Method and device for overhauling tailwater cooler

A technology for overhauling devices and coolers, which is used in hydropower, hydraulic engineering, hydropower stations, etc., can solve the problem of poor accuracy of underwater alignment installation and removal of tail water coolers, difficult underwater operations, and high risks. problems, to improve maintenance efficiency, reduce cavitation damage, and achieve good hydraulic conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

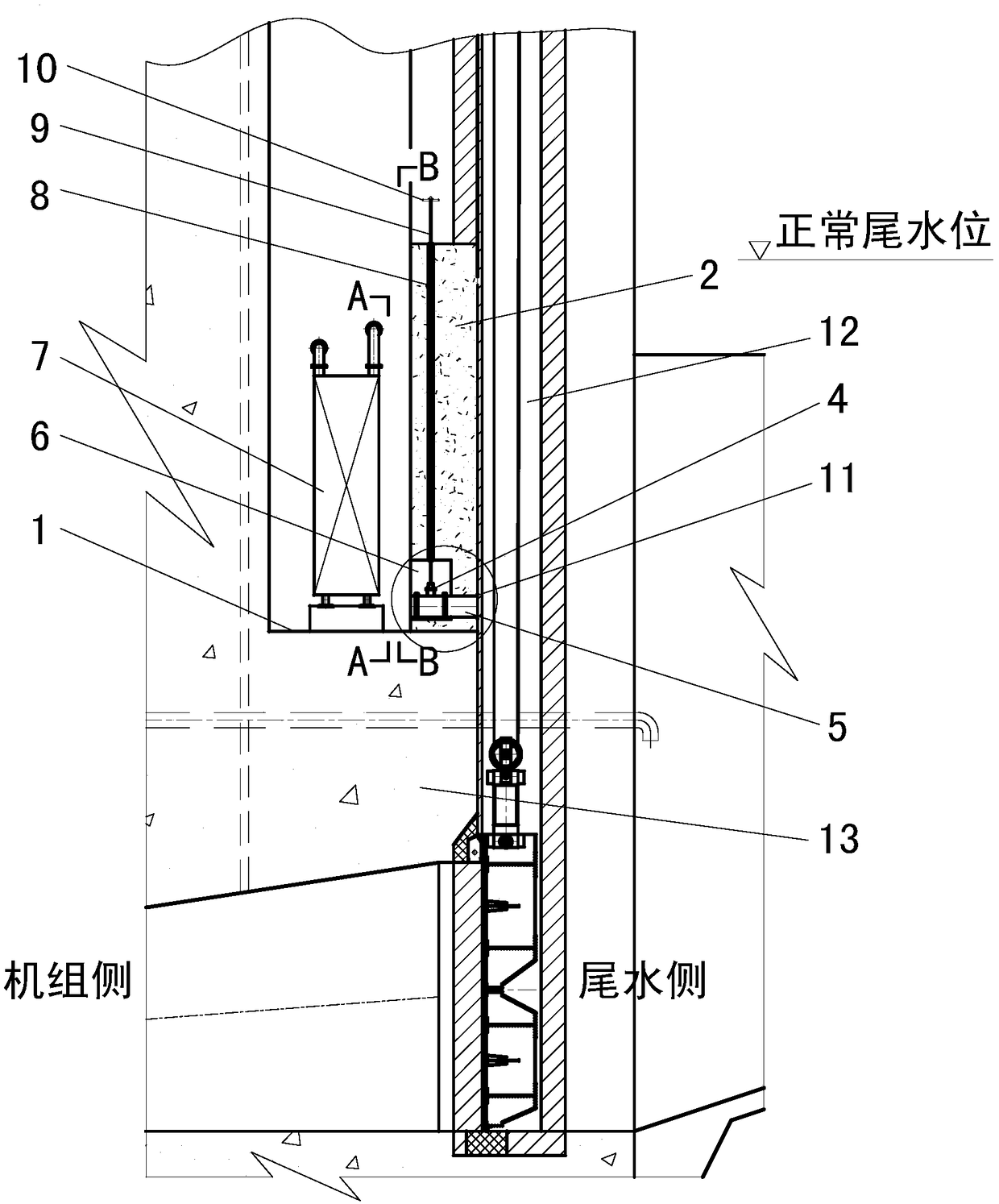

