction conditionsBreakwatersQuaysGeotextileEngineering

The invention relates to an ecological environmental-protection permeable spur dike structure which consists of a river bottom protection structure and a spur dike structure part; the river bottom protection structure consists of a geotechnical waterproof material layer, a grouted rubble layer, a rubble layer and a crushed stone layer from the bottom up sequentially; the crushed stone layer is simply laid within the range of the spur dike structure part; gabion net cages are arranged at the external edges of the river bottom protection structure, then the river bottom protection structure is leveled, and the spur dike structure part is arranged on the leveled crushed stone layer; the spur dike structure part is formed by splicing a dike root, a dike body and a dike head; the dike root is formed by splicing a plurality of entity components, the bottom of each entity component is a plane, and the upper part of each entity component is a sloping surface structure consisting of a riverside slope and a landside slope; the dike body is formed by splicing a plurality of permeable components; the upper parts of the permeable components are sloping surface structures consisting of riverside slopes and landside slopes; and permeable holes are formed in the middles of the permeable components. The permeable holes of the permeable components are arch-cave-shaped, so that flow turbulent fluctuation at the permeable holes and erosion to the dike body are reduced, and harm to fish in water is reduced.

Owner:CHONGQING JIAOTONG UNIVERSITY

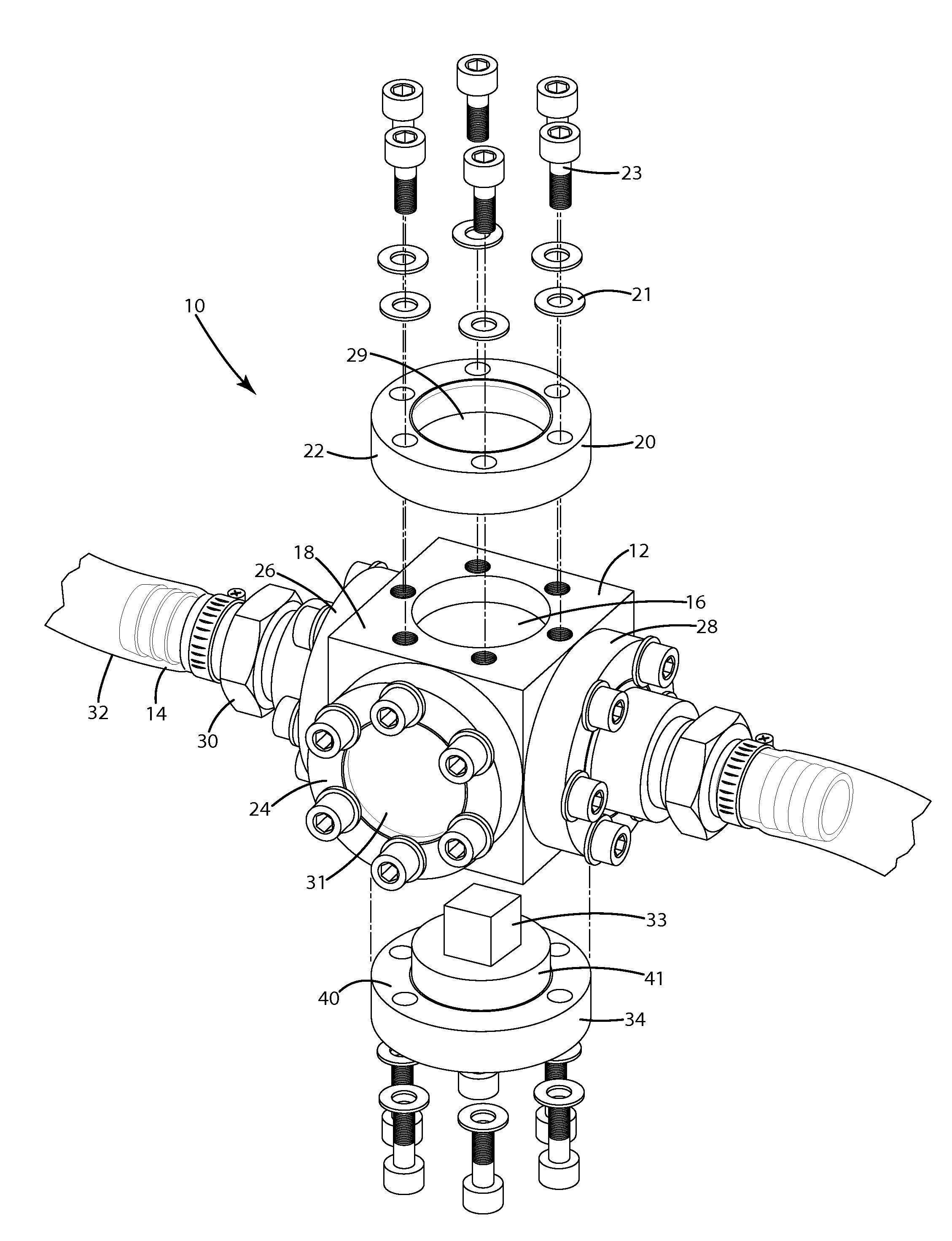

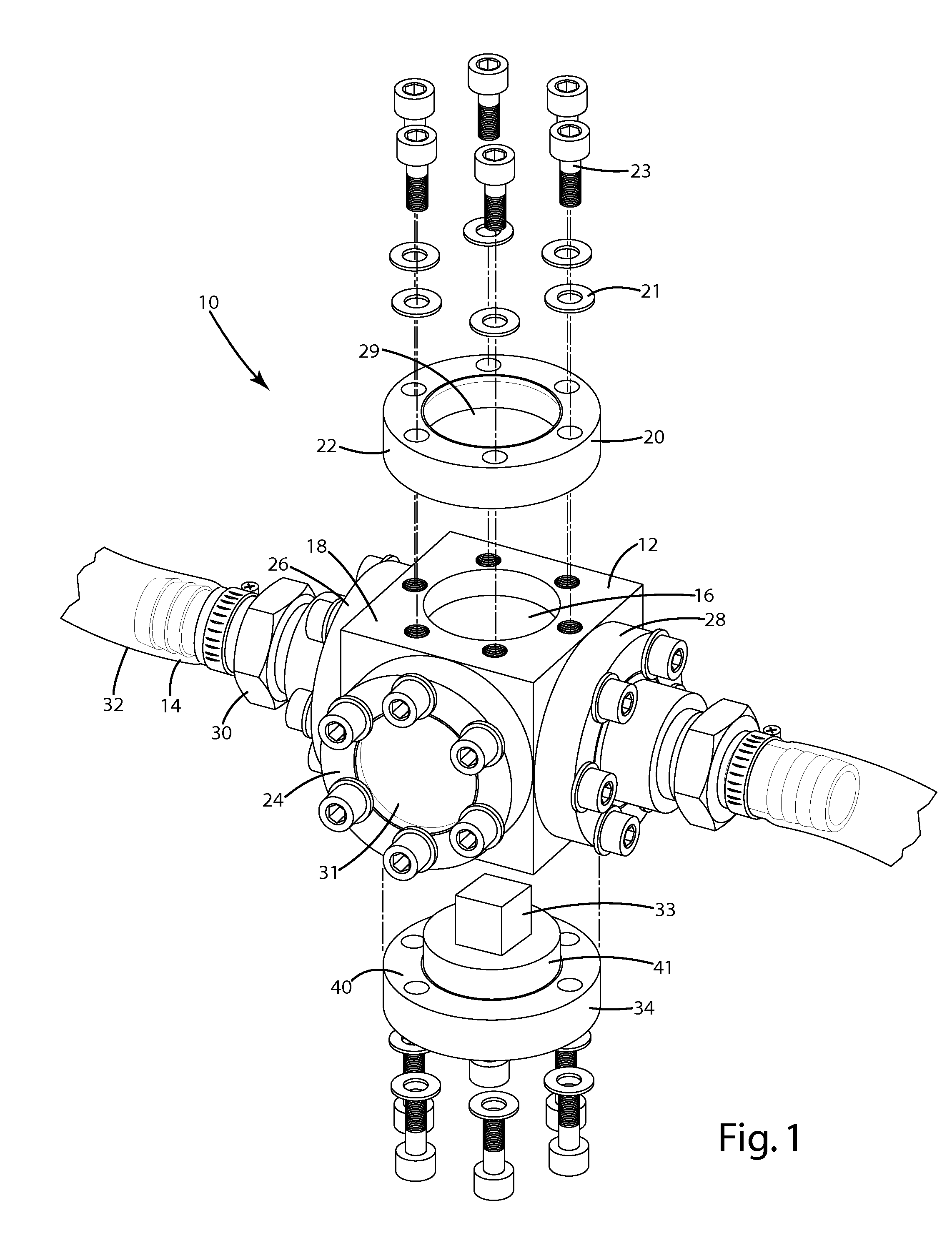

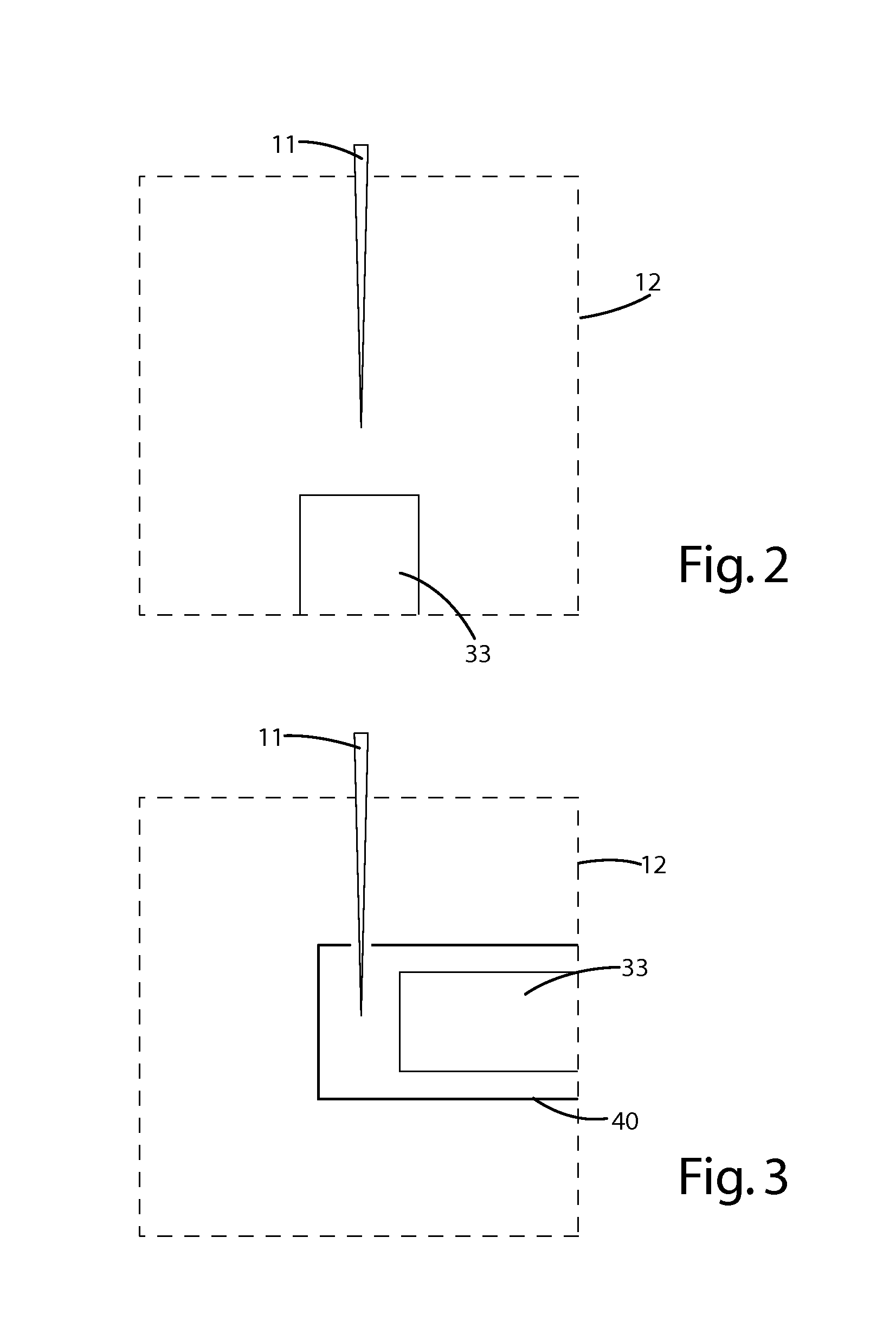

Repetitive pressure-pulse apparatus and method for cavitation damage research

InactiveUS20120118395A1Accurately cavitationMore efficient in generating shock wavesMaterial analysis using sonic/ultrasonic/infrasonic wavesElectric discharge heatingShock waveCavitation

An apparatus for inducing cavitation at a surface of a specimen includes a cavitation chamber, a window extending through the wall of the chamber to an area outside the chamber, a test specimen positioned within the chamber, and a cavitation media inside the chamber and in contact with the surface of the specimen. A laser light source is disposed outside the chamber, and is operable to provide a laser beam through the window and into the cavitation media. The laser light source generates a shock wave in the cavitation media, the shock wave causing cavitation at the surface of the specimen.

Owner:UT BATTELLE LLC

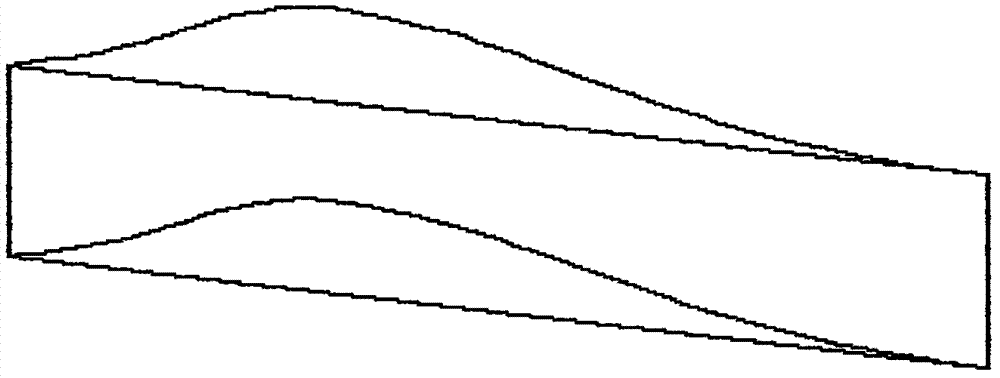

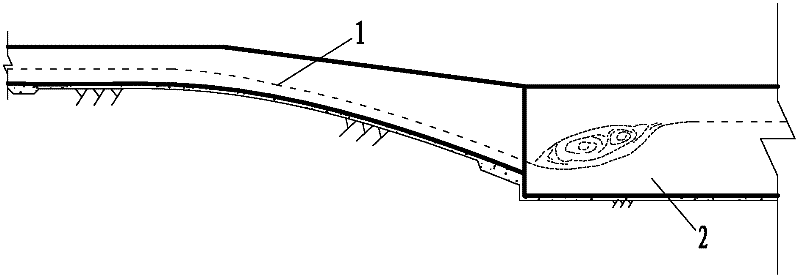

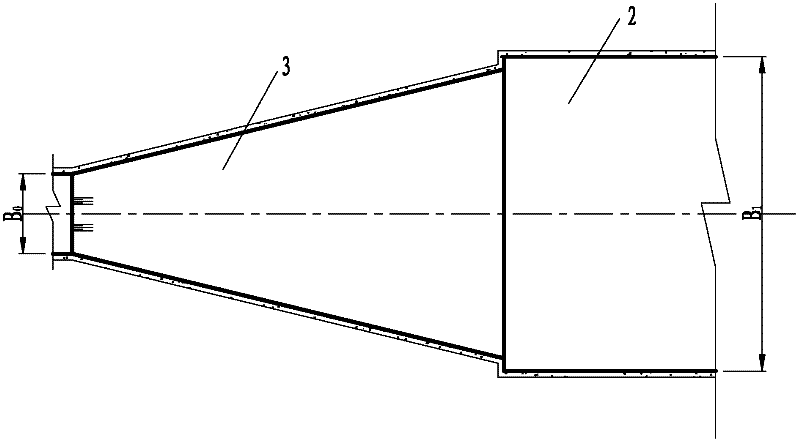

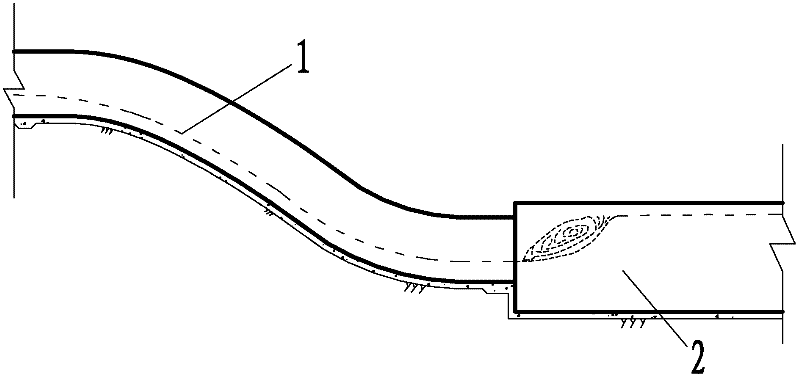

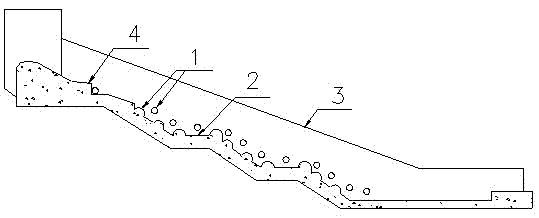

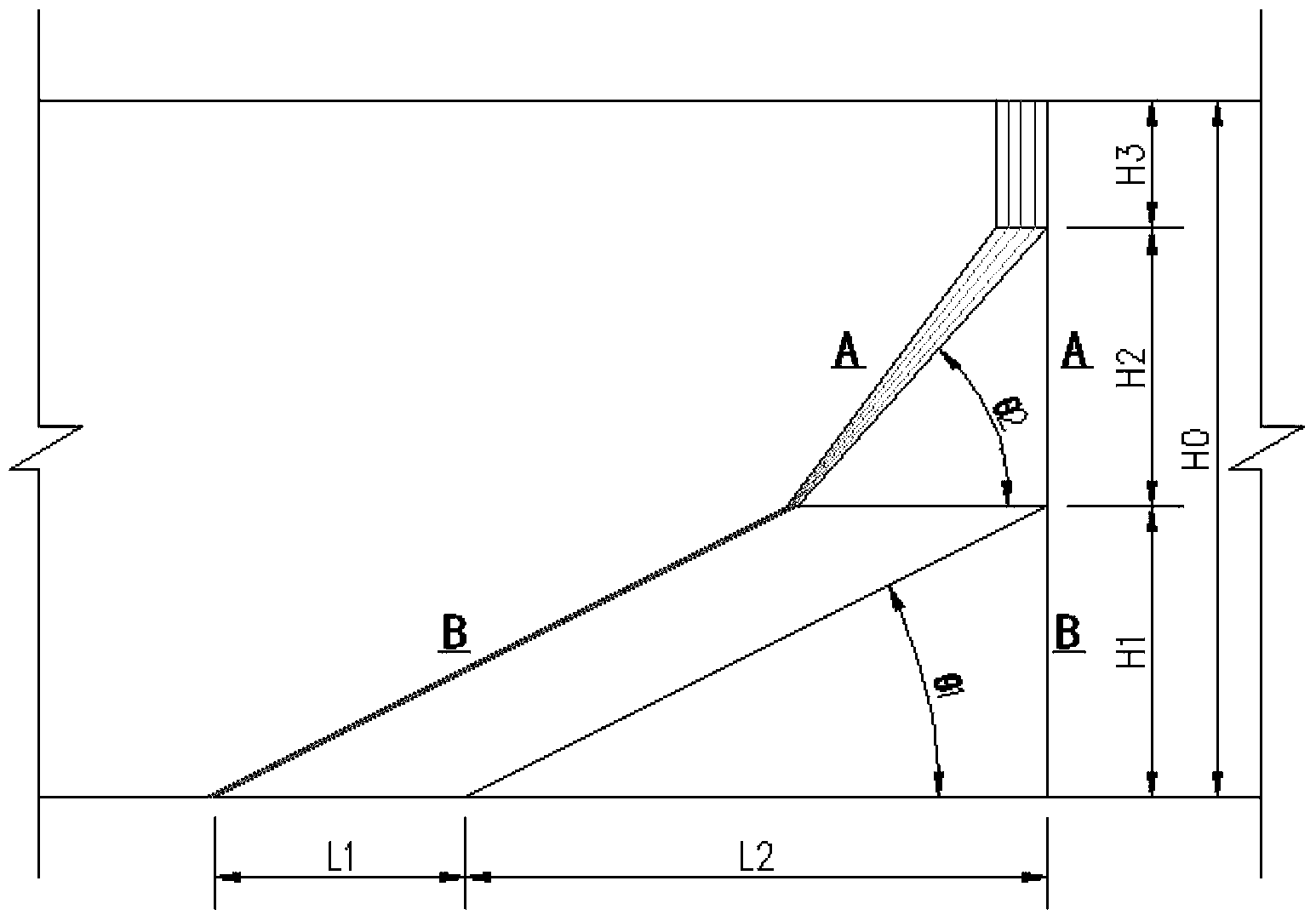

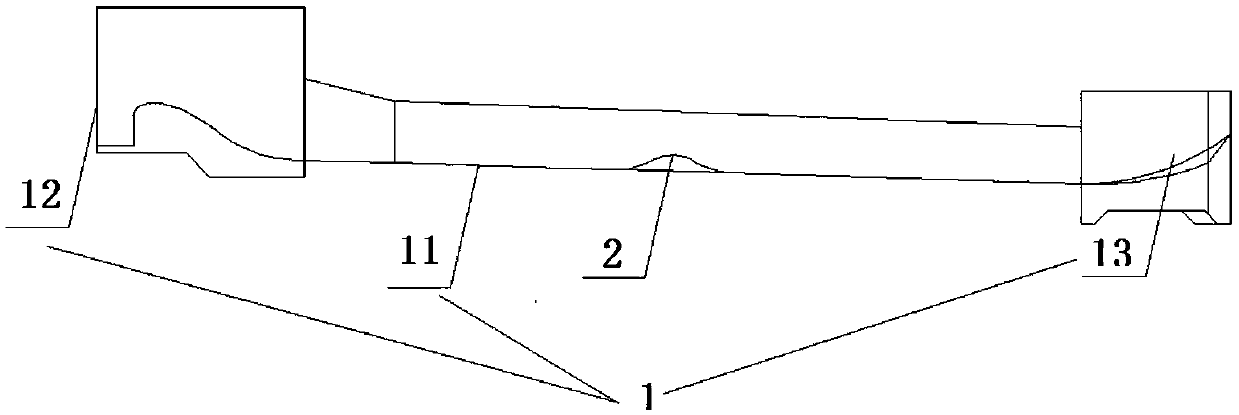

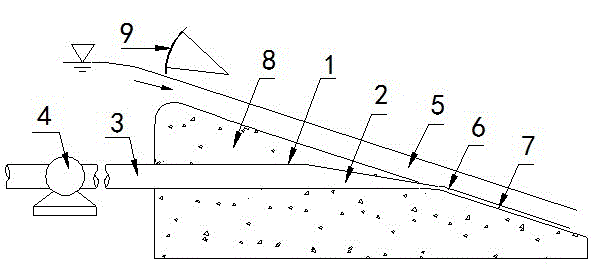

Facility for eliminating negative pressure of bottom plate at torrent diffusion slope-variable section of flood discharging tunnel

InactiveCN102251504AAvoid destructionReduce pressure changes along the wayBarrages/weirsWater flowPhysical model

The invention relates to a facility for eliminating the negative pressure of a bottom plate at a torrent diffusion slope-variable section of a flood discharging tunnel, The facility comprises a step-down floor and pressing holes, wherein the step-down floor is arranged in front of a negative pressure region of the bottom plate at a diffusion section of the flood discharging tunnel; the pressing holes are arranged at two ends of the step-down floor outside a side wall of the flood discharging tunnel; a hollow cavity formed between a jet flow surface generated by discharged water in the flood discharging tunnel flowing across the step-down floor and a step-down floor bottom plate surface is communicated with air through the pressing holes so that the negative pressure of the bottom plate of the flood discharging tunnel is reduced and partial damage of the bottom plate of the flood discharging tunnel is avoided. In general, the step-down floor height is 0.30-1.00m, and the sizes of the pressing holes are determined by factors, such as the step-down floor height, step-down floor aerating capacities, a negative pressure region range and the like. A physical model test result shows that the pressing facility provided by the invention can be used for effectively eliminating a negative pressure value of the bottom plate at the torrent diffusion section of the flood discharging tunnel, increasing water flow aerating concentration and improving the energy dissipation effect of a stilling basin.

