A pressurized water corrosion reduction structure for a water release structure

A technology for drainage structures and connecting pipes, which is applied in construction, water conservancy engineering, marine engineering, etc., can solve the problems of inability to reduce erosion damage, block the development and collapse of cavities and bubbles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

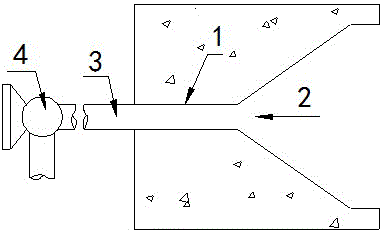

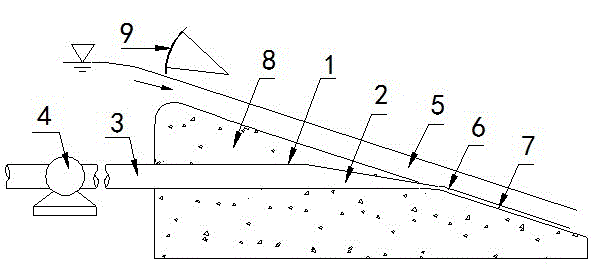

[0014] see Figure 1 to Figure 2 , the pressurized water corrosion reduction structure of the drainage structure includes a communication pipe 1 buried in the interior of the drainage structure 8; the inlet end 3 of the communication pipe 1 is externally connected to the pressure water device 4; the outlet end 2 of the communication pipe 1 is connected to the The flow wall 7 of the drainage structure 8 is connected, the outlet end 2 of the connecting pipe 1 is a trumpet-shaped flat orifice, and the connecting pipe 1 is a steel pipe; the water pressure equipment 4 is a water pump. The discharge structure 8 is provided with a discharge gate 9 , and the pressurized water equipment 4 is linked with the opening and closing system of the discharge gate 9 .

[0015] The drainage width of the drainage structure 8 is 5m, the connecting pipe 1 is a steel pipe, and its diameter is consistent with the diameter of the inlet and outlet of the external water pump 4, which is 650mm; the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com