Embedded part structure and gate system thereof

A technology of gates and embedded parts, which is applied in the field of embedded parts structure and its gate system, which can solve the problems of endangering the safety of the power station, complex maintenance and construction of the gate slot area, and lack of maintenance conditions for the gate slot at the exit, so as to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

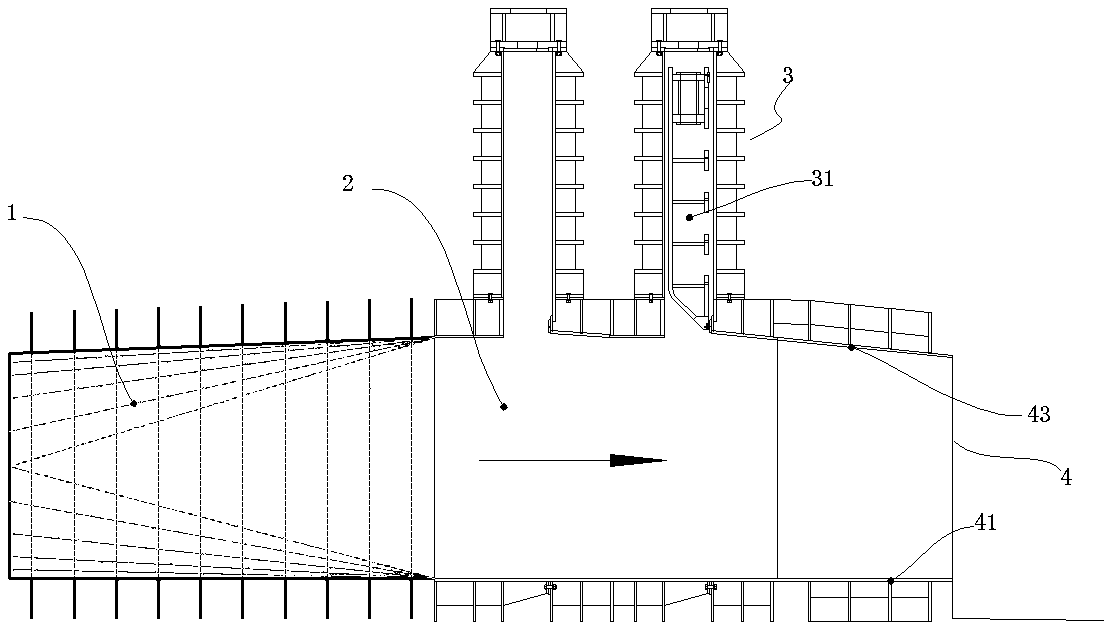

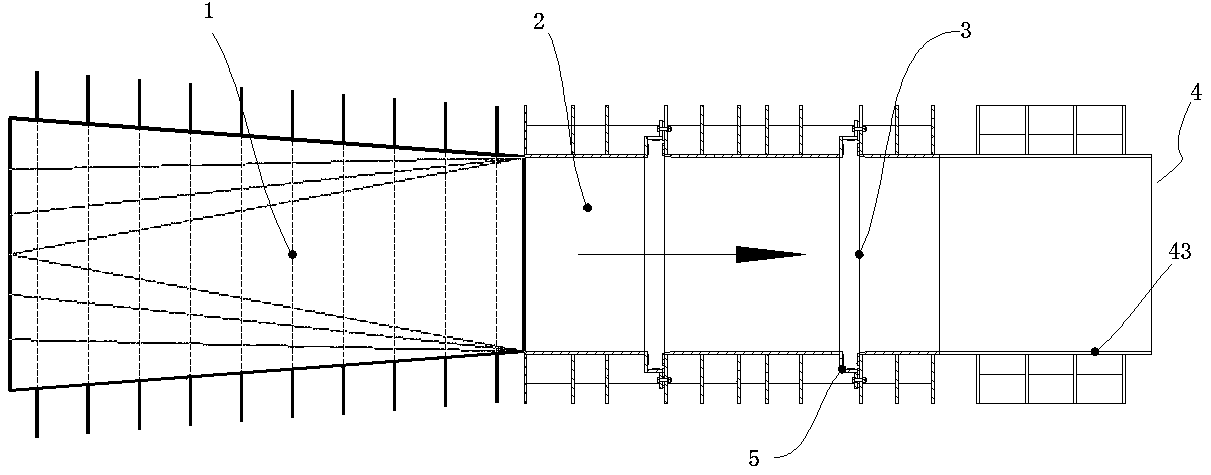

[0031] Such as Figure 1~2 As shown, an embedded part structure includes a main body section 2 with a rectangular cross section, a gate groove 5 arranged on the main body section 2 , and a pressure slope section 4 .

