An anti-cavitation spool structure

A cavitation and spool technology, applied to valve details, valve devices, sliding valves, etc., can solve the problems of hydraulic system efficiency reduction, failure, etc., to reduce cavitation damage, simple structure, and reduce spool cavitation The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

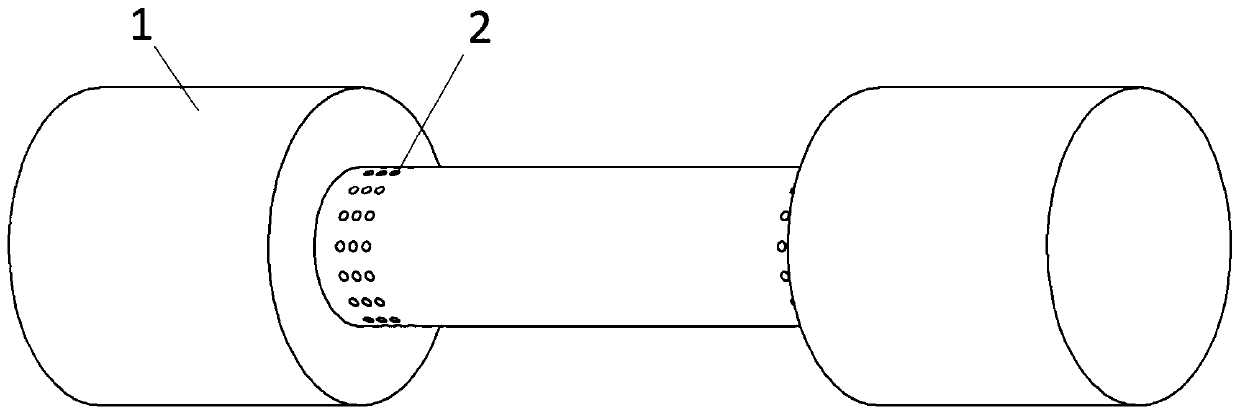

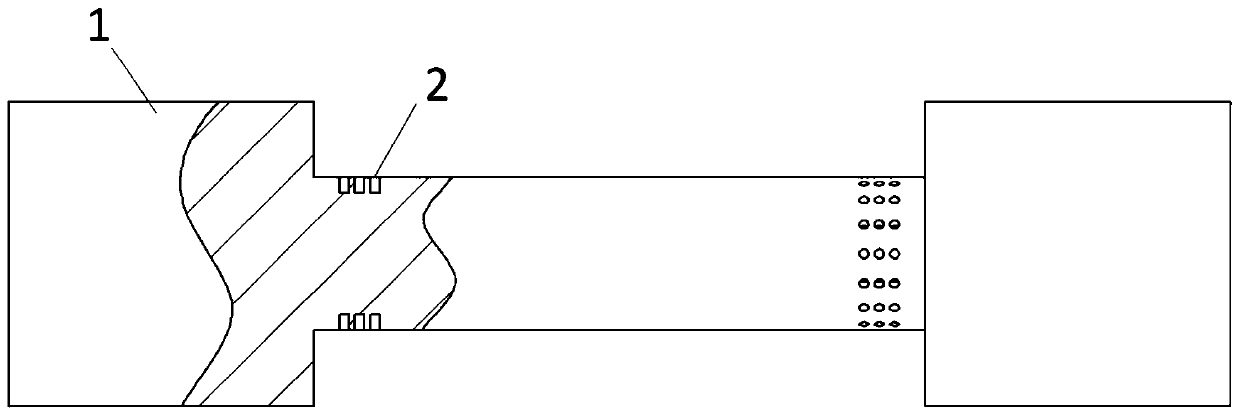

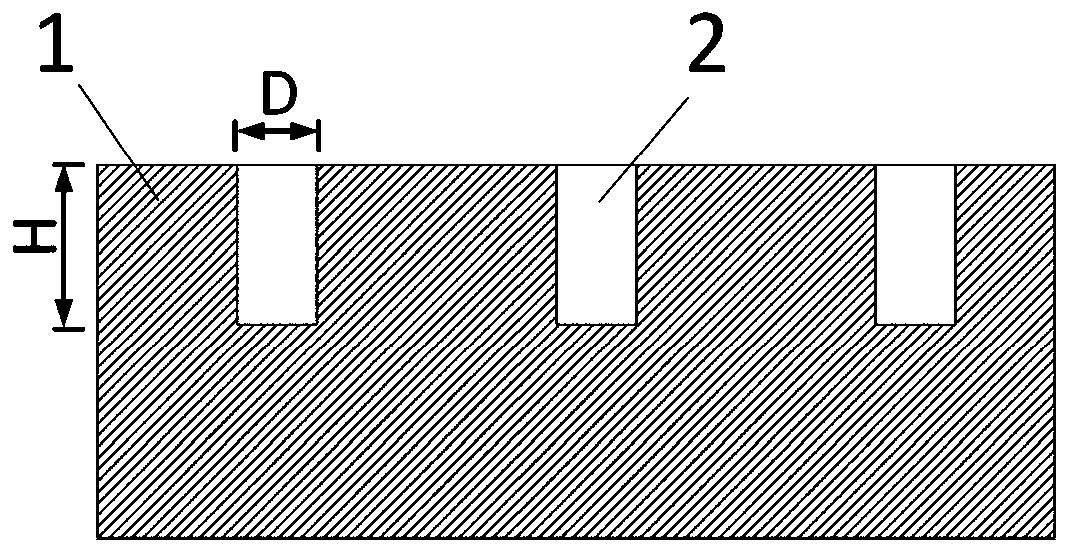

[0027] Such as figure 1 and figure 2 As shown, the embodiment of the present invention is aimed at the spool of the cylindrical valve in the slide valve. Blind holes are arranged along multiple circumferences on the peripheral surface of the cylindrical valve facing the liquid inlet as cavitation induction holes 2. The cavitation of each circumference The induction holes 2 are evenly spaced along the circumferential direction.

[0028] In a specific implementation, the diameter D of the cavitation induction hole 2 is 0.5mm-5mm, the depth H is 1mm-10mm, and H=2D. Preferably, the depth H of the induced hole is 2D.

[0029] Such as Figure 4 As shown, water flows through the slide valve during implementation. After testing, it is found that:

[0030] When the cavitation-inducing hole does not exist, the collapse jet of the cavitati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com