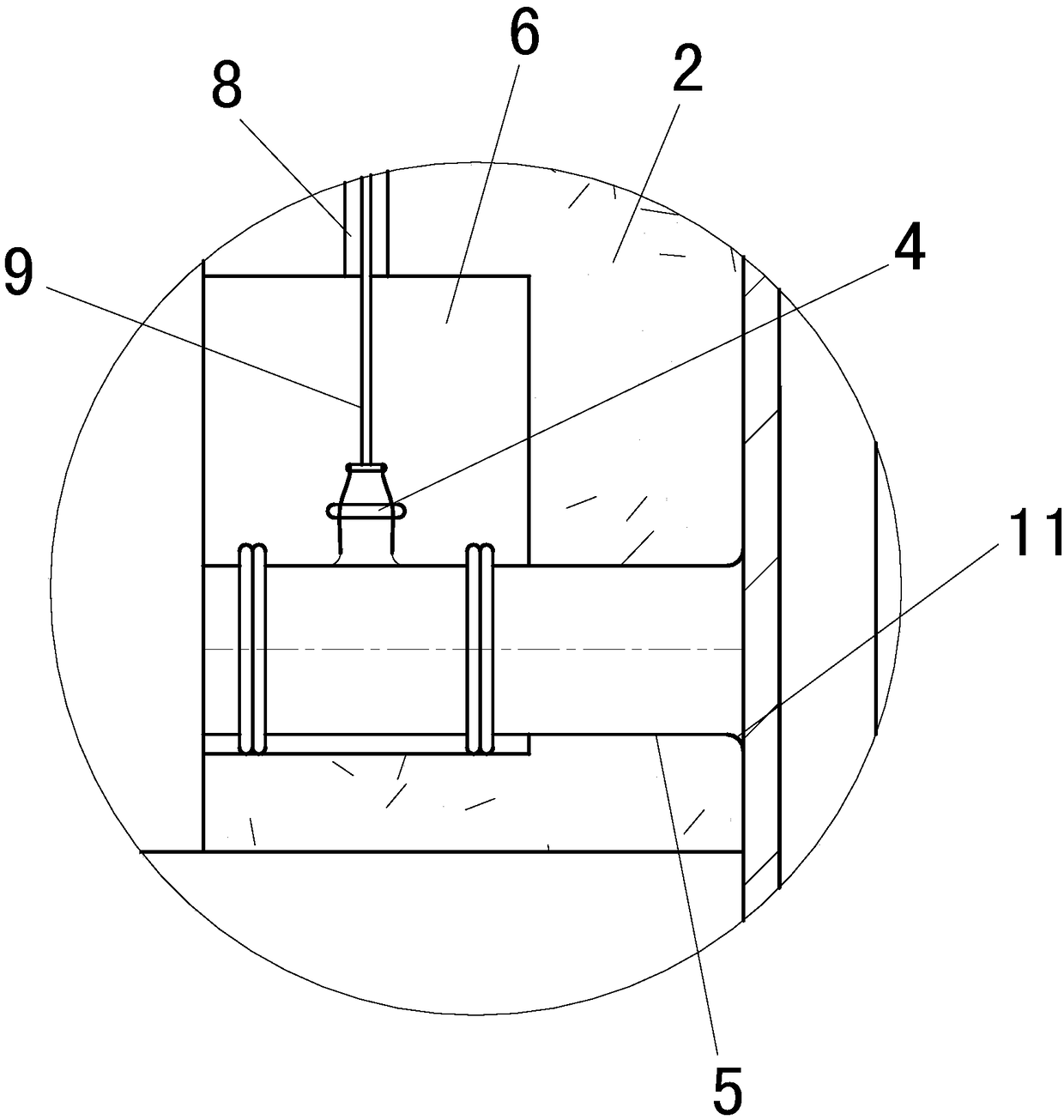

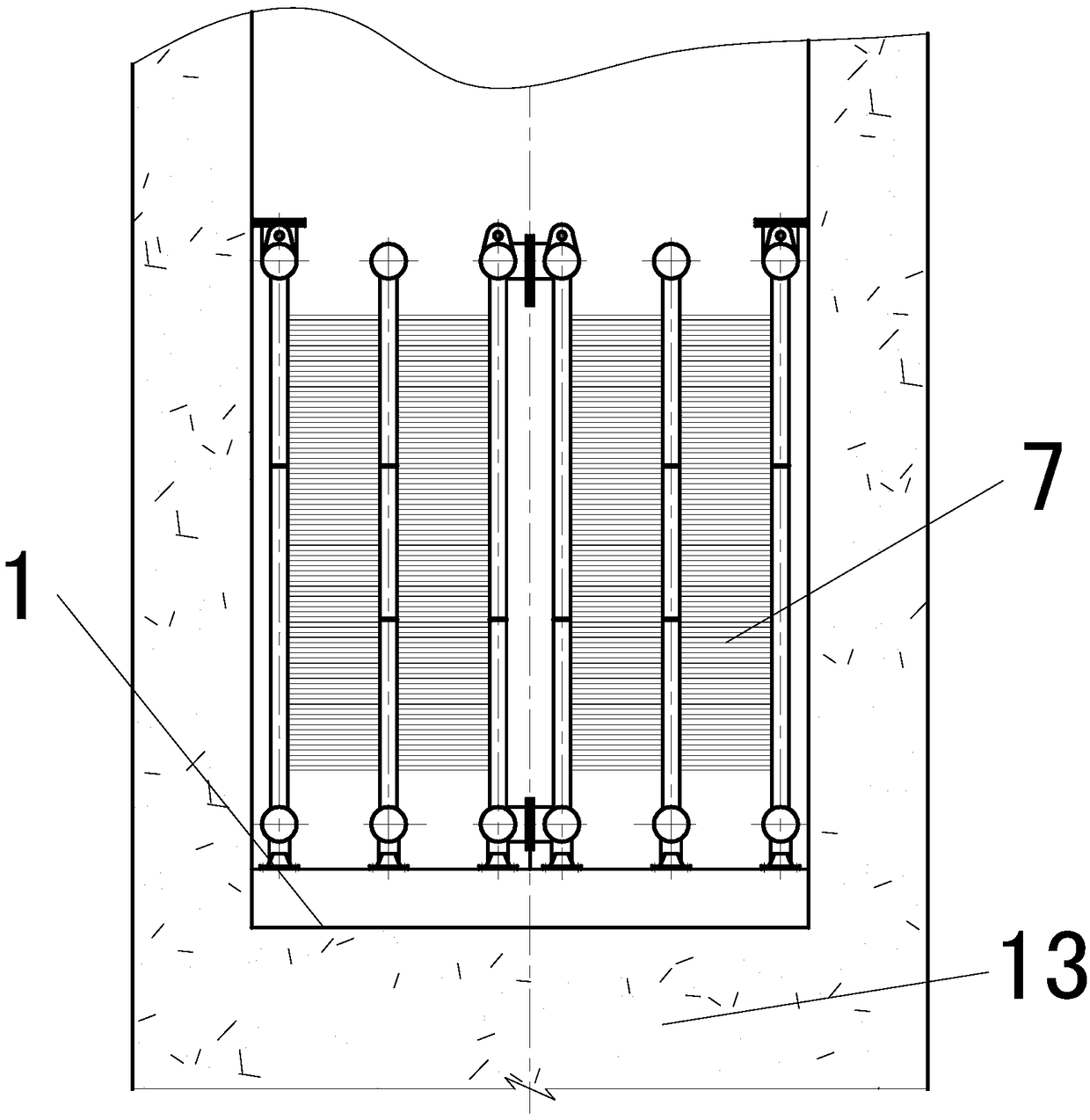

[0028] The maintenance method of the tail water cooler in this example is as follows: Figure 1~4 As shown, a water retaining wall 2 is set on the upper platform 1 of the parapet wall on the side of the unit, and a valve 4 arranged in an isosceles triangle 3 is arranged on the side of the water retaining wall 2 from top to bottom. The valve 4 communicates with the tail water side through a steel pipe 5. The steel pipe 5 is fixed on the retaining wall 2, and the valve 4 is located in the operating room 6. The tail water cooler 7 is set on the upper platform 1 on the top surface of the breast wall 13 on the unit side; the top of the water retaining wall 2 is slightly higher than the normal tail water level, and the water retaining wall 2 is provided with a vertical hole 8; the vertical hole 8 is used to place the connecting valve 4 of the operating rod 9; the handle 10 of the operating rod 9 is located above the top of the retaining wall 2; as figure 2 As shown, the outlet on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com