Owner:SICHUAN UNIV

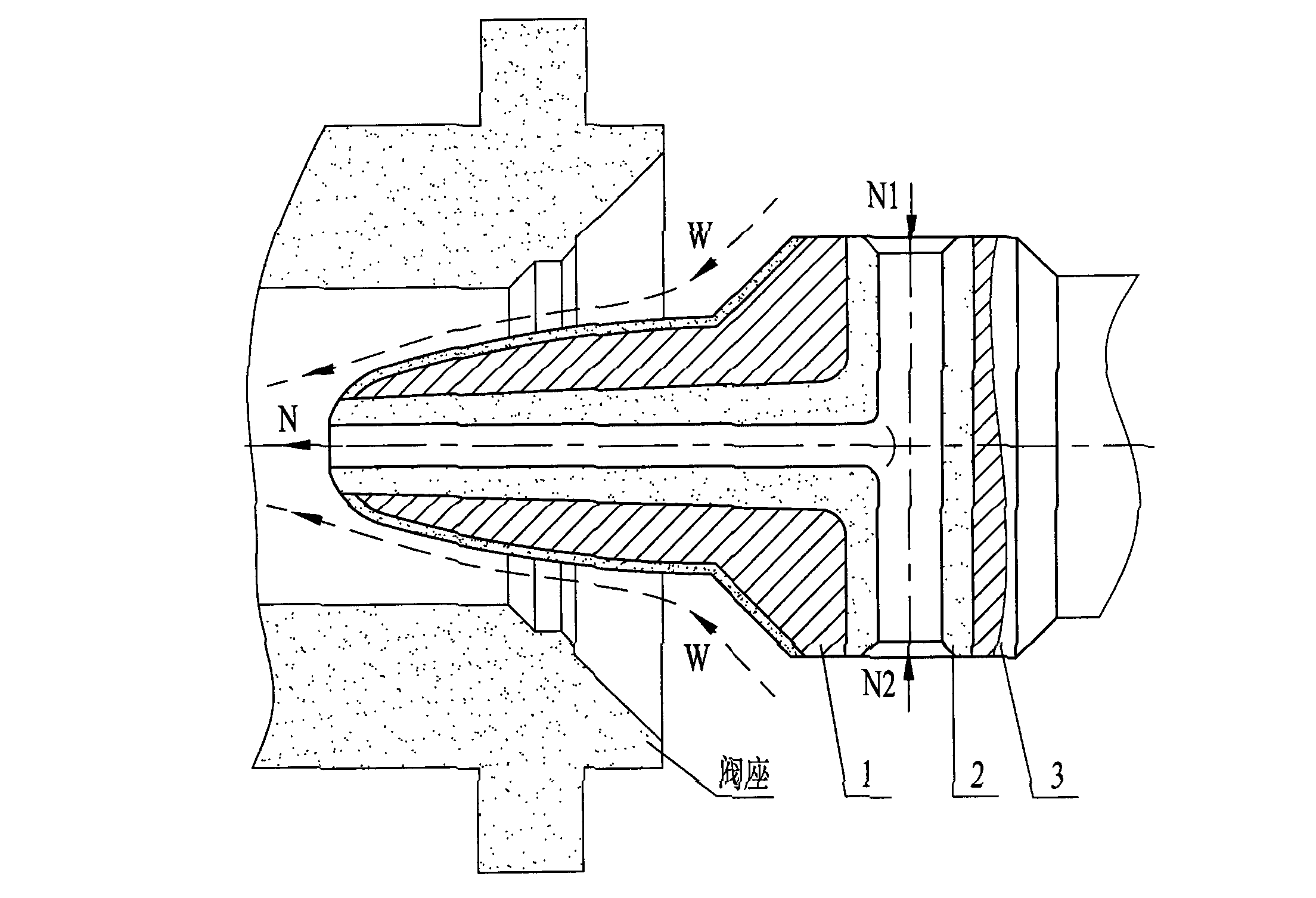

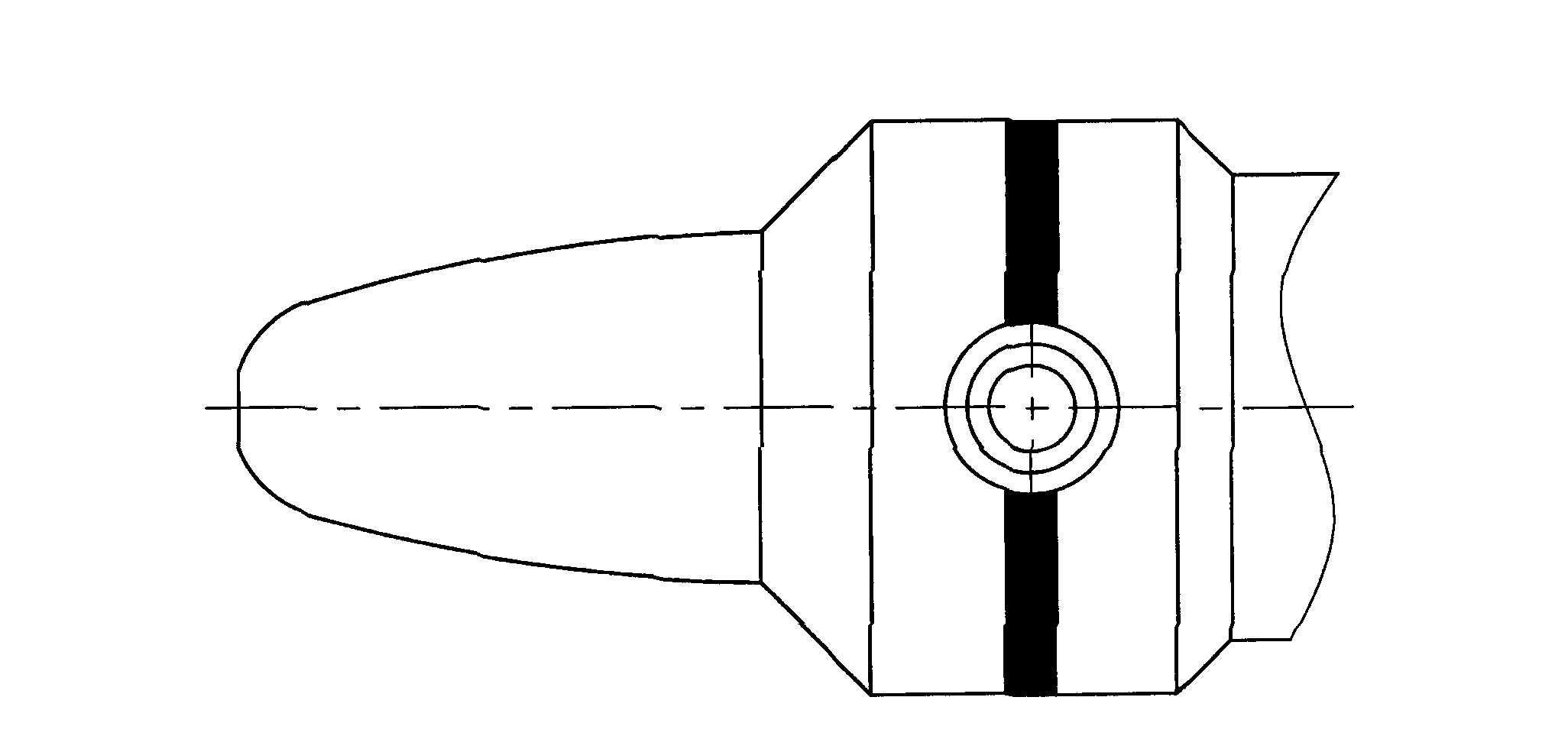

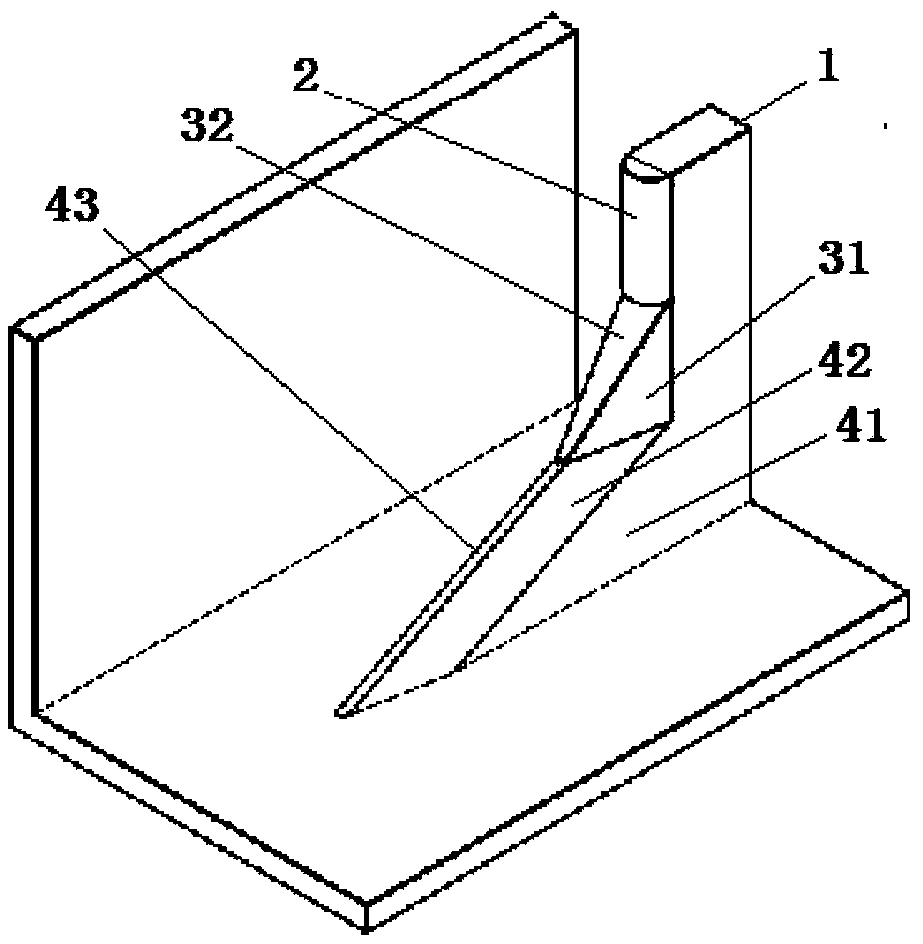

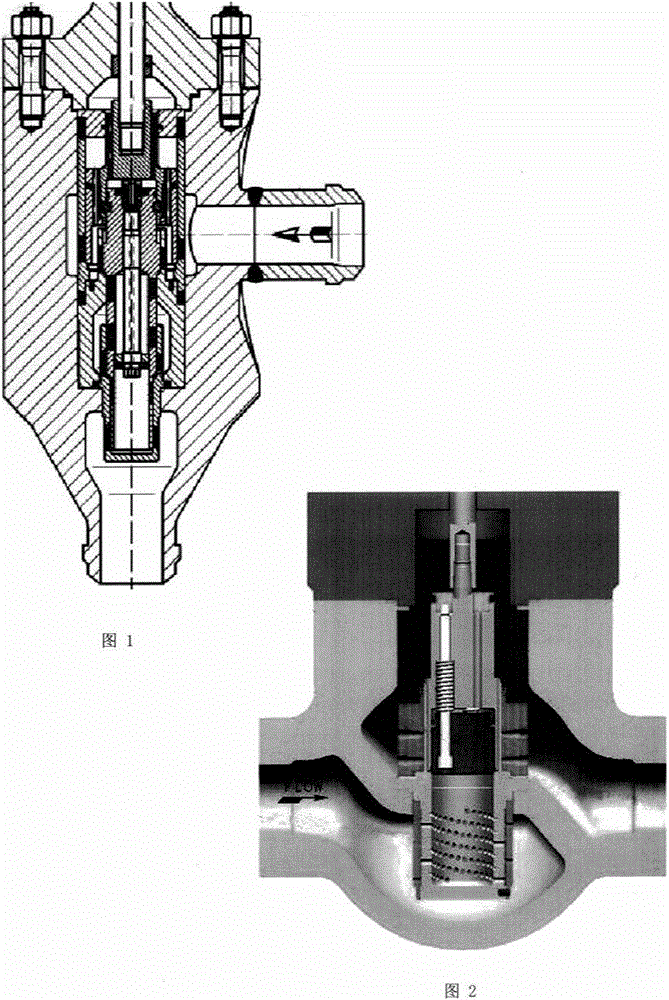

Spool component resistant to cavitation erosion and erosion wear for regulating valve

InactiveCN103062464AReduce solids flowReduce erosion wearEqualizing valvesSafety valvesEngineeringHigh pressure

The invention discloses a spool component resistant to cavitation erosion and erosion wear for a regulating valve. The spool component comprises a spool head, a spool internal throttling element and a spool tail. A horizontal section of the spool internal throttling element is inserted into a central hole of the spool head, and a vertical section of the spool internal throttling element is embedded to a hole formed by connection of the spool head with the spool tail. The spool component forms split-flow transmission of media from two flow passages inside and outside a spool through the spool internal throttling element, so that cavitation erosion and erosion wear damage of the spool can be reduced greatly; and the regulating valve adopting the spool component is better in symmetry of downstream flowing distribution, downstream pipeline erosion wear rate can be decreased, the size of the regulating valve is decreased on the same transmission conditions, and the spool component is applicable to transmission working conditions such as solid containing, high pressure difference, negative pressure outlets and the like and is simple in structure and easy to popularize.

Owner:饶杰

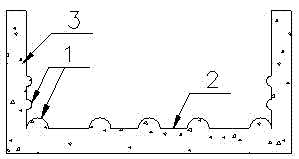

Discharge chute with projections

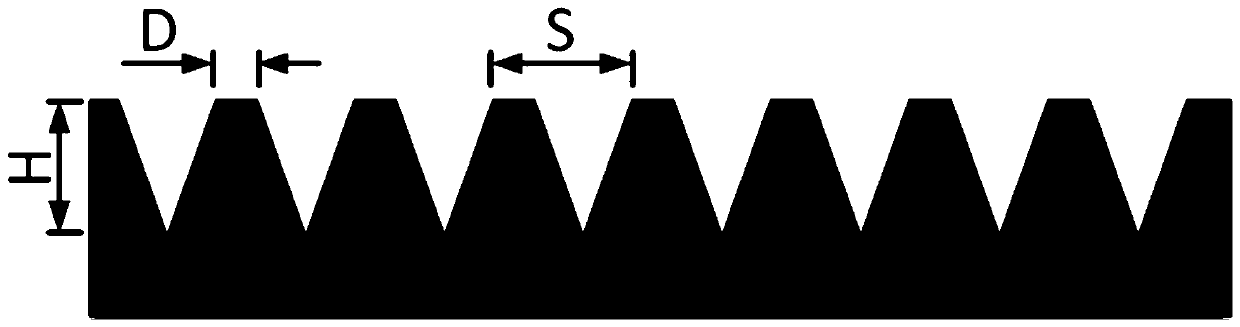

InactiveCN102926360AIncrease roughnessIncrease frictional resistanceBarrages/weirsCavitationWater flow

The invention discloses a discharge chute with projections, comprising a bottom plate and side walls at the two sides of the bottom plate. The bottom plate is in the folded line or inclined straight line shape, and the bottom plate and / or the side walls are provided with a plurality of projections. As the bottom plate and / or the side walls of the discharge chute are provided with projections, the roughness of the discharge chute is improved, the frictional resistance is increased, the turbulent energy dissipation rate is improved, a large amount of water flow energy is consumed, the risk of cavitation damage and erosion damage of the discharge chute is reduced, and the flood discharge safety is improved..

