Double seal linkage pilot spool structure of high pressure differential valve

A pilot spool and double-seal technology, which is applied in the direction of the valve's fluid energy absorption device, valve lift, valve details, etc., can solve the problems of reduced sealing ability of the valve, insufficient sealing ability of the hard sealing surface, and creep under pressure, etc. Achieve the effects of reducing erosion and cavitation damage, improving reliability and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

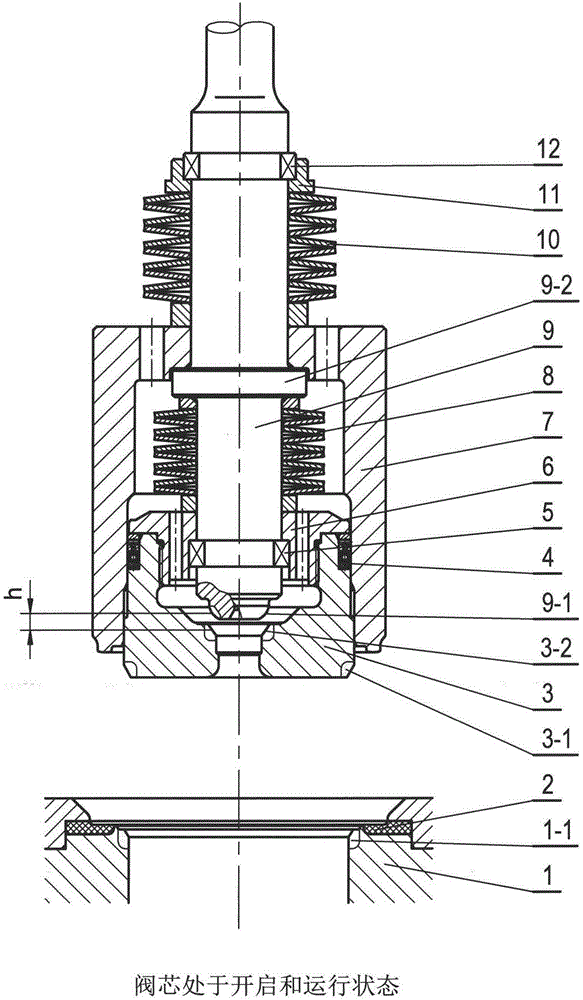

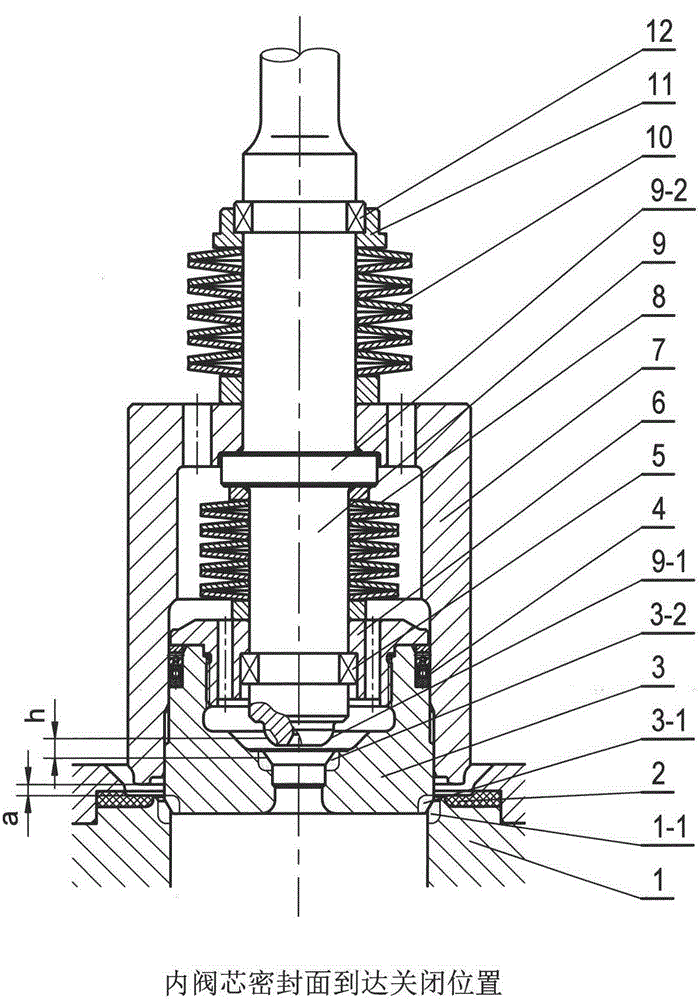

[0034] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

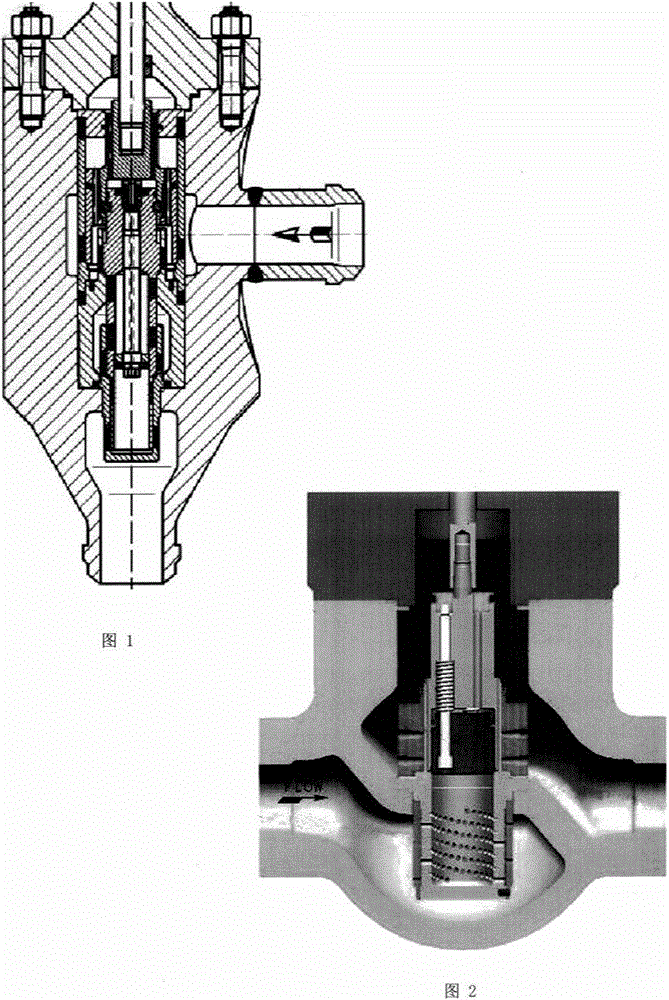

[0035] Such as Figure 3 ~ Figure 6 As shown, it is a schematic diagram of the technical solution for applying the double-seal linkage pilot spool structure proposed by the present invention to the structural design of the high pressure difference minimum flow regulating valve in thermal power plants. The valve is designed for the medium flow direction of the flow-close type with top in and bottom out.

[0036] The integral spool assembly structure of the valve is provided with two spools: the outer spool (7) and the inner spool (3). The outer spool (7) is cylindrical with a platform on the upper end, and its lower end surface is closed. The sealing surface coincides with the soft sealing ring (2) installed and fixed on the outside of the hard sealing surface (1-1) of the valve seat (1), and the outer circle lower end of the inner valve c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com