[0032] The structure of the slope section 4 includes a horizontal bottom surface 41 , two wall surfaces 42 perpendicular to the bottom surface 41 , and a top surface 43 . The bottom surface 41 , the side wall surface 42 and the top surface 43 are enclosed to form a hollow structure with closed sides and open ends. The top surface 43 is a slope surface that gradually slopes downward from the upstream to the downstream direction, so that the pressure slope section 4 forms a variable cross-sectional structure with a diameter that gradually decreases. The slope ratio of the top surface 43 is 1:10.

[0033] The upstream end of the slope section 4 is butted against the downstream end of the main body section 2 .

[0034] This embodiment also provides a gate system, ...

Embodiment 2

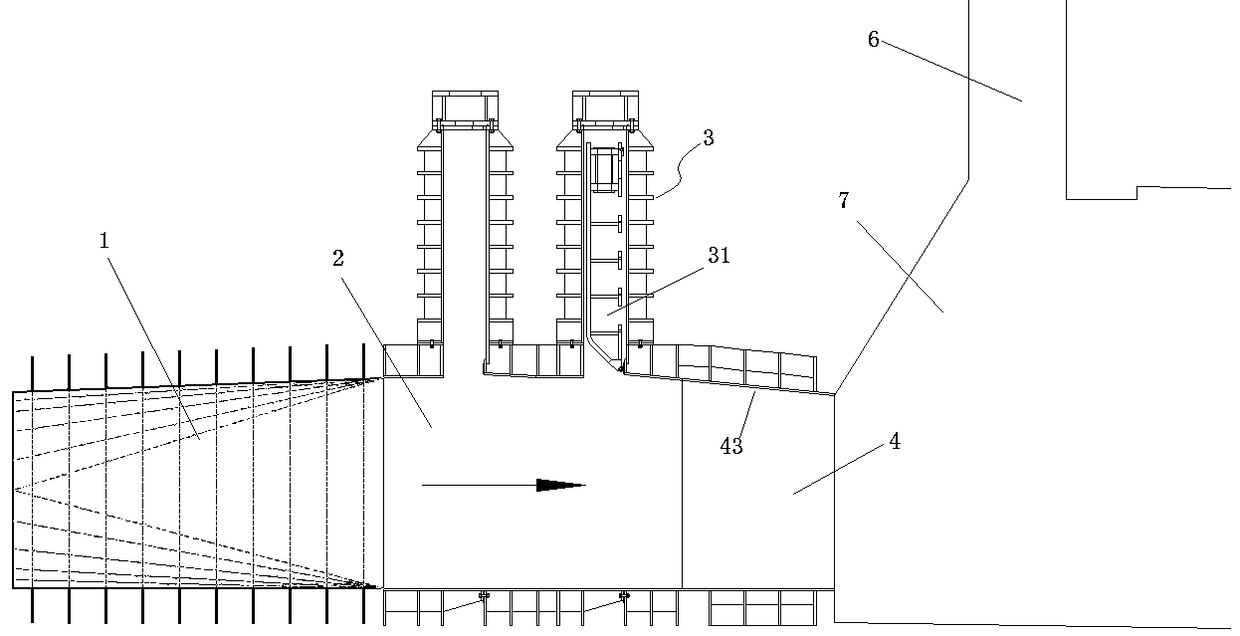

[0040] Such as image 3 As shown, repeat embodiment 1, the difference is that the construction location of embodiment 1 is outside the tunnel, the construction location of embodiment 2 is located in the tunnel, and the water head at the working gate 31 of embodiment 2 is 130.0m.

[0041] The circle-to-square transition section 1 , the gate mechanism 3 , and the embedded structure are all located in the tunnel 7 . In the tunnel 7, near the downstream end of the pressure slope section 4, there is a ventilation hole 6 communicating with the outside world. The junction between the downstream end of slope pressure section 4 and the tunnel adopts a sudden expansion design scheme.

[0042] The purpose of designing the vent hole 6 is to supply air to the outlet of the downstream end of the slope section 4, so as to balance the pressure change of the water flow from pressurized to non-pressurized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com