Owner:POWERCHINA ZHONGNAN ENG

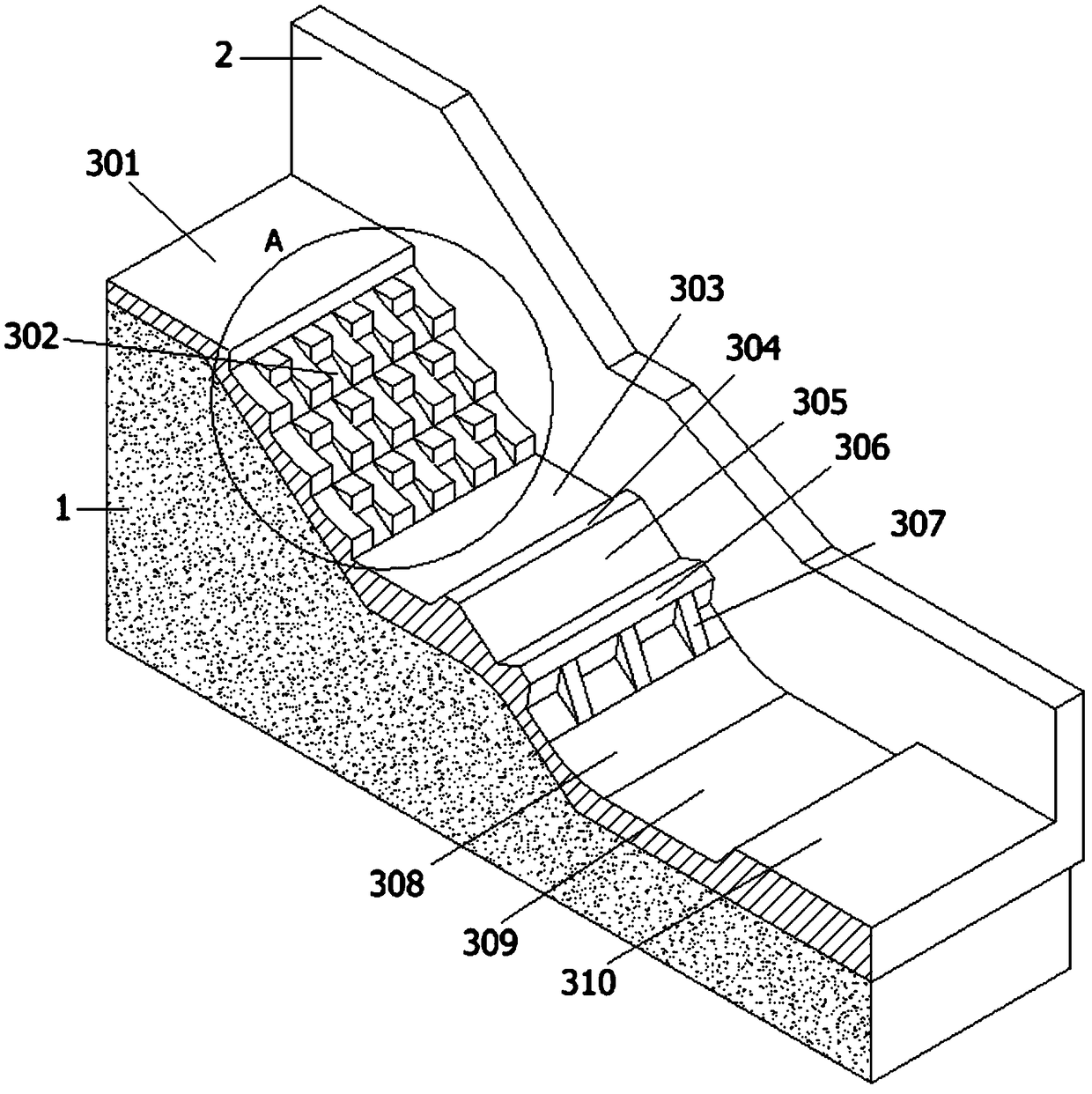

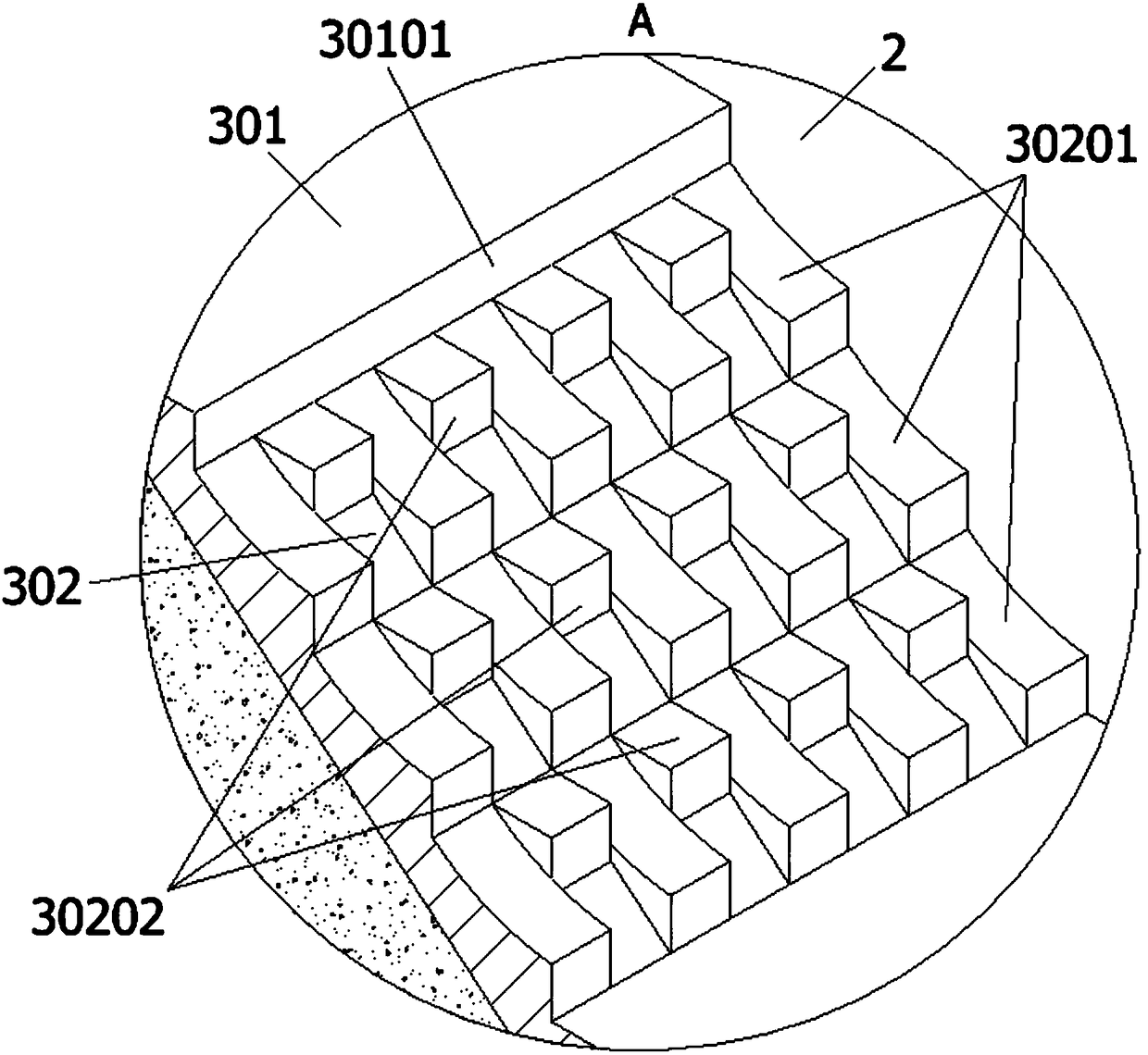

Release building structure for hydraulic engineering

InactiveCN108221843APromote formationGood for counteracting momentumBarrages/weirsHydraulic engineering apparatusArchitectural engineeringHorizontal axis

The invention provides a release building structure for hydraulic engineering. The release building structure for hydraulic engineering comprises a foundation and a downstream channel, wherein a spillway is arranged at the upper end of the foundation and spillway side walls integrated with the spillway are arranged at the left and right ends of the spillway; a first slope section is connected below a vertical section; a second deflecting flow bank is fixedly connected to the middle part of a second slope section; and the tail end of the second slope section is connected to a stilling pool through an arc-shaped section. Each group of first step block units which are uniformly arranged front and back vertically and e ach group of second step block units which are uniformly arranged front andback vertically are arranged in a spaced manner left and right, so that a generated jet flow and a rolling water flow generated by eddy with horizontal axis are contacted when the water flow passes through the first step block units and the second step block units every time to play a shearing role, so that contacted water flows have turbulent fluctuations to enhance the aerifying effect and diffusion of air bubbles in the water flows is enhanced.

Owner:卿何琳

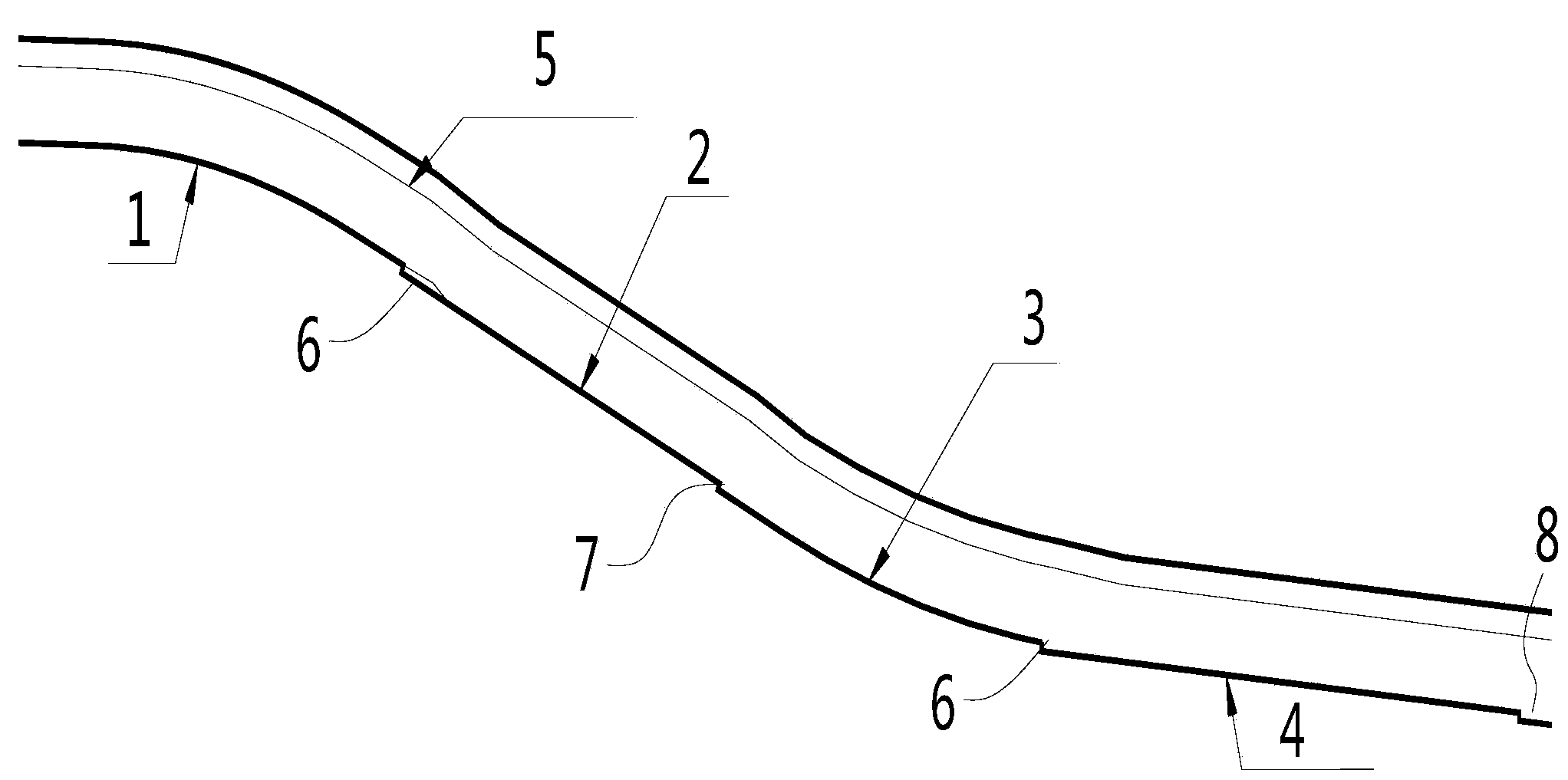

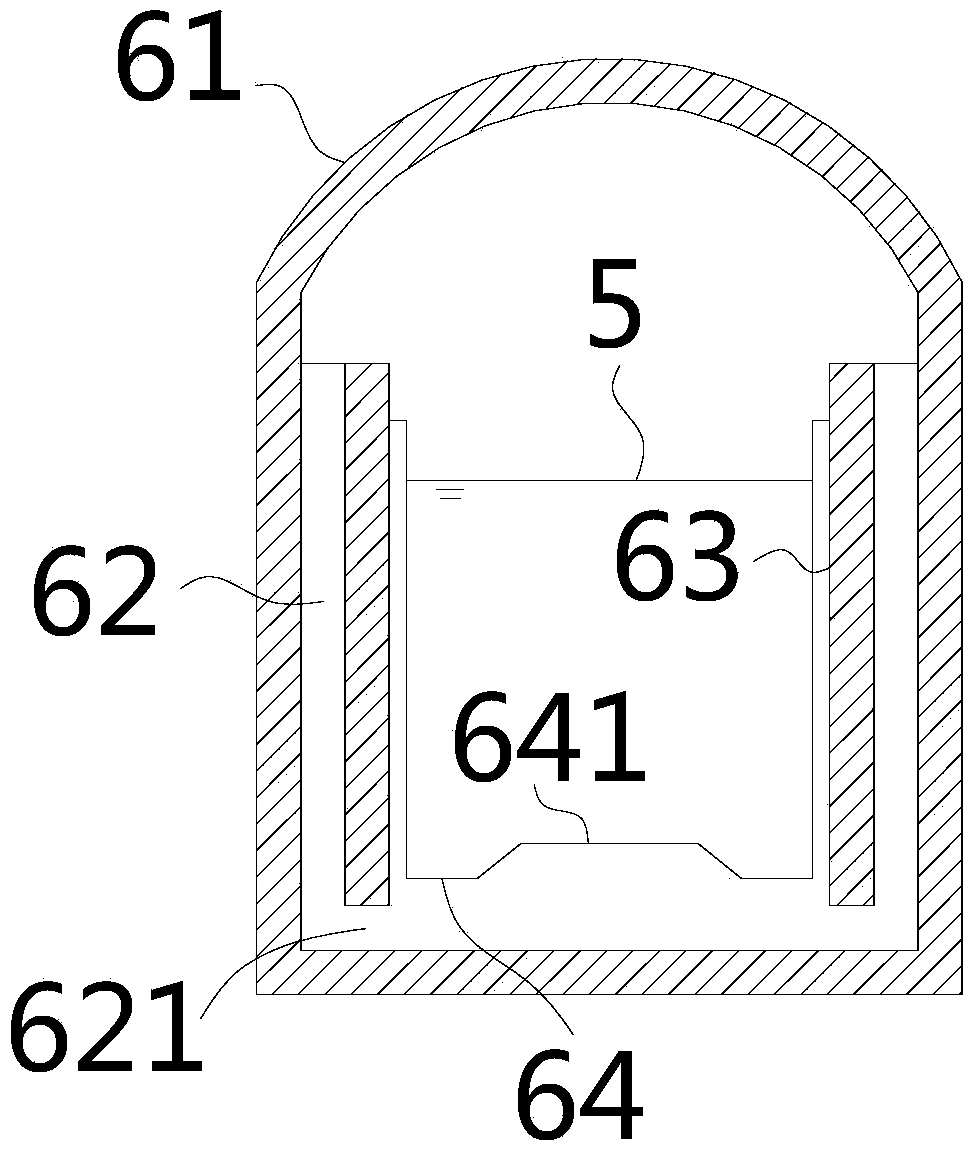

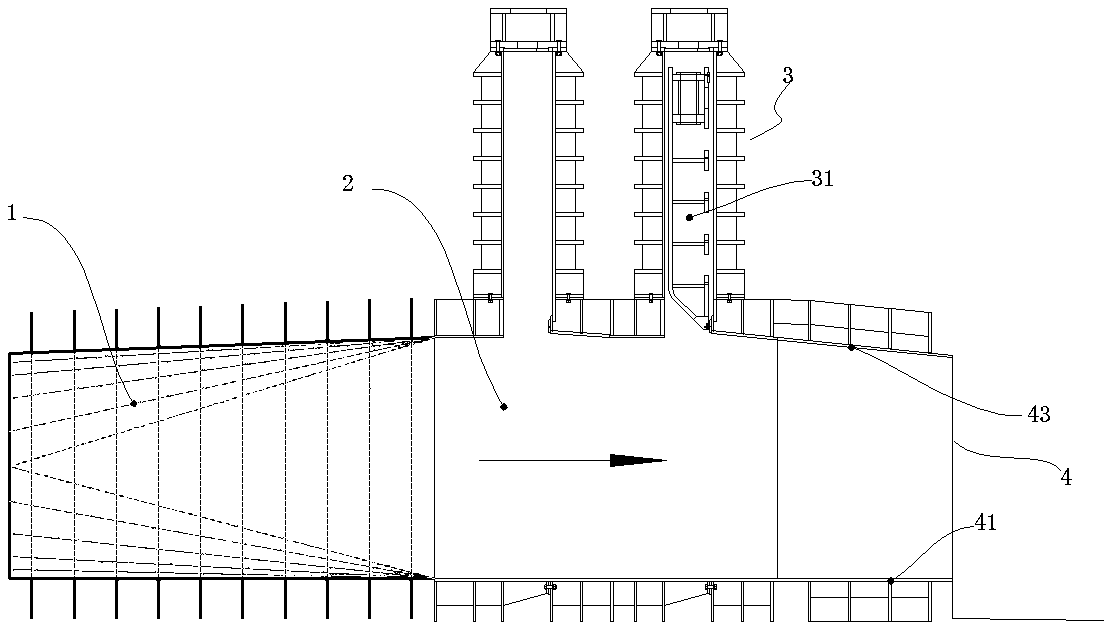

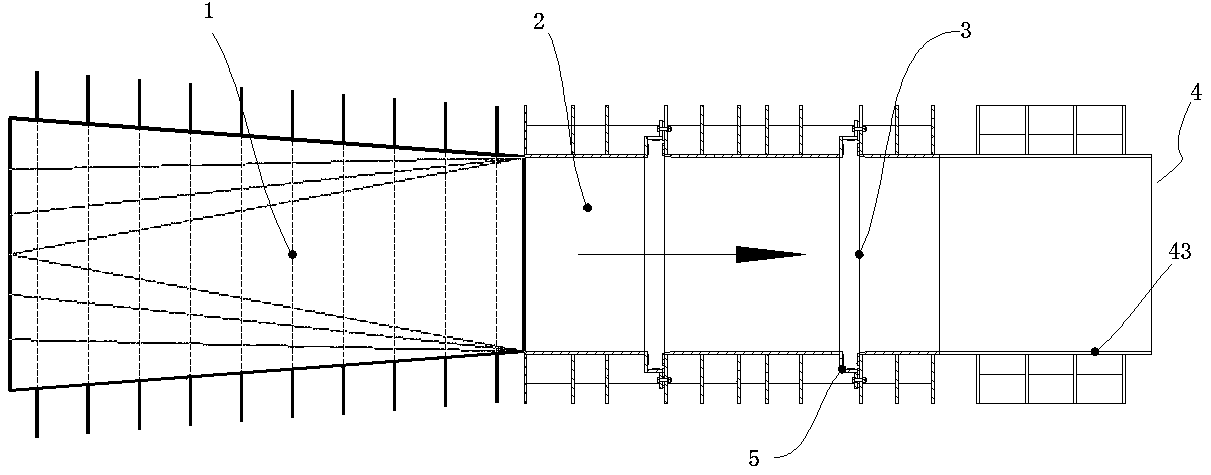

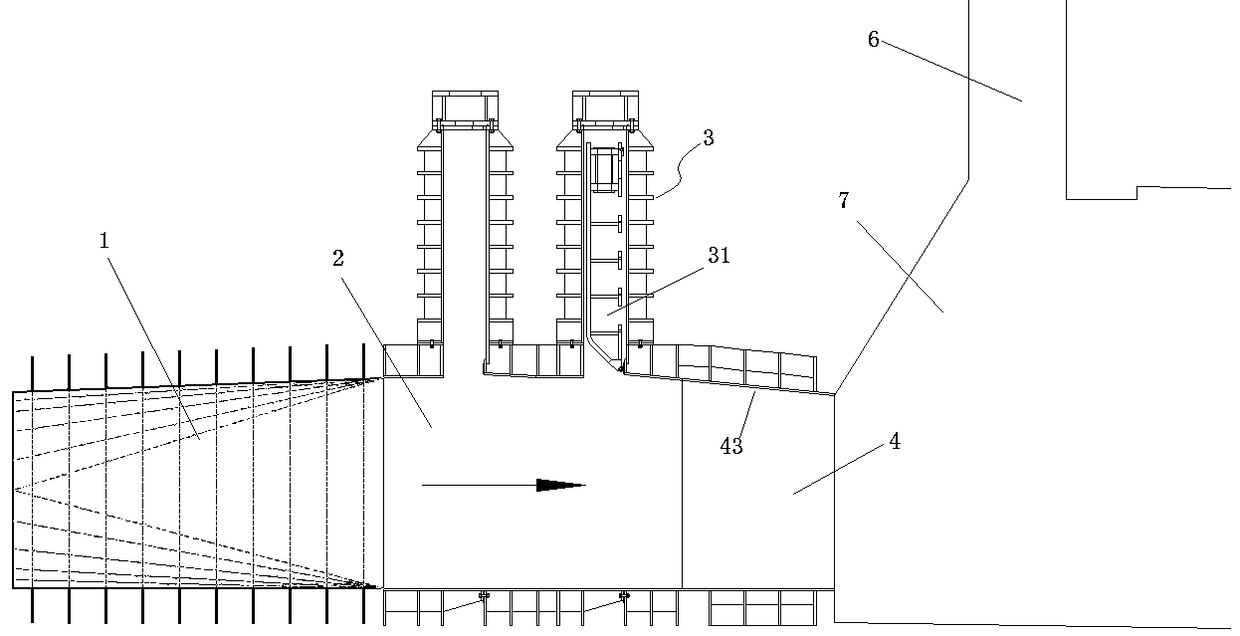

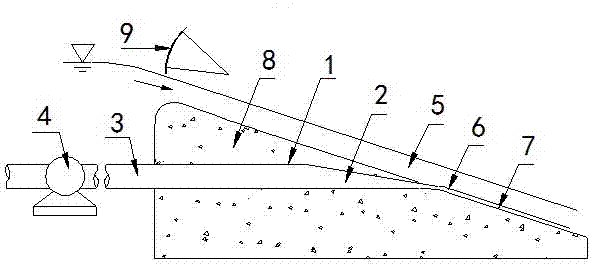

Aeration structure for Longluowei flood discharging tunnel

The invention relates to the field of water conservancy and hydropower, in particular to an aeration structure for a Longluowei flood discharging tunnel. The technical problem to be solved is to provide the aeration structure for the Longluowei flood discharging tunnel, which is capable of effectively reducing damage to an overcurrent surface of the flood discharging tunnel due to cavitation of high-speed flow. The aeration structure for the Longluowei flood discharging tunnel comprises a flood discharging tunnel, wherein the flood discharging tunnel is formed by connecting a tunnel initial segment, a slope segment, a reverse camber segment and a downstream slope segment in sequence, and at least one aeration aerator is arranged in the flood discharging tunnel. During actual use, the flood discharging tunnel is formed by connecting the tunnel initial segment, the slope segment, the reverse camber segment and the downstream slope segment in sequence, and air admission is carried out on flow in the flood discharging tunnel through the flood discharging tunnel, so that the small impact force on concrete of the overcurrent surface of the flood discharging tunnel, which is caused by flow cavitation due to turbulent fluctuation of high-speed flow, can be effectively reduced, and cavitation corrosion damage to the flood discharging tunnel is reduced, and thus the effects of smooth flow state of the flow and full aeration are achieved. The aeration structure is particularly suitable for construction of the Longluowei flood discharging tunnel.

