High attitude area dynamic water start-stop plane gate groove

A flat gate, high-altitude technology, used in hydraulic engineering, marine engineering, coastline protection, etc., can solve problems such as door slot cavitation damage, door leaf vibration, operation accidents, etc., to achieve sufficient gas infiltration, smooth flow state, guarantee The effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

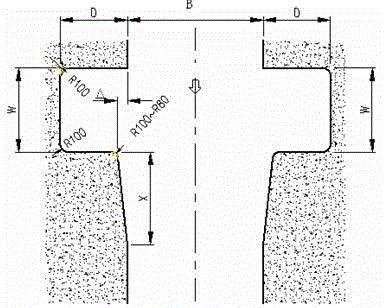

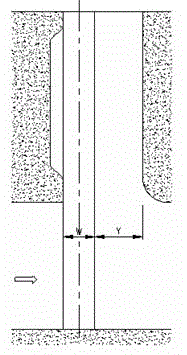

[0012] Such as figure 1 , figure 2 As shown, the high-altitude dynamic water opening and closing plane gate slot of the present invention includes a gate slot (that is, basically the same structure as the existing gate slot), and the ratio of the gate slot width W to the gate slot depth D is: W / D=1.7, the ratio of the downstream stagger distance △ to the door slot width W is: △ / W=0.08, the slope ratio formed by the downstream stagger distance △ and the slope length X is: △ / X=1:13; for the upstream water stop gate , the distance Y between the downstream surface of the gate slot and the downstream parapet is not less than 1.5 times the width W of the gate slot. The fillet at the staggered slope: R80. The inner fillet of the gate slot: R100. B is the width of the runner.

Embodiment 2

[0014] Such as figure 1 , figure 2 As shown, the high-altitude dynamic water opening and closing plane gate slot of the present invention includes a gate slot (that is, basically the same structure as the existing gate slot), and the ratio of the gate slot width W to the gate slot depth D is: W / D=1.9, the ratio of the downstream stagger distance △ to the door slot width W is: △ / W=0.12, the slope ratio formed by the downstream stagger distance △ and the slope length X is: △ / X=1:15; for the upstream water stop gate , the distance Y between the downstream surface of the gate slot and the downstream parapet is not less than 1.5 times the width W of the gate slot. The fillet at the staggered slope: R100. The inner fillet of the gate slot: R100.

Embodiment 3

[0016] Such as figure 1 , figure 2 As shown, the high-altitude dynamic water opening and closing plane gate slot of the present invention includes a gate slot (that is, basically the same structure as the existing gate slot), and the ratio of the gate slot width W to the gate slot depth D is: W / D=1.8, the ratio of the downstream stagger distance △ to the door slot width W is: △ / W=0.1, the slope ratio formed by the downstream stagger distance △ and the slope length X is: △ / X=1:14; for the upstream water stop gate , the distance Y between the downstream surface of the gate slot and the downstream parapet is not less than 1.5 times the width W of the gate slot. The fillet at the staggered slope: R90. The inner fillet of the gate slot: R100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com