Owner:POWERCHINA CHENGDU ENG

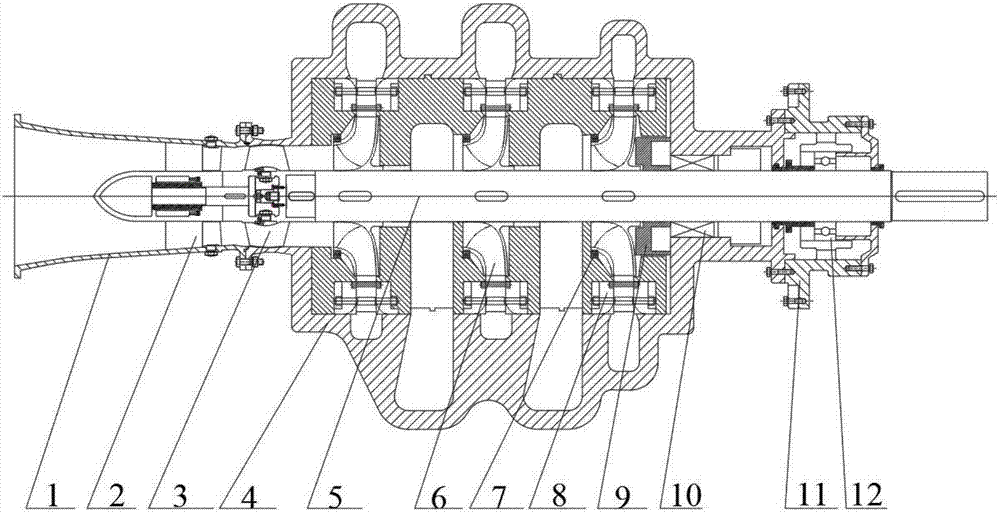

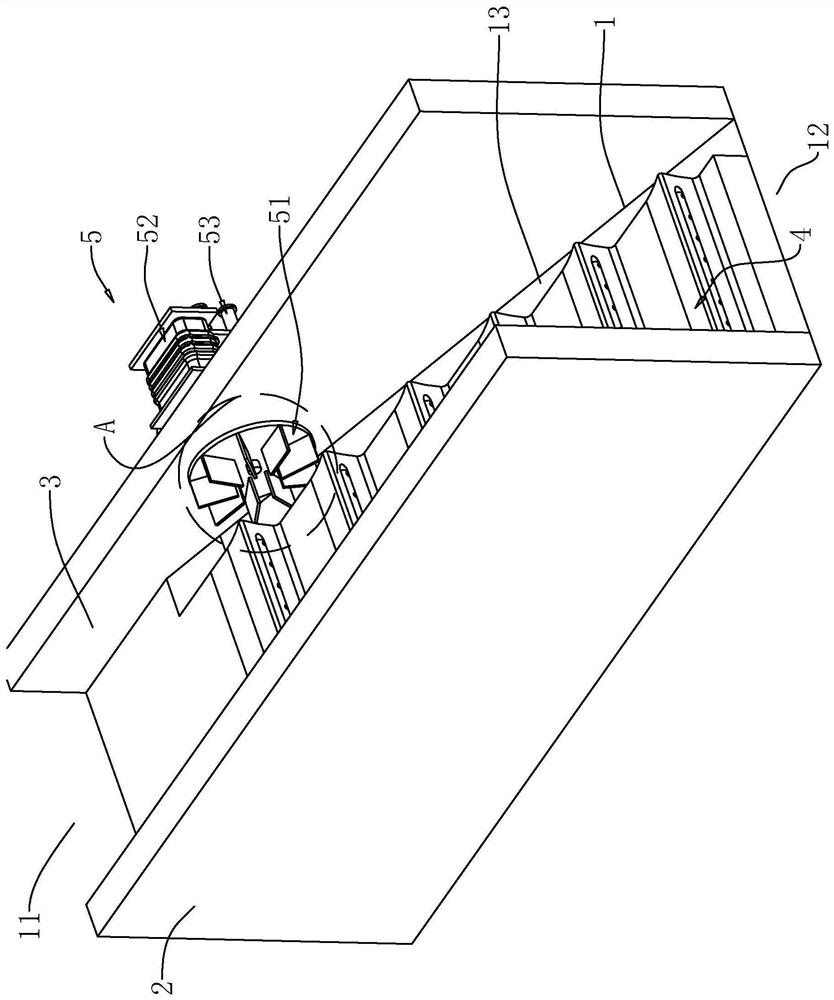

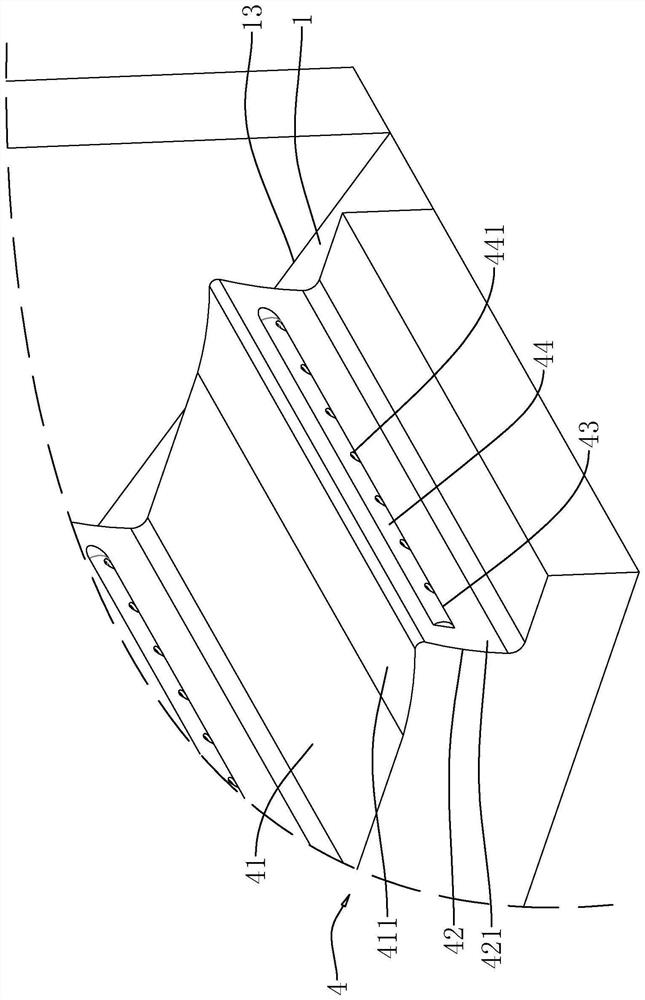

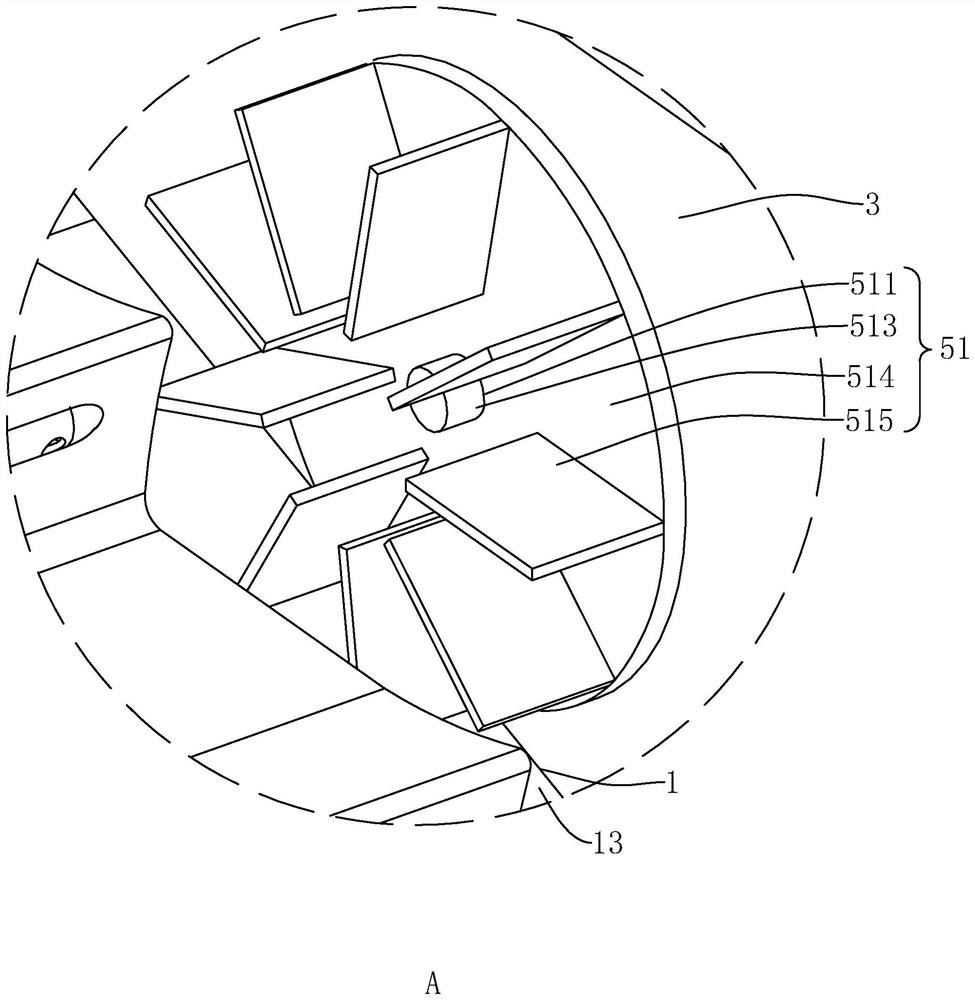

Multi-working-condition multi-stage turbine

InactiveCN106870243AImprove efficiencyImprove stabilityHydro energy generationReaction enginesImpellerCavitation

The invention provides a multi-working-condition multi-stage turbine. The multi-working-condition multi-stage turbine comprises a draft tube, a sectional type guide vane, an axial-flow impeller, a shell, a main shaft, centrifugal impellers, impeller rings, movable guide vanes, a balance disc, a mechanical seal, a bearing pedestal and a deep groove ball bearing. The multi-working-condition multi-stage turbine aims to improve the efficiency and the stability of the turbine under the variable working conditions. The multi-stage centrifugal impellers are suitable for recycling the energy with high energy head fluid. The movable guide vanes can play a role in flow adjustment, and can also be used for adjusting the inflow angle and reducing the inflow impact loss when the condition deviates from the designed working condition. Similarly, the sectional type guide vane is designed for adapting to different working conditions, and can effectively eliminate the circulation of water flow in the draft tube, and therefore the cavitation damage to the draft tube is greatly reduced, and the vibration of the draft tube is weakened.

Owner:JIANGSU UNIV ZHENJIANG RES INST OF FLUID ENG EQUIP TECH

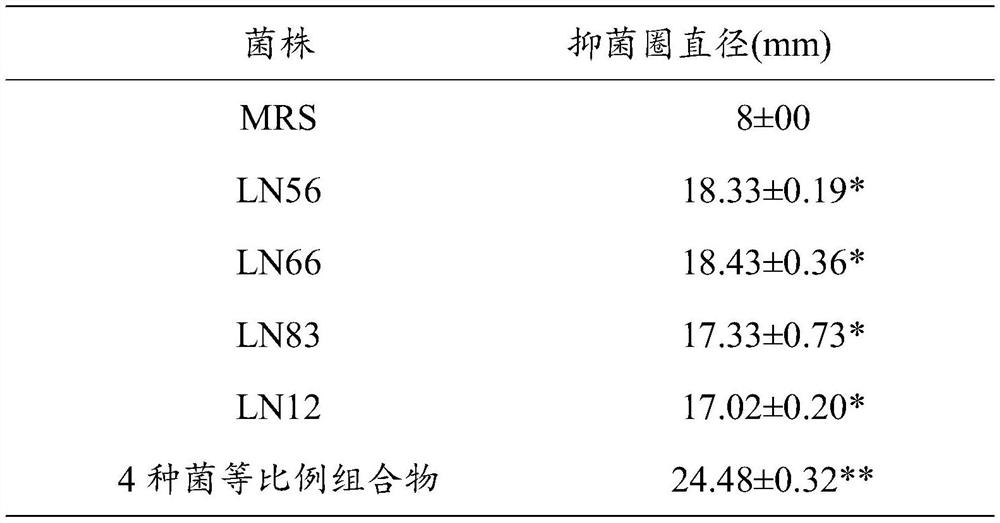

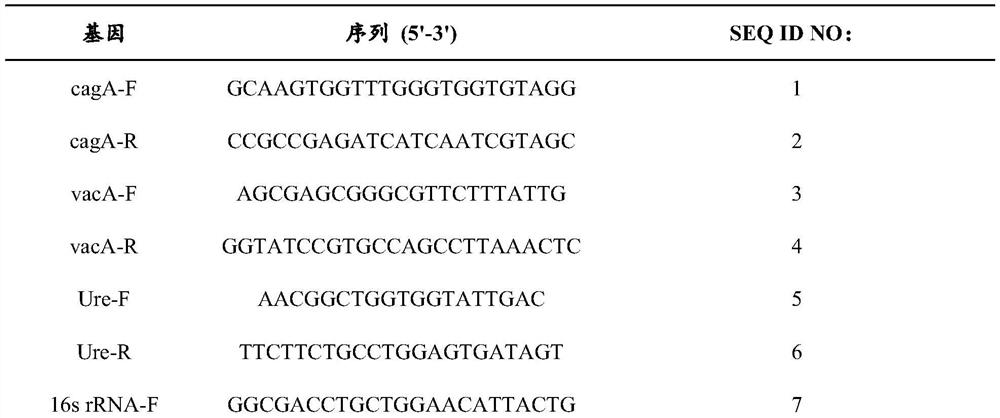

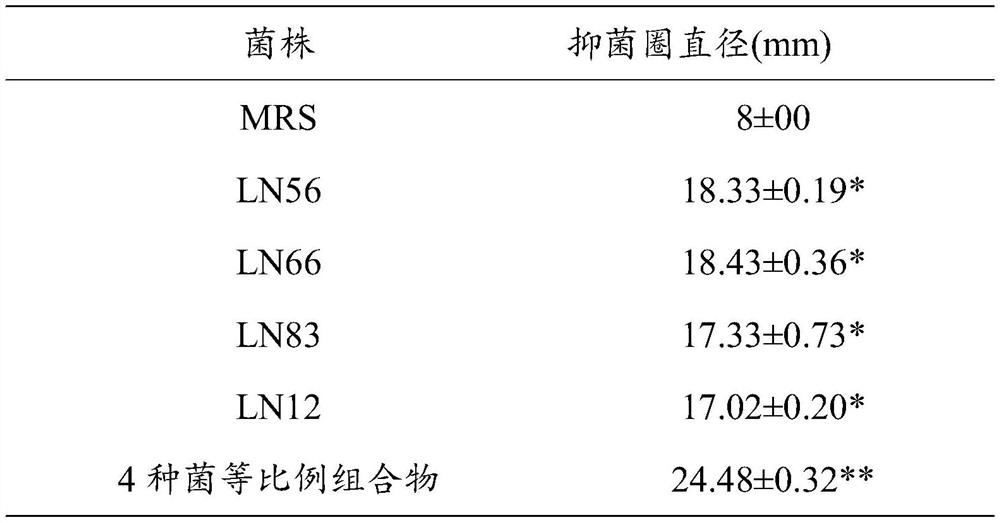

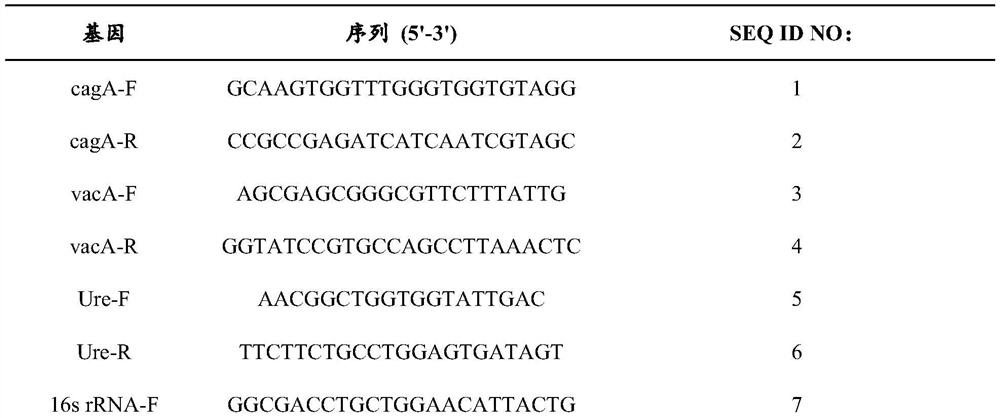

Probiotic composition for inhibiting helicobacter pylori and application

ActiveCN112458020AEnhanced inhibitory effectIncrease lethalityAntibacterial agentsBacteriaBiotechnologyLactobacillus salivarius

The invention provides a probiotic composition for inhibiting helicobacter pylori and application, and belongs to the technical field of foods and medicines. The probiotic composition comprises four probiotics of lactobacillus rhamnosus, lactobacillus plantarum, lactobacillus reuteri and lactobacillus salivarius. The probiotic composition has a synergistic inhibition effect on the helicobacter pylori, can significantly inhibit the growth of the helicobacter pylori, reduce the gene expression level of virulence factors CagA, VacA and Ure, can turn helicobacter pylori of a helicobacter pylori infection model mouse into negative, and can effectively reduce the number of helicobacter pylori in a human body or turn helicobacter pylori into negative. The four strains of the probiotic compositionhave a mutual synergistic effect, and the helicobacter pylori inhibiting effect of the probiotic composition is remarkably superior to the single application effect of each strain.

Owner:JIAXING INNOCUL PROBIOTICS CO LTD

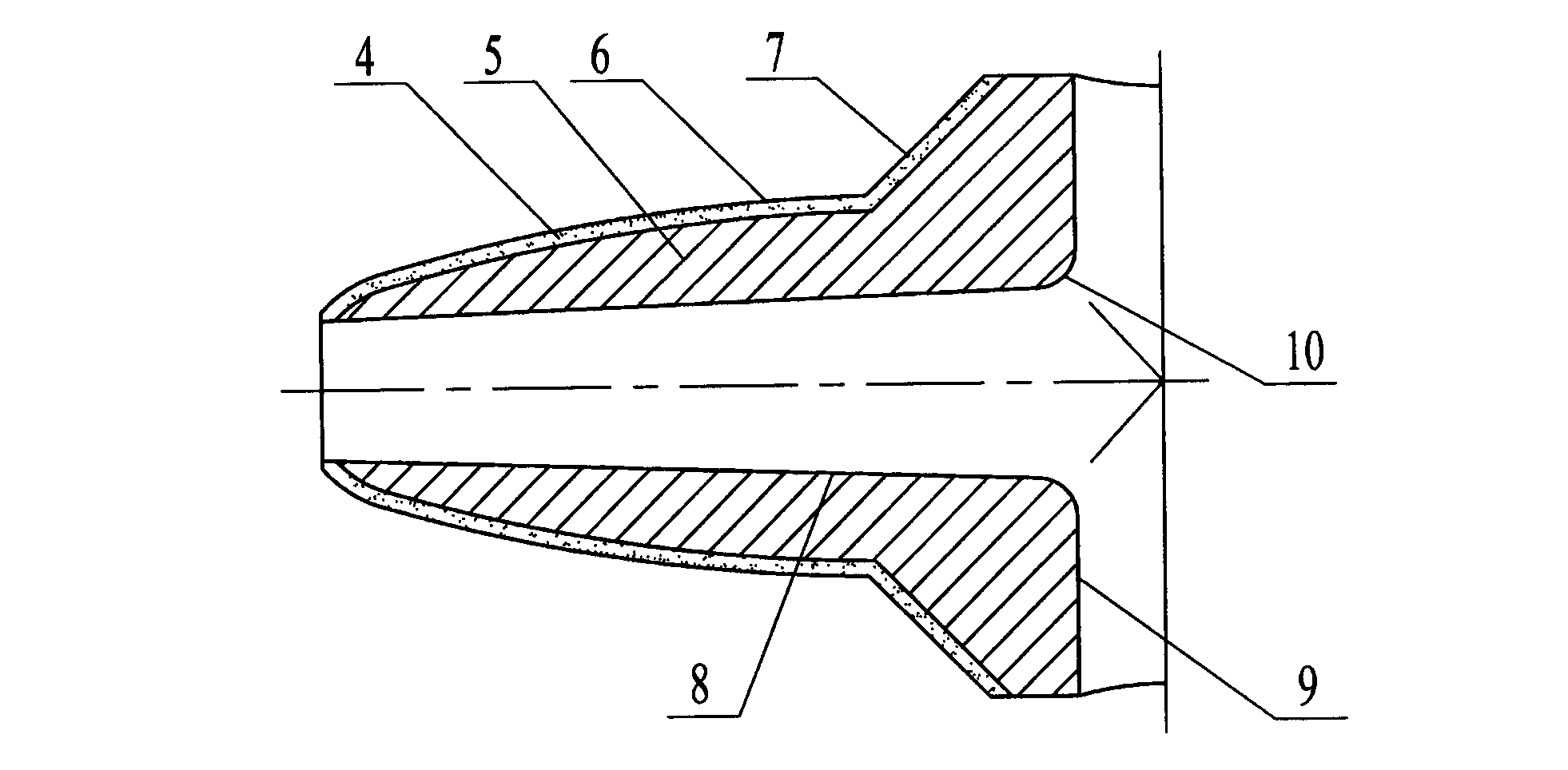

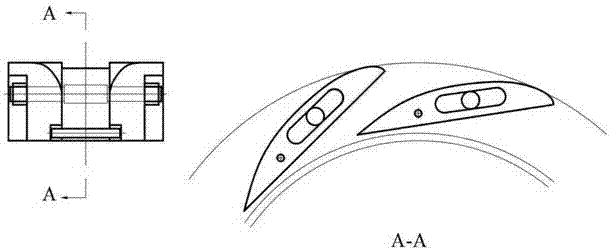

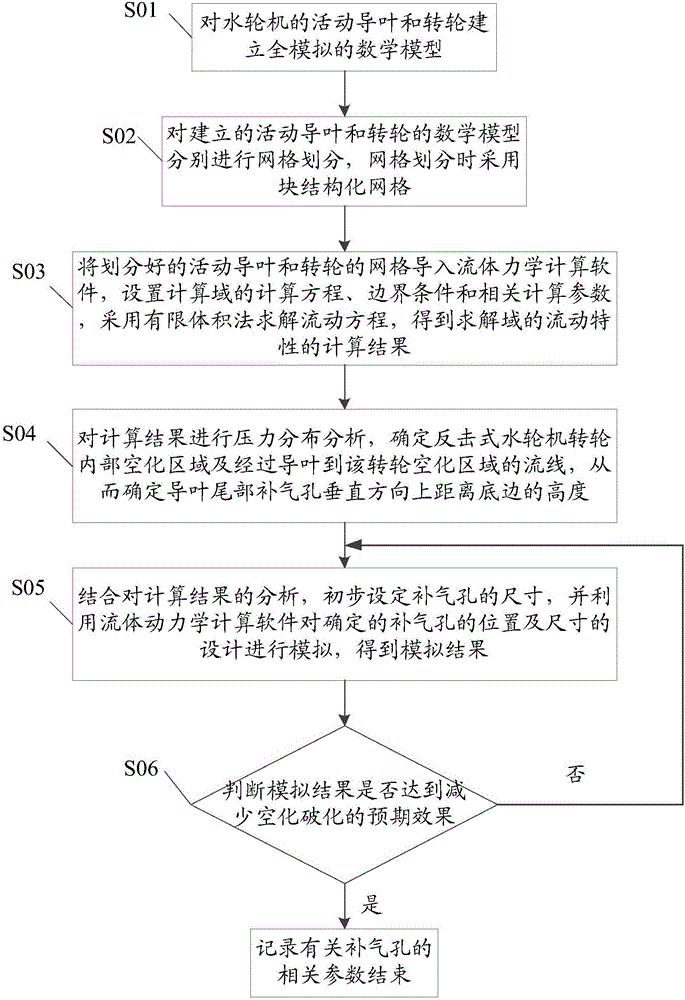

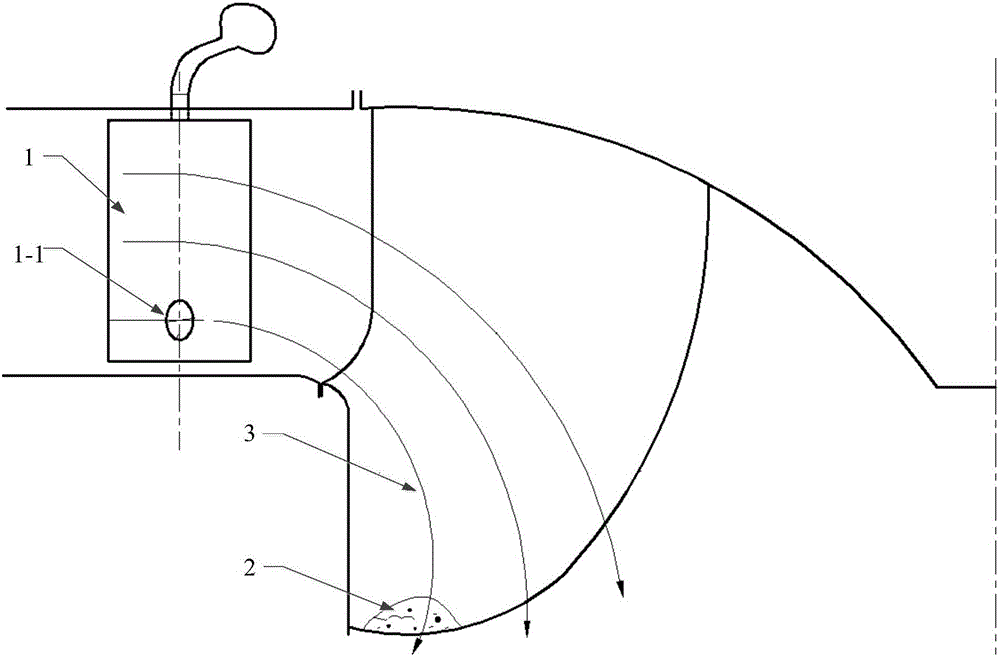

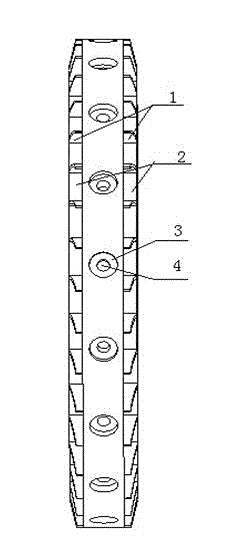

Pressure turbine and movable guide vane of same and air-compensating hole designing method for same

ActiveCN106485013AControl air concentrationThe solution accuracy is not highGeometric CADHydro energy generationCavitationMathematical model

The invention discloses an air-compensating hole designing method for a movable guide vane of a pressure turbine, and a pressure turbine and a movable guide vane. The air-compensating hole designing method comprises steps of building a full-simulation mathematic model for the movable guide vane of the turbine and a rotating wheel, carrying out mesh generation for the mathematic models of the movable guide vane and the rotating wheel, introducing well-divided grids of hydrodynamics calculation software to achieve a calculation result of flow characteristic of a solution domain, analyzing pressure distribution of the calculation result to determine an air-compensating hole position of the movable guide vane, primarily setting a size of the air-compensating hole based on an analysis of the calculation result, an simulating erosion reducing effect of the air-compensating hole to achieve the size of the air-compensating hole. According to empirical formula conclusion, air-compensating hole air entrainment concentration can be precisely controlled, so cavitation corrosion destroying degree of the interior of the pressure turbine rotating wheel can be effectively reduced; and problems of irrational design of the turbine anti-cavitation corrosion air-compensating structure, difficult processing and poor anti-cavitation corrosion effect can be solved.

Owner:XIHUA UNIV

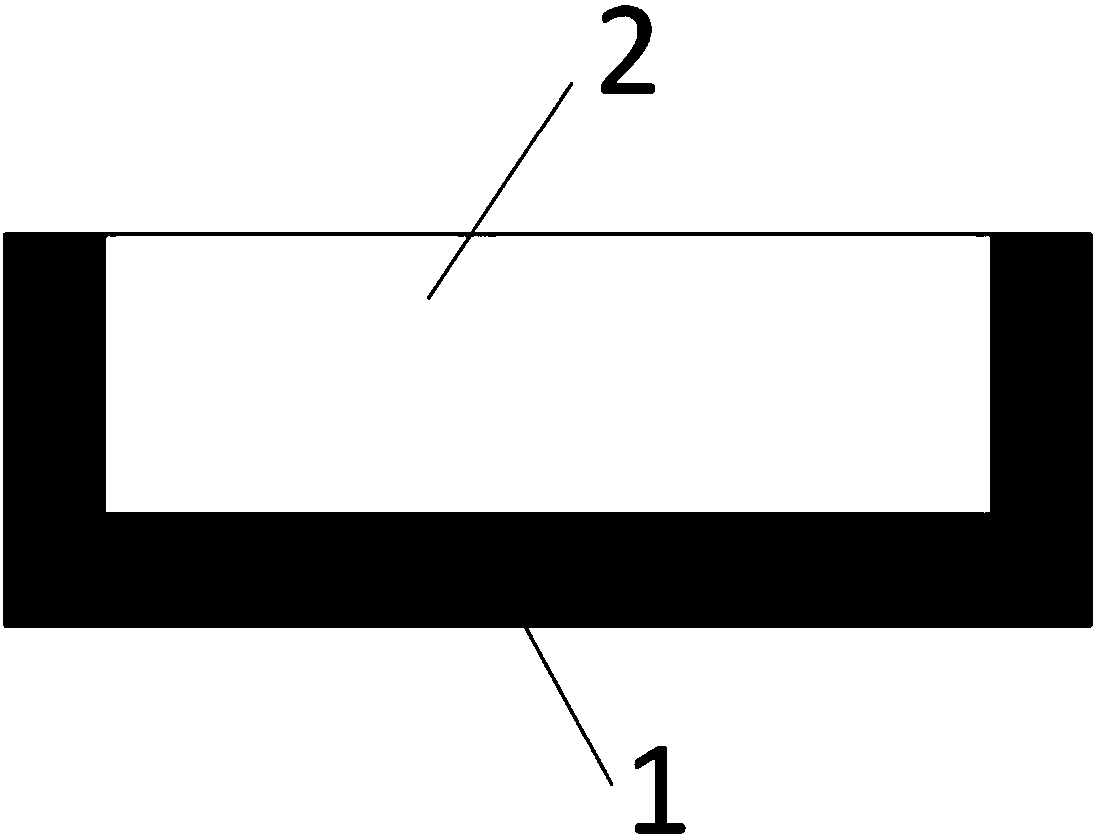

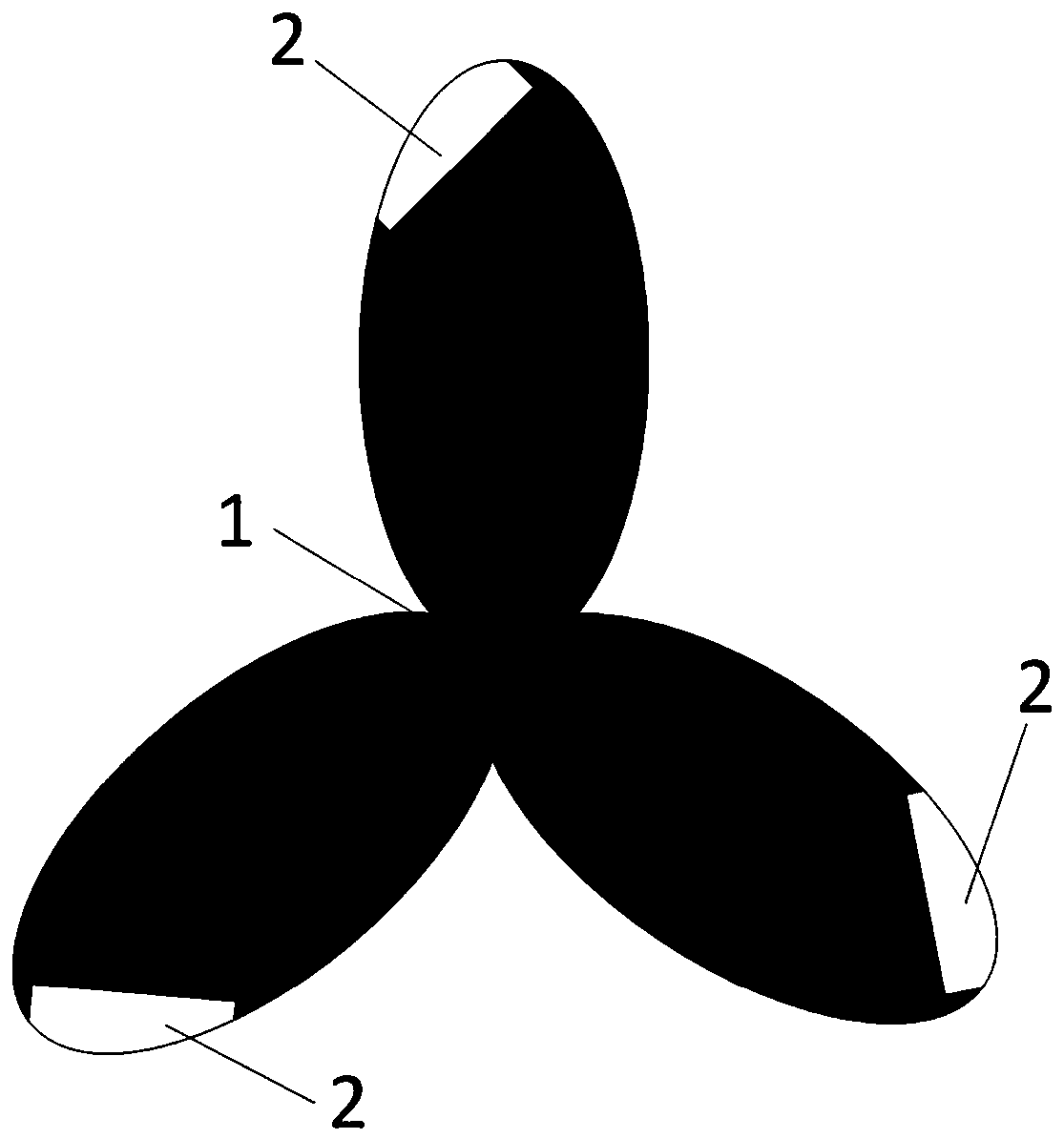

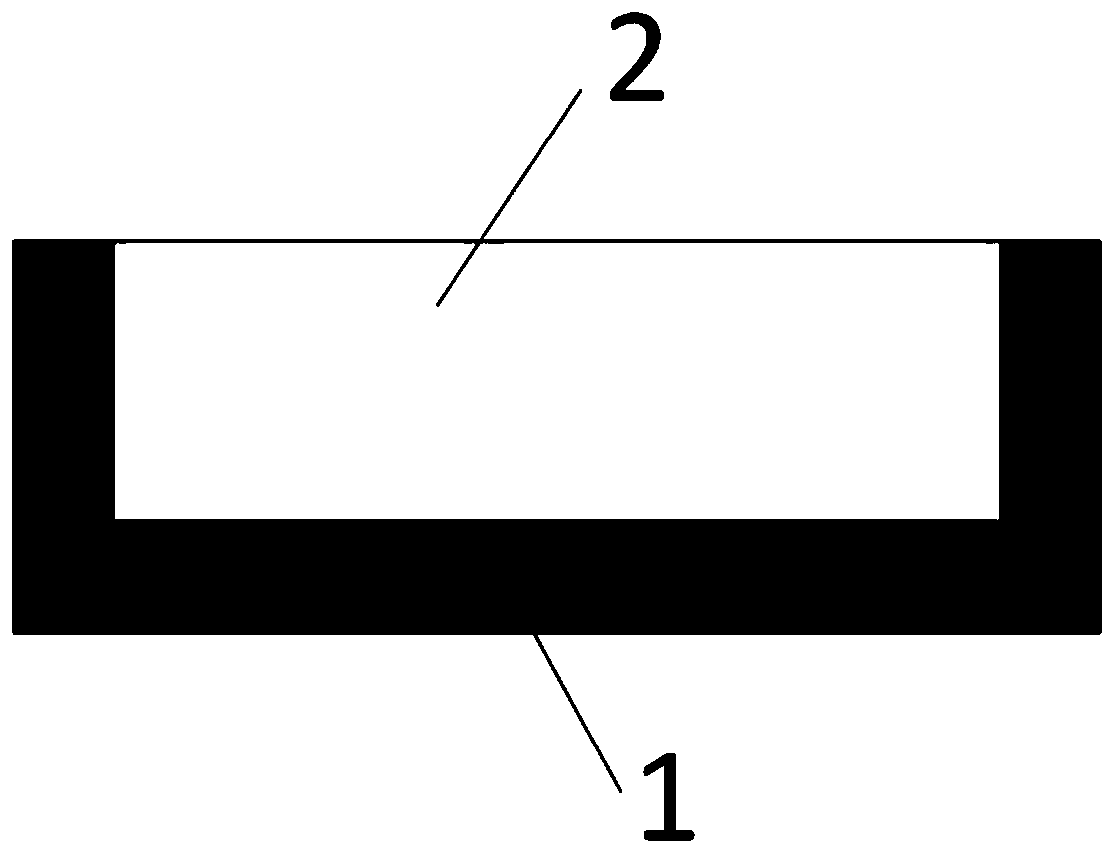

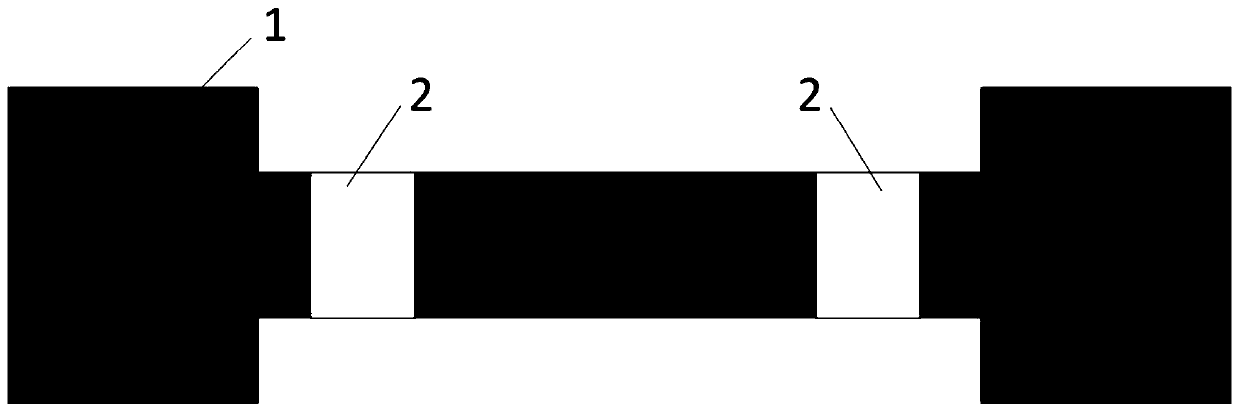

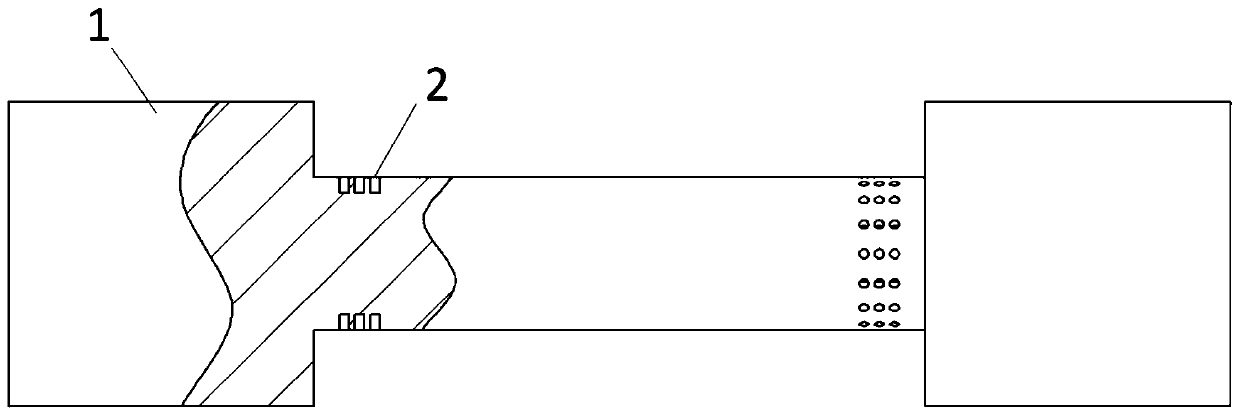

Cavitation-resistant structure surface layer

ActiveCN107587968AEasy to assembleFirmly assembledValve arrangementsPropellersCavitationSurface layer

The invention discloses a cavitation-resistant structure surface layer. The surface layer comprises a base and an elastic material layer arranged on the surface of the base and used for resisting cavitation; the elastic material layer is inlaid in or adheres to the base as a protective layer and is located on the portion or surface, impacted by liquid, of the base. By means of the cavitation-resistant structure surface layer, cavitation damage can be effectively inhibited, and thus important parts can be protected.

Owner:ZHEJIANG UNIV

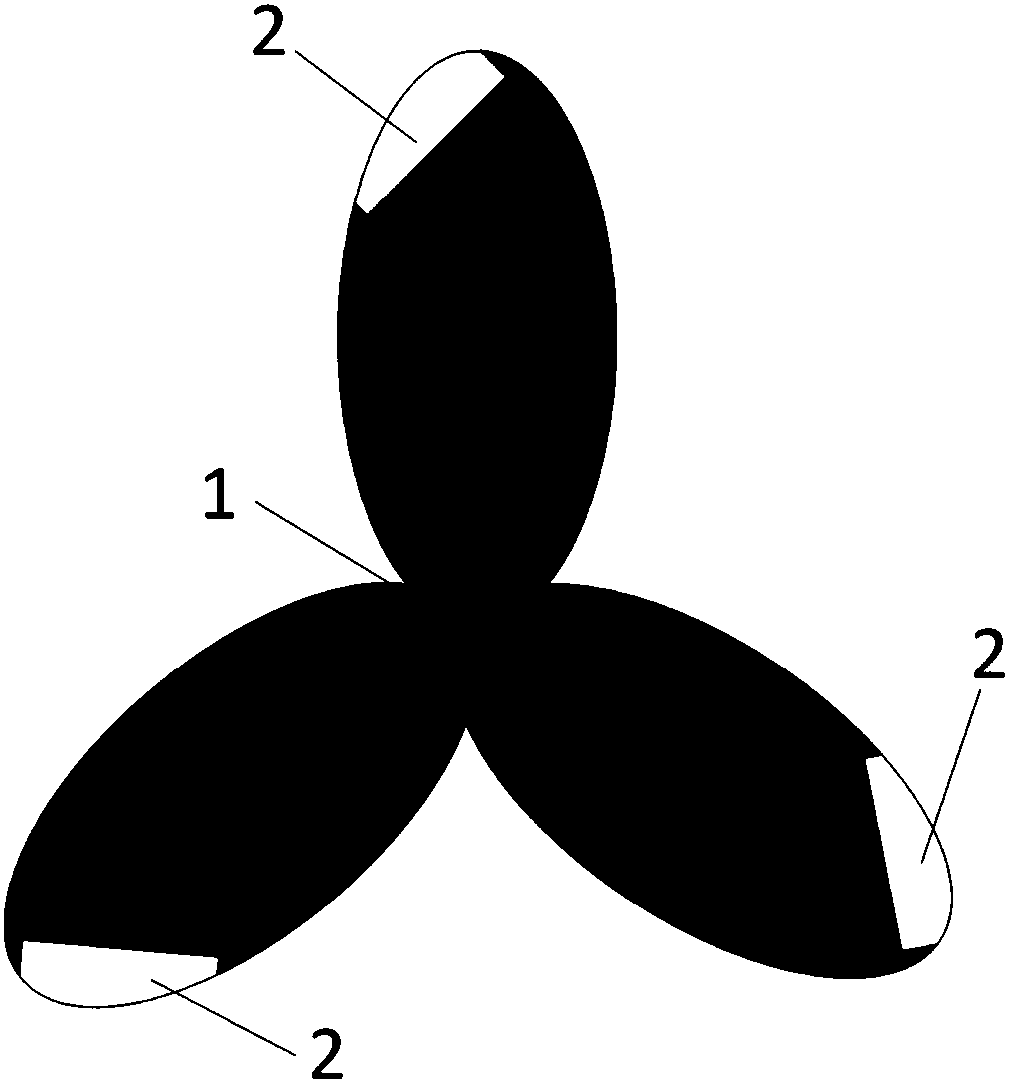

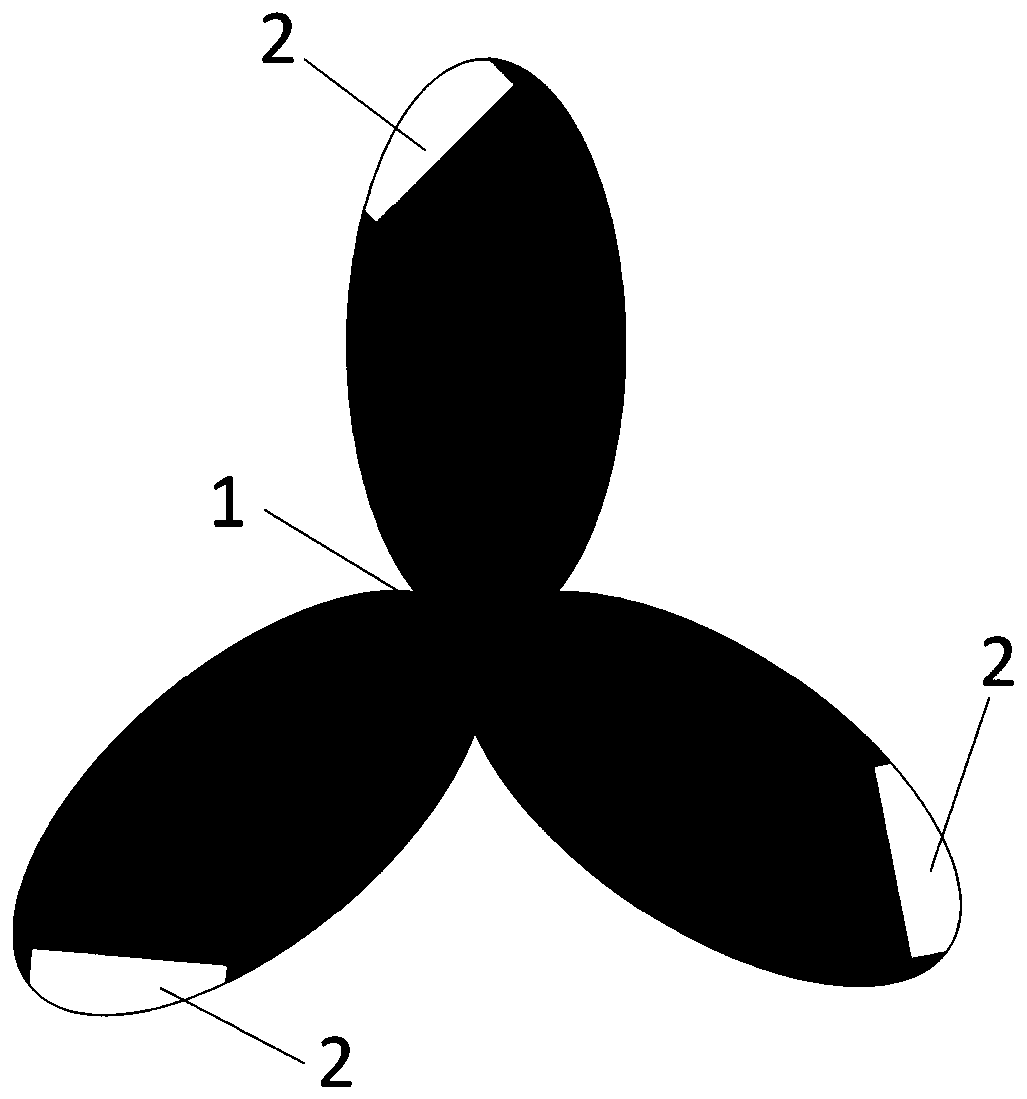

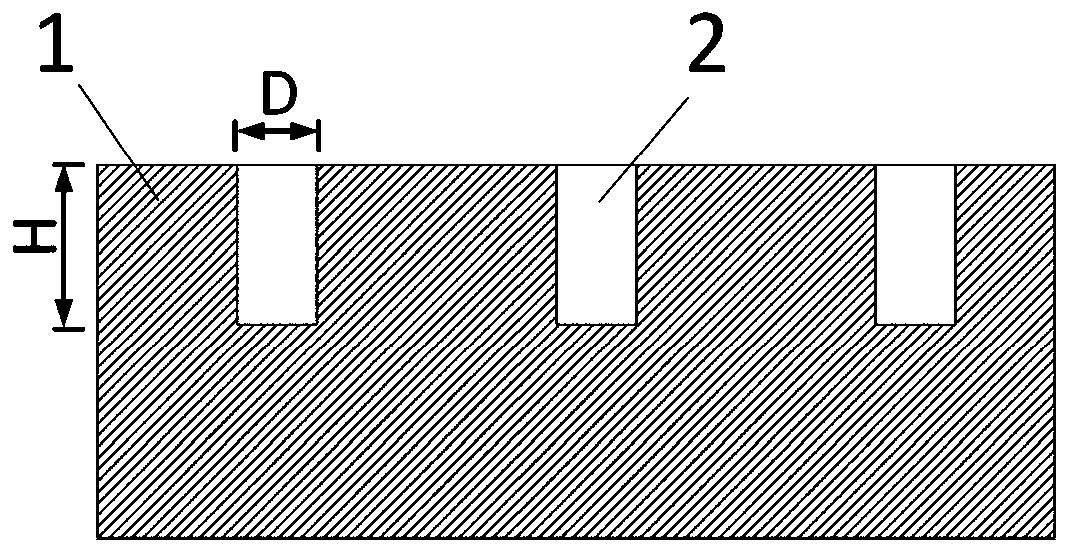

A kind of anti-cavitation microstructure surface layer

The invention discloses a cavitation-erosion-resistant microstructure surface layer. The cavitation-erosion-resistant microstructure surface layer comprises a base and a micro-protrusion or micro-groove microstructure which is arranged on the surface of the base and used for resisting cavitation erosion; an air film is formed by air contained in micro grooves formed between micro protrusions or air contained in the micro grooves, so that an air film layer which is used for resisting cavitation erosion is formed between a solid interface and a liquid interface through the microstructure; and the micro protrusions or the micro grooves serve as protecting layers and are arranged on the easy-cavitation surface of the base. According to the cavitation-erosion-resistant microstructure surface layer, the micro-jet speed during collapse of cavitation bubbles is greatly reduced, or even the micro-jet direction is changed to be away from the structure surface, so that damage to the surfaces of materials by cavitation and cavitation erosion is effectively inhibited.

Owner:ZHEJIANG UNIV

An anti-cavitation structure surface layer

ActiveCN107587968BChange directionChange speedValve arrangementsPropellersStructural engineeringMaterials science

The invention discloses a cavitation-resistant structure surface layer. The surface layer comprises a base and an elastic material layer arranged on the surface of the base and used for resisting cavitation; the elastic material layer is inlaid in or adheres to the base as a protective layer and is located on the portion or surface, impacted by liquid, of the base. By means of the cavitation-resistant structure surface layer, cavitation damage can be effectively inhibited, and thus important parts can be protected.

Owner:ZHEJIANG UNIV

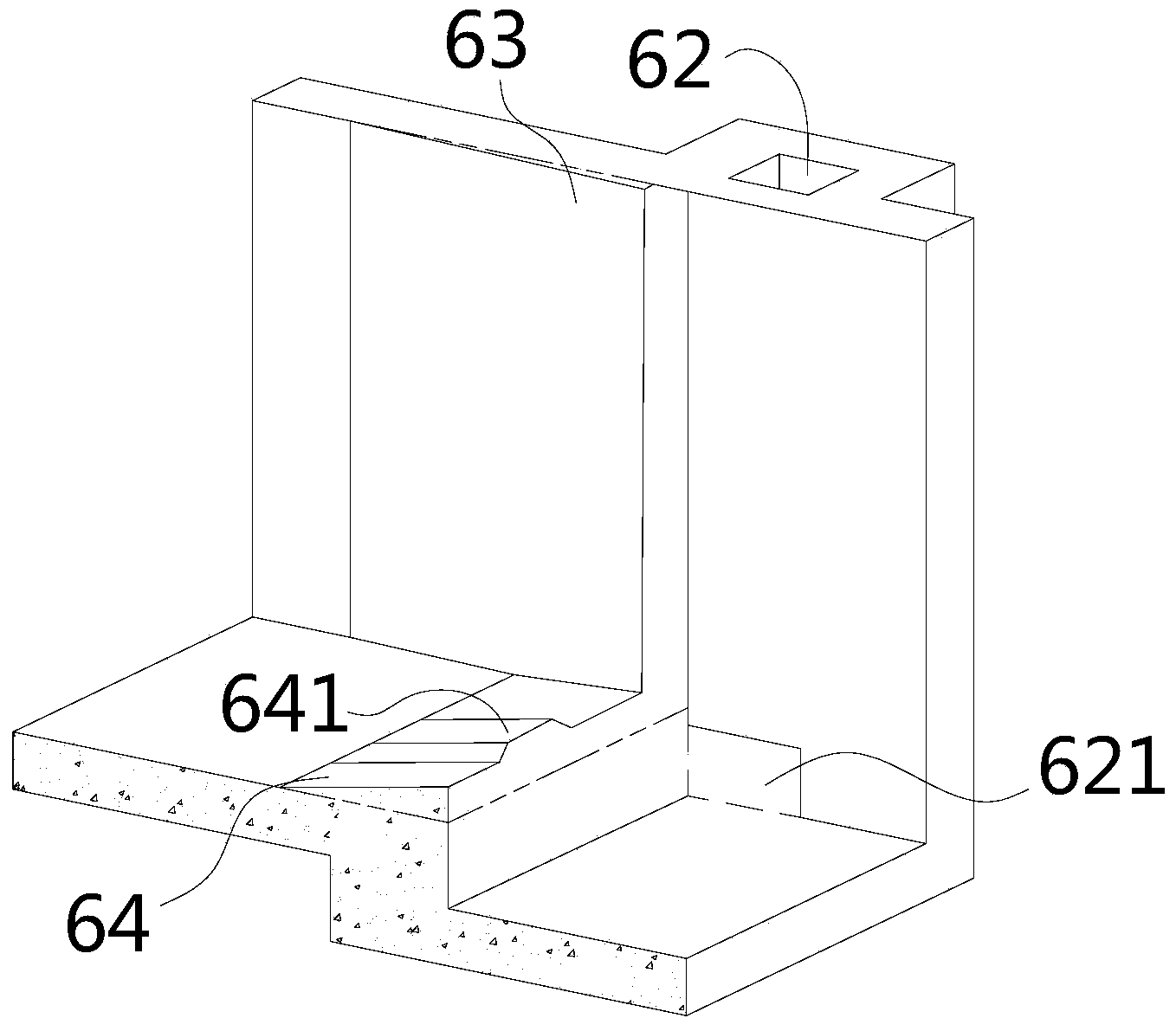

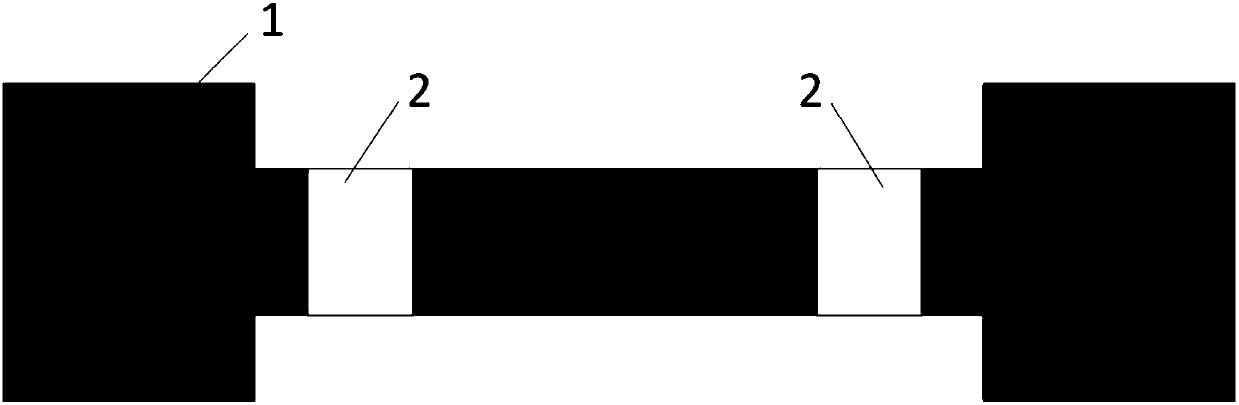

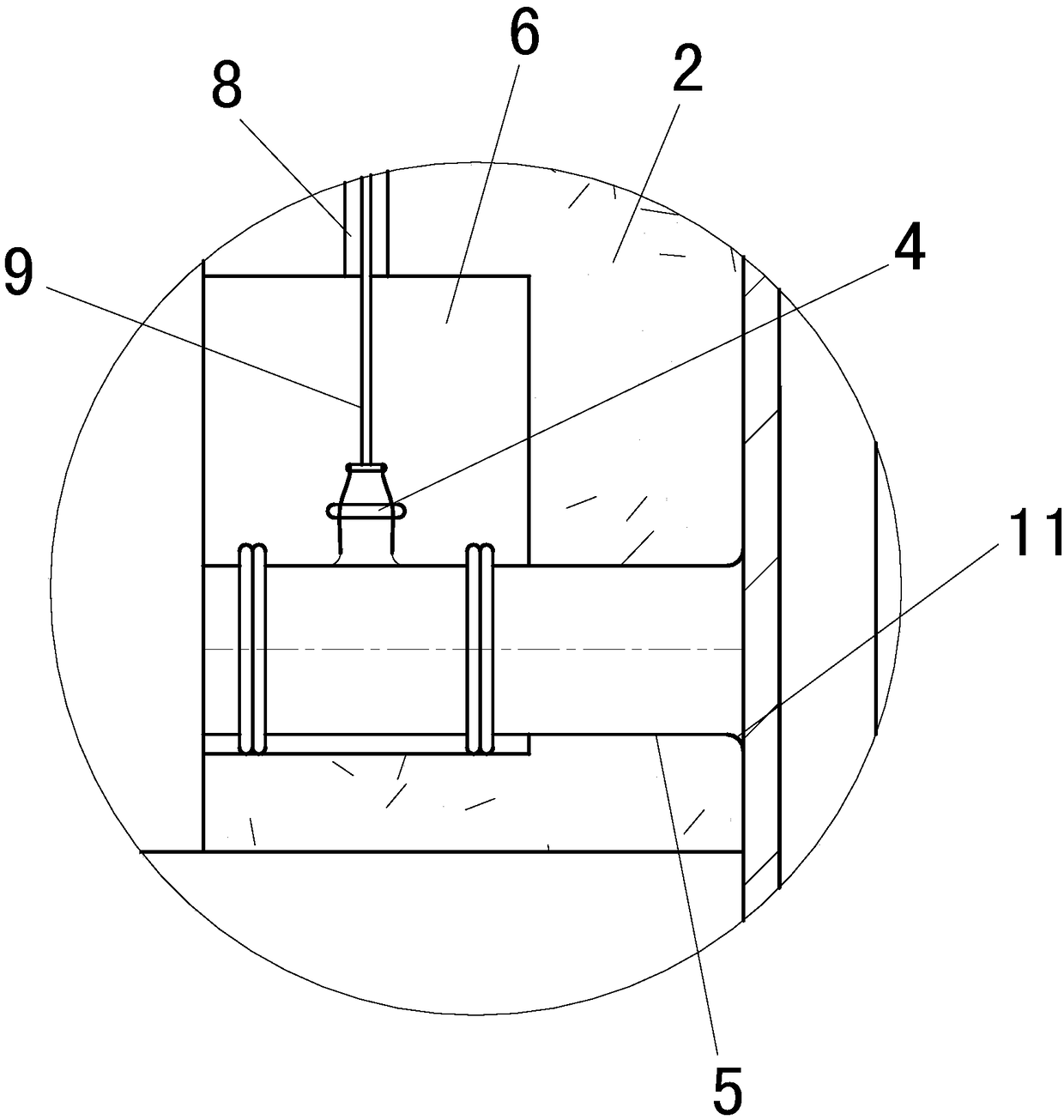

Embedded part structure and gate system thereof

The invention discloses an embedded part structure. The embedded part structure comprises a main body section with a rectangular cross section, a gate groove formed in the main body section and a pressing slope section. The pressing slope section structurally comprises a horizontally-arranged bottom plate face, two side wall surfaces perpendicular to the bottom plate face, and a top face. The bottom plate face, the side wall surfaces and the top face define a hollow structure with the periphery being closed and the two ends being opened. The top face refers to a slope face which is gradually tilted downwards from the upstream direction to the downstream direction. The pressing slope section forms a variable cross section structure with the caliber being gradually decreased. The upstream end of the pressing slope section is in butt joint with the downstream end of the main body section. By adoption of the embedded part structure, water flow flows to a non-pressure flow conversion area from a pressure flow area and is transferred to the downstream end of the pressing slope section from an original gate groove area, severe cavitation damage is also transferred to the downstream end ofthe pressing slope section from the gate groove area, and thus the gate groove area is protected. Meanwhile, the top face pressing slope of the pressing slope section is stable, water pressure in thegate groove area is increased, and cavitation damage to the gate groove area by high-speed water flow is reduced.

Owner:POWERCHINA ZHONGNAN ENG

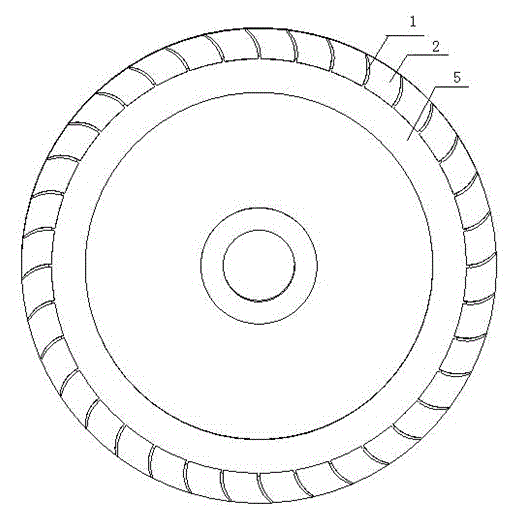

Balance disc used in solid-liquid two-phase flow conveying

ActiveCN103953568AReduce cavitation damageExtended service lifePump componentsPumpsChemical industryCavitation

The invention discloses a balance disc used in solid-liquid two-phase flow conveying. Blades uniformly distributed along the circumference at intervals are arranged at the edges of the circumferential surfaces at two sides of the balance disc; a notch slot is formed between each two adjacent blades; each blade is of a cylindrical rear bent blade; blind holes are uniformly distributed in the cylindrical side surface of the balance disc at intervals; bolts for adjusting balance disc counter weights are arranged in the blind holes in two sides in central symmetry; leaf springs and gaskets for finely tuning the counter weights are arranged between the bolts and the blind holes. The mechanical abrasion and the cavitation damage to the balance disc can be effectively reduced, the noise in the operation of a pump is reduced, and the service life is prolonged; when the balance disc is subjected to the dynamic balance adjustment, the balance quantity of the balance disc can be more conveniently adjusted under the condition that the counter weights on the surface of the disc body are not polished or spot-welded, and the vibration, noise and radial unbalance force which are generated in the motion process of the pump are reduced; the needs of pumps in the fields such as petroleum, chemical industry and water conservancy can be met.

Owner:ZHEJIANG SCI-TECH UNIV

Folded-line shape diversion pier of spillway

InactiveCN103276703BImprove the forceAvoid detachmentBarrages/weirsIsosceles trapezoidRight triangle

Owner:NORTHWEST A & F UNIV

Vertical plane interval regulating process for movable water-guiding vanes of water turbine

InactiveCN1403705AAccurate angle adjustmentPrecisely adjust the openingHydro energy generationReaction enginesVertical planeWater turbine

The regulating process includes the steps of: turning the speed regulating ring to the position of 5-100% relative opening and fixing; connecting the speed regulating rings and water guide blade regulating levers successively, regulating to designed lengths and angles precisely and locking; closing all the water guiding blades to almost zero interval via the speed regulating rings; searching and precisely measuring the maximum interval; trimming to regulate the interval of the water guiding blades to the maximum interval; and closing the water guiding blades to zero, measuring and checking all the water guiding blade intervals. The present invention results in no damage to profile of the water guiding blades, makes the water turbine run smoothly and raises the water sealing effect of the closed water guiding blades.

Owner:二滩水电开发有限责任公司二滩水力发电厂

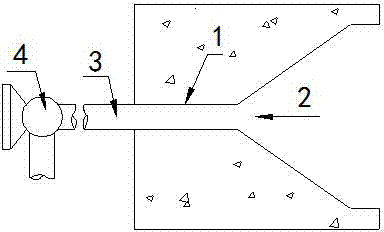

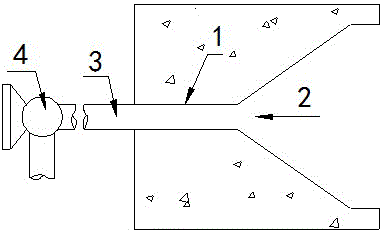

Pressurized-water corrosion inhibiting structure for water release building

ActiveCN103290817AReduce cavitation damageShorten speedBarrages/weirsWater flowEnvironmental engineering

The invention provides a pressurized-water corrosion inhibiting structure for a water release building. The pressurized-water corrosion inhibiting structure comprises a communication pipe embedded into the water release building. Pressurized-water equipment is connected with the outside of the inlet end of the communication pipe. The outlet end of the communication pipe is communicated with the flow-passing wall face of the water release building and is a flat porthole. The pressurized-water corrosion inhibiting structure can press and pour a low-flow-speed water body to the bottom of a high-flow-speed area of the flow-passing wall face so that a low-flow-speed area can be formed between the flow-passing wall face and the high-speed water flow, and the high-speed water flow can not directly act on the flow-passing wall face. Meanwhile, the high-speed water flow and the low-speed water flow generate the shearing, blending and entraining effect, a large amount of water flow kinetic energy is consumed, the bottom flow speed of the high-speed water flow can be lowered, water flow cavitation is inhibited, and damage of cavitation corrosion and flush corrosion is avoided.

Owner:POWERCHINA ZHONGNAN ENG

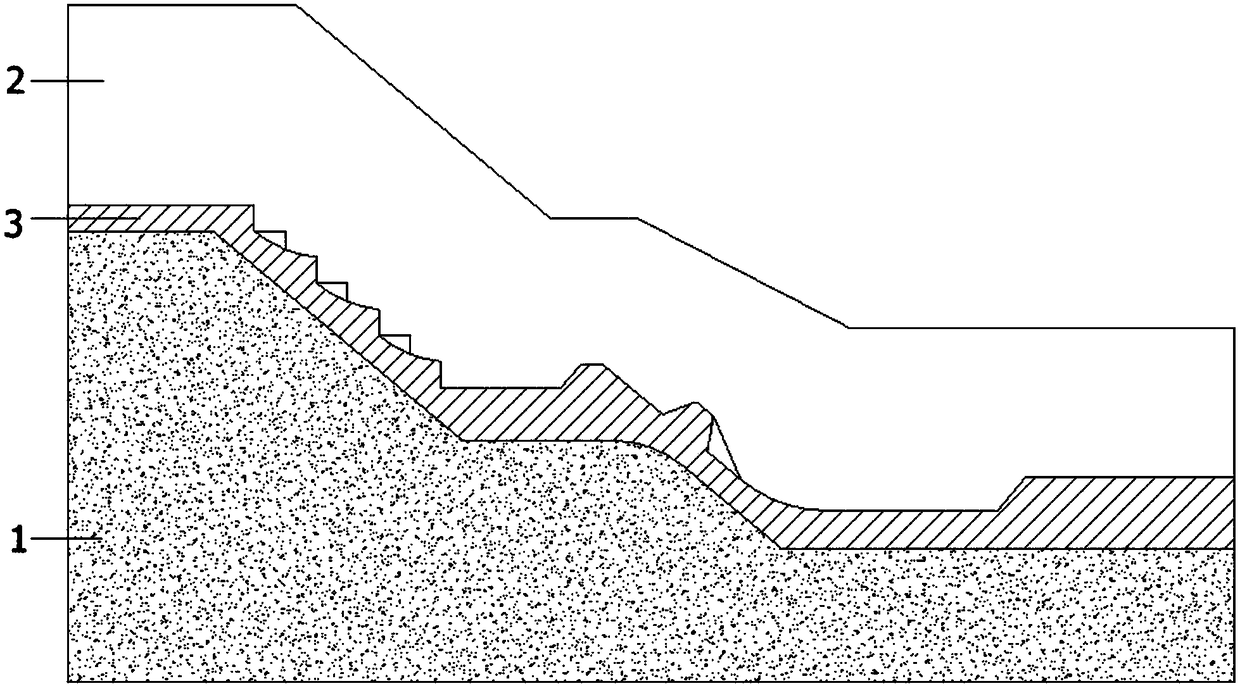

Dam spillway structure and construction method thereof

ActiveCN112281767AReduce cavitation damageImprove efficiencyBarrages/weirsStructural engineeringSpillway

The invention relates to a dam spillway structure and a construction method thereof. The dam spillway structure comprises an obliquely-arranged spillway body bottom plate, a first side plate and a second side plate, wherein the first side plate and the second side plate are formed on the upper end face of the spillway body bottom plate; one end of the spillway body bottom plate is provided with aninlet, and the other end of the spillway body bottom plate is provided with an outlet; the spillway body bottom plate inclines downwards from the inlet to the outlet; a plurality of step bodies are arranged at the upper part of the spillway body bottom plate in the drainage direction; each step body comprises a flat surface and a vertical surface; a vent groove is formed in each vertical surface;each vent groove extends in the extending direction of the corresponding step body; one end of each vent groove penetrates through the second side plate; and gas is introduced into each vent groove.The dam spillway structure has the effect of improving the energy dissipation rate of a spillway.

Owner:广东粤源工程咨询有限公司

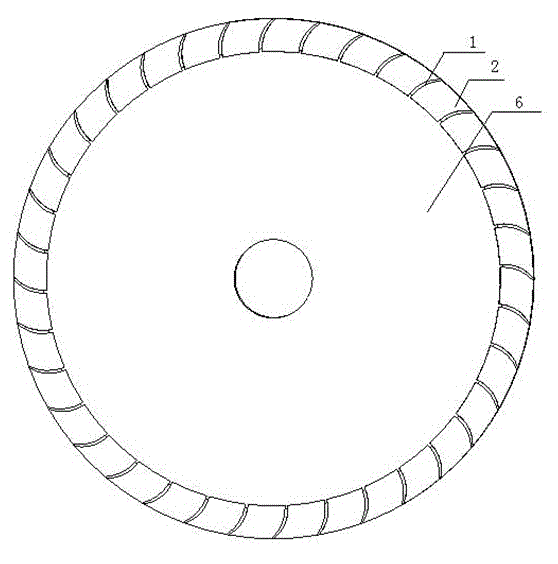

An anti-cavitation spool structure

ActiveCN107327628BChange directionChange speedValve members for absorbing fluid energySlide valveCavitationMaterials science

The invention discloses a cavitation resistant valve core structure. Cavitation induction holes used for cavitation resistance are formed in a part, likely to be cavitated, of a valve core. The part likely to be cavitated is the part or the surface, impacted by liquid, on the valve core. The cavitation induction holes are uniformly formed in the surface of the valve core along the circumference. The cavitation induction holes can effectively guide cavitation jets into the cavitation induction holes, and cavitation collapse jet kinetic energy is consumed through fluids in the cavitation induction holes, so that impact of cavitated bubble collapse jets on the important part of a valve body is avoided, and cavitation on the surface of the valve body is reduced or suppressed.

Owner:ZHEJIANG UNIV

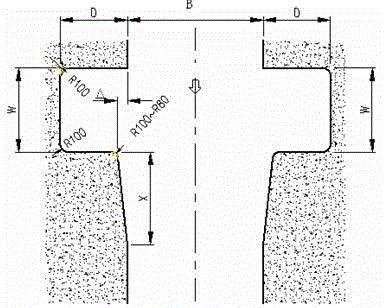

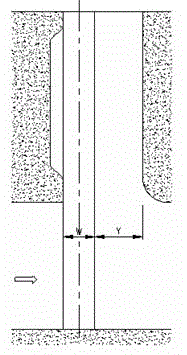

High attitude area dynamic water start-stop plane gate groove

The invention discloses a high attitude area dynamic water start-stop plane gate groove. The high attitude area dynamic water start-stop plane gate groove comprises a gate groove body, the ratio of the width W of the gate groove to the depth D of the gate groove is W / D=1.7-1.9, the ratio of the downstream alternate distance delta to the width W of the gate groove is delta / W=0.08-0.12, the slope ratio of downstream alternate distance delta to the length X of a slope is delta / X=1:13-15, and the distance Y between the downstream surface of the gate groove and a downstream breast wall is not smaller than 1.5 times the width W of the gate groove. Each circular bead formed in the corresponding slope alternate distance is R100-R80. Each internal circular bead of the gate groove is R100. By means of the high attitude area dynamic water start-stop plane gate groove, gate groove cavitation erosion and gate vibration brought by the gate groove cavitation erosion are reduced, and therefore the safety operation of the plane gate is guaranteed.

Owner:POWER CHINA KUNMING ENG CORP LTD

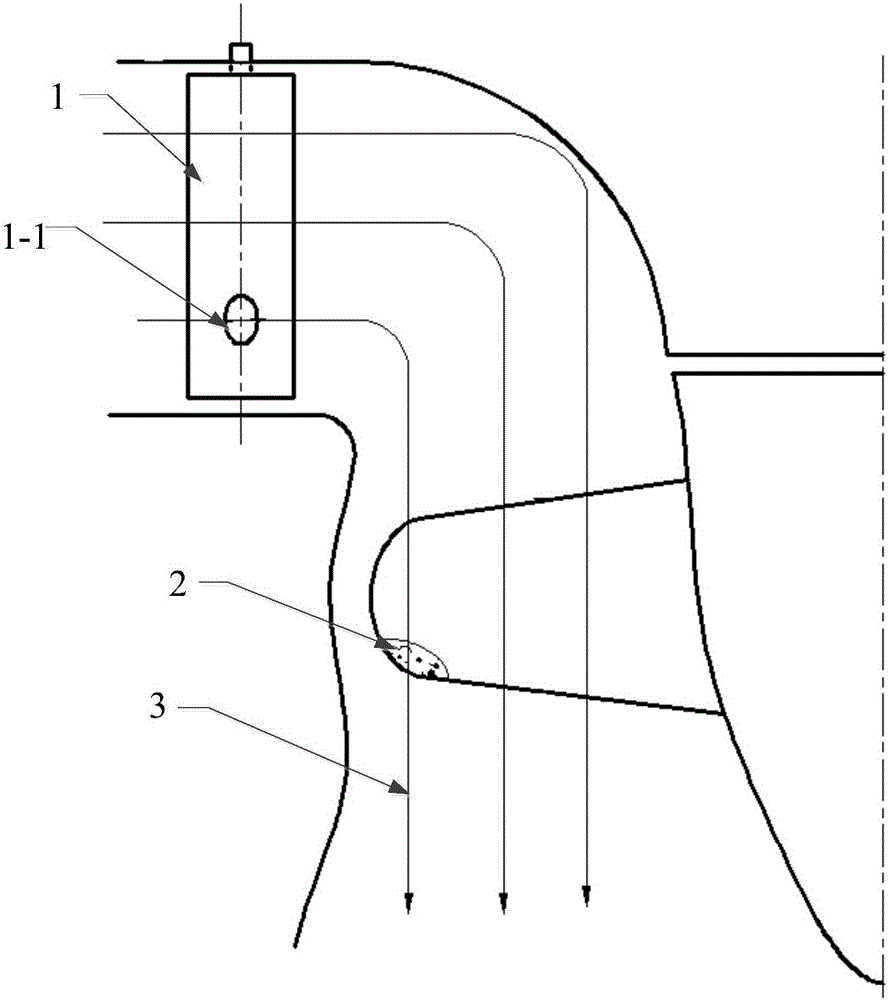

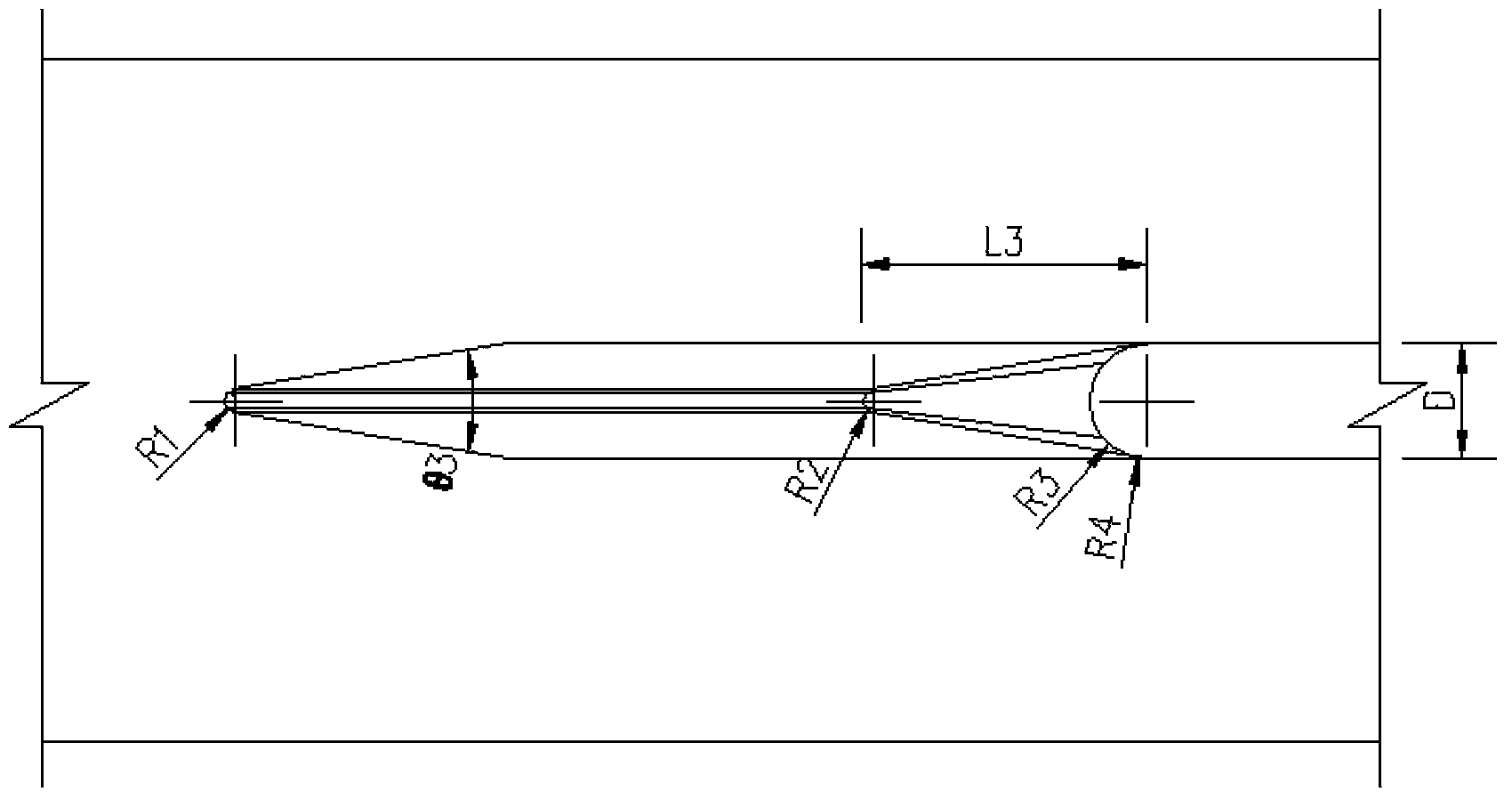

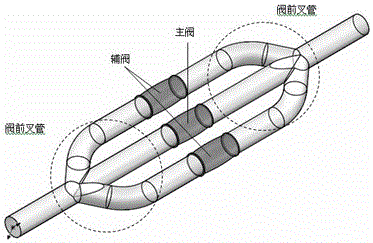

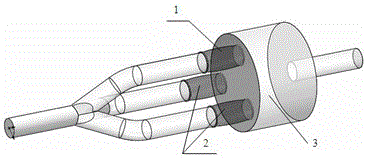

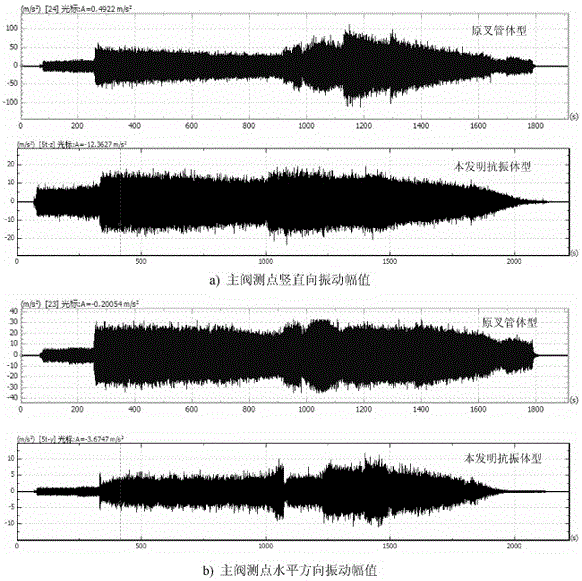

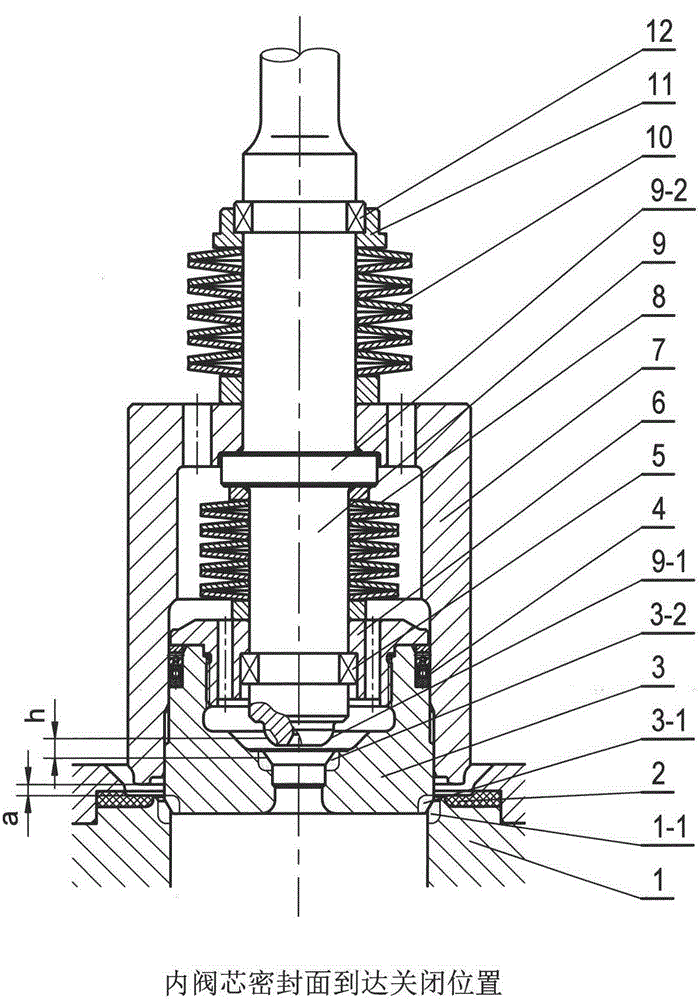

Optimum design method of hydraulic ship lifter valve system with anti-vibration performance

ActiveCN106638534AImproved fluidity after the valveEliminate low frequency vibrationVertical ship-liftingVibration amplitudeStress concentration

The invention relates to an optimum design method of a hydraulic ship lifter valve system with an anti-vibration performance. In order to reduce the vibration of the hydraulic ship lifter water delivery valve system generated under a high water head condition, the optimum design method provided by the invention is characterized by combining manners of 'optimizing a spatial arrangement type of three valves and improving a valve back pipeline shape', changing the original parallel arrangement of the three valves located at the same height into the spatial arrangement in a shape of the Chinese character 'Pin', and meanwhile, replacing a valve back multi-branch pipe joining section with an anti-vibration body with a 'cylindrical' shape, so that a valve back low-pressure vortex area is eliminated, the pulsating pressure is reduced, the flow velocity is reduced, and thus the aim of vibration resistance is achieved. According to the optimum design method of the hydraulic ship lifter valve system with the anti-vibration performance provided by the invention, the optimally designed anti-vibration body is provided with a circular flow section, so that the problem of stress concentration of vertex angles of a square structure is avoided, and design and construction can be carried out conveniently. A model test proves that the pulsating pressure of a valve back water flow and the vibration amplitude of a side wall of a pipeline can be effectively reduced, the valve back multi-branch pipe shape is simplified, and the safe operation of the hydraulic ship lifter water delivery valve system is ensured.

Owner:NANJING HYDRAULIC RES INST +1

Energy-dissipation flow channel structure capable of reducing flow speed

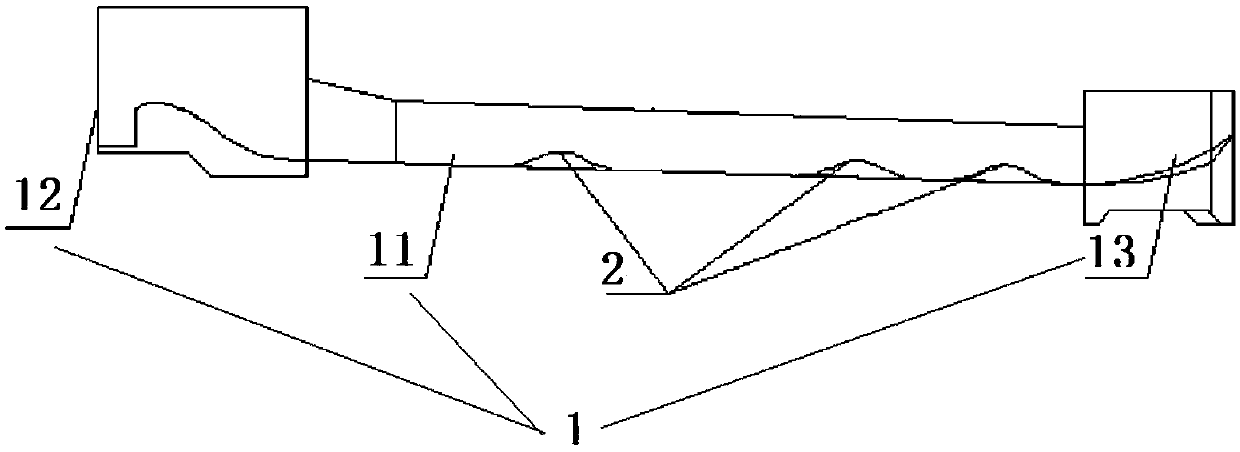

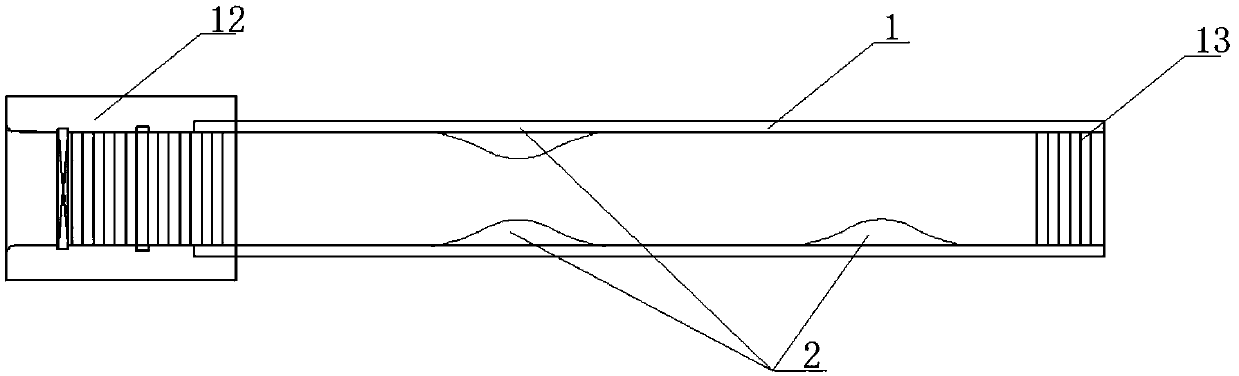

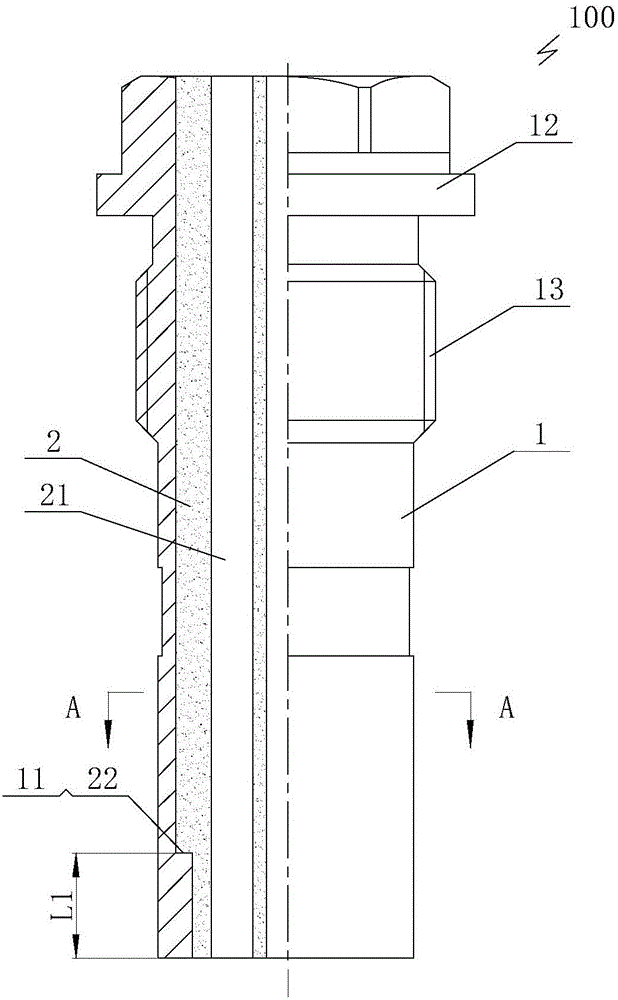

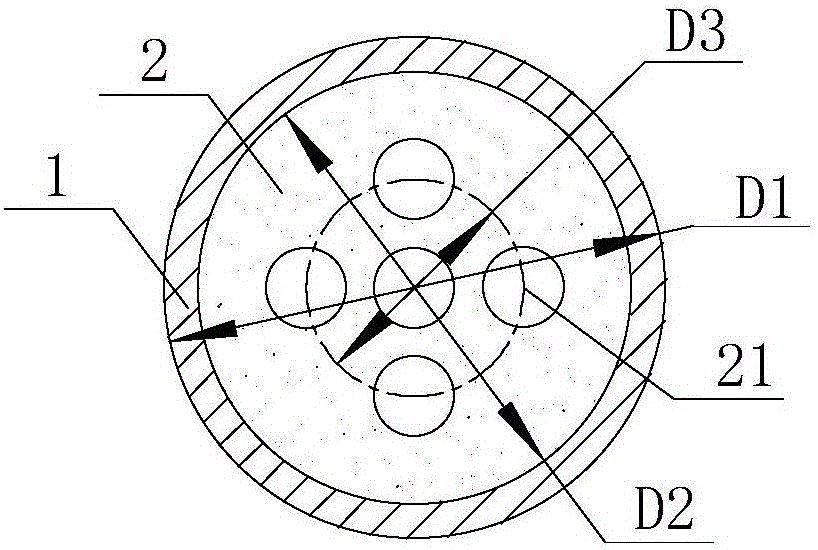

PendingCN109577292AReduce fluid turbulenceReduce cavitation damageBarrages/weirsWater-power plantsCavitationWater flow

The invention discloses an energy-dissipation flow channel structure capable of reducing flow speed. The energy-dissipation flow channel structure comprises a flow channel hole, a flow channel face isarranged on the flow channel hole, a flow channel inlet is formed in one end of the flow channel face, a flow channel outlet is formed in the other end of the flow channel face, and hump weirs are arranged on the flow channel face. According to the technical scheme, multiple hump weirs are arranged on the flow channel face, have different shapes, heights and sizes, and are staggered on the flow channel face, so that after fluid flows past the hump weirs, a good flow state is maintained, the phenomenon of turbulence of the flow state of the fluid is reduced, and the hydraulic condition is improved; meanwhile, sudden shrinkage and sudden expansion of the overflow cross section are caused by the hump weirs, the energy loss of water current is increased, the purposes of reducing the flow speed and adjusting the flow line and the flow state are achieved, and the probability that the fluid suffers from cavitation damage in the flow channel hole is reduced. The energy-dissipation flow channel structure has the advantages of being simple, convenient in construction, low in building cost and the like, and is suitable for various sluicing structures which need energy dissipation treatment.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD +2

A porous oil nozzle for oil and gas well testing

InactiveCN106121584AAvoid cloggingExtended service lifeWell/borehole valve arrangementsSealing/packingHigh potentialPetroleum engineering

The invention provides a porous oil nozzle for oil and gas well testing. The porous oil nozzle comprises a hollow oil nozzle outer sleeve; an oil nozzle inner core is fixedly sealed in the oil nozzle outer sleeve; the inside of the oil nozzle inner core is provided with a plurality of vertically-through and parallel inner core ducts. The porous oil nozzle for oil and gas well testing solves the problems that conventional oil nozzles are liable to breakage, high in replacement cost, and liable to cause environmental pollution, apparatus damage and high potential safety hazards. The porous oil nozzle for oil and gas well testing realizes multiple jets and reduces erosion damage, so that the service life of the oil nozzle is prolonged and environmental pollution and potential safety hazards are prevented.

Owner:CNPC GREATWALL DRILLING ENG +1

A probiotic composition for inhibiting Helicobacter pylori and its application

ActiveCN112458020BEnhanced inhibitory effectIncrease lethalityAntibacterial agentsBacteriaLactobacillus salivariusLactobacillus rhamnosus

The invention provides a probiotic composition and application for inhibiting Helicobacter pylori, belonging to the technical field of food and medicine. The probiotic composition of the present invention includes 4 strains of probiotics: Lactobacillus rhamnosus, Lactobacillus plantarum, Lactobacillus reuteri and Lactobacillus salivarius. The probiotic composition has a synergistic inhibitory effect on Helicobacter pylori, can significantly inhibit the growth of Helicobacter pylori, reduce the gene expression levels of virulence factors CagA, VacA and Ure, and can make Helicobacter pylori infection model mice Helicobacter pylori. It can effectively reduce the number of Helicobacter pylori in the human body or make the Helicobacter pylori in the human body turn negative. The four strains of the probiotic composition have synergistic effects with each other, and the effect of inhibiting Helicobacter pylori is significantly better than the individual application effect of each strain.

Owner:JIAXING INNOCUL PROBIOTICS CO LTD

Anti-bubble drag reduction method and system for ships

ActiveCN110304193BLow gas consumptionLow running costWatercraft hull designHydrodynamic/hydrostatic featuresEngineeringMechanical engineering

Owner:SHANGHAI MARITIME UNIVERSITY

A dam spillway structure and its construction method

ActiveCN112281767BReduce cavitation damageImprove efficiencyBarrages/weirsEngineeringStructural engineering

The application relates to a dam spillway structure and its construction method, which includes a channel bottom plate arranged obliquely, a first side plate and a second side plate formed on the upper surface of the channel bottom plate; one end of the channel bottom plate is the entrance, The other end is the exit, and the bottom plate of the channel body is inclined downward from the entrance to the exit; the upper part of the bottom plate of the channel body is provided with a plurality of steps along the drainage direction; the step body includes a straight surface and a vertical surface; There is a ventilation groove, the ventilation groove extends along the extension direction of the step body and one end runs through the second side plate, and gas is passed into the ventilation groove. The application has the effect of improving the energy dissipation rate of the spillway.

Owner:广东粤源工程咨询有限公司

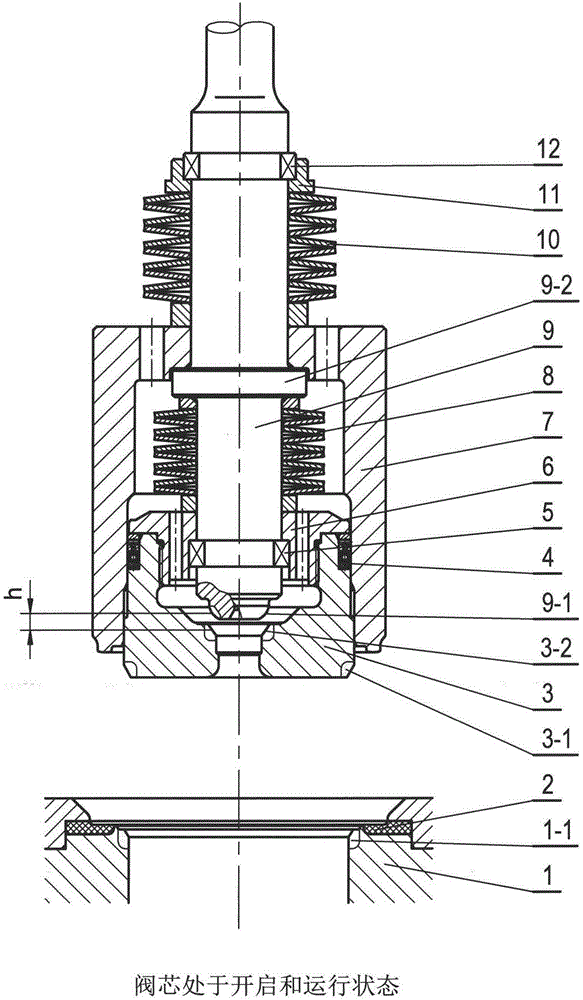

Double seal linkage pilot spool structure of high pressure differential valve

ActiveCN103939629BImprove sealingImprove use reliabilityValve members for absorbing fluid energyLift valveSpool valvePressure difference

The invention discloses a double-seal linkage pilot valve element structure of a high-pressure-difference valve. According to the technical scheme, a fixing ring is installed and fixed on an outer circle of the lower end of a valve rod, and an inner valve element assembly is installed and connected to the lower end of the valve rod through the fixing ring. An annular boss is arranged on the outer circle of the valve rod, and a lower spring is pre-tightened and installed between the annular boss and the inner valve element assembly of the valve rod in a sleeved mode. The outer circle of an inner valve element is enclosed by an inner hole of the lower segment of an outer valve element in a sleeved mode, the outer valve element and the inner valve element move relative to each other in the axial direction while the valve is closed up, and a sealing ring is located between the outer valve element and the inner valve element. A platform at the upper end of the outer valve element is located on the upper side of the annular boss of the valve rod, a spring thrust ring is fixed to the valve rod, and an upper spring is pre-tightened and installed between the spring thrust ring and the upper plane of the outer valve element in a sleeved mode. A plurality of balance holes are formed in a valve element cover and the upper end of the outer valve element. According to the technical scheme, the double-seal linkage pilot valve element structure of the high-pressure-difference valve has the advantages that the valve can achieve high sealing capacity, scour and cavitation erosion damage to the sealing face is reduced, meanwhile, the using reliability of the valve is improved, and the service life of the valve is prolonged.

Owner:沈阳古来科技有限公司

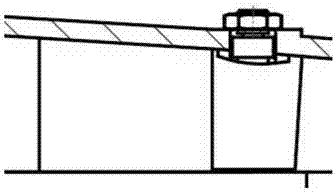

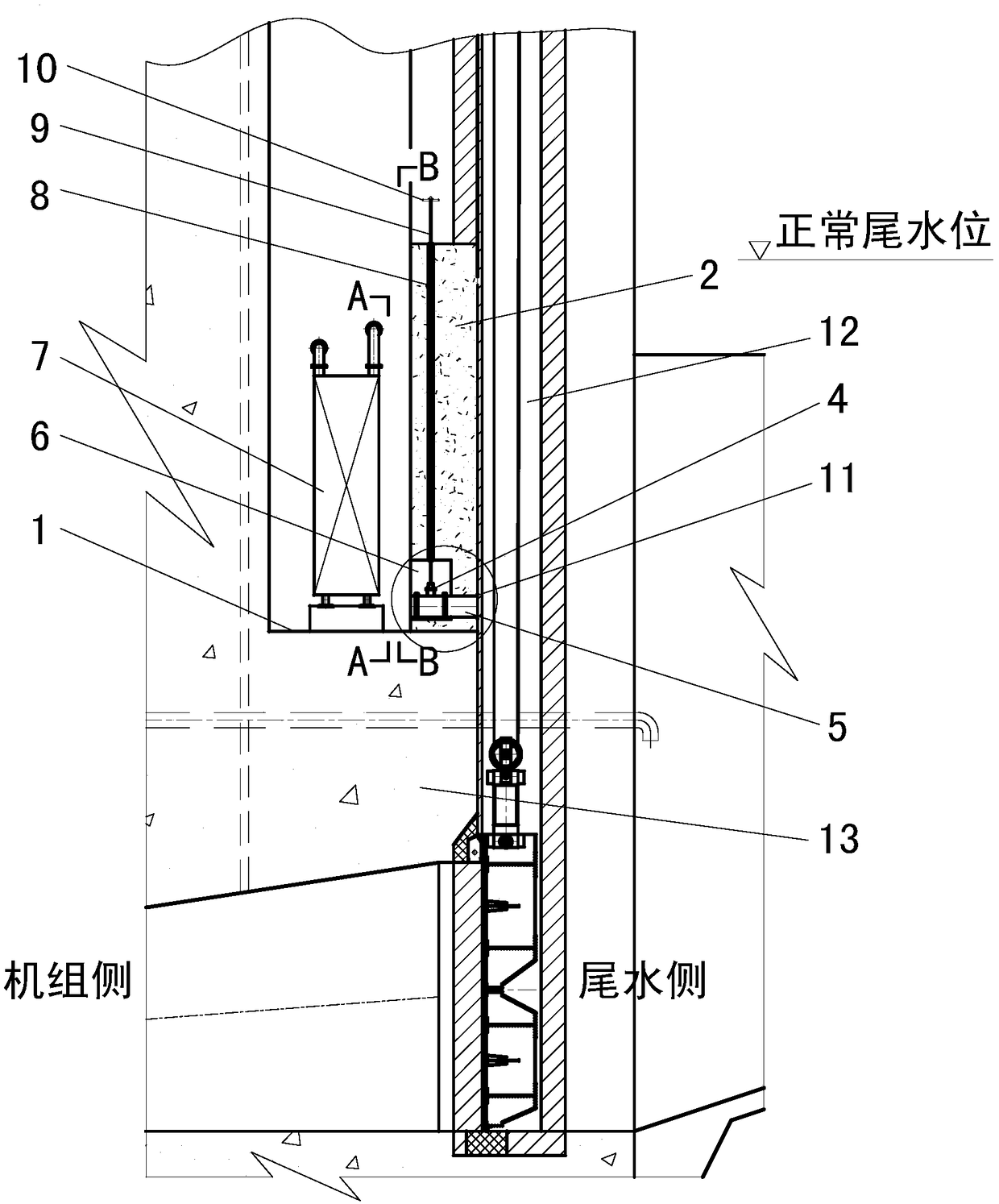

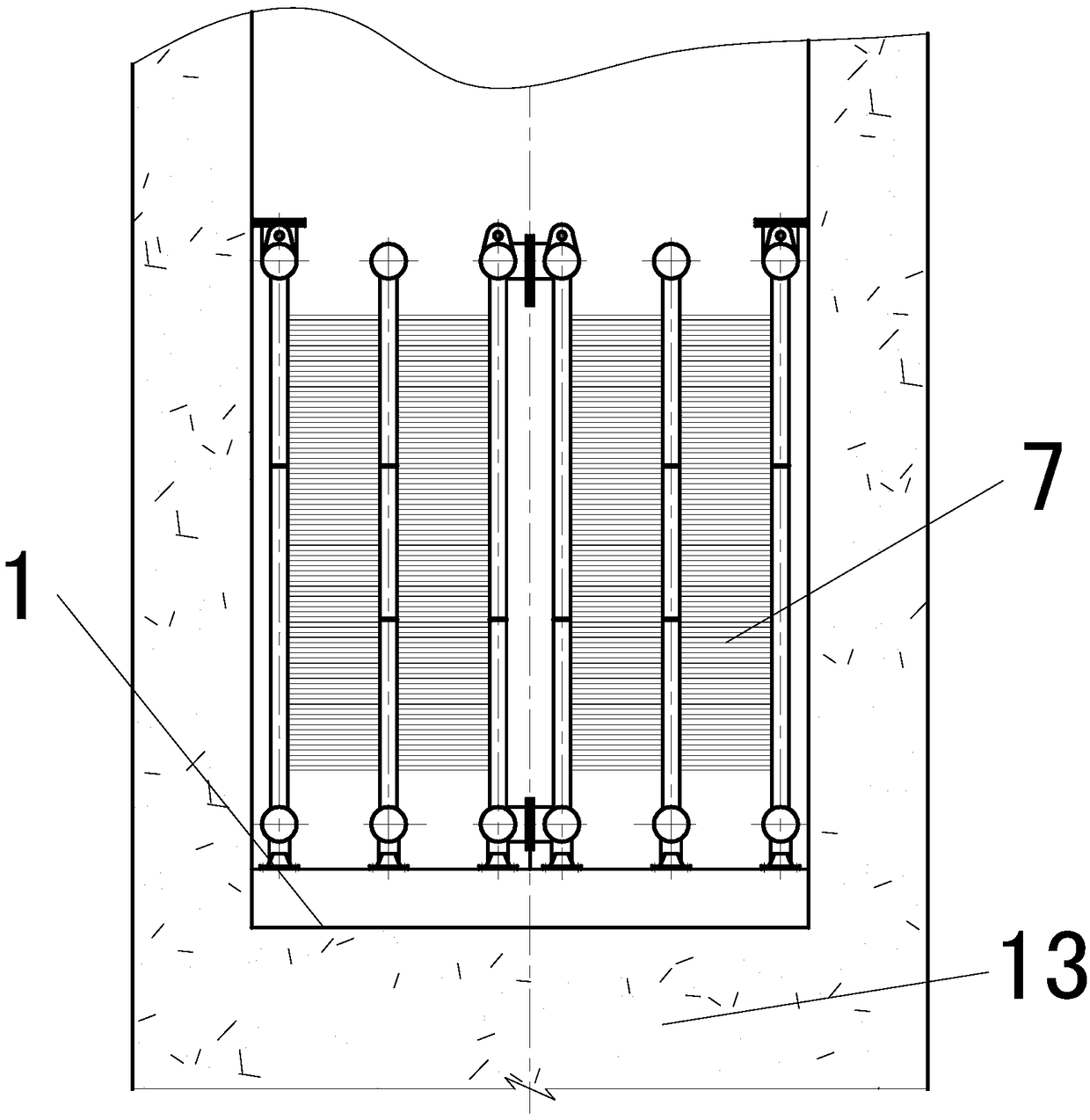

Method and device for overhauling tailwater cooler

PendingCN108824382AImprove personal safetyEasy maintenanceBarrages/weirsWater-power plantsEngineeringRetaining wall

The invention discloses a method and device for overhauling a tailwater cooler. The tailwater cooler is located at the top surface of an upper platform. According to the method, a water retaining wallis built on the edge of the top surface of the upper platform, wherein the top of the water retaining wall is slightly higher than the normal tailwater level or the elevation of the generating waterlevel of a unit; steel pipes communicating with a gate slot hole are arranged in the water retaining wall, valves are installed on the steel pipes, and when the tailwater cooler needs to be overhauled, all valves are closed first, and the water body on the side, close to the tailwater cooler, of the water retaining wall is discharged through a temporary water pump; afterwards, the tailwater cooleris overhauled; after overhaul work is completed and overhaul personnel leave the upper platform, water filling and pressure balancing are performed on the tailwater cooler side of the water retainingwall through the temporary water pump, and all the valves are opened so that water areas on two sides of the water retaining wall communicate with each other to realize cooling of the tailwater cooler. In the process of overhauling according to the method, the tailwater cooler does not need to be lifted away from the upper platform, underwater operation is not needed, and therefore overhauling and maintenance can be carried out very conveniently, overhauling efficiency can be improved, and the personal safety of the overhauling personnel can be ensured.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

A pressurized water corrosion reduction structure for a water release structure

ActiveCN103290817BReduce cavitation damageShorten speedBarrages/weirsWater flowEnvironmental engineering

The invention provides a pressurized-water corrosion inhibiting structure for a water release building. The pressurized-water corrosion inhibiting structure comprises a communication pipe embedded into the water release building. Pressurized-water equipment is connected with the outside of the inlet end of the communication pipe. The outlet end of the communication pipe is communicated with the flow-passing wall face of the water release building and is a flat porthole. The pressurized-water corrosion inhibiting structure can press and pour a low-flow-speed water body to the bottom of a high-flow-speed area of the flow-passing wall face so that a low-flow-speed area can be formed between the flow-passing wall face and the high-speed water flow, and the high-speed water flow can not directly act on the flow-passing wall face. Meanwhile, the high-speed water flow and the low-speed water flow generate the shearing, blending and entraining effect, a large amount of water flow kinetic energy is consumed, the bottom flow speed of the high-speed water flow can be lowered, water flow cavitation is inhibited, and damage of cavitation corrosion and flush corrosion is avoided.

Owner:POWERCHINA ZHONGNAN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com